TRANSITIONS IN POLYMERS

1/53

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

54 Terms

give some examples of natural polymers

collagen

silk

DNA

protein

natural rubber

give examples of everyday polymers

polystyrene

polyamide

low density polyethylene

give examples of aspects of dentistry that uses polymers

prosthodontics: denture bases and teeth, soft liners, custom trays, temporary restoratives

operative dentistry: dentine bonding agents, sealants, veneers

orthodontics: brackets, spacers, bracket bonding resins/ cements

endodontics: root canal sealants, rubber dams

equipment: mixing bowls, spatulas, protective eyewear

state advantages of dental resins

mechanically strong

physically stable

easily manipulated

excellent aesthetic qualities

chemically stable - in the mouth and in storage

biocompatible

reasonable cost

where are acrylic resins often used in dentistry

denture base material

what is another name for acrylic resins

PMMA

when was PMMA introduced

1936

what type of polymer is PMMA

thermoplastic amorphous polymer

what are advantages of PMMA

acceptable cost of material and processing method

good mechanical properties - rigidity, strength, wear resistance

biocompatible - tasteless, odourless, non-toxic, non-irritating, resistance to microbial colonisation

suitable manipulation/ processing properties - easy to mix, shapable, simple to process and cure

aesthetic properties - translucency and transparency

what are problems with PMMA

colour stability

shrinking problems

adhesion problems

how can the shrinking problems of PMMA be resolved

adding MMA (methyl methacrylate)

when were room temperature polymerising methacrylates introduced

1940

when were self curing dimethacrylates reinforced by a ceramic particle ‘filler’

late 1950s

when were PMMA resins replaced by more durable monomers such as bisGMA

1940

define polymer

polymer: a large, chain-like molecule made up of monomers

what type of bonds are the monomers in a polymer joined by

covalent bonds

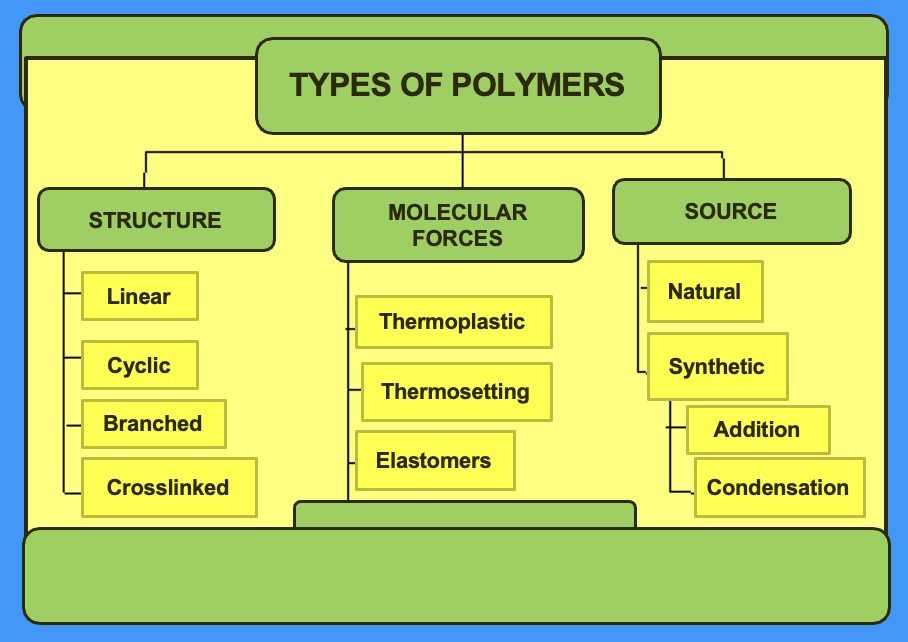

diagram showing polymer classification

what do the physical properties of polymers depend on

how their molecules are arranged i.e. polymer structure

the strength of the forces between these molecules i.e. intermolecular forces

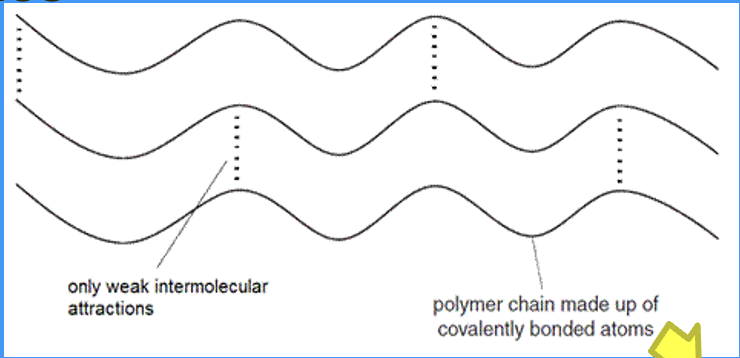

in a polymer, where are intermolecular forces present

weak intermolecular attract individual polymer chains together

when can covalent bonds join individual polymer chains together

in cross linking, covalent bonds can join individual polymer chains together

what factors do the strength and flexibility of the polymer depend on

chain length

side groups

branching

cross-linking

outline the factors influencing strength and flexibility of the polymer

chain length: generally, the longer the chains the stronger the polymer

side groups: intramolecular forces e.g. hydrogen bonding give stronger attraction between polymer chains

branching: straight, unbranched chains can pack together more closely than highly branched chains

