Concrete Technology

1/142

Earn XP

Description and Tags

EA's Self-Paced Course by Martin Larisch

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

143 Terms

What are the 2 main targets of a structural designer of reinforced concrete?

Determining the amount and location of the steel

Sufficient Cover to protect steel from environment, chemical attacks (corrosion) and fire

What do all these Concrete Mix acronyms mean?

ATIC

QRS

MWR

HWR

AEA

Re

PU

SS

RA

HP

SL

ATIC - Australian Technical Infrastructure Committee

QRS - Quarry Registration System

MWR - Mid (range) Water Reducing

HWR - High (range) Water Reducing

AEA - Air Entraining Agents

Re - Retarder

PU - Polyurethane

SS - Stabilised Sand or Steel slag

RA - Recycled Aggregate

HP - High Performance

SL - Slump

Properties of Self Compacting (Super Workable) Concrete? Background?

Low Viscosity

Greater Flow Rate

Good for flow through dense reo & fills voids under its own weight.

No external compaction.

Reduce costs of labour & construction time for placement & vibration

Less repairs due to poor placement & compaction

Reduced aggregate size

More fines

More high-range water reducers (superplasticiser)

Potential slower strength gain if large volumes of fly ash.

Made by Japan in the 80s to combact lack of skilled concreters. Implementing polycarboxylate-based high-range water-reducing admixture in the 90s, supported its rapid development.

What constitutes as a fine? What are the limits?

All materials passing 150-micron sieve (cements & other cementious materials). 500-600 kg/m3. Fine content impacts plastic shrinkage.

HRWR & PCE

High-Range Water Reducers (Superplasticisers). Polycarboxylates.

Dos and don'ts for self-compacting concrete

Do | Don't |

|---|---|

|

|

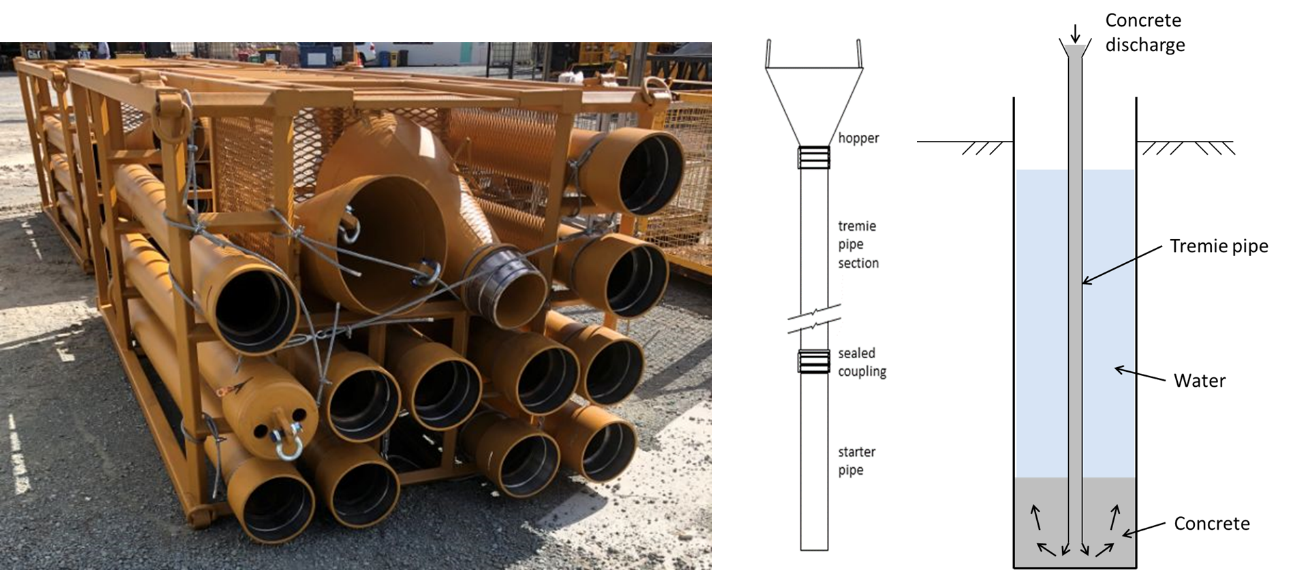

When is a Tremie used?

