Chapter 17: Working Capital Management - Inventory Control

1/23

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

24 Terms

Objectives of Inventory Management

Inventory is a major investment for many entities.

Manufacturing entities often carry inventory equivalent to 3-6 months’ worth of sales.

It is essential to reduce the levels of inventory held to the necessary minimum.

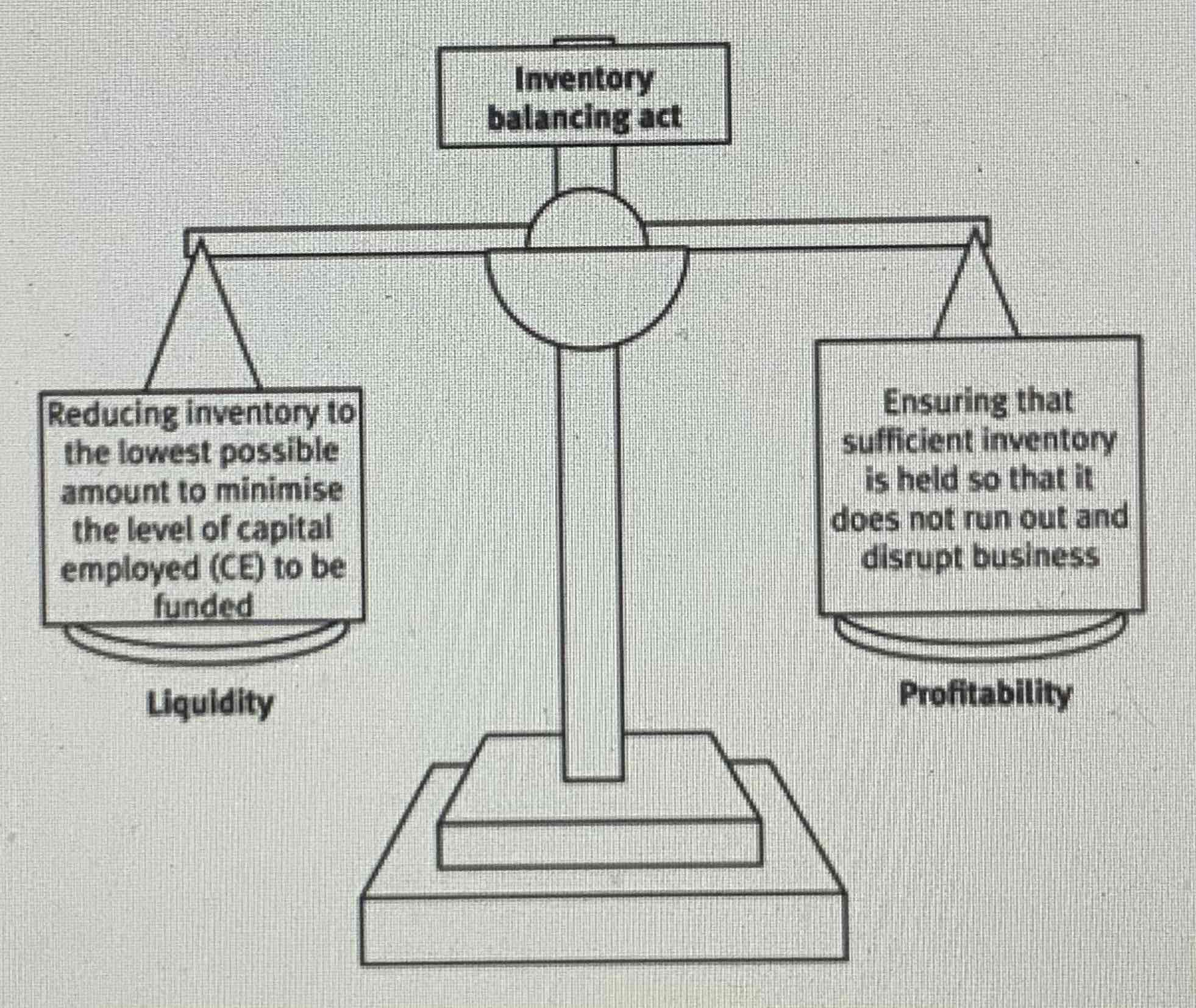

The balancing act between liquidity and profitability which might also be considered to be a trade-off between holding costs and stock-out/reorder costs, is key to any discussion on inventory management.

Costs of High Inventory Levels

The forgone interest that is lost from tying up capital in inventory.

