Insights into Food Production

1/63

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

64 Terms

Disadvantages of using a a single ingredient instead of a flavour system

More microbiological contamination risk. (EU - no preservatives in soft drinks bc of the hyginic handling)

Needs standardisation. More internal resources, quality control, and recipe development.

Complicated Supply Chain. Individual dosing, different suppliers, sometimes very small quantities to handle.

For the flavour system, it is spray dried (low aw) and the producer (eg, ADM) takes responsibility for production under the food grade hygiene conditions and standards.

Name beverage defects

Phenomenon that occurs over time that causes a negative reaction in a final consumer.

Visual Changes - eg, microbial spoilage that causes an increased CO2 production; turbidity due to pectin degradation.

Ring Formation - floating of oil or undissolved colour particles

Sedimentation → clearing down: supernatant becomes transparent

Floating → clearing up. Induced by enzymes or moulds.

Precipitation, floc formation - induced by the pH shift

Colour Changes

Slight sensory changes

Unpleasant Off-Taste

Ingredients Degradation

Neck Staining - more pronounced in PET

Desired characteristics of colours for soft drinks

Water-soluble or at least dispersable

Stability under acidic values (pH < 3.8), under heat stress (pasteurisation), over time at RT, with O2 (e.g., beta carotene is destroyed easily → asc.acid stabilization).

Suitable sensory properties: taste

Suitability of colour - 80% of the sensory perception is visual, first impression

What are main colours for beverages?

Brown - Caramel (cola - 40% in EU)

Yellow - ß-carotene

Red - anthocyanins

What are preferred emulsifiers?

Gum arabic

1-2% of it adsorbs at the oil surface (protein fraction adsorbs). It provides steric stabilisation (neg.charge) and avoids coalescence.

OSA Starch

They influence density and turbidity.

Why does one need additives for beverages?

Antioxidants = Protection from O2: especially for PET bottles that are more susceptible to permeation.

Acidifiers = adjust pH and support mouthfeel.

Stabilisers and thickeners. Locust bean gum - for low juice content, mouthfeel improvement - pectin, cellulose, emulsifiers - gum arabic and OSA starch.

Preservatives. If single ingredients are used for the production instead of a flavour system. Benzoates (E210-213) and sorbates (E200-203).

Why is Brix hard to use as a standardising method when sugar is used as a sweetener?

Under acidic conditions, sugar undergoes inversion = sucrose → fructose + glucose

Mw of separate compounds is bigger as water is attached (360 vs 342 g/mol).

Briefly descrive mango production

Storage in the ripening chambers: manual check, automatic control of T and time

Sorting, two-stage washing, cutting (manual) and pulp extraction (gently with big screws)

Destoning, mixing

Asceptic filling, sterilization, storage

What is the major problem in tropical fruit purees, concentrates and nectars?

Colour change because of the browning.

Enzymatic browning. PPO = polyphenol oxidase.

Counteraction: heat inactivation of the enzymes, reducing agents addition, reducing pH, dearation

Non-enzymatic: Maillard. Formation of melanoids.

Lower T, reducing pH, dearation

What is called tea?

Product produced from a tea plant - Camelia sinensis

Why do tea impurities occur, and which chemical is of concern?

From machine plucking

Pyrolidizine alkaloids - natural plant protection chemical

Acute liver damage & cancer

What enzymes are responsible for black tea colour? When they are set free?

Polyphenol oxidase (PPO) and peroxidases (POD) → theaflavins and thearubigins

They are set free during the withering step (drying)

30% of a dry leaf are extractable polyphenols.

So, for green tea 💚, there is a mild inactivation with steaming (Japan) or roasting (China)

Two methods for tea crushing and why is it done

Orthodox method → tea leaves appearance

Crush Tear Curl (CTC) → powder for tea bags

It is done to extract all the flavours and for the fermentation to start.

What is tea cream?

It is a precipitate that occurs due to the reaction btwn theaflavins, thearubigins, and caffeine.

pH and amount of dry solids (25-35%) dependent

In what way is orange as a fruit different from an apple?

From orange, one can get cold pressed oil and oliophase (volatile)

Ways to extract flavour compounds

Distillation

Solid Phase Extraction

Cone Spinning Column

Cross modal interaction of taste

Aroma

Taste

Texture and Moutfeel

What are flavourings according to the law

Products not intended to be consumed as such, which are added to food in order to impart or modify odour and/or taste

“Flavouring Substance” is the main group

Difference between peach extract and natural peach flavour

Peach extract - 100%

Natural peach flavour - 95% fruit

Raw materials for beverage production

Water: natural mineral, spring, demineralized

Acids: support antioxidants and increase effectiveness of preservatives

Citric Acid: monohydrate and anhydrate

Phosphoric Acid: cola drinks, very aggressive.