Tremie concrete is used when fresh concrete must be placed under water or fluid.

For foundation elements like bored piles or retaining walls like diaphragm, secant piled, or contiguous piled walls must often be carried out using the tremie method if groundwater levels are high or drilling support fluids like bentonite or polymer-based fluids are used to temporarily stabilise the pile excavation.

Key 'dos and don'ts' for tremie concrete

Do | Don't |

|---|---|

|

|

Key 'dos and don'ts' for marine concrete

Do | Don't |

|---|---|

|

|

Key 'dos and don'ts' for shotcrete

Do | Don't |

|---|---|

|

|

What is req content of cementious material for producign high quality self-compacing concrete?

400-600 kg/m3. Addition of fly ash & micro silica is advantageous to limit heat of hydration and control viscosity & segregation resistence

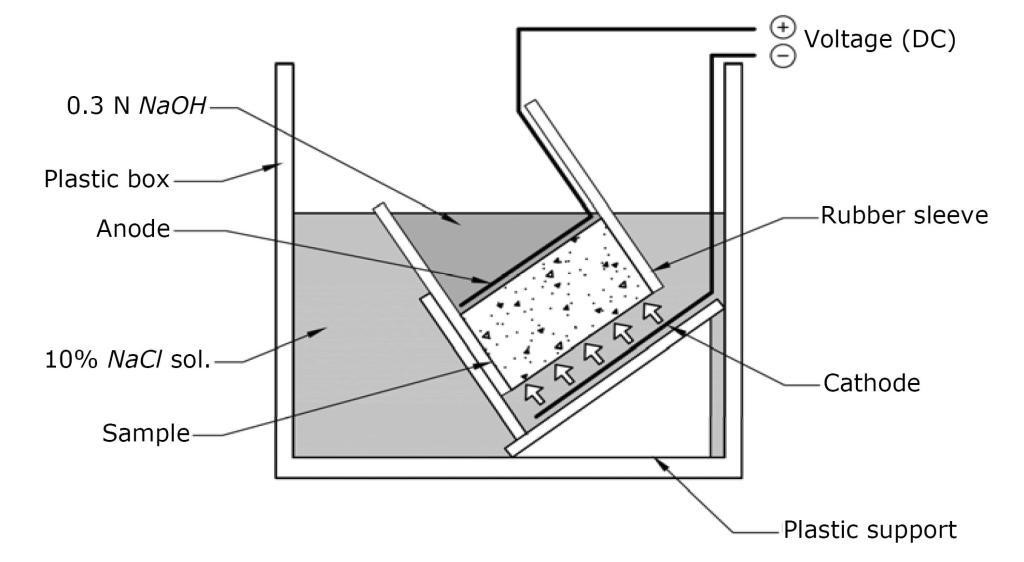

What test checks a mixes chloride resistence the quickest? What do they do?

Rapid Permeability Test (Nordtest Build 492). Tests chloride ion levels with depth. Tested on 28 day samples.

Dissolve chloride ions are forced through section of slice due to applied voltage in approx. 24 hours.

Dissolved chloride ions are forced through the section of the slice due to an applied voltage, in approximately 24 hours.

After the exposure of the specimen, it is split into two halves and the section is sprayed with a solution of silver nitrate. This leads to a precipitation of grey-white silver chloride in the part of the section that was penetrated by chlorides during the test. The penetration depth is easily measured as shown in the accompanying image showing the test set-up of the rapid permeability coefficient test.

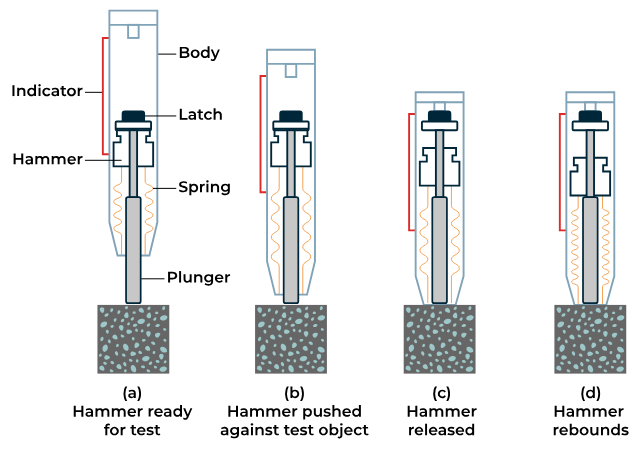

Non-Destructive Testing method?

