Tablet formulation and excipients

1/53

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

54 Terms

what are tablets

Solid dosage forms containing medicinal substances with/without suitable diluents

have many shapes and designs, which depend on a die set

die set consists of two punches: upper punch and lower punch, and a die cavity

what are the advantages of a tablet to a patient

Accurate dosage/minimum variability

Ease of administration

Elegance

Convenience (Light & compact)

what are the advantages of a tablet to a manufacturer

Suited for large-scale production

Variation & low cost.

Special release profiles possible

Easy/cheap to package & ship

what are the disadvantages of tablets

Swallowing

Poor wetting / slow dissolving drugs

Dosage

Bitter taste

Oxygen/moisture sensitive may require coating

how are tablets formed

powder formulation

compressions

the manufacturing of tablets is hard as it involves different components/excipients like diluent, binder, glidant and disintegrant

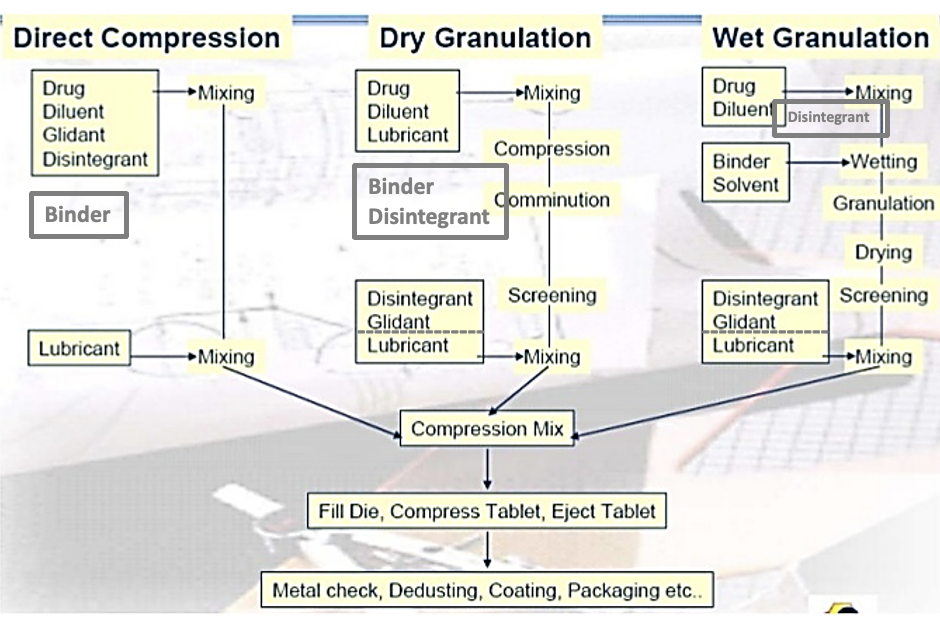

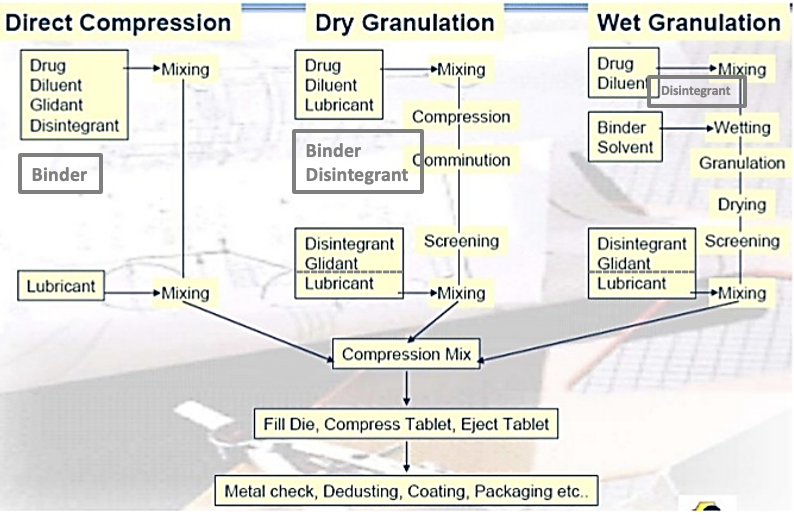

what are the three methods of tablet manufacturing

dry compression

dry granulation

wet granulation

each method consists of a different number of steps

what components are needed for a good tablet

API (active pharmaceutical ingredient)

excipients

what are examples of excipients

Diluent

Binder/Adhesive

Glidant/lubricants

Disintegrants

Coloring agents

Flavoring agents

Coating agent

what are the minimum characteristics for the design and formulation of compressed tablets