Lactic Acid

Malic Acid

Sugars or Sweeteners/Polyols

What is the goal when creating sweetness with sugar substitute?

To mimic the sucrose curve

Onset Sweetness

Peak Sweetness

Core Sweetness

Lingering Part

Full Body, moutfeel

Sweeteners have a later peak and lingering part

Order mainly used organic acids by strength to decrease pH

Citric > Malic > Lactic Acid (number of carboxyl groups)

What are the regulations for stating vitamins on the package?

They should be present at the end of the expiration date at 15% RDA

Water-soluble vitamins are easy

Fat-soluble are emulsified or encapsulated

Two most important preservatives

Benzoic (in benzoate form) and Sorbic Acids

Benzoic Acid shouldn’t be present in drinks with vit.C

They’re inhibiting bacterial growth, but not killing bacteria

Benzoic Acid is effective against yeasts and bacteria. Sorbic Acid - against moulds.

Typical pH of beverages and cola, orange juice, Apfelschorle, Ice Tea

Typical <3.8, right on the border with E.coli growth region

Cola: 2.8

Orange Juice: 3.2

Apfelschorle: 3.6

Ice Tea: 3.8

CO2 of cola, orange juice, Apfelschorle, Ice Tea

Cola: 8 g/l

Orange lemonade: 6.5-7 g/l

Apfelschorle: 4.5 g/l

Ice Tea: 0 g/l (most sensitive to spoilage)

How are Döhler and ADM making life of beverage producers easier?

They are pre-mixing target formulas: flavours, colours, juices, concentrates etc., so that the main producer just has to add water, sweetener, and acid.

What does Brix measure?

Soluble dry matter in a liquid → sugar content

Frequency of MO contamination

90% yeasts = turbidity, sedimentation, CO2 formation, fermented smell

6% bacteria - diacetyl smell

4% moulds

Methods of beverage preservation

Physical: pasteurization

Chemical: preservatives, velcorin

Why is beer naturally preserved?

Hops bitter substances

Alcohol

Lack of easily metabolised nutrients

That leads to lower pasteurisation T

Viscosities for plate and tubular heat exchangers

Plate: low viscous. Smaller volume, cost saving

Tubular: high viscous. Pulpy, with fibers etc

Why preservatives arent used at neutral pH?

Only the undissociated form of acid is able to enter the cell (lipid membrane)

Neutral pH > pKa => dissociated acid => unable to enter the cell

Cold disinfection of beverages

Velcorin

It is placed right before bottling

No sensory impart, not necessary to declare

Pre-filtration or flash pasteurization is needed, as the system requires low microbial load.

There is always a risk of contamination with bottling, because bottling fillers aren’t hermetically sealed unless there’s an aseptic filling.

Soft Drinks Production Steps

Compounds Delivery

Water Treatment

Syrup Preparation: mixing of compounds with sugar and water

Beverage Mixing: dilution with water

Pasteurisation

Carbonation

Filling and Bottling

Why is enterpreneurship needed in food tech?

To transform the system, which is not on track for health, climate, and resource goals.

Systemic Pressure: population growth, urbanisation, climate change, biodiversity loss

Innovation Gap: deeper changes of production processes happen in smaller and more agile companies

Translating Science into Practice

Ideas: Alt Proteins, Upcycling, local sourcing

New Food Technologies examples

Processing Innovations: new texture, safety profiles that support healthier and lower-impact products. Revo Foods: funghi-based salmon.

Digitalisation: innovative tools to optimize production, reduce losses and increase transparency. SkoneLabs: AI layer for IoT and sensors.

Scaling Novel Concepts: mostly done by smaller companies rather than big players.

Role of StartUps

Drivers of Change: concrete pilots for new ways of production

Complementing incubements: de-risking new approaches that big companies can scale via partnerships and investments.

What is “from idea to market”?

Support of promising food innovations from early prototyping up until the market adoption. These technologies can be then used by farmers, industry and consumers across Europe.

Barriers that hold Europe from realising its full potential

Due to the existence of “double valley of death”

Regulatory approval, scale up and market adoption take years → cash burns.

Pre-commercialisation gap. No investments for the prototype.