Schmidt/Rebound Hammer

Rebound Hammer Principle: Measures rebound of an elastic mass → rebound depends on surface hardness.

Surface Hardness: Higher rebound = harder surface; lower rebound = weaker concrete.

Concrete Strength Link: Low strength/stiffness concrete absorbs more energy → lower rebound value.

Test Method:

Press plunger against concrete surface.

Increase pressure until hammer impacts.

Read rebound value (Q-value) from scale.

Strength Estimation: Use manufacturer’s conversion tables to estimate compressive strength.

Other Non-Destructive Tests: Can locate reinforcement and assess corrosion potential.

Overall Purpose: Non-destructive tests provide insight into member behaviour and condition without damaging the structure.

What is the chloride test you conduct when more time is available?

Chloride Diffusion Test (Nordtest Build 443).

Measures the charge which passes across a hardened concrete specimen. Specimen needs to be soaked in saltwater for min. 35 days but can go for up to months.

The test is $$$

3 Do’s of Validation & Testing

Carry out slump testing on a level surface

Rod concrete inside slump cone prior to testing

Apply sufficient moisture to surface when carrying out slump tests

3 Dont’s of Validation & Testing

Accept a collapsed slump—carry out another test and if the slump still fails, reject the concrete.

Lift the slump cone too fast or too slow—find the right balance.

Ignore permissible tolerances on slump testing.

Difference between Chloride Diffusion test vs. the Rapid Permeability test

Diffusion is more realistic but more expensive and requires more time

Why is the Rapid Choride test more inaccurate?

Chloride particles are ‘drawn’ through hardened concrete by applying an electrical charge as shown.

3 concrete strength tests as per AS 1012

Compressive strength testing - Concrete Cylinder

Indirect tensile strength testing - Concrete Cylinder

Flexural strength testing - Concrete Beam

Explain the Indirect Tensile Strength Test

Tensile Strength is approximately 5-8% of max compressive strength of unreinforced concrete

AKA “Brazilian” or “Splitting test”

150×300mm concrete cylinder placed horizontally & apply compressive force to it.

AS 1012.10

Explain the Flexural Strength test

Determines tensile strength of concrete in flexure. Used on pavements.

AS 1012.9

Gives higher value for tensile strength than indirect test. When nominating tensile strength, the test type should clearly be outlined

How to perform shrinkage & creep tests

AS 1012.3. Prisms of concrete are set and creep is monitored using gauges at each end

List the 3 type of cracks that form in plastic concrete (pre-hardened)

Plastic settlement cracks - Follows reo. Fixed by re-compaction whilst workable

Plastic shrinkage cracks -

Most concrete shrinks as much as 0.5 mm/m & plastic shrinkage shall be limited to 0.85 mm/m (as per AS1379).

Caused by excessive evaporation (sun, wind).

Random & unconnected cracking

Usually 200-600mm. Can be up to 2m. Few mm deep

How to control:

Change water / m3

Specify max w/c ratio & use stiffest mix design that can be pleced

Use largest nominal max size aggregate that is practical. 10mm max agg usually requires ~15L more water per m3 to get the same slump as concrete with 20mm agg

Use Water reducing, set controlling admixtures w/ good performance in shrinkage tests

Clean, course sand & specify shrinkage limit cement (Type SL)

Prevent evaportaion: Mist spray, wind screens, sun shades, plastic sheet cover

Evaporation retardant sprayed on surface after screeding

Cracks caused by movement of formwork

In general, if cracks that occur before hardening are detected early enough (prior to the stiffening of concrete), they can be easily rectified by either re-compacting, re-trowelling or re-floating the concrete surface

How do cracks form after hardening?

Drying shrinkage, movement or settling of teh ground, or applying higher loads than concrete was designed for.

How to remediate hardened concrete?