Compactibility → ability of excipients to compress well + maintain strong VDW forces (aids binder/adhesive)

Fluidity → abiility of a substance to flow (aids granulation+flow)

Lubricity → for Ejection of Tablets and prevent sticking to the walls of the dye/punches (aids lubricants)

what are diluents (fillers)

Bulking agent that mainly consist of carbohydrates and some inorganic salts

consist of 10-50% of powder formulation

Must meet criteria of good compressibility

physically and chemically stable

inert (won’t interact with drugs)

Must be biocompatible (no allergic reactions)

what are common diluents

lactose

glucose

sucrose

starch

sugar alcohols: sorbitol, mannitol, xylitol

cellulose

Dicalcium Phosphate dihydrate (Emcompress)

what is cellulose and why is it used as a diluent

polysaccharide consisting of linear chain of many glucose molecules linked by glycosidic linkage

biocompatible (no allergic reactions)

chemically inert

good compactability and disintegration properties → used as a binder and disintegrant

(but hydroscopic so can go through hydrolysis)

most common example of cellulose is MCC

why is Dicalcium Phosphate dihydrate (Emcompress) used as a diluent

their particles tend to break to increase the size of granules and improve flowability

this is helpful in mixing and tablet formation

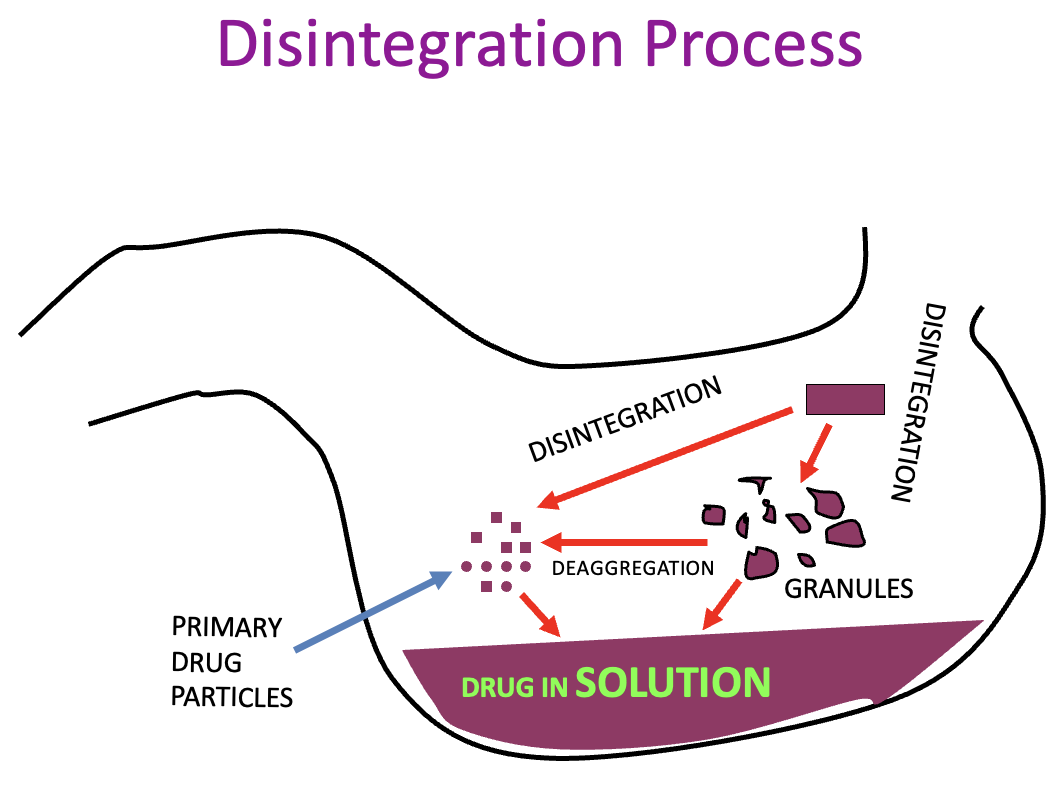

what are disintegrants

substances routinely included in tablet formulations and many hard shell capsule formulations

promote moisture penetration and dispersion of the matrix of the dosage form in dissolution fluids to expose primary drug particles

