metals: steel framing

1/80

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

81 Terms

steel type:

cold formed steel

use case:

trusses/lighter weight framing & decking

steel type:

open web steel joist

use case:

floor support & trusses/lighter weight framing decking

steel type:

high strength, low alloy

use case:

beams and columns

steel type:

weathering steel

use case:

beams and columns

steel type:

wide flange

use case:

floor support & beams and columns

steel type:

stainless steel

use case:

corrosion resistant

steel type:

hss (hollow structural section)

use case:

beams and columns & trusses/lighter-weight framing

steel type:

cast iron

use case:

strongest in compression but most brittle

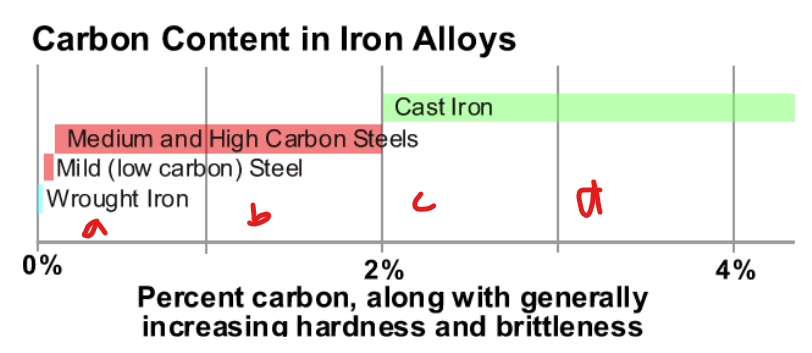

carbon content in iron alloy

greater proportions of carbon generally increase the hardness and brittleness of the iron alloy

carbon content in iron alloy graph

a. strong in tension/malleable

b. most commonly used for “structural steel”

c. strong in tension/compression (not prone to failure)

d. most brittle, prone to sudden failure

wrought iron

little or no carbon

strong in tension, weaker in compression

malleanle (easily shaped) and soft

mild steel (low carbon steel)

most common alloy for modern structural steel

not more than 0.3% carbon

small amounts of other metals improve strength, toughness, and other qualities

medium/high carbon steel

more than 0.3%, less than 2% carbon

strong in both tension and compression

ductile (not prone to sudden failure)

cast iron

2%-4% carbon

strong in compression

less strong in tension

brittle (vulnerable to sudden failure)

steelmaking

in a traditional steel mill, iron ore is the best raw ingredient

first, it is processed into molten iron in a blast furnace

then followed by conversion to steel in a second operation

steelmaking cont.

molten steel being tapped from an electric arc furnace into a vessel called a “ladle”

casting (steelmaking)

as the molten steel begins to solidify, it is cast into shapes ranging from plain rectangles or rounds to more complex cross sections, such as beam blanks, that approximate the shape of finished beam products

rolling mill

structural shapes are produced in a rolling mill

prior to rolling, the beam blanks are reheated to the necessary temp.

recycled content

about 25-35% recycled content

In North America, much of the structural steel is made from recycled scrap in mini mills using electric arc furnaces, converting scrap into new steel without needing to make iron from ore.

primary products are flat-rolled stock, such as steel decking and other sheet products