Epoxy Resin placement might be possible ($$$)

Cracking at control joints or controlled by steel reinforcement is acceptable

Can putting cold water on curing concrete on a hot day cause cracking?

Yes as cold water contracts the concrete and create tension cracks. Use warm water

What is Thermal cracking? What are the rules of thumb with concrete temperatures?

If dimensions exceed 1m in thickness anywhere. High temperatures and large gradients of temps inside the member causes cracks during the cooling phase

It may also facilitate Ettringite formation - A concern with durability of piles

Temperature of concrete should not exceed 70 ᵒC

100kg of General Purpose (GP) cement is 14 ᵒC above ambient temperature during hydration

400 kg/m3 of GP would result in 56 ᵒC above ambient temp, therefore, ambient temp can only be 14 ᵒC or less

300 kg/m3 of GP & 100 kg/m3 of fly ash would result in 42 ᵒC above ambient fresh concrete temperature, ambient temp can be 28 ᵒC

Usually controlled by using blended cement using fly ash or granulated blast-furnace slag, by chilling mix water, or insulation concrete member sufficiently

List 3 types of concrete joints

Control: Installed in wet concrete using grooving tool or saw. To prevent shrinkage cracks. Depth of 25-33% of slab to be effective. If too late, cracks may have already formed. If too early, joint might not be clean. Often in squares. Spaced at distance of 20-30x the slab thickness in unreinforced concrete. In reinforced concrete, spacing can be increased and depends on amount of steel used.

Isolation/Expansion: Typically filled with rubber or other elastic materials & filling should cover depth & length of joint.

Construction/Cold Joint: Reo runs through joint to connect to future member. Existing concrete to be thoroughly cleaned & roughened before new member’s pour to support bond.

What is consistency?

the ability of the concrete to hold its shape when unsupported and to do so without segregating or falling apart. The most commonly used test for this is the slump test.

Slumps tolerances as per AS1012 & AS1379

Specified slump, mm | Tolerance, mm |

|---|---|

<60 | ±10 |

≥60, ≤80 | ±15 |

>80, ≤110 | ±20 |

>110, ≤150 | ±30 |

>150 | ±40 |

If the first sample fails can you try again?

Yes. Concrete should be rejected if the 2nd fails.

How do you see teh cohesion of a mix from a slump test

Tap the board after the test is complete. Harsh mixes fall apart.

When can a sample be taken of concrete

After 0.2 m3 is poured

In a slump test, how many times does the sample need to be rodded? Will it get rejected if wood or rebar is used as tamping rod? or # of layers?

25 for both layers. Yes it will get rejected

What contributes to the air content in a mix

Sand

Cement

Air-Entraining Admixture

What is the percentage (%) of volume is air in air-entrained concrete

4-6%

Why make air-entrained concrete if it often makes the concrete weaker?

Workability and Freezing-Thawing condtitions.

Friction of concrete is reduced

3 Do’s & 3 Don’ts of placement

Do:

Sufficiently compact concrete in its plastic state (never let concrete dry out and stiffen because it will be too difficult to compact).

Keep the concrete moist at all times for efficient curing.

Clean and roughen the existing concrete at a construction joint (this will ensure sufficient bonding with the new concrete member).

Don’t:

Touch the formwork with an internal vibrator (poker).

Place concrete directly from the truck without a chute (the chute helps to avoid segregation).

Spread or move concrete sideways with the poker as it may cause segregation. Always use a shovel for sideways spreading.

What AS discusses testing for air entrained concrete? 3 ways to test for a concrete’s air content

AS 1012.4

Pressure is applied to fresh concrete & reduction in the volume is measured. Don’t user this for porous aggregates

Same as first* refer AS1012.4

Volumetric method involving displacment of entrained air with water. Lightweight & Porous aggregates.

What should specified air content be within for the specified air content when tested?

1.5%

Equation for density?

Mass/Volume (kg/m3)

What is Ettringite

Ettringite is a mineral and a product of cement hydration, a hydrous calcium aluminum sulfate with the formula Ca₆Al₂(SO₄)₃(OH)₁₂·26H₂O.