can break tablet to expose the particles for therapeutic action

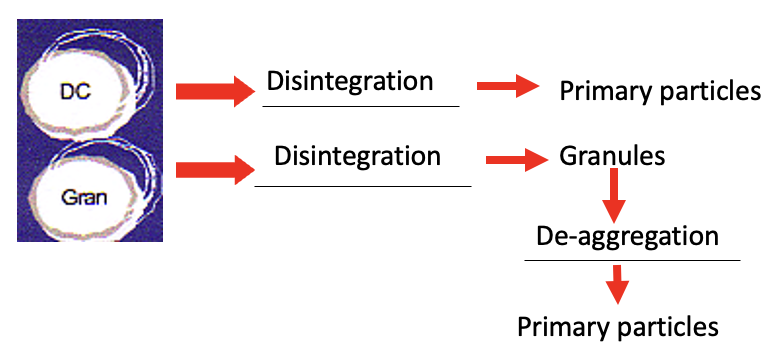

what is the disintegration process

if tablet made from granules, it will disintegrate from granules into individual particles

If made by direct compression method, they will break into individual components as powders are directly compressed into tablets, without granulation process

therefore, dissolution is generally quicker with direct compression tablets

what does it mean if all disintegrants are hydroscopic

they absorb moisture, drawing liquid into the tablet

usually swell and disintegrate, breaking the tablet into pieces

give examples of disintegrants

Starch

Modified Cellulose or Super Disintegrant

Cros-carmellose sodium

Sodium Starch glycolate

why is starch used as a disintegrant

it is effective when used up to 10%

mode of mechanism is through swelling properties → starch is considered as elastic in nature

de-form under pressure

energy-rich → energy is released when in contact with water, which breaks the tablet

why is modified cellulose or super disintegrants like cros-carmellose sodium and Sodium Starch glycolate used as disintehrants

they swell due to cross linking, which breaks the tablet

they don’t dissolve but absorb water due to cross linkages

generally used from 1-5% in tablet formation

when more than 8% of super disintegrant used, disintegration time increases because above 8% they make jelly/jelling→ viscosity increases

when using wet or dry granulation methods, when are disintegrants added

we add half before granulation (intrangular) and half after granulation (extrangular)