structural shapes

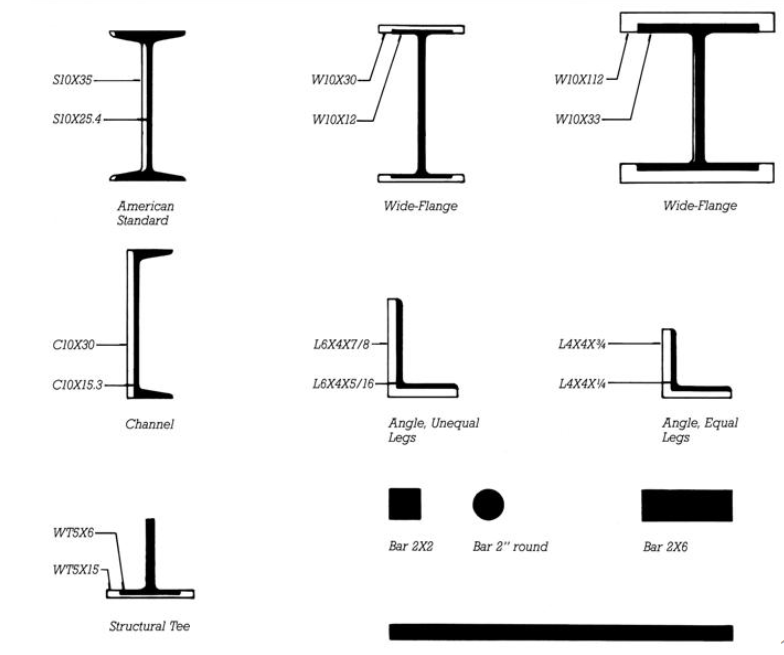

wide flange (w-shape): the most commonly used shape for beams and columns

channels, angles, tees: ofr trusses, lighter weight framing, and other miscell. uses

shape designation

W10×30

W: wide flange shape

10: nominal/theoretical depth (inches)

30: 30 lbs/lineal ft

wide flange shapes

taller more narrow profiles are

best for horizontally spanning

elements such as beams and

girdersthicker, more balanced (same

dimension both ways) used for

vertical spanning elements such

as columns.

aisc steel construction manual

dimensions page: dimensional data

properties page: shape properties related to structural stiffness and strength calculations

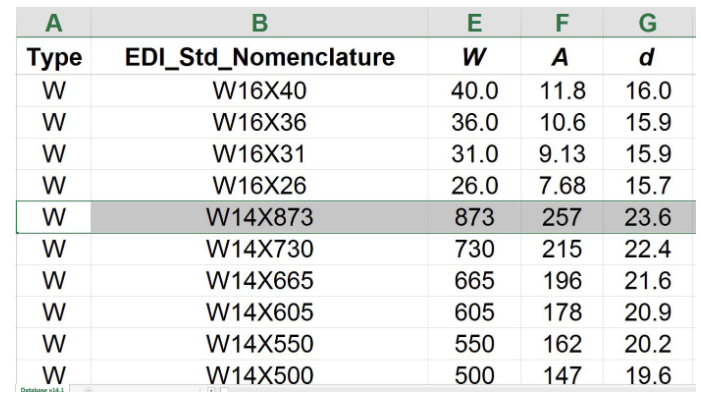

some exceptions in sizing

size designations are

nominal, not always an

accurate indication of

actual depth.a W14 x 873 is 23.6" deep!

other shape designations

S: American Standard beam

(“I-beam”)MC: Miscellaneous channel

C: American Standard channel

L: Angle

WT: T-shape cut from W shape

HSS: hollow structural section

hollow structural sections (hss)

hollow square, rectangular,

round, and elliptical shapesare used for trusses, structurally efficient

column sections, and where

the simple external profile is

desirableExample designation:

HSS 8 x 8 x ½

8"x8"x½" wall thickness

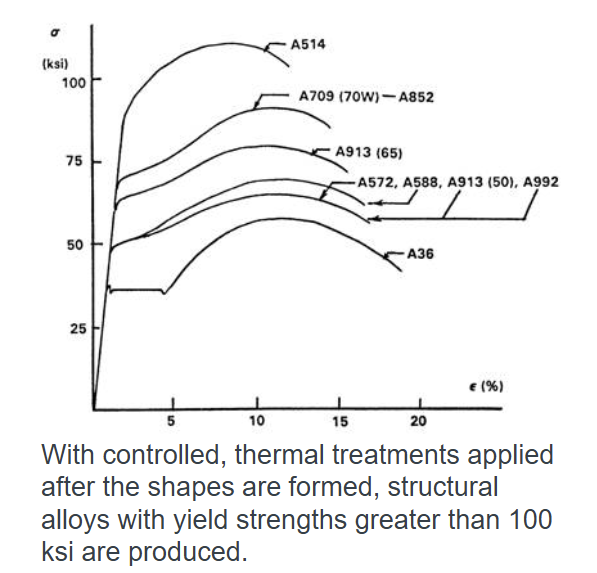

high strength, low alloy steels

use of stronger steel alloys

permits savings in weight and

reductions in the size of

structural elements, reducing

costs

weathering steel

surface oxidation

adheres to base metal,

limiting further rusting.

