Separation of Particles from a Gas

1/90

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

91 Terms

What factors influence the choice of separation methods for particles from gases?

Factors include size, density, shape, stickiness, friability, erosiveness, surface charge, and other characteristics of the particles.

What is the most common method for removing very fine particles from gas streams?

Filtration.

How do wet scrubbers work in gas cleaning?

Droplets are either directly sprayed into the incoming dusty gas or the gas shears a source of liquid into droplets.

What is a key advantage of filtration in gas cleaning?

High efficiency in removing fine particles.

What are some disadvantages of wet scrubbers?

Oscillating pressure drop, wear of filter material, and handling and disposal of spent filter cartridges or bags.

What principle do centrifugal and cyclonic devices use to separate particles from a fluid?

Centrifugal force based on density or size.

What is a disadvantage of centrifugal or cyclonic devices?

Low efficiency for particle sizes below their 'cut size' and usually higher pressure loss than other separator types.

What is an advantage of centrifugal or cyclonic devices?

The collected product remains dry and is usually useful.

What are the two types of centrifugal or cyclonic devices mentioned?

Swirl tubes and cyclones.

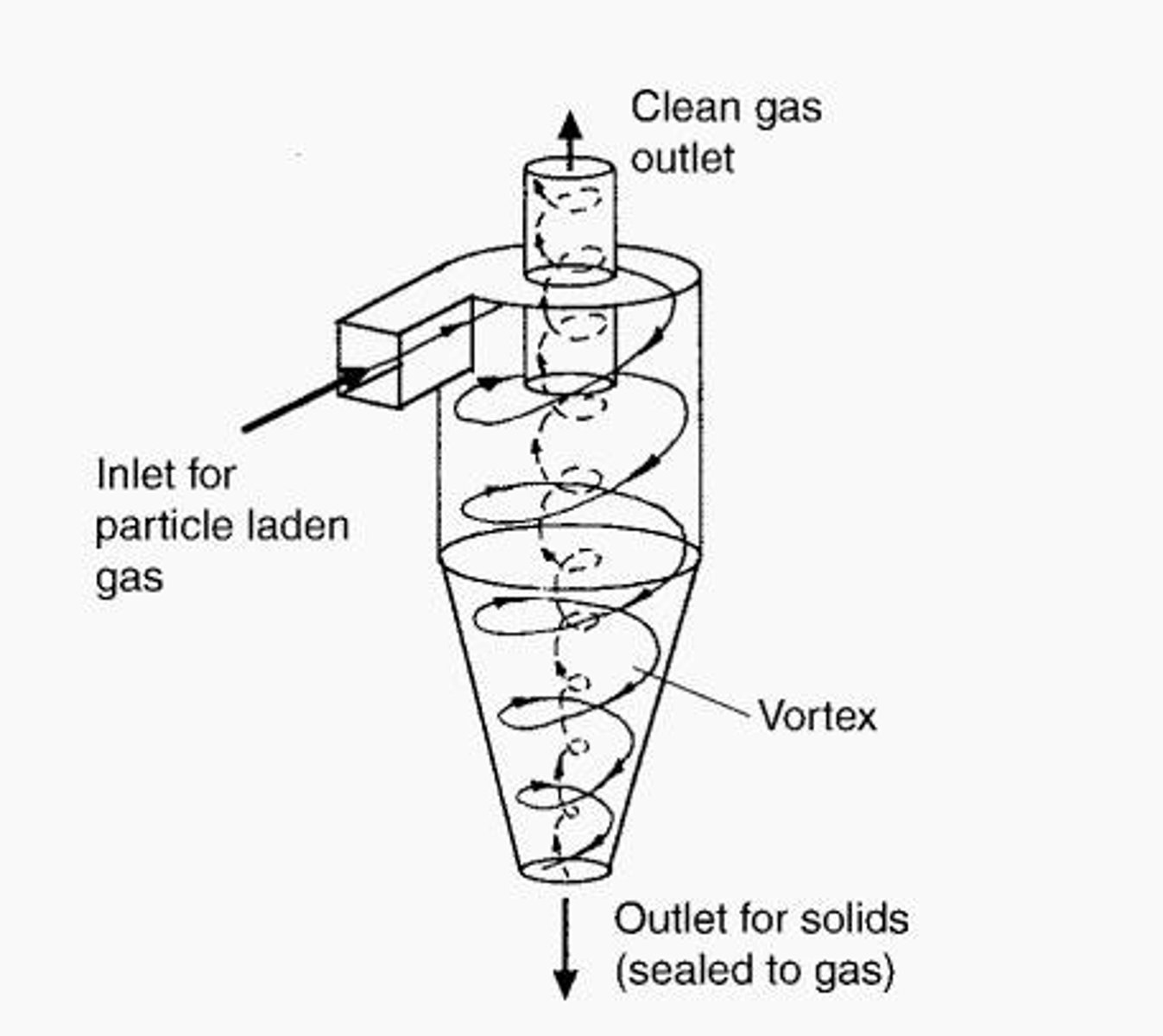

How do gas cyclones operate to separate particles?

Particles are subjected to centrifugal forces that move them radially outwards against the inward flow of gas towards the cyclone's surface.

What happens to the gas flow in a gas cyclone?

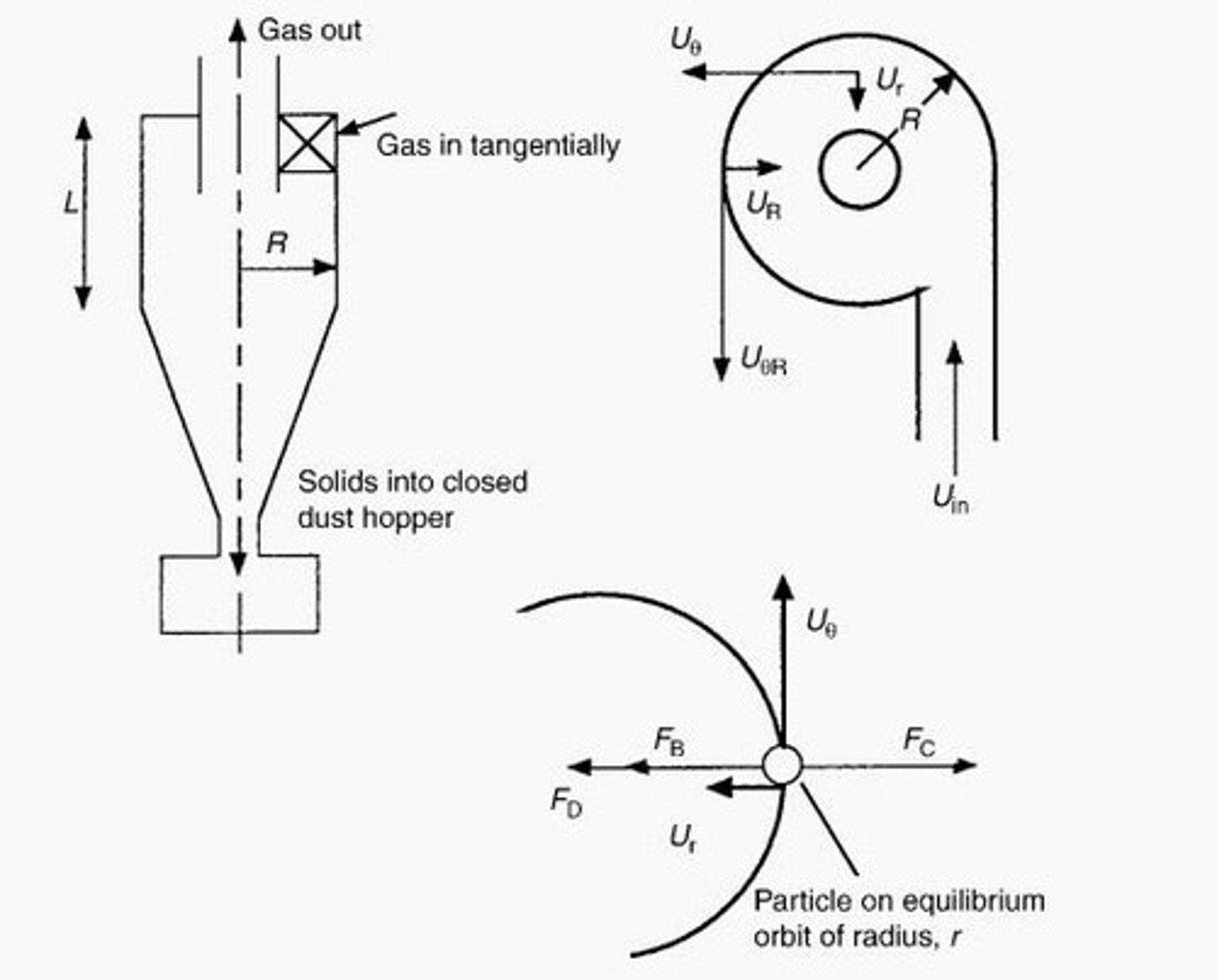

Inlet gas is brought tangentially into the cyclone, creating a vortex; the gas leaves via the outlet at the top.