half will break the tablets, other half will break granules individually

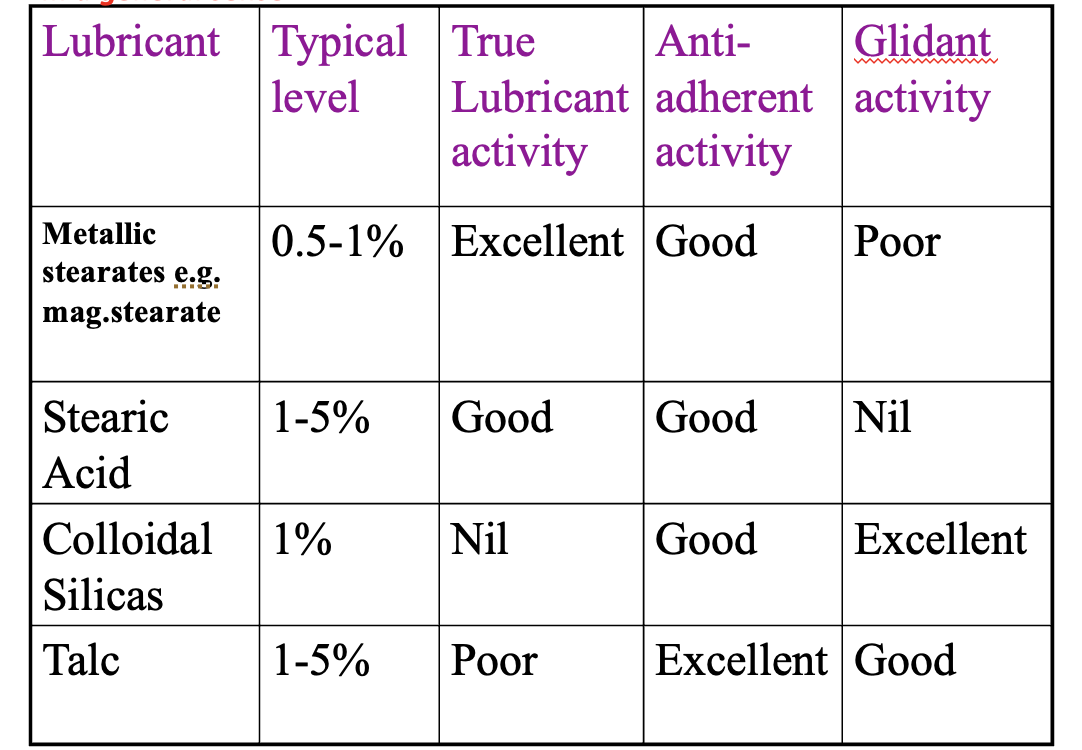

what are the three main roles of lubricants in tablet formation

true lubricant (reduce friction during tablet compression/ejection)

anti-adhesion (prevent tablet/particles sticking to surfaces)

glidant (improves flow of particles)

what will happen if lubricant isn’t present in powder formulation

it may cause capping and fragmentation of tablets

Capping → either upper or lower part of tablet separates horizontally from main body of tablet upon ejection during compression process

fragmentation/elimination → tablet is horizontally fractured into many distinct layers upon ejection

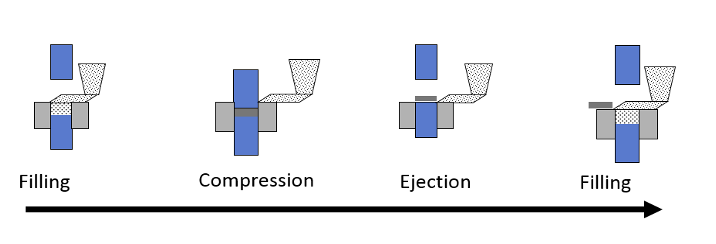

what three phases does tablet compression consist of

filling

compression

ejection

types of lubricants

metallic stearates is the best lubricant due to its excellent true lubricant activity → prevents friction between surfaces of particles

but has poor glidant activity → can be fixed by adding a separate excipient as a glidant

why are lubricants effective

they are hydrophobic (not water soluble) e.g. magnesium stearate

what are the issues with lubricants

mixing for too long increases disintegration and dissolution time

powder mixing causes slight heat generation so hydrophobic layer over the particles/granules, prevents moisture penetration

high amount of lubricant can interfere with bonding and soften tablets

particles of lubricants adhere to surfaces of large particles and reduce bonding between particles during compaction, forming tablets of lower strength

what are glidants

improve flowability of granules or particles from hoppers and into die cavity during compression

enhances flowability of direct compression mixtures, but can be used in granulation for high production speed

poor powder/flowability can cause weight variation among tablets

the optimum concentration is related to the amount needed to just coat the bulk powder particles

traditionally, talc used in tablet formulation as a glidant in conc of 1-2%, but now most commonly used is colloidal silica in a very low conc of less than 1%

what is a binder

adhesive agents which glue a number of various particles to each other to make a granule

helps hold tablet together and improves compactability

this size enlargement process improves flowability

used before wet granulation (binders are dissolved in a suitable solution either (water or alcohol), the liquid binder is referred to as granulation liquid

in dry granulation, we use them as a dry binder before compaction (slugging/compact mass/tableting)

what are flavouring agents

for pleasant taste to mask unpleasant taste

coats the tablets/granules.

