Industrial Hygiene

1/58

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

59 Terms

Industrial Hygiene

science of protecting health and safety through anticipation, recognition, evaluation and control of workplace conditions that may cause workers injury or illnes

Types of health hazards

Chemical

Biological

Physical

Ergonomic

Chemical Hazard Forms

Solids

Liquids

Gases and Vapors

Aerosols- dust, mist, fumes

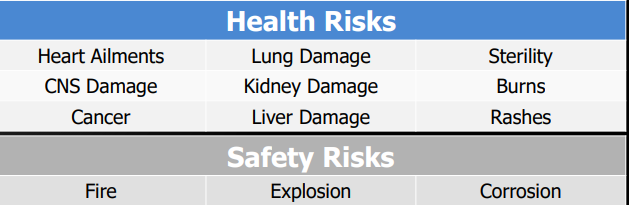

Effects of chemical exposure

Exposure entry routes

Inhalation

Ingestion

Absorption

Injection

Inhalation

Breathed in (Most common route)

Ingestion

Swallowing via eating or drinking

Absorption

Drawn through skin or eye surface

Injection

Penetration through the skin

Warning Signs of Potential Chemical Exposure:

Dust, mist, smoke in the air

• Accumulation of particulates (dust) on surfaces

• Unusual tastes and/or smells

• Eye, nose, throat, upper respiratory, and/or skin irritation

Examples of chemical exposure symptoms:

• Eye, nose, throat, upper respiratory, skin irritation

• Flu-like symptoms

• Difficulty breathing

• Fatigue

• Loss of coordination

• Memory difficulties

• Sleeplessness

• Mental confusion

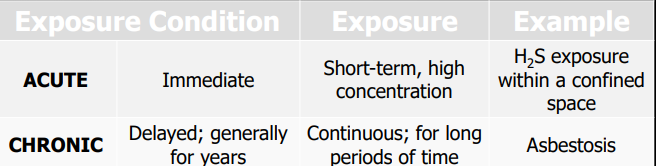

Health Effects

Toxicology

The science that studies the poisonous or toxic properties of substances

Local (direct) effects:

• Irritation (dryness, redness, cracking) - fiberglass

• Corrosion (chemical burn) - acid

• Upper Respiratory Track Infection – inhaling particles

Systemic effects:

Hepatotoxins

Nephrotoxins

Neurotoxins

Hepatotoxins

Cause liver damage

• Carbon tetrachloride, nitrosamines

Nephrotoxins

• Cause kidney damage

• Uranium, halogenated hydrocarbons

Neurotoxins

Cause nerve damage

• Mercury, lead, carbon disulfide

Hematotoxins

Cause blood system damage

• Carbon monoxide, cyanides

Anesthetics

Depress nervous system

• Hydrocarbons, propane, isopropyl ethers

Factors affecting exposures:

form and innate chemical activity

• dosage, especially dose-time relationship

• exposure route

• age

• sex

• ability of chemical to be absorbed

• metabolism

• distribution within the body

• excretion

• presence of other chemicals

Chemical Hazards and Control (Elimination and Substitution)

Engage

Inventory and Prioritize

Identify

Assess and Compare

Select

Test

Evaluate

Engineering controls

Ventilation – local (hood) / general (dilution)

• Process and equipment modification

• Isolation/automation

Administrative controls

• Establish written programs & policies

• Training

• Monitor/measure exposure levels

• Inspections and maintenance

• Restricted area signage

• Develop SOPs

PPE

• Respirators

• Gloves

• Safety glasses

• Long clothing

Worksite analysis – assessing exposures:

• Air monitoring – personal and area

• Noise monitoring

• Observation – PPE use and work practices

• Ventilation measurements

• Wipe samples – surfaces and personnel

PELs, or permissible exposure limits:

OSHA’s regulations that establish the acceptable amount or concentration of a substance in the workplace

• Intended to protect workers from adverse health effects related to hazardous chemical exposure

Substance-specific standards

Established by OSHA to identify specific requirements

• Potentially exposed workers must be monitored and protected

Components of substance specific standards: (in general)

• Air monitoring

• Control of exposure

• Engineering controls

• Work practices

• Respiratory protection

• Medical surveillance / removal (lead)

• Recordkeeping

• Worker training

Hexavalent chromium:

Toxic form of chromium;

• Known to cause cancer

• Compounds are man-made and widely used •

Major source of exposure during “hotwork” on stainless steel and other alloy steels containing Cr (VI)

Asbestos:

• Mineral fibers – chrysotile, amosie, crocidolite, tremolite, anthophylite, actinolite, and chemically treated/ altered forms

• Known carcinogen; can cause chronic lung disease, as well as lung and other cancers

• Used in numerous building materials and vehicle products

• Exposure potential during construction and ship repair; as well as manufacturing of products containing asbestos

Silica:

• Important industrial material found abundantly in the earth’s crust; most common form is quartz

