iron, rust and redox

1/34

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

35 Terms

what is oxidation in terms of hydrogen and oxygen?

gain of oxygen and loss of hydrogen

what is reduction in terms of hydrogen and oxygen?

loss of oxygen and gain of hydrogen

what is oxidation in terms of electrons?

loss of electrons

what is reduction in terms of electrons?

gain of electrons

how can you remember oxidation and reduction in terms of electrons?

OILRIG

oxidation is loss

reduction is gain

what is the manufacturing of ammonia (NH3) known as?

the Haber process

nitrogen + hydrogen <->

ammonia

nitrogen + hydrogen <-> ammonia

N2 + 3H2 --> 2NH3

what is a redox reaction?

reactions in which oxidation and reduction occur simultaneously

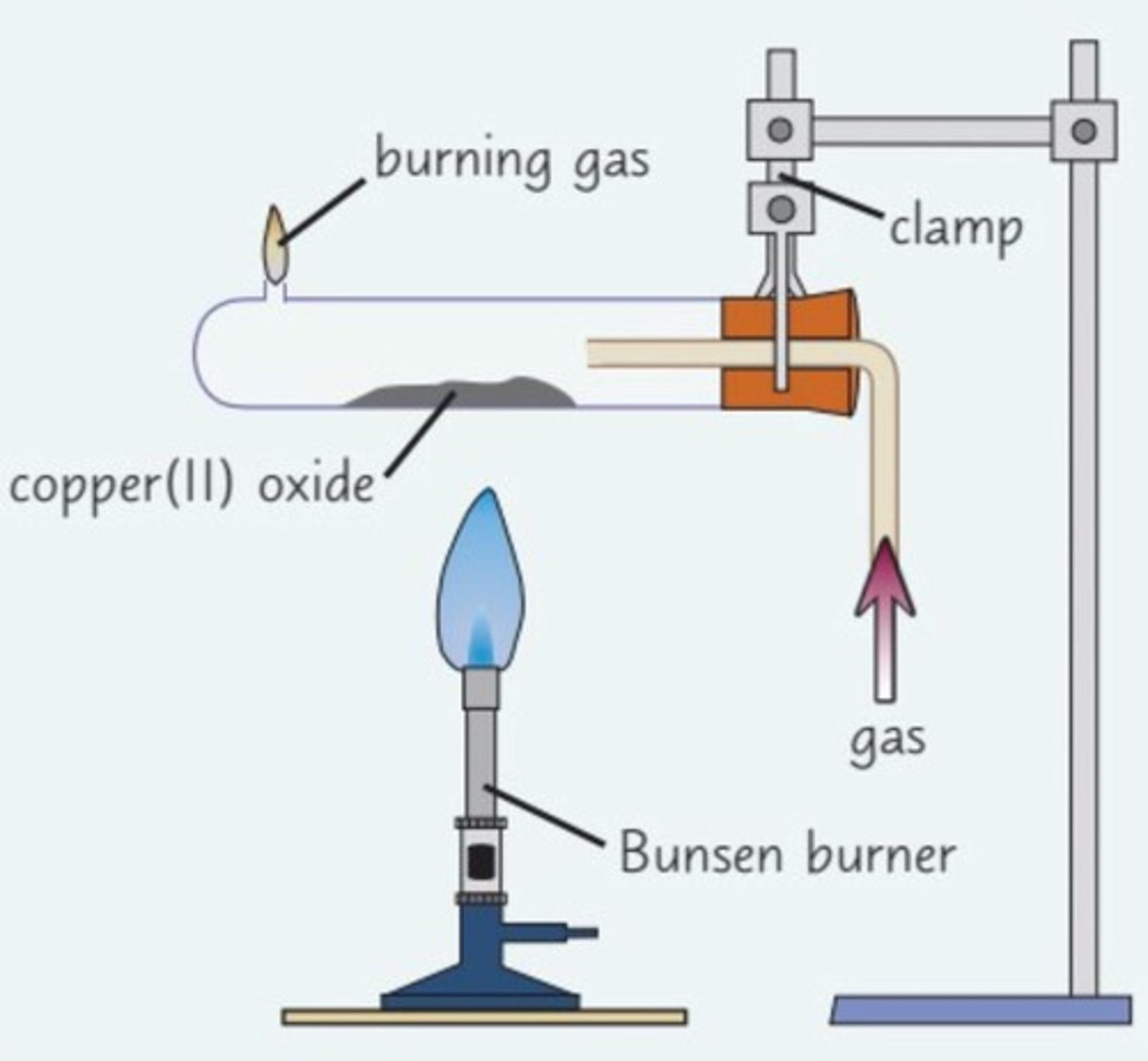

the reaction of hydrogen with copper (||) oxide

the gas is hydrogen

the reaction of hydrogen with copper (||) oxide. observations?

red-brown solid produced. steam will form around glass tube

the reaction of hydrogen with copper (||) oxide. what happened to the copper oxide? (include balanced symbol equation)

CuO + H2 -> Cu + H2O (g)

The CuO has been reduced as oxygen is removed.

The hydrogen is the reducing agent

Equation for combustion of hydrogen

2H2 + O2 -> 2H2O

chemical name for rust

Hydrated iron (III) oxide

chemical formula for rust

Fe2O3.XH2O

what is reacted with iron to form rust?

oxygen and water

what metals rust?

only iron, the other metals corrode

name a drying agent

anhydrous calcium chloride

Is rusting an oxidation or reduction reaction?

oxidation as iron gain oxygen

uses of iron and steel

1. buildings, bridges

2. ships, cars

3. nails

problems with rusting

1. dangerous

2. unsightly

what are most methods for rust prevention?

barrier methods

how does painting the steel prevent rusting?

puts a layer on the iron, providing a protection layer so that oxygen and water cannot come into contact with the iron.

used on bridges/large objects

how does galvanising the steel prevent rusting?

Zinc (usually used in galvanising steel) is more reactive than iron so by putting a coat of zinc on the iron, it will react with the oxygen and water first, protecting the iron.

when is the barrier method oil/grease used?

moving parts (e.g bicycle chains)

when is the barrier method plastic coating/rubber coating used?

when a soft surface is needed (e.g. handle bars and garden furniture)

sacrificial protection

magnesium bars put onto iron oilrigs. Mg is more reactive than Fe, so it will react first - protecting the Fe.