What are the two classifications of cyclones based on construction and orientation?

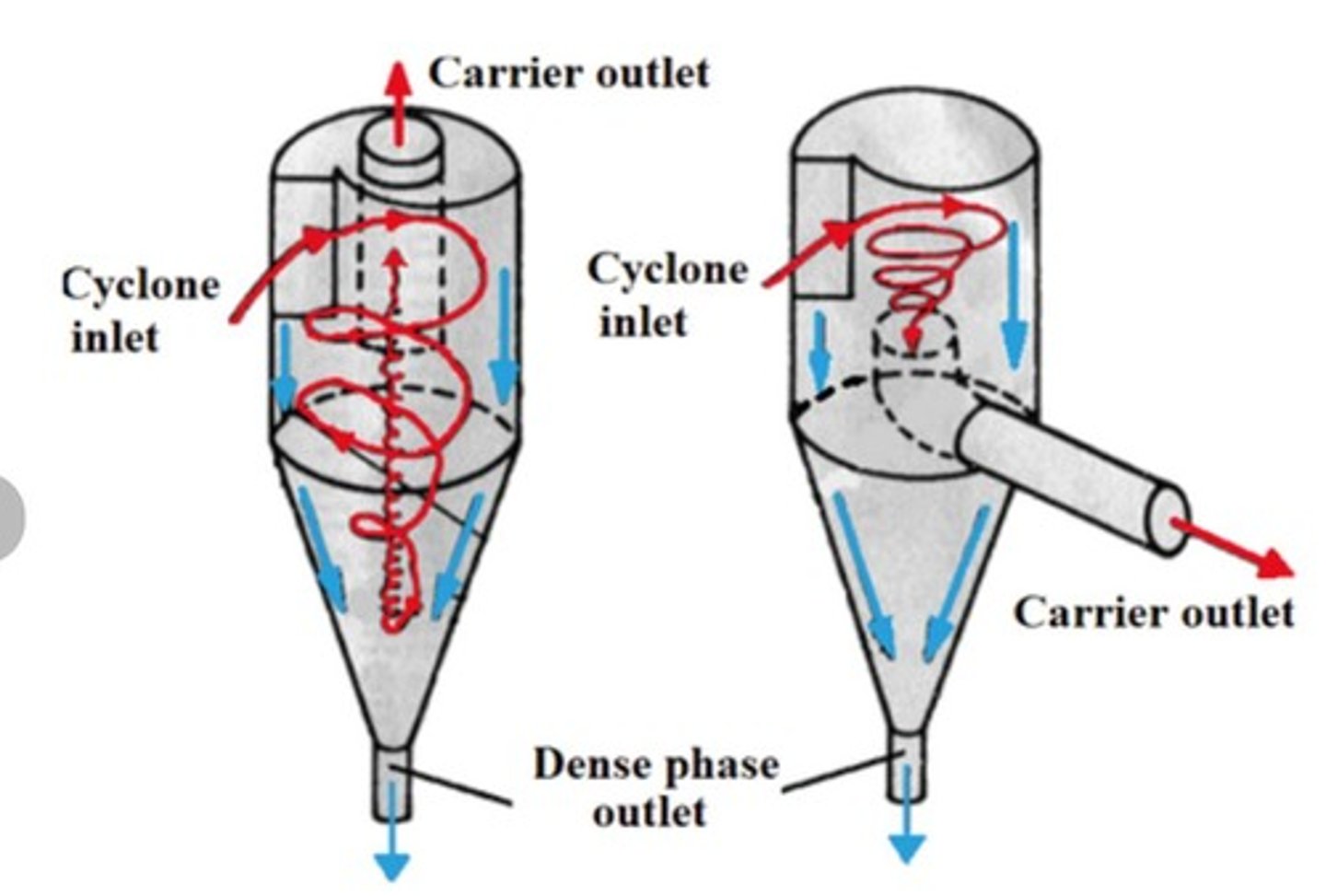

Reverse flow and uniflow.