stainless steel

added nickel and chromium

forms self-protecting oxide

layer that provides long

lasting protection against

corrosion

cold-formed steel

deforming steel in its cold state

causes realignment of the steel

crystals and increases its strength.corrugated steel decking (right)

steel studs and joists

high-strength wire for concrete

prestressing strands

open-web steel joists (owsj)

lightweight pre-manufactured

trussesmade from both hot- and cold-

formed componentsdepths range from 8 in. to 6 ft

used for floor support

how do we join steel?

riveting: not widely used today

bolts: faster assembly on site

welding: more cost effective

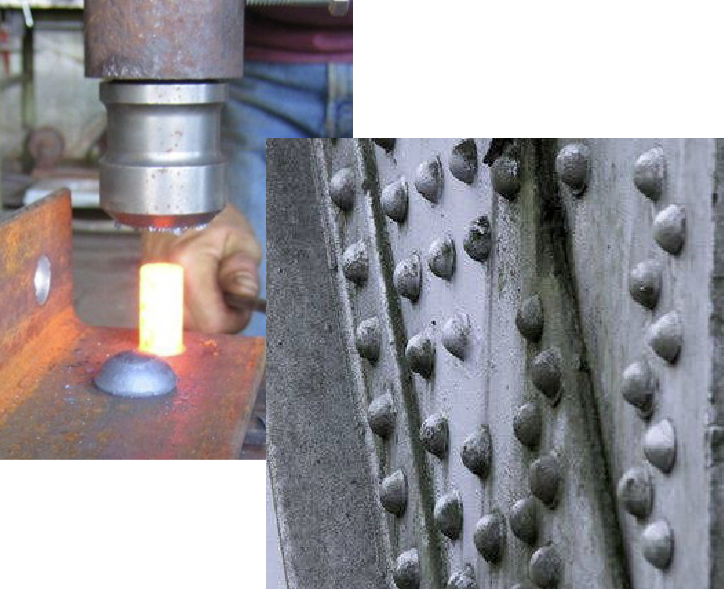

riveting

white-hot fastener is inserted

through holes in members to be

fastenedfastener is hammered to

produce a head on the plain endas the metal cools, it contracts,

and tightly clamps the steel

membersmostly found in historic

structures. Rarely used in

modern construction

bolted connections: carbon steel bolts

relatively low strength

limited uses, such as fastening

light framing elements or

holding temporary connections

bolted connections: high strength bolts

carbon steel bolts not used

often.instead, we tend to use high-

strength bolts:stronger than common bolts

used for fastening primary

structural members

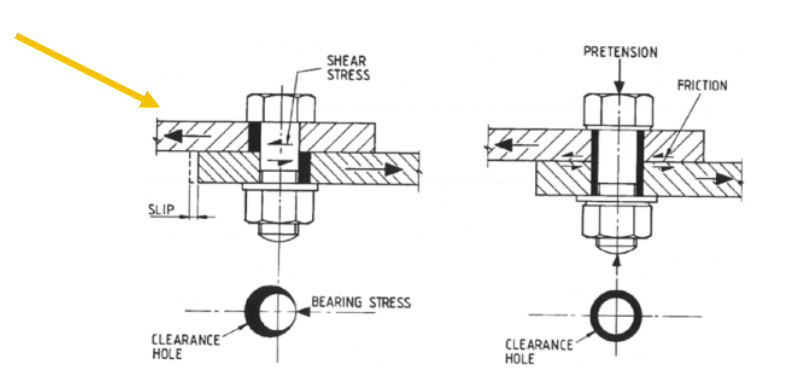

bearing-type connection

body of bolt resists movement between connected members by bearing directly against sides of bolt holes (left).

bolt is stressed in shear.

connection will slip before it reaches full strength.