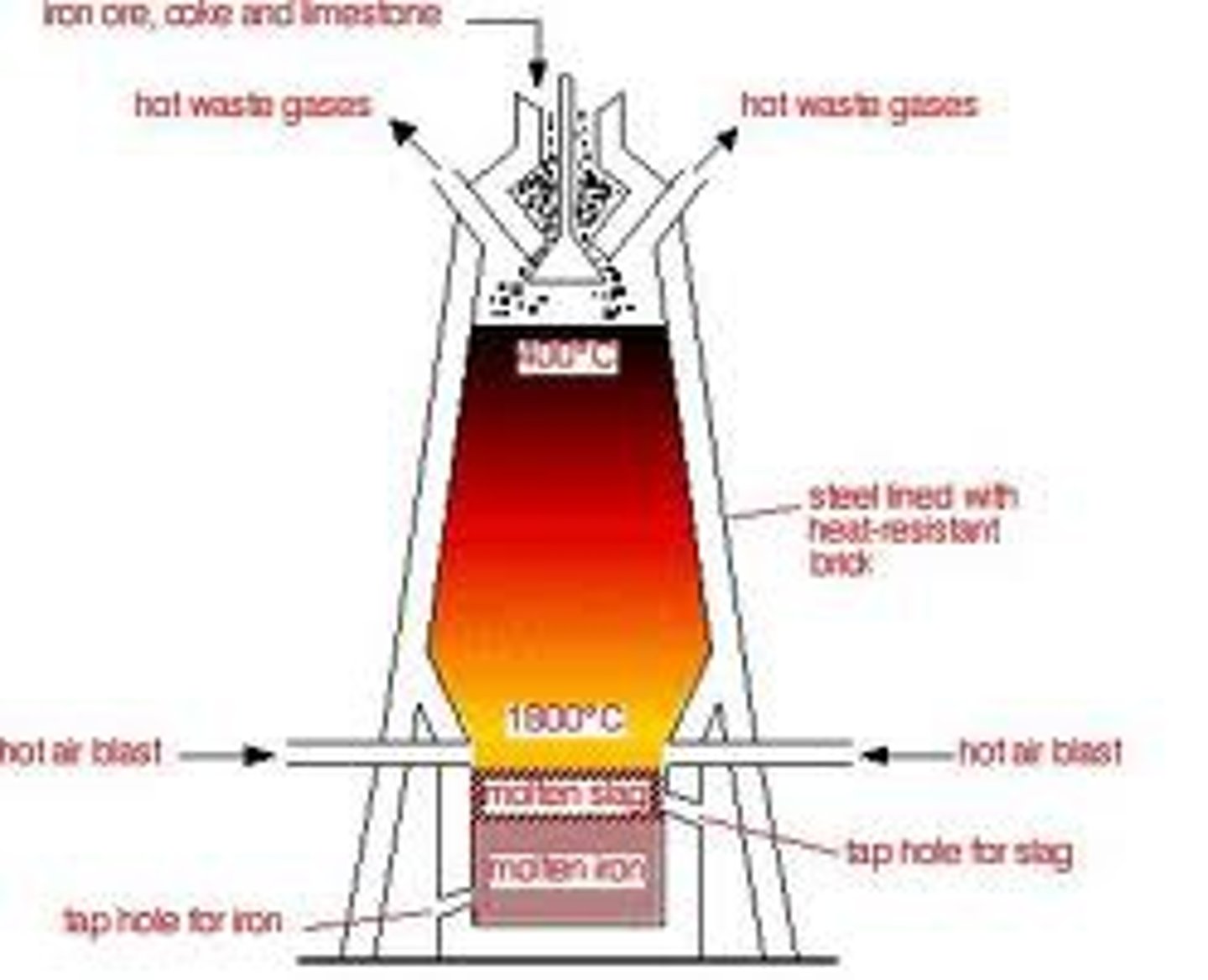

Blast Furnace

extraction of iron using carbon

iron ore

haematite

limestone (calcium carbonate)

CaCO3

haematite (iron ore)

iron (|||) oxide

Fe2O3

coke

carbon

C

Blast Furnace: Stage one

PRODUCTION OF REDUCING AGENT (CO)

1. C + O2 -> CO2 (oxidation)

Coke reacts with hot air to form carbon dioxide. This is exothermic -ΔH. The carbon is burned (combustion)

2. CO2 + C -> 2CO

The carbon dioxide reacts with more coke to form carbon monoxide - the reducing agent

Blast Furnace: Stage two

REDUCING IRON (|||) OXIDE

3. Fe2O3 + 3CO -> 2Fe + 3CO2 (redox)

Once carbon monoxide is formed, it reacts with Fe2O3, reduces it and forms Iron.

Blast Furnace: Stage three

REMOVING ACIDIC IMPURITIES

Haematite is not pure Fe2O3 - it contains acidic impurities such as silicon dioxide, to remove this we need a base.

4. CaCo3 -> CaO + CO2 (thermal decomposition)

The limestone breaks down once it enters the blast furnace. CaO - a base is formed

5. CaO +SiO2 -> CaSiO3

The base CaO reacts with the acidic SiO2 to form calcium silicate (slag), which is removed at the bottom of the blast furnace.