» polymers with higher density, more crystalline and therefore stronger

cross-linking: if polymer chains are linked together by covalent bonds, the polymer is harder and more difficult to melt

define crystallinity

crystallinity: the degree of structural order

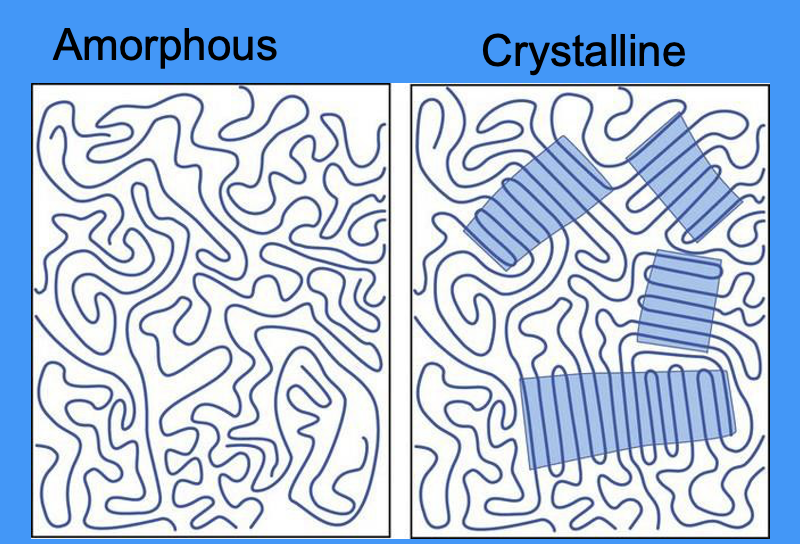

diagram showing amorphous and crystalline structures

lines = chains of polymers

what do the highlighted areas in the crystalline diagram represent

crystal-like ordered structure of randomly packed polymer chains

give examples of amorphous polymers

acrylonitrile butadiene styrene (ABS)

atactic polystyrene

polycarbonate

polyisoprene

polybutadiene

give examples of crystalline polymers

nylon

crystalline PET (CPET)

syndiotactic polystyrene

Kevlar and Nomex

polyketones

what polymer properties does crystallisation affect

optical properties

mechanical properties

thermal properties

chemical properties

outline thermoplastic polymers

linear/ branches structures

flow when heated and can be reshaped upon heating

easily moulded and extruded into films

give an example of a thermoplastic polymer

polypropylene

outline thermosetting polymers

crosslinked structures

cannot be reshaped upon heating

hard and durable

give an example of a thermosetting polymer

epoxy resin

outline elastomers

rubbery polymers

can be stretched easily

return to their original dimensions when the applied stress is released

give an example of an elastomer

natural rubber

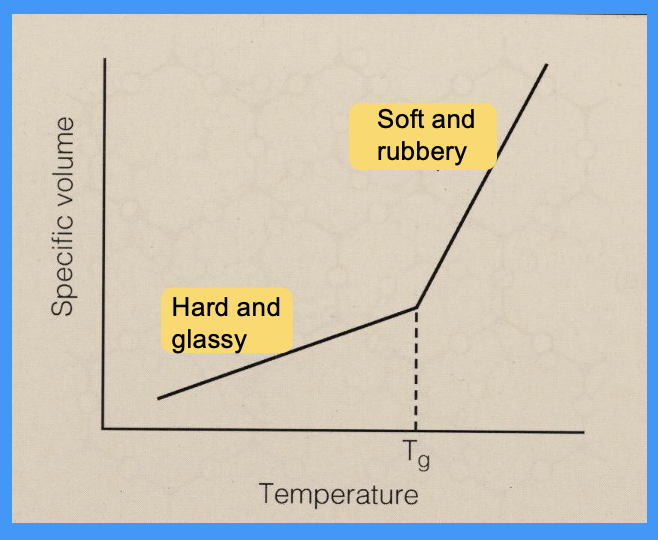

what is Tg

Tg: glass transition temperature

the temperature at which the polymer chains begin to flow past each other

the polymer is soft, rubbery and easy to handle but NOT melted

graph showing Tg

is Tg higher or lower than the melting temperature

Tg is always lower than the melting temperature (Tm)

the ______ the secondary bonds the _____ the Tg

the weaker the secondary bonds the lower the Tg

define polymerisation

polymerisation: the chemical reaction in which monomers of a low molecular weight are converted into chains of polymers with a high molecular weight

monomer molecules are bonded by covalent bonds

what are the types of polymerisation

addition

condensation

define addition polymerisation

addition polymerisation: occurs when a reaction between two molecules produces a larger molecule without the elimination of a smaller molecule