are thermolabile (heat-sensitive)

often mixed with the granules as an alcohol solution

can be added with powder formulations using direct compression methods

what are colorants

used to dress up the tablets to make it more attractive

helps with Identification e.g. for older patients

can help with patient compliance

what are the two main manufacturing methods

Direct Compression (DC) method

Granulation method

Wet Granulation

Dry Granulation

what is Direct Compression (DC) method

simple method to reduce production time and cost as it only contains two major steps: mixing/blending and compression

mix/blend all the excipients together containing diluents, glidants, disintegrants in the drug

sieve

then before compression, lubricant can be mixed

followed by direct compression

blend → sieve → blend → compress

what is the starting point for making a new tablet formulation

the size of the dose

low doses

<25 mg

most of the tablet will be excipients

API should equally mix with excipients to give required dose in each tablet → important to achieve a content of uniformity

high dose

>250 mg

Most of the tablet will be drug/API

good compatibility and flowability properties

what manufacturing method is preferred for low dose drugs

direct compression method

because we blend/mix all the excipients with the drug/API and compress it straight away

If there are any problems in compression e.g. lack of compactibility/flowability, direct compression fillers (DC filler or DC excipients) can be used

what are the advantages of direct compression over granulation

more economical due to less time

avoids heat and moisture due to no solvent

when made from mostly MCC (diluent), better flowability due to large particles and high compressibility

what are the disadvantages of direct compression

segregation → content of uniformity/distribution of active ingredient can be affected in low dose drugs, causing segregation (the process when one of the ingredients based on their size, shape or density can be separated out from the rest of the powder formulation)

not practical for large doses → if drug possesses poor flowability/compactability, then granulation method is better

requires tight control over excipients → in terms of properties like flowability, disintegration and compactability etc. If excipients don’t possess these properties, its expensive to produce new DC excipients

punch wear → DC may damage the punches as powders are directly compressed into tablets using high compression

dust

what is granulation

size-enlargement process in which primary powder particles adhere to form larger, multi-particle entities called granules

what is the need for granulation

prevent segregation (the separation of one ingredient from the rest of the formulation)

flow improved (as increase in particle size reduces particle interaction)

improve the compaction characteristics (as addition of binder produces tablets of required mechanical strength)

reduces dust (as no fine particles present in granules)