Holding costs:

Storage

Stores administration

Risk of theft/damage/obsolescence

Costs of Low Inventory Levels

Stock-outs:

Lost contribution

Production stoppages

Emergency orders

High reorder/setup costs

Lost quantity discounts

Key Determinants of Good Inventory Management

The optimum reorder level (ROL) - how many items should be left in inventory when next order is placed.

The optimum reorder quantity or economic order quantity (EOQ) - how many items should be ordered when the order is placed.

Lead Time

The lag between when an order is placed and the item is delivered.

Buffer Inventory

The basic level of inventory kept for emergencies. A buffer is required because both demand and lead time will fluctuate and predictions can only be based on best estimates.

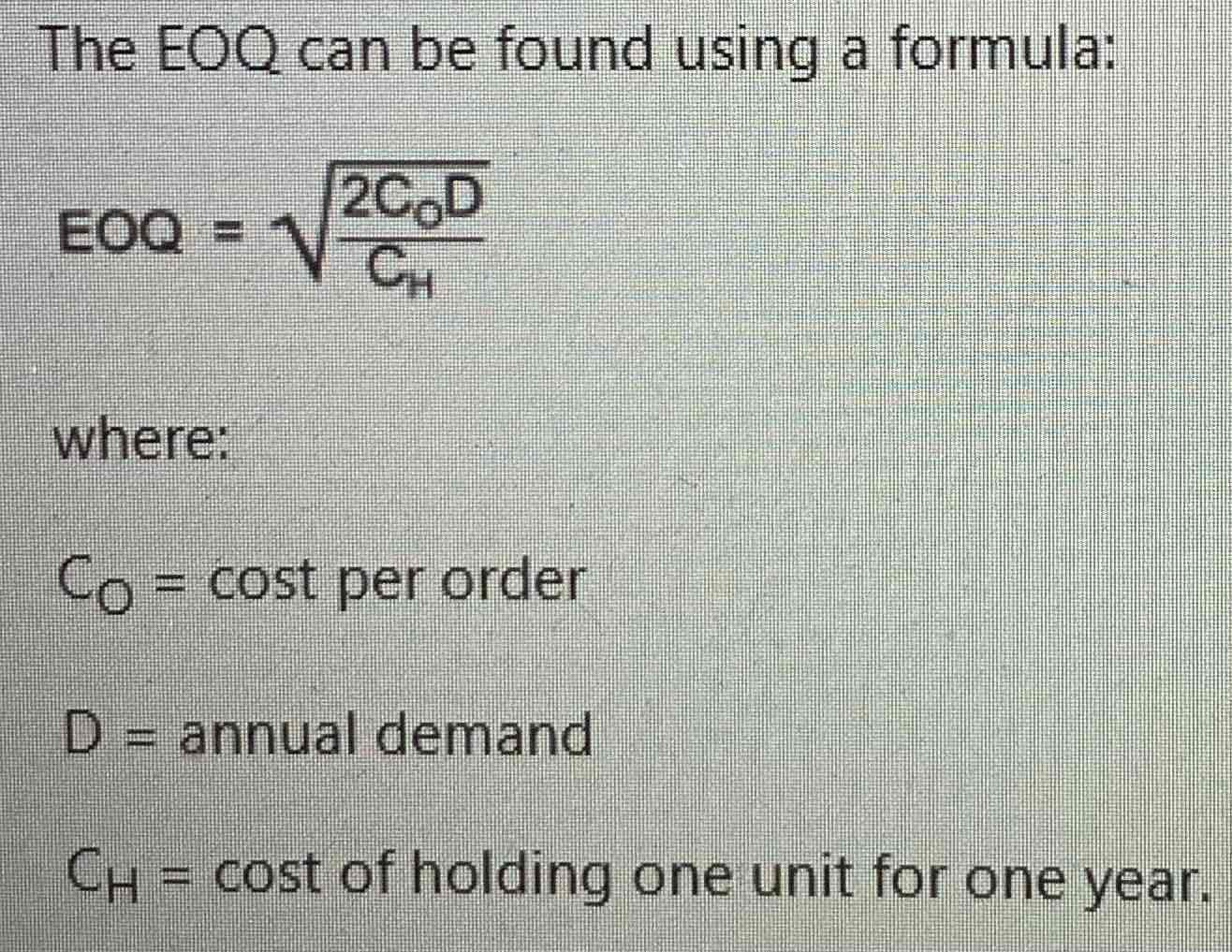

Economic Order Quantity (EOQ)

For businesses that do not use a just in time (JIT) inventory management systems there is an optimum order quantity for inventory items known as EOQ.