End of research phase → no government support.

No proof at a scale.

Angel Investors, Incubators.

Scaling gap. Commercialisation step. Regulatory approbal, support in bigger scaling.approval

Too big for angel investors but too risky for banks.

Venture Capitals, Strategic Investors.

Strategies novel‑food startups use to cross the valley

Staged business models: Offering B2B ingredients, licensing technology, or

starting with less regulated applications to generate earlier revenue while working

toward full food approval.

Smart regulatory strategy: Integrating regulatory planning from day one and

avoiding data gaps that cause re‑submissions to approval authorities. Such re-

submissions can bey a key cause of failure e.g. in food‑biotech.

Blended finance: Combining VC with grants, corporate partnerships and public

innovation funds targeted at sustainable food and bioeconomy infrastructure to

bridge the long pre‑market phase

Typical IP in food tech

Brand & image: Trademarks protect your start‑up and product names, logos,

slogans and sometimes distinctive packaging or product shapes (e.g. Toblerone

bar, Coca‑Cola bottle).

Product and tech: Patents can cover genuinely novel technical inventions such as

new processes, equipment, ingredients or formulations, but rarely a simple “recipe”

as such

Content & design: Copyright protects marketing copy,

photos, websites, packaging graphics and recipe text

(expression), while registered designs can protect the

appearance of packaging or product shape.

Know‑how: Trade secrets protect confidential information

that has economic value because it is secret, such as a

proprietary recipe, formulation, process parameters,

supplier lists or pricing models.

What can be a trade secret?

Recipe

Process (or patented)

What is IP?

Bundle of legal rights that protect intangible assets of a company: brand, recipes, technologies, logo, confidential know-how

Pros and cons of IP in comparison to patent

Pros:

No extra costs for the implementation

Unlimited in time

No public disclosure

Cons:

Once leaked, can’t be taken back from the society

If someone reverse engineers it, there’s no way to take it back

Strong secrecy measures

Many food companies go for IPs

Why making a start up based on pains?

Focusing on unmet needs and problems

Concepts derived from real frustrations land better than the “cool tech” ones

What did Nestle smartly do for its growth?

Built products around routines: so if one field slows down, the other accelerates.

Coffee and cocoa, baby food, dairy, sweets, sauces, cosmetics etc

Beneftis of apple in comparison to citrus pectin

High inner firmness

Regular distribution of ester groups

Good spreadability and reversibility

Less tendency to syneresis

High resistance toward mechanical stress

Basic pectin solution

Disperse pectin in 5-10 times the amount of sugar or syrup

Add into fruit or water

Cook at Brix <30

Add rest of the sugar

When one should think about beta-elimination in pectin?

At high T and high pH. Happens more often my HM pectin.

Why for pectin shelf life is technically non restricted?

Because over time pectin only slightly loses degree of esterification

Requirements for gelation of HM pectin

Sugar → attracts water, so the water layer around pectin is removed

Acid → H+ groups to neutralise carboxy-groups → charge repulsion is removed, chains come together → hydrogen bonds and hydrophobic interactions are formed

As HM pectin depends on sugar, it is used for high Brix products.