what are the similarities between dry and wet granulation

improve flowability, particle size, and die filling

both contain many steps and so are time consuming compared to direct compression

what is the traditional granulation method

wet granulation

involves wetting the powders with binder solution (glue) and drying

two main methods of wet granulation

wet massing techniques

fluid bed granulation

not suitable for heat/water sensitive drugs → DC is used

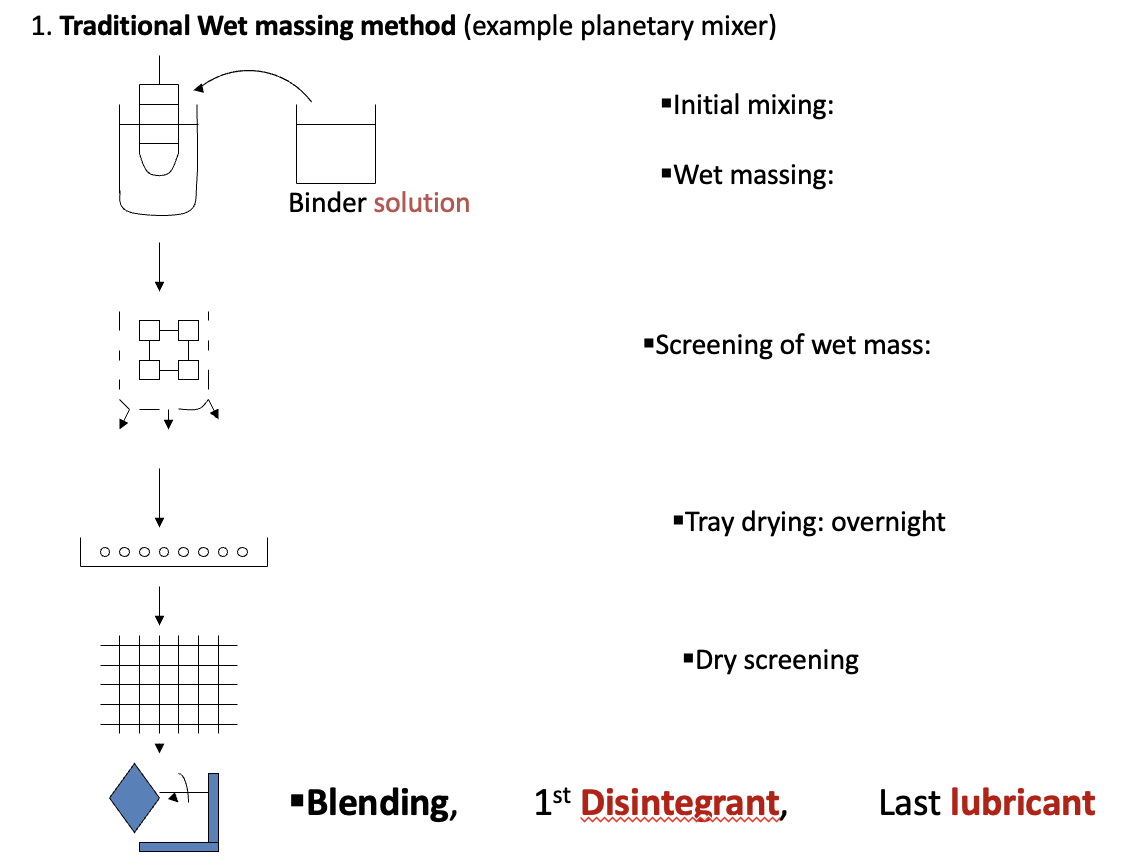

what are the steps of traditional wet massing method

initial mixing of drug and diluent using a planetary mixer

wet massing formed by addition of binder solution

screening of wet mass by passing through a mesh-sieve to make granules

tray drying overnight: granules transferred to trays/dried in oven for few hours depending on temperature conditions

wet can checked from time to time until no further increase in mass

dry screening: dry granules passed through sieve/mesh again for potential sticking of granules to each other

blending/mixing with disintegrant, then lubricant

granules are then ready for compression

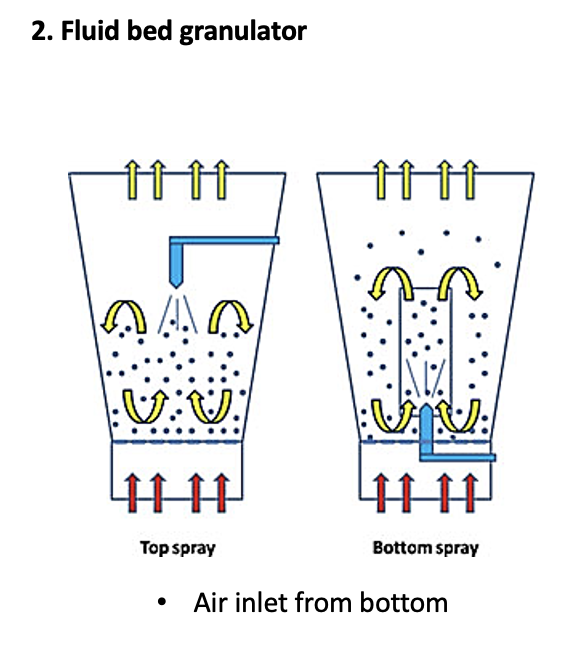

what is the fluid bed granulator

a multi-purpose, processing equipment commonly used in pharmaceutical industries

mixing, granulation and drying are carried out simultaneously

how does the fluid bed granulator work

powder material placed over perforated plate

hot, filtered air blown through perforated plate to fluidise particles and mix powder

granulating fluid pumped from a reservoir through spray nozzle positioned over the bed of particles.

