inventory manegeement

1/21

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

22 Terms

Main reason for holding inventory

To cope with unpredicted changes in demand

Three forms in which inventories are stored

Raw, wip, finished goods

Y r raw inventories stored.

-allows continuous production

-businesses can increase rate of prodiction easily to meet increased demand

Y r WIP inventories stores?

-reduces lead time

-balances production lines by saving time and reducing workload

-natural and essential part of the cycle

Y r finished goods stored in inventories

-to meet customer demands efficiently and effectively

-cope with sudden changes in demand

-goods r held until sold to final customers

Y is an effective inventory management important?

-to ensure that there r sufficient inventories during sudden change in demand

-poor management of inventories will lead to delay in supply

-to reduce risk of out of date products being stored

What is inventory management

Process of ordering, storing and using a company’s inventory

What r the costs of holding inventory

-opportunity costs

-storage costs

-risk of products becoming out of date/obsolete

Benefits for holding inventory

-allows continuous production

-reduces risk of lost sales - gives more choice to customer.

-large orders will get u bulk discounts

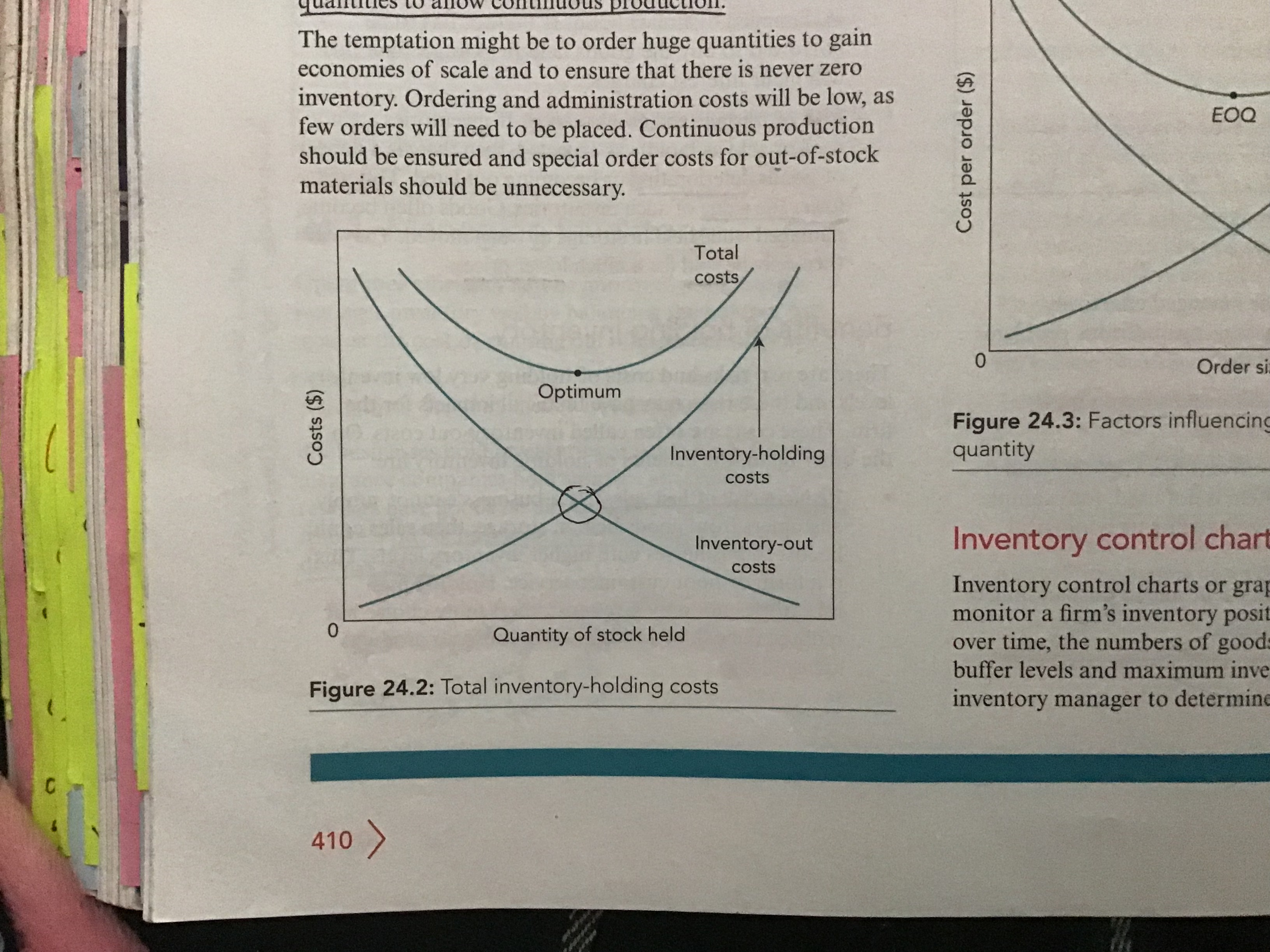

What is optimum order size

the right level of inventory

Economic order quantity

Calculating the optimum order size taking into account the delivery and storage costs

Supply chain

Network of all the businesses and activities involved in creating a product for sale

Supply chain management

Handling the entire production flow of a product from raw materials to finished goods

what does supply chain management do

-reduce time taken to deliver, produce products

-minimise costs

-speeding up new product development

-improve customer service and profits

-establishing excellent communication between buinesse and within the workforce

Two type of inventory management

JIT and JIC

What’s JIT

JIT is just in time inventory management.. in this, businesses hold little to almost no inventories and store only the required amount of goods for a given time period. They aim to avoid holding inventories

What’s JIC

JIC is just in case inventory management. They always have a buffer inventory and they aim to avoid running out of inventories.

Benefits of jit

-reduced storage costs

-reduced capital invested

-reduced opportunity costs

-more space available

-less chances of inventories losing value over time and shifts in customer preferences

Disadvantages of jit

-company reputation at stake

-delay in supply means delay in production

-accurate forecasts of demand is essential so a highly skilled forecast system is required

-frequent small deliveries incur more delivery charges

Advantages of jic

-continuous production

-much less need for accurate demand forecast

-eveonomies of scale from large bulk orders is possible

Disadvantages of jic

-products may lose value over time

-high capital needed

-high storage costs

Conditions for successful JIT

-Accurate demand forecasts

-flexible workforce

-advanced technology