How does the gas flow differ in uniflow and reverse flow cyclones?

In uniflow, gas enters at one end and leaves at the other; in reverse flow, gas enters through a tangential inlet at the top, creating a confined vortex.

What is a common application of cyclones in industry?

Separation of particles from gas streams.

What is the role of the outer vortex in a gas cyclone?

It pushes the solids at the wall downwards and out of the solids exit.

What is the significance of the 'cut size' in centrifugal separators?

It refers to the particle size below which the separator has low efficiency.

What is a disadvantage of operating centrifugal devices under low solids-loading conditions?

They usually have higher pressure loss compared to other separator types.

What type of particles can wet scrubbers efficiently remove?

Small particle sizes.

What is a potential issue with the operation of filtration systems?

Wear of the filter material.

What is the main function of gas cleaning methods?

To remove particles from gas streams.

Why is filtration considered a high-efficiency method?

Because the particle-containing droplets have a larger diameter than the dust particles, allowing for easier separation.

What are some characteristics of particles that affect their separation from gas?

Size, density, shape, stickiness, friability, erosiveness, and surface charge.

What is the typical shape of a cyclone's body?

Cylindrical body shape.

What are the two classifications of gas cyclones based on body size?

High efficiency and high rate.

What characterizes high efficiency designs of gas cyclones?

They have long bodies and small openings.

What characterizes high rate designs of gas cyclones?

They have shorter bodies and larger openings, allowing for a larger volume with lower capture rates.

What is the total pressure drop in a gas cyclone composed of?

The sum of five components: inlet contraction, particle acceleration, barrel friction, gas flow reversal, and exit contraction.

How is the total pressure drop in a gas cyclone typically measured?

It is measured between the inlet and gas outlet and is usually proportional to the square of the gas flow rate.

What does the Euler number (Eu) represent in the context of gas cyclones?

The ratio of pressure forces to inertial forces acting on a fluid element.

How is the Euler number related to cyclone pressure drop?

It is a resistance coefficient that relates the cyclone pressure drop (Δp) to a characteristic velocity (v).

What is the characteristic velocity (v) in gas cyclones?

It is defined based on the cross-section of the cylindrical body of the cyclone.

What forces act on a particle in a gas cyclone?

Drag, buoyancy, and centrifugal force.

What determines the equilibrium orbit of a particle in a gas cyclone?

The balance between drag, buoyancy, and centrifugal forces.

What is the critical particle diameter for separation in a cyclone?

The diameter for which particles with an equilibrium orbit radius greater than or equal to the cyclone body radius will be collected.