TSS >60% and pH < 3.2

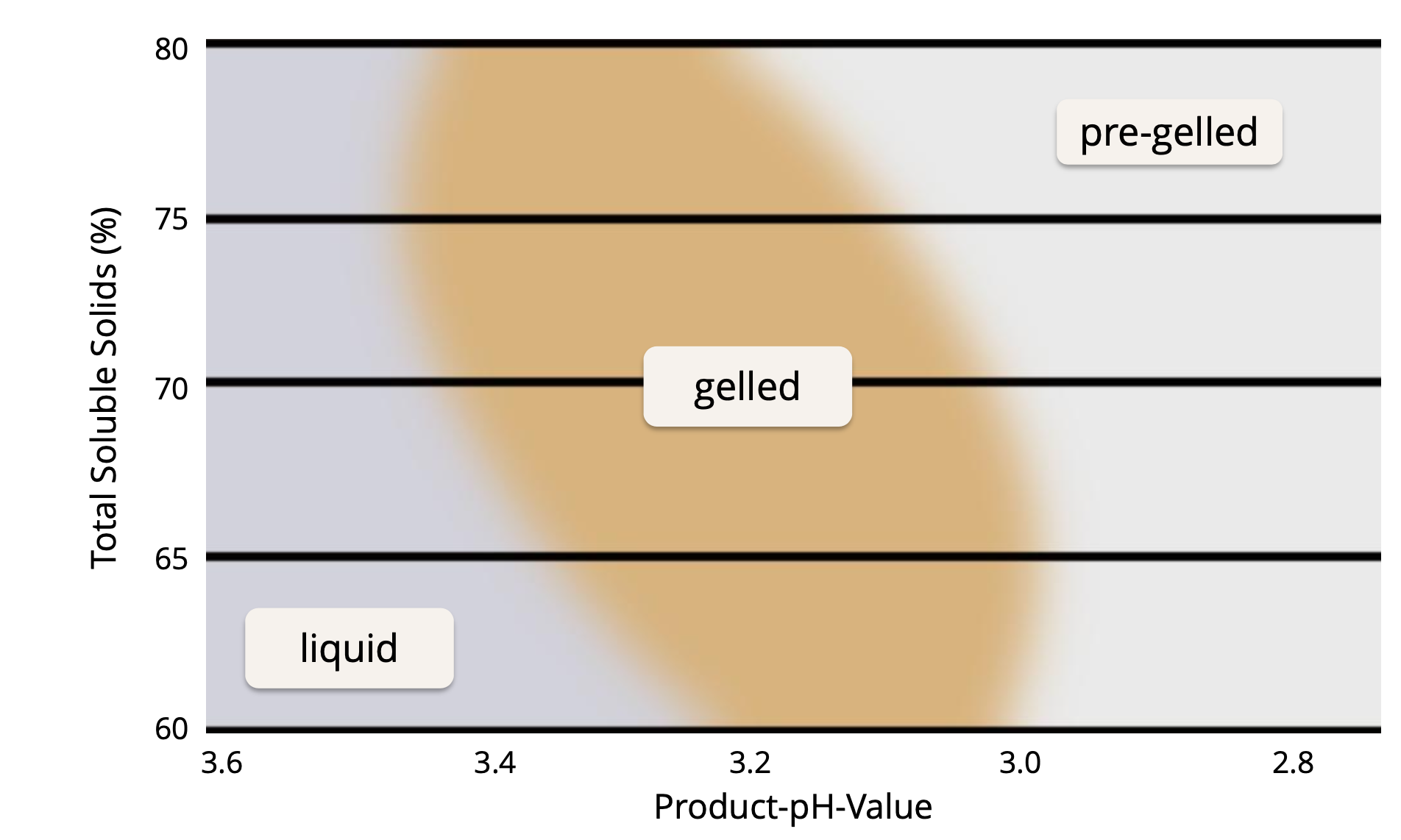

Setting range of HM pectin

Pre gelation is more desired than liquid form, so producers often overdose pectin a bit, to achieve pre-gelation.

