BT5 Reinforced Concrete Floor Systems

1/64

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

65 Terms

Reinforced concrete

one of the most widely used materials in modern construction because of its strength, versatility, and adaptability.

Floor systems in reinforced concrete structures

plays a significant role in the overall lateral stability of the building.

Slab

A flat, horizontal structural element used in buildings to create floors, ceilings, and roofs.

Slab

It is typically made of reinforced concrete and designed to support loads such as people, furniture, and equipment.

beams, columns, or walls.

Slab distribute these loads to the supporting:

One-way systems

load transfer occurs primarily in one direction

Two-way systems

load transfer occurs in two directions

One-Way Slab

A slab supported by parallel beams or walls, where the longer span is more than twice the shorter span.

Short span

primary load transfer direction in a one-way slab

Corridors, small rooms, and simple rectangular layouts

Application of one-Way Slab

Simple design, easy to construct

key advantage of a one-way slab

up to 3–4 m

maximum economical span for a one-way slab

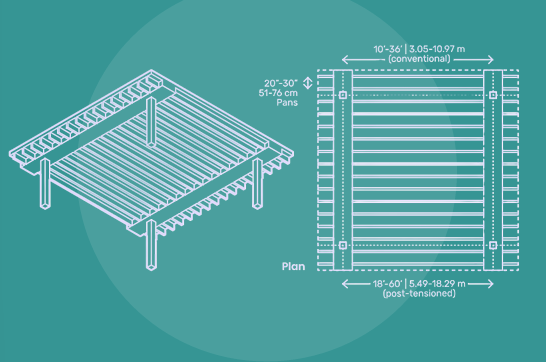

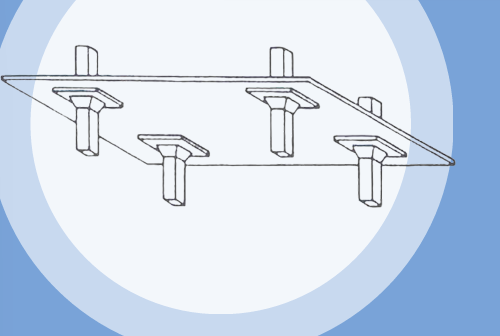

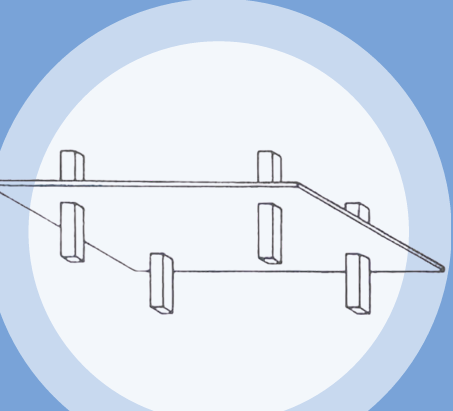

One-Way Joist (Ribbed) Slab

A slab system where closely spaced, narrow beams (joists) run in one direction, with a thin topping slab above

Through ribs to supporting beams or walls.

primary load transfer direction in a one-way joist ribbed slab

Reduced concrete volume and weight; longer spans possible compared to plain slabs

key advantage of a one-way joist (ribbed) slab

Medium-span floors where weight reduction is critical

application of a one-way joist (ribbed) slab

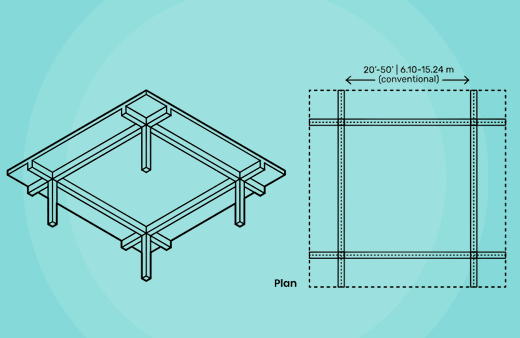

Two-Way Slab with Beams

A slab supported on all four edges, with beams running along the perimeter or grid

Distributes load in both directions

primary load transfer direction in a Two-Way Slab with Beams

Square or nearly square floor panels

applications of a Two-Way Slab with Beams

Greater efficiency in load distribution; allows larger spans compared to one-way slabs

advantages of a Two-Way Slab with Beams

Flat Slab System

A slab directly supported by columns without beams, often thickened at the column locations

Drop panels

What structural feature is often added to flat slabs to resist punching shear?

Directly from slab to columns

primary load transfer direction in a Flat Slab System

Flexibility in architectural planning; reduced floor-to-floor height; easy installation of services integration

key advantage of Flat Slab System

Requires careful design against punching shear; not ideal for very heavy loads.

main limitation of flat slabs system

Offices, hotels, residential high-rise buildings, parking garages.

application of flat slabs system

Flat Plate System

Similar to flat slab but without drop panels or column capitals

Simplified construction, uniform thickness, ideal for moderate spans and light to medium loads.

Advantages of Flat Plate System

Apartments, condominiums, hotels.

