IB DT: Topic 4.3: Scales of production

1/13

Earn XP

Description and Tags

credits: https://docs.google.com/presentation/d/1QTzUZIaE_CCXjoNr5ehb5cAMGPkhOU93HwapAiQKJ9w/pub?start=false&loop=false&delayms=3000&slide=id.g6d179b444_637

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

14 Terms

what is craft production?

small scale production centred around manual skills - made by a person with a deep set of manual skills where only rudimentary machinery is used. products such as wedding dresses, jewellery and ceramics use this scale of production.

what is one off production?

where only one or a few specialist items are required - would include a prototype before batch or volume production.

what are some noticeable features of one-off production?

designed and made to a client’s exact specification

labour and material costs are high

a high level of design and manufacturing skills are needed

what is vernacular design?

when traditional crafts are used to support local communities - local people, local materials, developing products for the local environment (e.g. inuit snow goggles). often an important part of the economy in developing countries.

what is batch production, and what are some characteristics of it?

when set quantities of a product are manufactured to order. requires a high level of design, pattern making, and sampling skills. materials are cost-effective and manufacturing costs are lower than one-off production.

what is mass production?

the production of large amounts of standardised products on production lines, permitting very high rates of production per worker.

what is continuous flow (CFM)?

a production method used to manufacture, produce or process materials without interruption (24/7). this eliminated the extra cost of starting and stopping the production process - highly automated with very few workers.

what is mass customisation?

a sophisticated CIM system that manufactures products to individual customer orders. the benefits of an economy of scale are gained whether the order is for a single item or for thousands. the basic form of the product is constant but using flexible CAM systems the product can be customised in terms of combinations, texture and patterns.

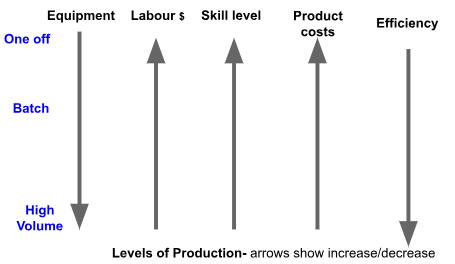

how do you choose the right production method?

consider the product being made and the size of the market

one-off: small firms operating in the service sector to cater to individual needs

batch: group orders

flow or continuous: used to mass produce standardised items

how do economies of scale work?

lead to lower unit costs and process - there is usually a trade off between unit costs and meeting specific customer needs

advantages and disadvantages of one off

advantages: unique, high-quality products; workers more motivated and take pride in their work

disadvantages: labour intensive (high selling prices); production can take a long time, cost a lot; economies of scale not possible

advantages and disadvantages of batch

advantages: lower unit costs; offers the customer some variety and choice; materials can be built in bulk (cheaper)

disadvantages: workers less motivated as work becomes repetitive; goods have to be stored until they are sold (expensive)

advantages and disadvantages of mass

advantages: lower labour costs; materials purchased in large quantities; large numbers of goods are produced

disadvantages: very expensive machinery; workers not motivated; production process has to stop for repairs; inflexible production processes

advantages and disadvantages of continuous

advantages: minimal labour costs, materials can be purchased in huge quantities, unlimited goods produced

disadvantages: very expensive machinery; inflexible production (which has to stop for repair)