It crystallizes in the trigonal system and forms during the normal setting and hardening of Portland cement. In some cases, delayed ettringite formation can lead to expansive stresses and cracking in concrete structures. Its unique crystal structure also allows it to function as an effective ion exchanger, capable of sequestering toxic heavy metals and radionuclides.

What is Yield?

The comparison of the theoretical weight of the mix constituents with the actual weight of the mix for a similar volume

or

Yield is the volume of fresh concrete produced in a batch, expressed in cubic meters. It is calculated by dividing the total mass of the material by the measured density of the freshly mixed concrete.

What is the ideal Yield in a mix?

2-5% tolerance

How to calculate yield

Total mass of cement, aggregates, water, and admixture in a batch of 6.00 m3 is 14,265 kg

Concrete density (unit weight) of 2330 kg/m3

Theoretical volume of fresh concrete = 14,265 kg / 2330 kg/m3 = 6.12 m3

Yield = 6.12 m3 / 6.00 m3 = 1.021 (2.1%).

Is under vibration or over vibration more common in normal class concrete?

Under vibration

Why does bleeding happen?

What AS explains testing of bleeding?

How is it tested?

Bleeding occurs naturally but may occur if tto much water or cement paste is in the mix

AS 1012.6

Cylindrical test. Water from bleeding drained via pipette at intervals until amount collected during 30 mins is less than 5 mL.

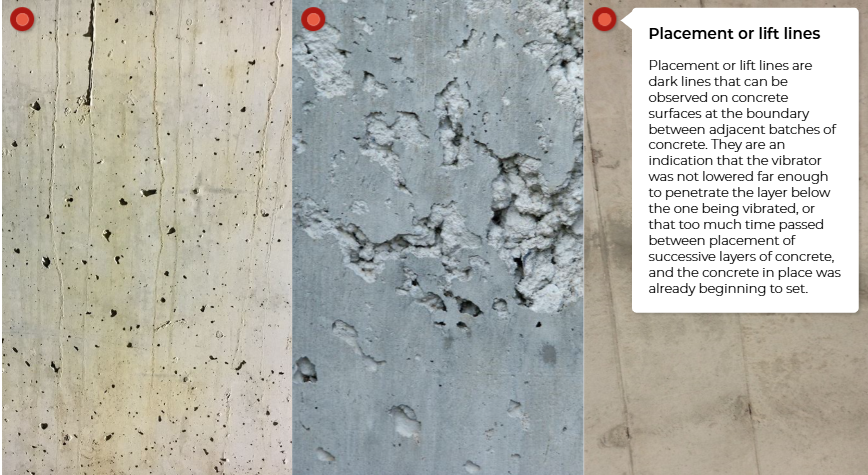

Name the 3 imperfections that occur due to insufficient consolidation?

Bug Holes - Surface air voids. Sometimes regarded as natural if small. Issue if there is a lot and they’re large as cover might be limited. Prevented by formwork release agents or mix design.

Honeycombs - ‘Aggregat’ or ‘rock pockets’. Cement paste does not fill all spaces between aggregate. Repair or removal of the concrete section

Placement/Lift Lines - Dark lines between adjacent batches of concrete. Prove that vibrator was not lowered far enough to benetrate below layer, or too much time passed between placement of successive layers and concrete had set.

List the 10 surface defects and why they happen

Issue | Properties of fresh concrete | Placement | Compaction |

Honeycomb | Insufficient fines, low workability, early stiffening, excessive mixing, too large an aggregate for placing conditions | Excessive free fall, too thick a layer (lift) of concrete in forms, drop chute omitted or of insufficient length, too small a tremie, segregation due to horizontal movement | Vibrator too small, too low a frequency, too small an amplitude, too short immersion time, excessive spacing between immersions, inadequate penetration |

Air surface voids | Lean, sand with high fineness modules (FM), low workability with low FM sand, excessive cement content, particle degradation, excessive sand, high air content | Too slow, caused by inadequate pumping rate, undersized bucket | Too large an amplitude, external vibration inadequate, head of vibrator only partially immersed |

Form streaking | Excess water or high slump | Improper timing between placing and timing | Excessive amplitude or frequency for form design |

Aggregate transparency | Low sand content, gap-graded aggregate dry or porous, excessive coarse aggregate, excessive slump with lightweight concrete | Excessive external vibration, over-vibration of lightweight concrete | |