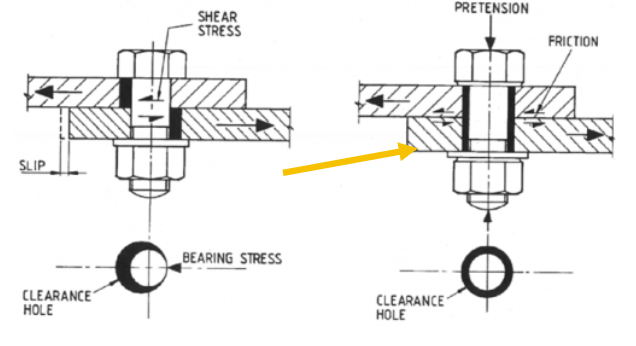

slip-critical connection

bolt is tensioned to such an extent that movement in the joint is resisted

by friction between the adjoining "faying" surfaces of the members

themselves (right).

• bolt is very highly stressed, but in tension.

• no slippage

bolt tensioning

with slip-critical connections, proper bolt

tension must be assured.turn-of-nut method: Nut is tightened

some additional fraction of a turn

after achieving a snug condition.

load indicator washers

when bolt is adequately tensioned,

protrusions on the washer are flattened.bolt tension is verified by inserting a gauge between bolt head and washer.

squirt dye for bolt tensioning

some load indicator washers squirt dye

when adequate tension is achieved, making inspection easier

tension control bolt

when bolt is adequately tightened, the splined end snaps off

bolt tension is verified by visually inspecting for splines.

t.c.b. also allow tightening with access to only one side of the bolt.

welding

steel surfaces to be joined are heated to a molten state

additional molten metal is added from the electrode

in finished joint, members are fully fused

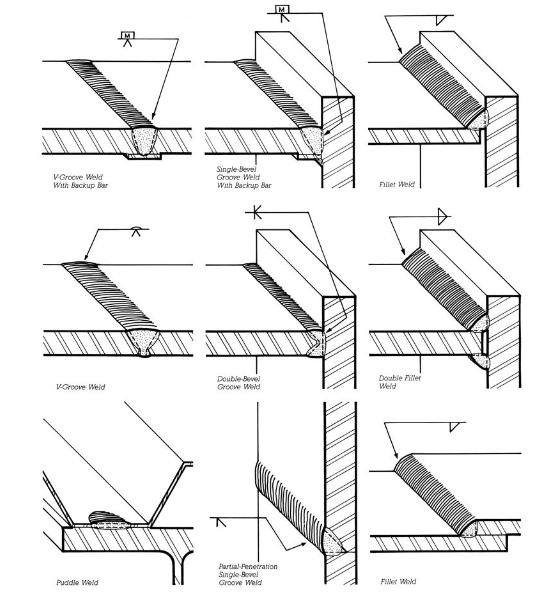

welding terms

fillet welds: easy to make, little

joint preparation requiredgroove welds: require properly

shaped and spaced jointspuddle welds: fasten metal

decking to structural members

structural stability of welding

welds critical to structural stability may be inspected/tested (ultrasonic, magnetic, etc.) to ensure their soundness and freedom from hidden flaws.

details of steel framing

connection types

shear (simple connection)

moment (fully restrained)

steel frames

braced frame (simple connection)

moment connection (fully restrained)

shear walls

shear connection

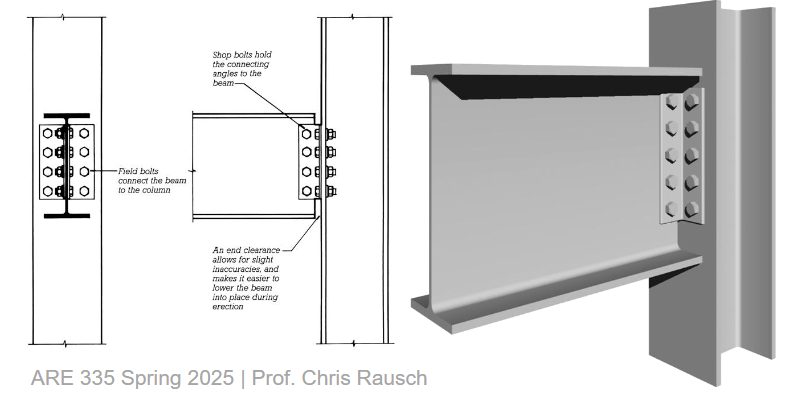

angles, plates, or tees connect web of beam to side of column.

angles are usually joined to beam in the fabricator's shop.

beam/angle assembly is bolted to the column in the field

shear connection (simple connection)

transfers gravity loads from beam to columns.

not sufficiently rigid to transfer bending forces.

modeled structurally as if it is free to rotate, or hinged.

