Product Design

1/50

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

51 Terms

Total Stress

S = normal + shear

Stress

F/A

Strain

change in length / original length

units of stress

N/m²

Units for strain

dimensionless

Area of cylinder

pi r²

elastic modulus

A measure of a material's stiffness, defined as the ratio of stress to strain.

Gigapascals

10^9

Pascal

N/m²

elastic modulus for rubber

0.01 to 0.1 Gpa

elastic modulus for plastic

0.7 to 14 GPa

elastic modulus for steel

200 GPa

delta strain (e prime)

change in b over b (lateral strain —> perpendicular to applied force

poissons ratio

v = - lateral/longitudinal strain = -e’/eIt quantifies the ratio of transverse strain to axial strain in a material under load.

ductile

bends before break. goes back to original shape. deform significantly under stress before fracturing

brittle

does not bend before it breaks. chalk. broke without bending at all

elastic deformation

reversible; object will return to original shape

plastic deformation

irreversible; after large deformation, which is initially elastic

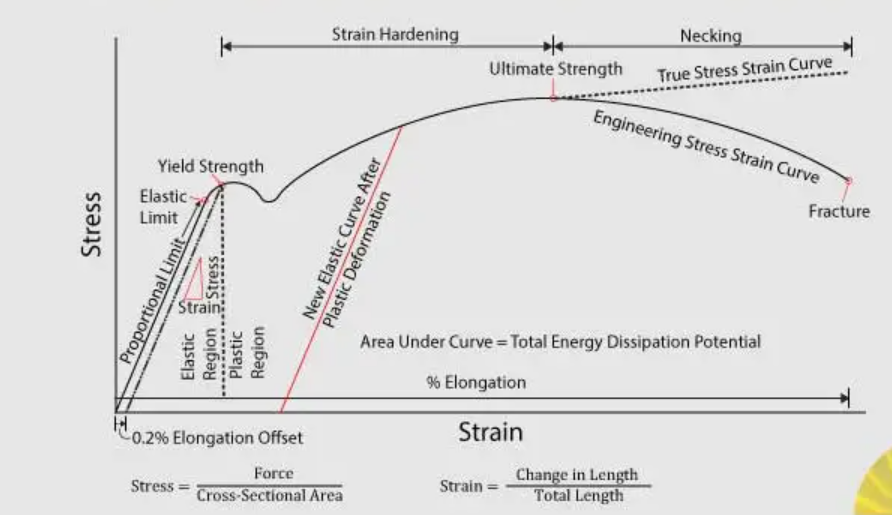

stress strain curve

graph showing relationship between stress and strain in materials

failure

for most ductile materials, failure occurs if we have reached yield strengthand the material cannot withstand further loading.

factor of safety

allowed stress = yield strength / n

polymers

long chains of repeating molecules that exhibit unique mechanical and thermal properties, making them suitable for various applications in product design.

is wood a polymer

yes

is skin a polymer

yes

the raw material to make most plastics is oil

True

thermosets (heat + permanent)

epoxy resin is an example

thermoplastics

most common with toys; heated and harden again to original state when cooled. molded to complex shapes. easy to reshape

common thermoplastics

ABS, PVC, PolyPropylene (PP), PolyEthylene (PE), PolyStyrene (PS), Acrylic, PolyCarbonate (PC), POlyEsters (PET), PolyAmide (Nylon)

ABS

hard with high impact resistance; takes color well with excellent surface finish. Consumer product cases. Most expensive out of PVC, PP, PE. Examples: Legos, suitcases

PVC

Cheap, heavy, rigid, durable. Vinyl toys. Examples: CDs, rubber duck, inflatable boat

PolyEthylene PE

most common plastic. cheap, flexible, easy to mold. Examples: crates, shampoo bottles, milk container, plastic bags

PolyPropylene PP

similar to PE but more rigid, doesn’t fatigue hinge/snap. examples: straws, markers, pill bottles

polystyrene PS

clear, hard, cheap. makes styrofoam.

crazing

network of small voids or cracks

PolyMethyl MethAcrylate (PMMA)

acrylic, plexiglass, transparent like glass, hard, brittle. Examples: lamps, fish bowl

polycarbonate

the “engineering” plastic. expensive, tough, rigid, clear. Safety glasses, laptops, hard hats

Polyethylene terepththalate (PET,

cheap, transparent, food products, barrier to moisture, easy to recycle: plastic soda bottles, ketchup bottles, t shirt, peanut butter jar

which is commonly used to manufacture groccery bags?

low density Polyethylene

which is the following is used to make CDs?

polycarbonate is very tough and optically transparent

what type of plastic used to make styrofoam?

polystyrene

compression molding

for complex parts with various thickness. thermosets and some advanced thermoplastics

extrusion

like pasta extruder. constant profile extrusion (pipers0. high volume bc dies are expensive

injection molding

for thin, constant parts. mass production because molds are expensive. think forks, legos

thermoforming (vacuum forming)

for thin sheets, simples one sided forms. glass transition, relaxing the chain

blow molding

for open thin walled hollow parts. Milk jugs, most bottles

rotational molding

for simple closed hollow shapes. good for inexpensive large parts

what process is used to make plastic pipers

extrusion molding

which process best for making plastic die?

The most appropriate process for making a plastic die is A. Injection molding.

Here's why:

Injection molding: involves injecting molten plastic into a mold cavity, where it cools and solidifies, forming the desired shape. This method is well-suited for creating complex shapes and intricate details, making it ideal for producing the precise geometry of a die.

Blow molding: is used for creating hollow plastic parts, not solid dies.

Plastic forming: refers to shaping plastic materials, but it doesn't involve the same level of precision and repeatability as injection molding for creating a die.

Extrusion molding: is used to make long, continuous shapes, not solid dies.

which process would be most appropriate for making a plastic drinks bottle

The most appropriate process for making a plastic drinks bottle is B. Blow molding.

Explanation: Blow molding is specifically designed to create hollow, thin-walled plastic objects like bottles, making it the ideal choice for this application.

Why other options are incorrect:

A. Injection molding:

While injection molding can create solid plastic parts, it's not as efficient for hollow objects like bottles. It's better suited for solid components like bottle caps.

C. Plastic forming:

This is a general term encompassing various plastic manufacturing techniques, including blow molding, injection molding, and others. It doesn't describe a specific process.

D. Extrusion molding:

Extrusion molding creates a continuous plastic tube, which is then used in other processes like extrusion blow molding, but it's not the primary method for making bottles on its own.

which process is most appropriate for making a thin plastic bowl

The most appropriate process for making a thin plastic bowl is B. Blow molding.

Explanation: Blow molding is specifically designed to create hollow, thin-walled plastic parts by inflating a heated plastic tube within a mold, making it ideal for producing items like bottles and bowls.

Why other options are not as suitable:

A. Injection molding:

While injection molding can produce thin parts, it's better suited for more complex shapes and solid parts. It may not be as efficient for thin-walled hollow items like a bowl.

C. Thermoforming:

Thermoforming involves heating a plastic sheet and forming it into a mold. While it can create thin parts, blow molding is generally more efficient and cost-effective for hollow shapes.

D. Extrusion molding:

Extrusion is used to create continuous profiles like pipes or rods. It's not designed for hollow, thin-walled shapes like a bow