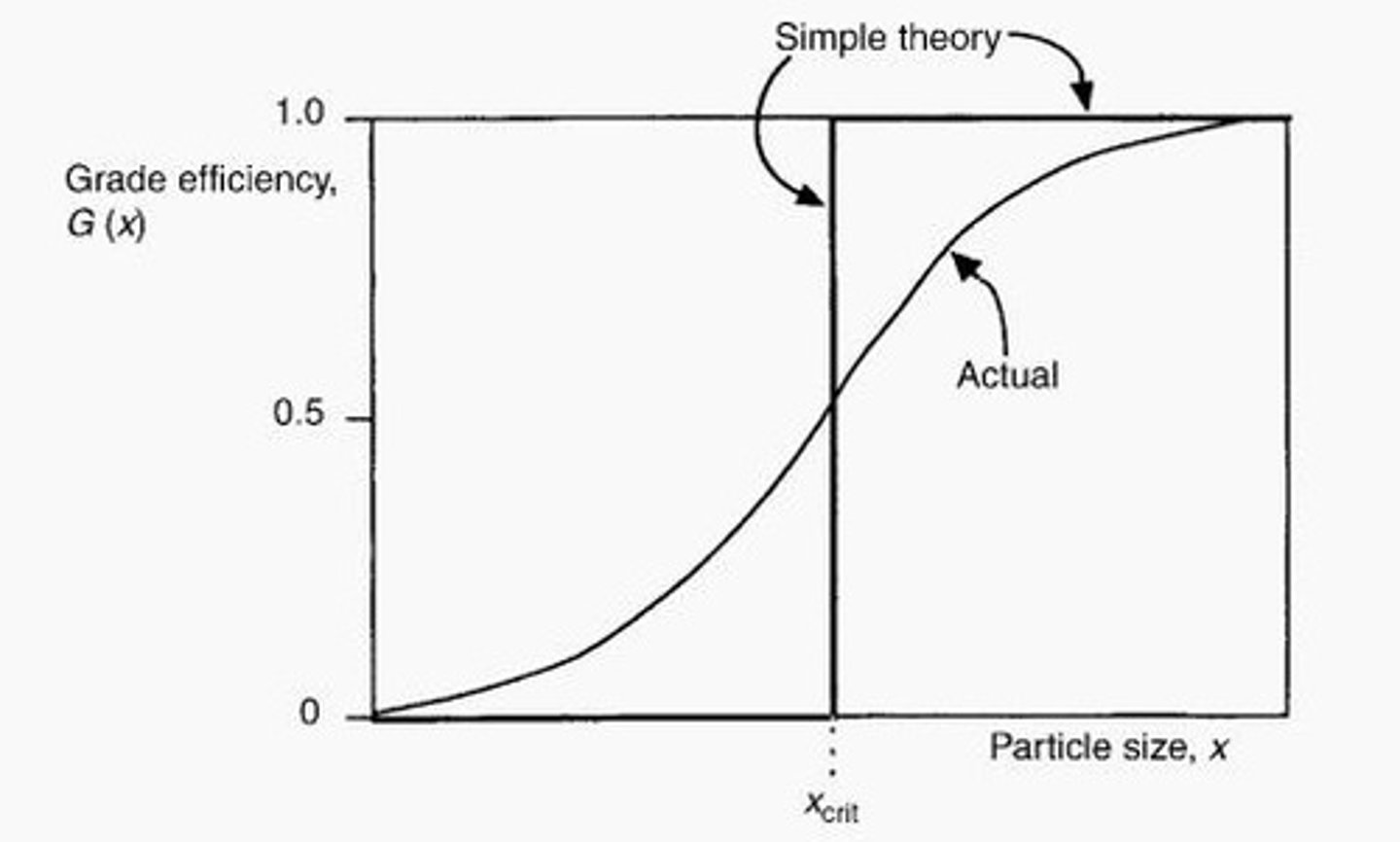

What does the cyclone grade efficiency curve typically look like?

It is usually S-shaped due to gas velocity fluctuations and particle-particle interactions.

What is x50 in the context of cyclone efficiency?

The particle size for which the grade efficiency is 50%, also known as the equiprobable size or cut size.

What happens to particles larger than xcrit in a gas cyclone?

They are generally collected, while particles smaller than xcrit are not collected.

What is the significance of the drag force in a gas cyclone?

It is caused by the inward flow of gas past the particle and acts radially inwards.

How can the efficiency of separation in a gas cyclone be theoretically analyzed?

By predicting an ideal grade efficiency based on the diameter of particles.

What is the effect of gas velocity fluctuations on cyclone efficiency?

They can result in some particles larger than xcrit being lost and some smaller particles being collected.

What is the relationship between cyclone geometry and the Euler number?

The Euler number is practically constant for a given cyclone geometry and independent of the cyclone body diameter.

What is the primary purpose of gas cyclones?

To separate particles from a gas stream based on size and density.

What is the role of buoyancy forces in a gas cyclone?

They act on the particle moving with a tangential velocity at a given radius.

What is the mathematical representation of the Euler number?

It can be solved using Equation 9.1.

What is the simplest definition of characteristic velocity for gas cyclones?

It is based on the cross-section of the cylindrical body of the cyclone.

What is the concept of x50 cut size in cyclone efficiency?

It expresses the efficiency of a cyclone as a single number independent of the feed solid size distribution.

What does the Zenz method provide regarding cyclone efficiency?

It provides an equation for dpth, the theoretical size of a particle collected by the cyclone at 50 percent collection efficiency.

What theory underlies the Zenz method's equation for particle collection in cyclones?

The residence time theory of particle collection.

How is the particle size collected at 50 percent efficiency defined in cyclone operation?

It is the particle size that reaches the wall by the time it exits the cyclone.

What is the total efficiency of separation, Et, in cyclone operation?

It is defined as the fraction of the total feed that appears in the coarse product collected.

How can total efficiency of separation be mathematically calculated?

Using Equation 9.5.

What does grade efficiency, G(x), represent in cyclone operation?