AISC Simple Connection (SC)

seated connection (shear conn.)

another version of shear connection is a

‘seated connection’ which relies on an angle below the beam and above.this is used when connecting a beam to a column web

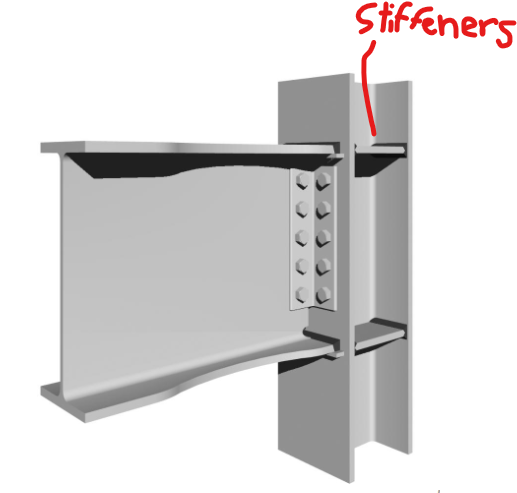

moment connections

transfers gravity loads and bending forces.

beam flanges are joined to column.

column is reinforced to carry bending forces.

beam is restrained from even small rotations.

AISC Fully Restrained (FR)

beams/columns in mom. conn.

a pair of beam-column moment

connectionsfull penetration welds join top and bottom beam flanges to column and column reinforcing plates

dog bone cut (mom. conn.)

"dog bone" cut creates a zone of weakness.

in extreme seismic event, this area will deform plastically, protecting the more brittle welds from failure.

single common bolt holds beam temporarily prior to welding.

stabilizing building frame

rectangular geometry of the building frame must be made stable against lateral forces by:

diagonal bracing

moment-resisting frame

shear walls

braced frame

diagonal bracing creates stable, triangular geometry

can be constructed with shear connections between beams and columns (free to rotate).

moment resisting frames

some or all of the beam-column connections are moment connections

capable of resisting rotations between the members, making the frame stable

shear walls

rigid vertical walls or core structures resist lateral forces.

remainder of frame relies on shear connections.

usually concrete (occasionally heavy steel plate)

bolted web and welded flanges (connection)

the shear tab is deep enough to position

the bolts clear of the column flanges for easy access.AISC Fully-Restrained (FR)