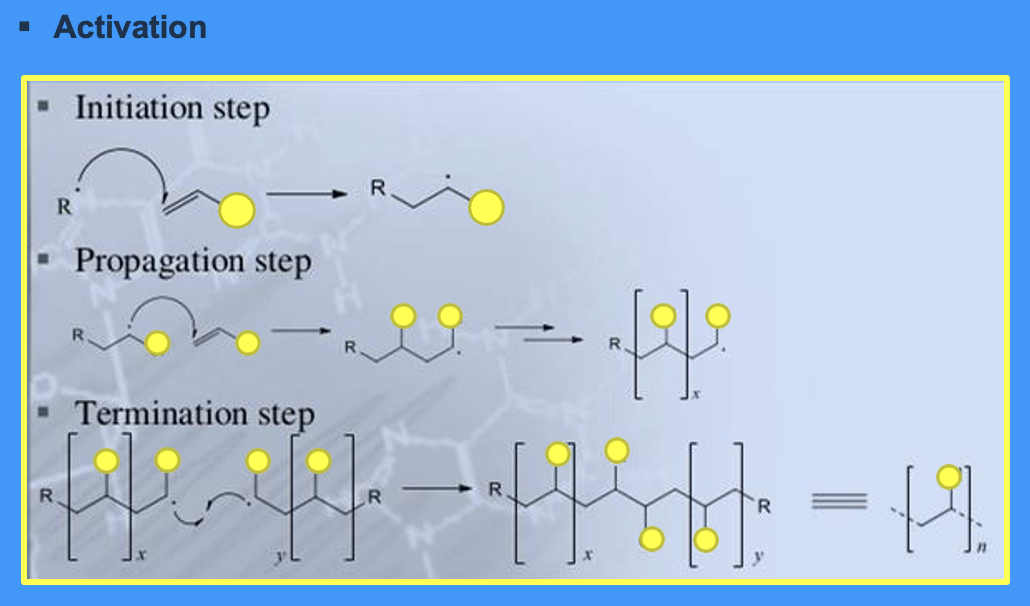

what are the steps of addition polymerisation

activation

initiation

propagation

termination

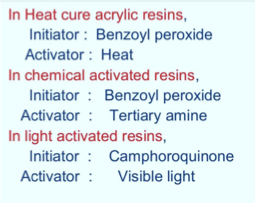

what are the common activators in the activation stage

heat

chemical compounds e.g. tertiary amines

light

what initiates polymerisation

free radical (a molecule with only one free electron) created by the activator

what occurs in the propagation stage

reaction of an active chain with a monomer

what occurs in the termination stage

2 radicals join to make a big polymer

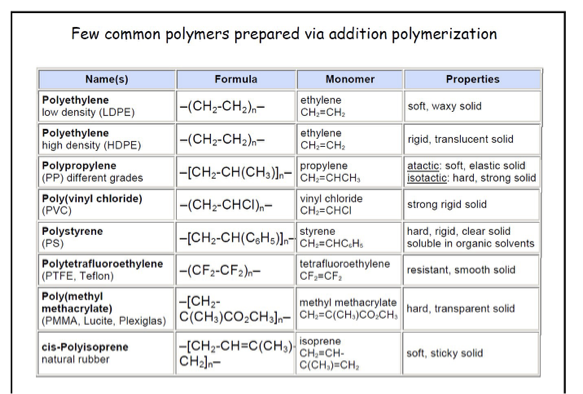

table showing common polymers prepared via addition polymerisation

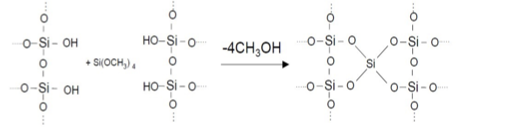

define condensation polymerisation

condensation polymerisation: occurs when a reaction between two molecules produces a larger molecule with the elimination of a smaller molecule

diagram showing example of condensation polymerisation

what is a copolymer

copolymer: two different types of monomers from different polymers are joined chemically in the same polymer chain, creating a new molecule

more noticeable in mechanical properties

what is a blend

mixing polymers prior to moulding

polymers generally miscible

» achieve moderate changes in mechanical properties

e.g. PLA + PCL

what is a plasticiser

small molecule added to the polymer that reduces attraction forces between polymer chains

» big effect in mechanical properties

lowers Tg and elastic modulus so good for brittle polymers

give an example of a composite

glass reinforced polymer

define resin-based composite

resin-based composite: highly crosslinked resin reinforced by a dispersion of amorphous silica or organic resin filler particles and/ or fibres bonded to the polymer matrix by a coupling agent