It describes the efficiency with which the cyclone collects particles of a certain size.

How is grade efficiency, G(x), mathematically defined?

As the mass of solids of size x in coarse product divided by the mass of solids of size x in feed.

What is the relationship between grade efficiency and total efficiency of separation?

It is expressed in Equation 9.8.

What dimensionless group is used for the scale-up of cyclones?

The Stokes number.

What does the Stokes number characterize in cyclone performance?

It characterizes the separation performance of geometrically similar cyclones.

How is the Stokes number mathematically defined?

As the ratio of the force required to change a particle's direction to the drag force available.

What happens to the tendency for particles to impact the airway walls as the Stokes number increases?

The tendency for particles to impact increases.

Is the Stokes number dependent on Reynolds number for large industrial cyclones?

No, it is independent of Reynolds number.

What is the typical range of pressure drops for correctly designed cyclones operating at ambient conditions?

Between 50 and 150 mm of water gauge (WG).

How does pressure drop affect cyclone efficiency?

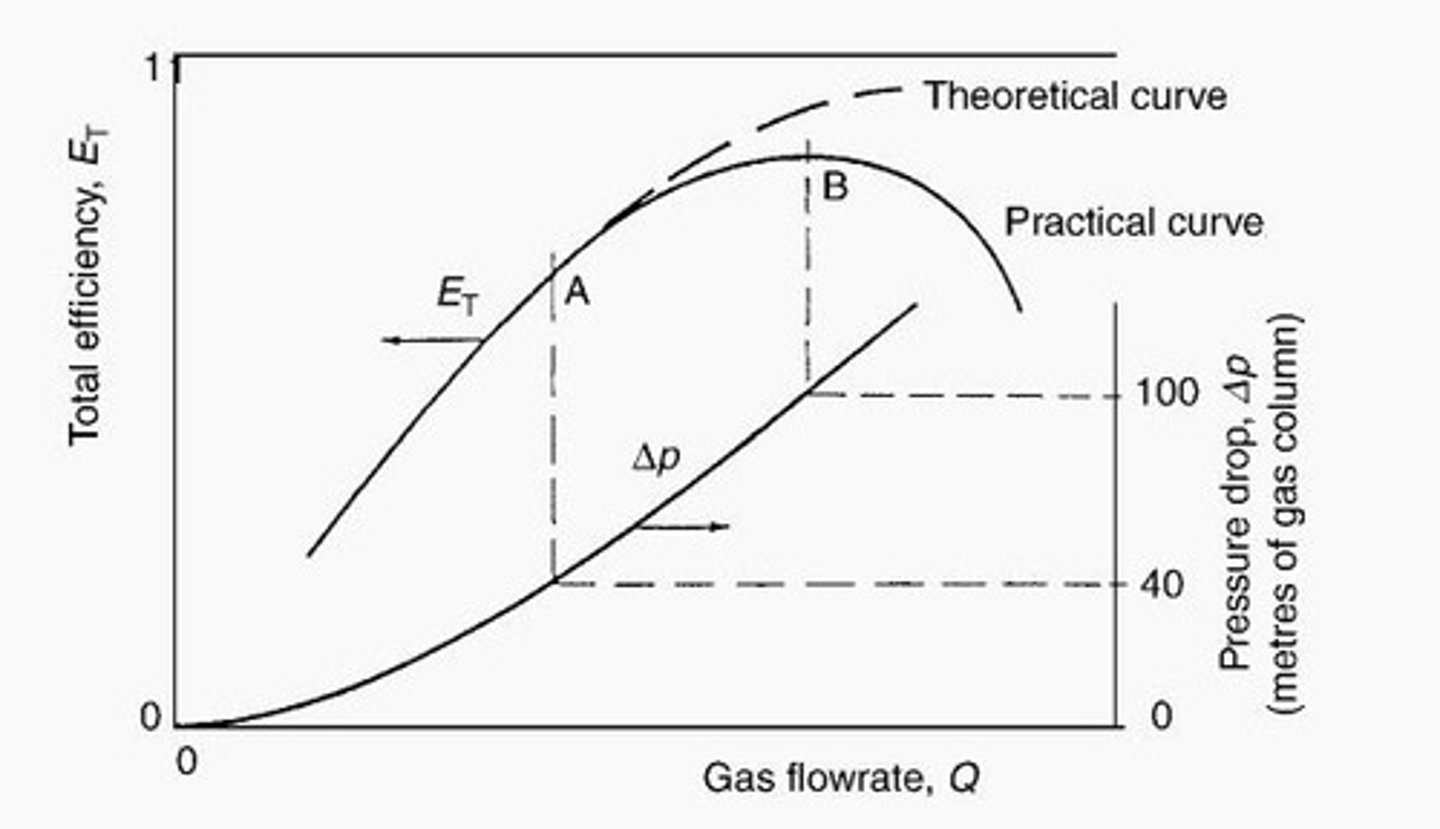

Efficiency is affected by pressure drop, with total efficiency falling at high flow rates due to increased turbulence.

What is the effect of high flow rates on cyclone operation?

Re-entrainment of separated solids increases with increased turbulence.

What is the significance of the equations provided in the notes (Equations 9.3 to 9.9)?

They relate the size distributions of the feed, coarse product, and fine product.

What is the mass flow discharged from the solids exit orifice called?

The coarse product, Mc.

What is the mass flow rate leaving with the gas referred to as?

The fine product, Mf.

What assumption is made regarding particles within the cyclone for calculating efficiencies?

Assuming no breakage or growth of particles.

What is the relationship between cyclone efficiency and gas flow rate?

Total efficiency of separation and pressure drop vary with gas flow rate.

What is a key characteristic of gas cyclones regarding their efficiency?

Their efficiency is significantly affected by pressure drop or flow rate.

What happens to the total efficiency curve of cyclones at high flow rates?

It falls away due to increased re-entrainment of separated solids caused by turbulence.

What is the recommended pressure drop range for most cyclone designs operating at ambient conditions?

Between 50 and 150 mm of water gauge (WG).

How does dust loading affect cyclone efficiency?

High dust loadings (above about 5 g/m³) generally lead to higher total separation efficiencies due to particle agglomeration.

What are the two main groups of cyclone designs?