the fluid causes the primary particles to adhere when the droplets and powders collide

escape of material from granulation chamber prevented by exhaust filters, which are agitated to reintroduce the collected material into the fluidised bed

sufficient liquid of binder solution is sprayed to produce granules, hot air makes granules dry uniformly to give uniformed granules

the spray is turned off but the fluidizing air continue to dry the granules.

what are the advantages and disadvantages of wet granulation

advantages

spherical shapes made

binder keeps particles in a uniformed form → easier to compress

granules prevent segregation and eliminate dust formation

disadvantages

heat and moisture sensitive due to use of solvent

longer disintegration time as tablets disintegrate into granules, then individual particles

many steps so labour intensive and time-consuming

what is dry granulation

converts primary powder particles using pressure, without the intermediate use of a liquid (dry binder used, not solvent)

avoids liquid-heat combinations that might cause degradation of heat-sensitive materials

what are the two major steps for dry granulation

in first step after mixing , powder formulation compressed in compact mass/flakes/slugs

slugs/flakes converted intr granules and pass through mesh/sieve, followed by mixing with disintegrant and finally lubricant

granules compressed into tablets

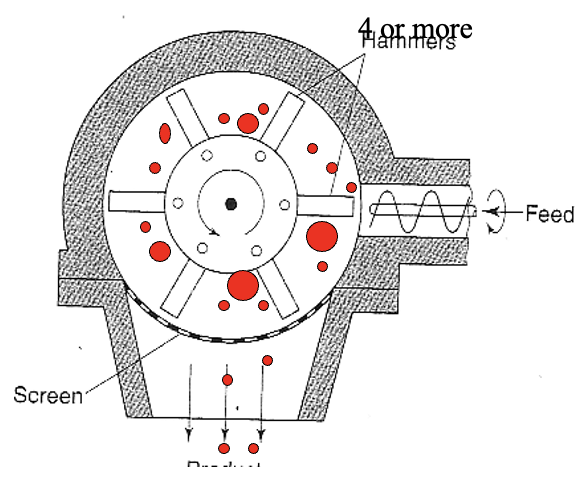

what is slugging in dry granulation

dry powders compressed using a conventional tablet machine or a large heavy-duty rotary press

the compact made in the process (typically 25 mm diameter, 10-15 mm thick) is termed a ‘slug’ → bigger tablets

hammer mill is suitable for breaking the compacts (convert slugs into granules)

high velocity of hammer causes brittle fracture (small granules are less prone to fracture than larger granules)

granules retained by screen/mesh at bottom to allow only granules of required size through

what are roller compactors

alternative gentler method to making slugs

powder mix is squeezed between two rollers to form a compressed sheet

sheet is weak and breaks into flakes

flakes broken using gentler treatment (screening alone) to form granules

what are the two equipments necessary for dry granulation

machine for compressing the dry powders into compacts mass or flakes

mill for breaking up the compacts mass or flakes into granules.

summary of the different manufacturing methods

diagram showing the stages of DC and granulation to give primary particles

tablets from DC exposes primary particles (active ingredients) much quicker than tablets manufactured form granules

summary steps for wet granulation

1. Milling of drugs & excipients

2. Mixing of milled powders

3. Preparation of binder solution

4. Mixing of binder solution with powder mixture to form wet mass

5. Coarse screening of wet mass using 6 to 12 mesh screen

6. drying of moist granules

7. Screening of dry granules through 14 to 20 mesh screen

8. Mixing of screened granules with disintegrate + mixing with lubricant

9. Tablet compression

summary steps for dry granulation

1. Milling of drugs & excipients

2. Mixing of milled powders

3. Compression into large, hard tablets, to make slugs

4. Screening of slugs

5. Mixing with disintegrant + Mixing with lubricant

6. Tablet compression

summary steps for direct compression

1. Milling of drugs & excipients

2. Mixing of mill powder

3. Tablet compression