Assumptions of EOQ

Demand and lead time are constant and known

Purchase price is constant

No buffer inventory held as it is assumed that it is not needed since demand and lead times are known with certainty

EOQ with Quantity Discounts

Discounts may be offered for ordering in large quantities. If EOQ is smaller than the order size needed for a discount, should the order size be increased above the EOQ?

EOQ with Quantity Discounts: Calculation

Calculate EOQ ignoring discounts.

If the EOQ is below the quantity qualifying for a discount, calculate the total annual inventory cost arising form using the EOQ.

Recalculate total annual inventory costs using the required order size for each discount.

Compare the cost at 2 & 3 and select minimum cost alternative.

Repeat for all discount levels.

EOQ with Quantity Discounts: 2 Cost Methods

Annual Cost of Purchasing = Holding Costs + Ordering Costs + Purchasing Costs

Annual Cost of Ordering = Holding Costs + Ordering Costs

Both give same answer regarding savings for EOQ.

Criticisms of EOQ

It is based on simplifying assumptions, such as constant and predictable material usage rates.

It will not indicate the optimal purchase quantity when there are price discounts for buying larger quantities.

It ignores the problem of managing stock-outs.

It is inconsistent with the philosophy of just-in-time management and total quality management.

Inventory Management Systems: Periodic Review (Constant Order Cycle)

Inventory levels are reviewed at fixed intervals (monthly). The inventory in hand is then made up to a predetermined level accounting for:

Likely demand before the following review

Likely demand during the lead time

Slow Moving Inventory

Aged inventory analysis should be produced/reviewed regularly so that action can be taken:

Elimination of obsolete items

Slow-moving inventory items only ordered when actually needed (unless minimum order quantity is imposed by supplier)

Review of demand level estimate on which order decisions are based.

Inventory Management Systems: Just in Time (JIT)

A series of manufacturing and supply chain techniques that aim to minimise inventory levels and improve customer service by manufacturing at the exact time and quantities required at competitive prices.

In JIY systems the balancing act is dispensed with. Inventory is reduced to an absolute minimum or eliminated altogether.

JIT Suppliers

JIT manufacturers prefer single suppliers for high quality, frequent, reliable deliveries.

Suppliers benefit from long-term purchase orders and better forecasting.

Long term contracts and single sourcing improve product quality and shift inventory problems to suppliers.

Require smaller, more frequent loads with tighter schedules & penalties for non-delivery, hauliers become manufacturers partners.

Inventory holding costs are low but ordering costs are high.

Inventory Control Systems

Reorder level system (where inventory is ordered at a particular set order level)

Periodic review system (where inventory is checked and ordered at set periods in time)

Mixed systems incorporating elements of both.

Calculating Reorder Level (ROL): Known Demand & Lead Time

Having decided how much inventory to reorder (EOQ) the next problem is when to reorder (ROL)

ROL is the quantity of inventory on hand when an order is placed.

When demand & lead time are known with certainty the ROL may be calculated exactly:

ROL = demand in the lead time

Calculating Reorder Level (ROL): Variable Demand or Lead Time

ROL will be calculated as:

Maximum Demand X Maximum Lead Time

This will lead to the creation of buffer stock.

Buffer Stock

Quantity of inventory that should not usually be needed but that might be needed if actual demand during the supply lead time exceeds the average demand or if lead times are longer than expected. Buffer stock has a cost, the annual cost of holding buffer stock is the amount of the buffer stock multiplied by the annual holding cost for one unit of the inventory item (not needed for exam).

Optimum Buffer Stock Level

Where there is uncertainty, an optimum level of buffer stock (or inventory) must be found depending on:

Variability of demand

Cost of holding inventory

Cost of stock-outs

Inventory Warning Levels

Two warning levels might also be used to indicate when the quantity of an item in inventory is either:

Higher than should be expected

Below the buffer stock level

If gathering quantity of inventory goes outside these levels, inventory manager should monitor position carefully and take action.

Maximum Inventory Level

= Reorder Level + Reorder Quantity - (Minimum demand per day/week in units X Minimum reorder lead time)

This occurs when new new order delivered by supplier with minimal demand within minimal lead time.

Minimum Inventory Level (Buffer Inventory Level)

= Reorder level - (Average demand per day/weel in units X Average reorder lead time)