High efficiency designs (e.g., Stairmand HE) and high rate designs (e.g., Stairmand HR).

What characterizes high efficiency cyclones?

They provide high recoveries and have relatively small inlet and gas outlet orifices.

What is a key feature of high rate cyclone designs?

They have lower total efficiencies but offer low resistance to flow, with larger inlets and gas outlets.

What are the critical zones for abrasion in gas cyclones?

The cylindrical part just beyond the inlet opening and the conical part near the dust discharge.

What is attrition in the context of gas cyclones?

The break-up of solids that occurs during collection, particularly affecting larger particles.

In what type of systems is attrition most detectable?

In recirculating systems such as fluidized beds.

What is a common cause of blockages in cyclone operation?

Overloading of the solids outlet orifice.

What happens when a cyclone experiences a blockage?

The cyclone cone fills with dust, pressure drop increases, and efficiency falls dramatically.

What factors can cause blockages in cyclones?

Mechanical defects in the cyclone body or changes in the chemical or physical properties of the solids.

Why is the design of solids discharge important in gas cyclones?

To prevent powder build-up that can disrupt the strong vortex inside the cyclone.

What are diplegs in the context of fluidized beds with internal cyclones?

Vertical pipes that return collected entrained particles into the fluidized bed.

What is the purpose of connecting cyclones in series?

To increase recovery by using a primary cyclone of medium or low efficiency followed by more efficient designs.

How does decreasing cyclone size affect the x50 cut size?

It reduces the achievable x50 cut size for a given geometry and pressure drop.

What is the benefit of splitting large gas flows into multiple smaller cyclones operating in parallel?

It allows for meeting both the desired operating pressure drop and x50 cut size requirements.

What is the role of the solids discharge orifice in cyclone operation?

It is crucial for the correct functioning of a gas cyclone, preventing build-up of solids.

What is the effect of high flow rates on cyclone performance?

Increased turbulence leads to re-entrainment of solids, reducing efficiency.

What is the relationship between particle concentration in suspension and cyclone efficiency?

Higher concentrations can enhance separation efficiencies through agglomeration.

What are the characteristics of high rate cyclone designs?

They have larger inlets and gas outlets and are usually shorter than high efficiency designs.

What is a common mechanical defect that can lead to blockages in cyclones?

Bumps on the cyclone cone or protruding welds.

What is the significance of the cyclone cone's design in preventing blockages?

It must be designed to minimize the risk of dust accumulation that can lead to blockages.