Applications of Flat Plate System

Less resistance to punching shear compared to flat slab.

Limitations of Flat Plate System

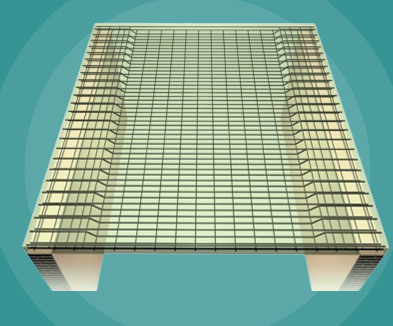

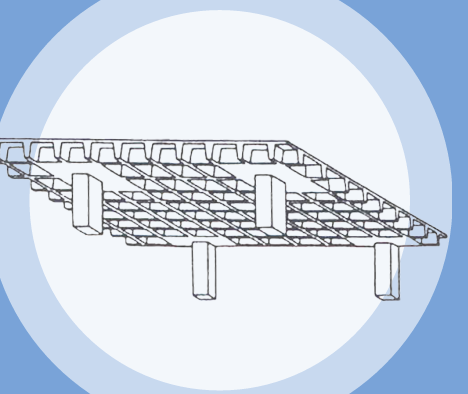

Waffle Slab (Two-Way Ribbed Slab)

A slab with a grid of ribs in two directions, usually cast using reusable forms.

Two-way distribution through ribs to columns and beams

load transfer of Waffle Slab (Two-Way Ribbed Slab)

High load-carrying capacity, lightweight, excellent for long spans, aesthetically expressive ceiling pattern.

advantages of Waffle Slab (Two-Way Ribbed Slab)

Auditoriums, theaters, large halls, industrial buildings.

applications of Waffle Slab (Two-Way Ribbed Slab)

Formwork cost is higher; not economical for small-scale projects

Limitations of Waffle Slab (Two-Way Ribbed Slab)

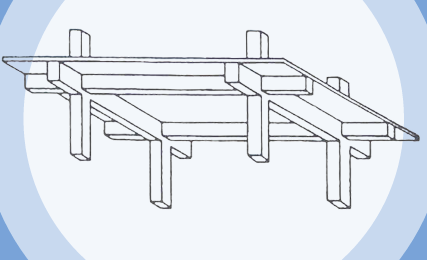

Beam and Slab Floor System

Slabs spanning between beams, which in turn transfer loads to columns.

Traditional, versatile, economical for moderate spans

Beam and Slab Floor System advantages

Residential and commercial structures with repetitive grids

Beam and Slab Floor System applications

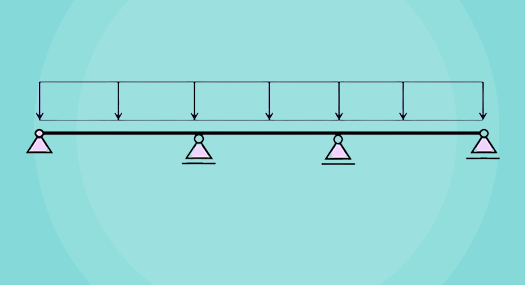

Continuous Beam Systems

Multiple spans of beams supporting slabs, designed to minimize deflection and optimize reinforcement

Efficient in material use, lower moments at supports

Continuous Beam Systems advantages

Multi-span corridors, repetitive long-span structures.

Continuous Beam Systems applications

Post-Tensioned Slabs

Reinforced concrete slabs in which steel tendons are tensioned after casting, improving span capacity.

Long spans with thinner slabs, reduced deflection, efficient material use

Post-Tensioned Slabs advantages

Parking structures, bridges, commercial buildings with open floor plans.

Post-Tensioned Slabs applications

Requires specialized labor and equipment

Post-Tensioned Slabs limitations

Post-tensioned slab

the goal is to achieve a 30-meter span with minimal deflection

Hollow Core Slabs (Precast RC Option)

Precast, prestressed slabs with hollow longitudinally.

Lightweight, quick installation, large spans possible.

Hollow Core Slabs advantages

Warehouses, offices, precast construction projects

Hollow Core Slabs applications

Transport and handling costs; limited flexibility for penetrations

Hollow Core Slabs limitations

Span length

short, medium, or long spans

Load requirements

light, moderate, or heavy.

Architectural constraints

ceiling height, service integration, aesthetics

Construction method

cast-in-place vs. precast, availability of formwork, construction timeline

Economy

material cost, labor skill, formwork reuse

Deflection and vibration control

serviceability requirements

Resistance to punching shear under heavy vehicle loads

In selecting between flat slab and waffle slab systems for a multi-level parking garage, which factor would most strongly favor the waffle slab?

ONE WAY SLAB PIC

ONE WAY JOIST RIBBED SLAB PIC

TWO WAY SLAB WITH BEAMS PIC

FLAT SLAB SYSTEM PIC

FLAT PLATE SYSTEM PIC

WAFFLE SLAB TWO WAY RIBBED PIC

BEAM AND SLAB FLOOR SYSTEM PIC

CONTINUOUS BEAM SYSTEMS PIC