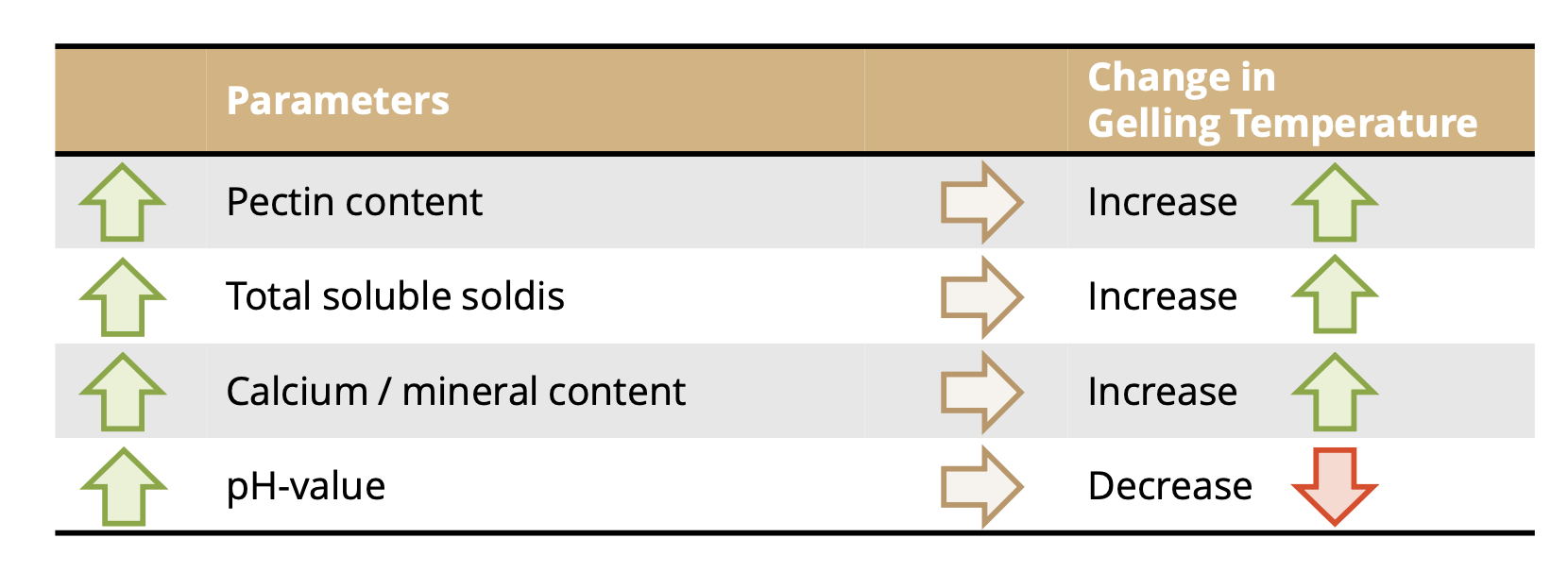

How do increases in pectin content, TSS, calcium, and pH affect change in gelling T?

What benefits does LM amidated pectin have?

More tolerance to process variation, as gelling mechanism doesn’t depend on pH and T as much.

More elastic and less firm texture, typical for Ca-based gels.

Lower Ca amount is needed. At low Brix, sometimes no Ca is needed, as amidation alone is sufficient.

Important Characteristics of the Adsorption Materials

Particle Size and Distribution. Range of particle size, distribution. Impact on pressure loss and transfer rate. Smaller particles → higher transfer rate. High distribution → bigger pressure loss.

Inner/specific surface. Inversely proportional to pore diameter. Proportional to porosity.

Density. Of individual particles and bulk.

Porosity and Pore Size Distribution.

Distribution of Pore radii. Adsorption and ion exchange - micropores. Transport - macro- and mesopores.

Application of adsorbents

Waste water treatment

Food: debittering of juices, removal of FFA from oil, recovery of phenolics (e.g., hesperidin from orange peels), enrichment of lactic acid

Purification and isolation of proteins = valorisation

What are 2 ways of industrial usage of adsorbent materials?

Fixed Bed Process. Adsorbent is packed in a column, while adsorbtive flows. Continuous. Need bed regeneration when it is exhausted in capacity. Several columns are connected in series.

Stirred Tank. Adsorbent particles are added to a tank → Liquid is mixed with an agitator → Adsorption happens while stirring → After treatment → adsorbent is separated (filtration/centrifuge). Increase in the number of process steps reduces the resin amount needed.

Fluid Bed Process. Sorbent and fluid are contacted in countercurrent mode. Flow rate is controlled via the quantification of target compounds at the

inlet and outlet. Can be destroyed by the particles.

Ways to produce silica-based adsorbents

Route A — Precipitated / Colloidal Silica

Sodium silicate + acid (H₂SO₄ or HCl)

Polymerization of silicic acid → hydrated SiO₂ particles

Forms a gel-like precipitate

Washed, dried, and activated → porous silica

Route B — Sol–gel process

Controlled hydrolysis and condensation

Produces silica hydrosol → gel → porous solid

More uniform 3D network. Better pore control = slower process.

Route C — Fumed silica (pyrogenic)

SiCl₄ reacted at 1000–1200 °C

Forms very fine SiO₂ particles

High purity, small primary particles

Silanol Groups → polar and hydrophilic

Most important resin

Polystyrene cross-linked with divinylbenzene (PS–DVB)

Styrene → forms the chain

Divinylbenzene (DVB) → links chains together → cross-linking

Three types of adsorbent resins

Resin type | Cross-linking | Porosity | Use |

|---|---|---|---|

Gel type | Low | Swelling pores | Small ions/molecules |

Macroporous | Medium | Permanent pores | Organics, large molecules |

Hypercrosslinked | Very high, very high adsorption capacity | Microporous | Aromatics, pollutants |

How can one affect the properties of silica gel

By changing concentration, pH, and T

What does cross-linking determine?

Pore Size

Swelling

Mechanical strength

Adsorption behaviour

How does functionalization turn adsorbents into ion exchangers?

Cation: sulfonation, –SO₃H

Anion: chloromethylation + amination, –NR₄⁺