• Can cause lung diseases, including silicosis and lung cancer, as well as kidney disease

• Exposure to respirable crystalline silica

• Inhalation of small particles in air

• Common with operations such as cutting, sawing, and drilling

Lead:

Blue-gray, heavy metal occurring naturally in Earth’s crust

• Can harm many of the body’s organ systems; variety of ailments

• Exposure

• Inhalation and/or ingestion of airborne particles containing lead

• Occurs in most industry sectors, including manufacturing, wholesale trade, transportation, construction, remediation, and even recreation

Welding Fumes

Content depends on components of base metal, coatings, and/or filler materials; and welding temperatures

• Potential health effects

• Acute exposure: eye, nose, and throat irritation; dizziness; nausea

• Prolonged exposure: lung damage; various types of cancer, including lung, larynx, and urinary tract

• Certain fumes and gases can lead to additional health issues

Exposure to welding fumes affected by:

Welding process

• Materials used

• Location (outside, enclosed space)

• Work practices

• Air movement

• Use of ventilation

Toxic atmospheres:

Confined spaces and Hazardous atmospheres

Confined spaces

storage tanks, process vessels, bins, boilers, ventilation or exhaust ducts, sewers, underground utility vaults, tunnels, pipelines, opentop spaces more than 4’ in depth (pits, tubs, vaults)

Hazardous atmospheres

Oxygen-deficient

• Hydrogen sulfide

• Carbon monoxide

Biological hazards and control

Insects

Animals

Contaminated Soils

Poisonous Plants

Water/Sewage

Bloodborne Pathogens

Possible effects of exposure to biological hazards:

Mild, allergic reactions

• Serious medical conditions

• Death

• Most virulent and prevalent biological agents

Protection against biological hazards:

• Practice universal precaution with:

• Blood

• Bodily fluids

• Practice personal hygiene

• Provide proper first aid

• Cuts/Scratches

• Vaccinations

• Wear proper PPE/clothing

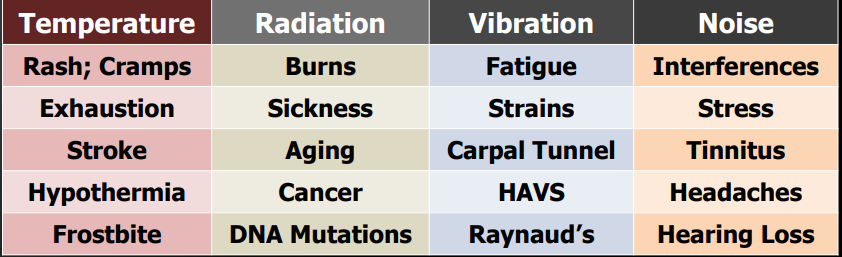

Types of Physical Hazards

Temperature, Radiation, Vibration, Noise

Effects of exposure to physical hazards:

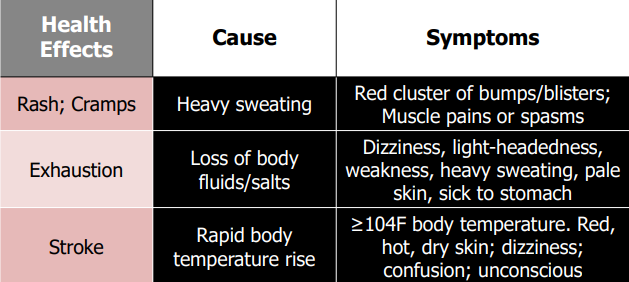

Exposure to heat

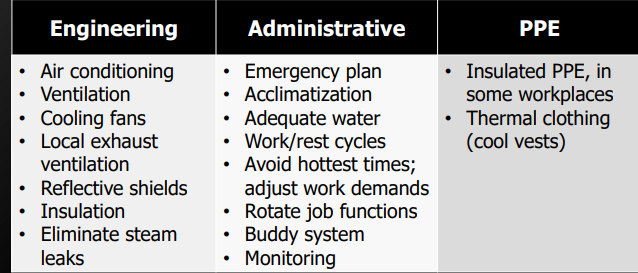

Protection against heat:

Eliminate or substitute hazard, whenever feasible

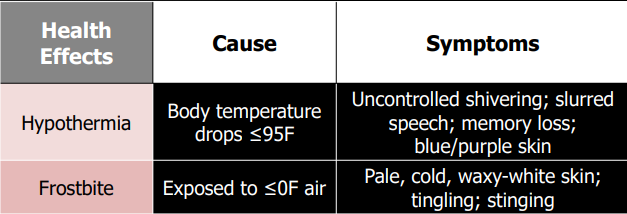

Exposure to cold:

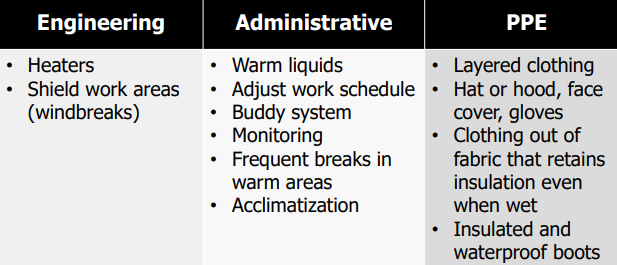

Protection against cold:

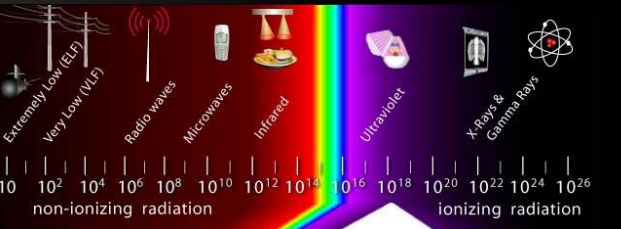

Exposure to radiation:

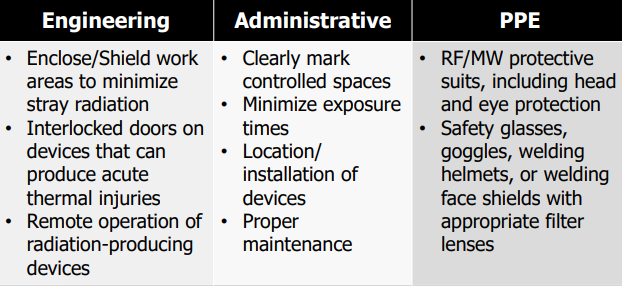

Protection against radiation:

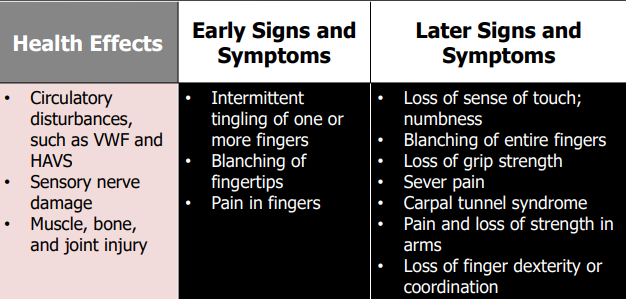

Exposure to vibration:

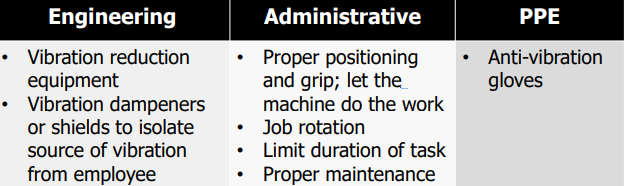

Protection against vibration:

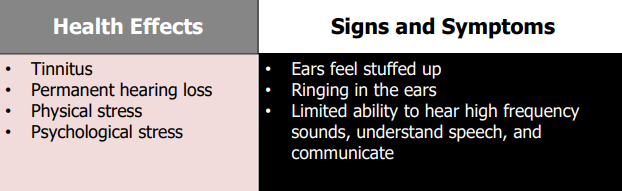

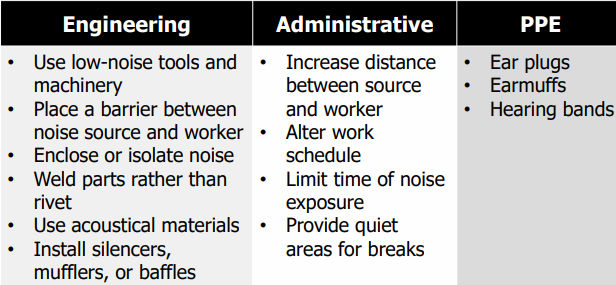

Exposure to noise:

Noise

prolonged exposures to 85 dB can lead to hearing loss

prolonged exposures to 85 dB can lead to hearing loss

When to wear hearing protection

Noise or sound level exceeds 90 dBA (OSHA) • Recommended when exceeds 85 dBA (NIOSH)

• What to wear as hearing protection

Personal comfort preference

• Long-term/Single use (plugs)

• Short-term/On and off (muffs)

• Consider NRR

Effects of exposure to ergonomic hazards:

• Musculoskeletal Disorders (MSDs)

• Exposure to ergonomic risk factors for MSDs increases a worker's risk of injury

• Repetition

• High force

• Awkward postures

• Work-related MSDs are among the most frequently reported causes of lost or restricted work time.

Risk factors for MSDs:

• Overexertion

• Repetitive tasks

• Awkward posture/positions

• Localized pressure

• Cold temperatures

• Vibration

• Combined exposure

Protection against ergonomic hazards:

• Use ergonomically designed tools

• Use correct work practices

• Proper lifting techniques

• Ask for help when handling:

• Heavy loads

• Bulky/Awkward materials

• Properly fitting PPE