construction process timeline

1. Preparation of Structural Drawings (Structural Engineer)

2. Preparation of Shop Drawings (Fabricator)

a) Detailed fabrication & erection drawings

b) Detail each piece and connections

3. Submission & Approval

4. Order “stock” lengths

5. Fabricate each piece (after Shop Drawing Approval)

6. Ship to Jobsite

7. Erection (Erector)

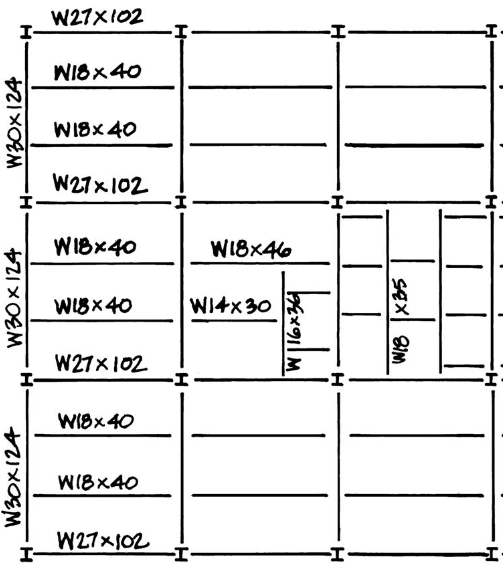

steel framing plans

shows sizes and locations of

steel membersdimensions have been omitted

from the plan in pic

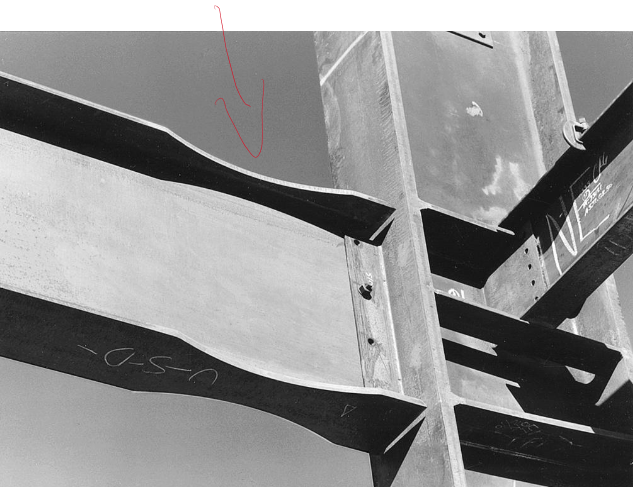

steel framing plans examples

W30 girder-column connection: girder to column flange

W27 beam-column connection: beam to column web

W18 to W30 connection: coped beam-girder

steel detailing and farbication

fabricator makes shop drawings based on contract documents

each component is dimensioned

each connection fully detailed with dimensions of all connection angles, holes, bolt diameters and types of welds

shop or field connections identified

type of bolted connection

after modifications by GC, A & E, materials ordered from rolling mill

components fabricated in shop, shipped to site for erection

fabricator’s role

the fabricator prepares shop drawings showing the configuration of each member.

drawings are reviewed by

architect and structural engineeralso shares responsibility for design of the steel connections, based on more general requirements provided by the structural engineer.

building information modeling

more recently, using bim systems, steel

fabrication information and details

made by the structural engineer in the building model can replace fabricator shop drawings.

steel fabricator

fabricator prepares steel members and delivers them to the construction site

workers cut to length, cope, drill, punch, weld, and add tabs, angles, plates and other accessories to members from the approved shop drawings.

band saw cuts heavy members to size

fabricated members are stacked using overhead crane, awaiting transportation to the construction site

members are individually labeled to correspond to information on the erection drawings.

steel erector

assembles steel members delivered to the construction site.

may or may not be same entity

as fabricator.workers are called ironworkers

steel frame erection sequence

erect columns

install beams and girders

plumb structure

complete (weld or tighten) all connections - including diagonal bracing

install edge angles & decking

start next tier

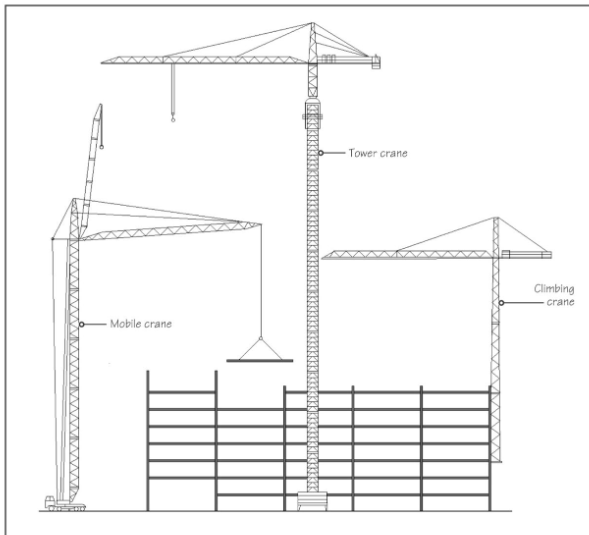

cranes used for steel frame erection

mobile, tower, and climbing cranes

structural steel erection (1st tier columns)

column base plate

distribute loads

attachment to fdn.

often shop welded

holes must match

anchor bolts in ftg

coulmn set to proper elevation

Options:

Leveling Plate

set in grout prior to column erection

Leveling Nuts

nuts set to elevation prior to steel erection

Shims

metal shims set to proper elevation

plumbing structures

as the frame is erected, temporary cables with turnbuckles are used to plumb up (make vertical) the frame.

steel decking

corrugated steel decking laid over

the framing is the most common

floor and roof decking material.the decking is puddle welded to

framing memberssteel decking comes in a variety of

profiles and depths to suit different

load and span conditions.

metal decking attachments

mechanical fastener (self-tapping screws)

welding (common for floor deck)

shear studs

welded to tops of beams, through metal decking

once concrete is poured, the beams, decking, and concrete act together structurally as another form of composite construction

composite metal decking

functions as formwork for concrete and steel reinforcement

often in combination w/ shear studs

creates a shear connection between

deck & frameincreases carrying capacity

produces lighter, stiffer, & less costly

frame

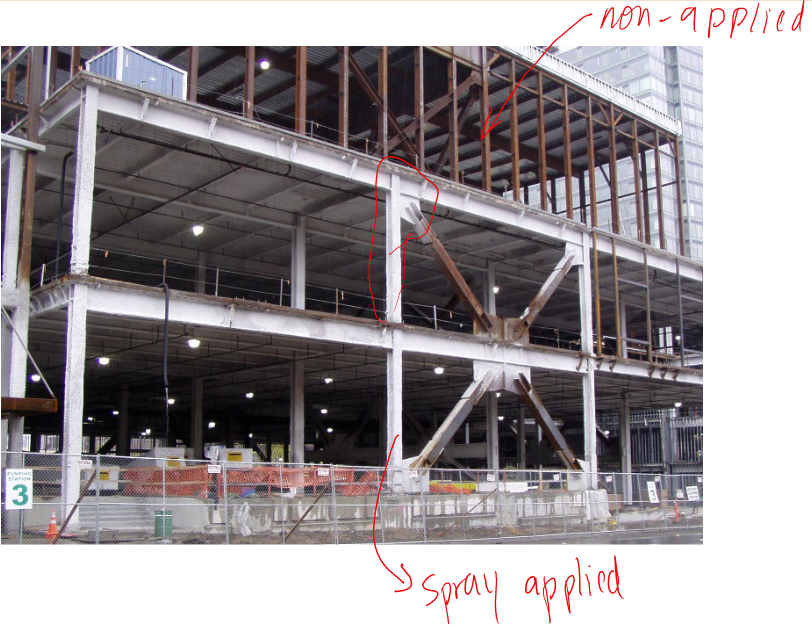

fireproofing

above roughly 500-600 F,

steel rapidly looses strengthfireproofing acts as insulation, protecting steel from the heat of fire

fireproofing materials

concrete

plaster

gypsum board

gypsum wallboard

spray-applied insulation

loose insulation within

column cover

spray-applied fire resistive material (sfrm)

most common approach

to achieve an equal level of protection, lighter members need more insulation than heavier ones, since lighter members heat up more quickly

spray-applied fireproofing, in progress, applied to framing in a steel high rise structure (in pic) (thickness is greater on columns)

metal decking does not require additional fire protection

steel & building codes

without fire protection:

building heights & areas severely limited

with proper fire protection:

unlimited building heights & areas permitted for most occupancy groups

corrosion: 2 basic causes

ferrous metals oxidize rapidly when exposed to moisture, salt, chemicals

galvanic action between different metals

corrosion protection approaches

stainless steel (Type 316) should be used in critical exposures/applications

isolate/insulate incompatible metals

e.g., plastic washers

rust-inhibitive protective coatings

reduce ambient moisture & humidity; increase local air circulation

sacrificial galvanic anodes (temporary/time based)

corrosion protection approaches (temp. & perm.)

temporary protection

prime coat (red-brown color)

permanent protection (method varies with environment, and type of steel)

large exposed structural steel

acrylic, epoxy

polyurethane coating most permanent for exterior application

cold formed or light structural steel

galvanizing (zinc coating metallurgically bonded to steel)

early detection of corrosion: how?

currently, when accessible, via E-M

current & ultrasound technologiesbeing studied:

fiber optics

“smart paint” which changes color in the presence of corrosion

sensors