Subsidence cracking | Low sand, high water content, too high slump, poorly proportioned mix | Too rapid | Insufficient vibration and lack of re-vibration |

Colour variation | Non-uniform colour of materials, inconsistent grading, variation in proportions, incomplete mixing; calcium chloride can cause darker colour; too high a slump | Segregation (slump too high) | Vibrator too close to form, vibration next to forms variable, overworking the concrete |

Sand streaking | Lean over-sanded mixtures and harsh wet mixtures deficient in fines | Too rapid for type of mix | Excessive vibration, excessive amplitude, overworking the concrete |

Layer lines | Wet mixture with tendency to bleed | Slow placement, lack of equipment or manpower | Lack of vibration, failure to penetrate into previous layer |

Form offsets | Excessive retardation of time of setting of concrete | Rate too high | Excessive amplitude, non-uniform spacing of immersion, horizontal movement of concrete |

Cold joints | Too dry, early stiffening, slump loss | Delayed delivery, layers (lifts) too high | Failure to vibrate into lower layer (lift), insufficient vibration |

Pump rates in m3/hr? Distances? Do you need to prime/lube it by pumping a ‘priming

mortar before starting?

50-200m3

50m veritcally to 500m horizontally

Yes

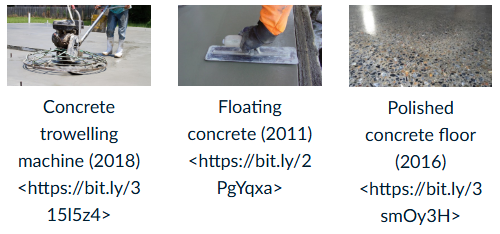

List the 5 types of concrete finishes

Floating - done by hand or with a power float, but power floating leaves a better finish than hand-floating. Floating helps compact and level the surface and close minor cracks.

Trowelling - another method of surface finishing and is how dense, hard, smooth and durable surfaces can be achieved. The surface should be trowelled twice and can be done either by hand or with a power trowel. All the edges of a concrete slab should be finished with a special edging tool to achieve a stronger edge, which is less prone to chipping.

Joints - should be planned before placing and are usually formed into the concrete during finishing (you'll be covering joints in detail later in this module). The achievement of a skid-resistant surface can be done by drawing a broom across the surface of the concrete. The broom can be drawn in straight or 's' shape lines.

Polished concrete - by using liquid polishes, latex coatings, chemical sealers or grinding, to expose the aggregates. Care should be taken to avoid surface cracks in polished concrete applications.

Exposing the aggregate - another architectural finish. Typically, normal class concrete is used. After placement, the coarse aggregate will be exposed from the firm (not fully hardened) surface by forceful brushing or washing away the cement paste until the aggregates are exposed.

What is curing? How to cure?

To prevent surface cracks, evaporation is reduced. Lack of curing can weaken the concrete by up to 50%. Curing happens after placment, compaction & finishing.

Maintain temp & moisture content for at least 3-7 days after placement. Allows ongoing hydraulic cement hydration & pozzolanic reactions to occur (if reqd).

Moisten surface & edges for moisture. Ensures hardened, abrasion resistant surface is developed & surface dusting is reduced

How to cure:

Cover in plastic foil - Avoids wind & sunlight evaporation. Don’t leave a mark.

Mist spray - twice daily for up to 7 days. Don’t over water.

Membrane-forming curing compounds - Waxes, natural & synthetic resins & solvents. Applied by brush, spray or roller. Single application is normally enough. Do not walk on concrete until dry. Don’t put on surfaces that need additional layers of concrete, paint, tiles or carpet

Wet mats - Cotton mats, rugs or other absorbent coverings. Keep damp with applications of water or cover with plastic.

Plastic membrane - Don’t put on aesthetic concrete slabs as wrinkles can affect texture. No discolouration though

Don’t want concrete surface to dry before cement is hydrated

Hot weather’s affects?

🔥Hot Weather Concrete

Can cause problems with mixing, placing, curing → reduced long-term strength & serviceability.

Wind, sun, dry air worsen effects → rapid evaporation.

Risks:

Non-uniform surface & low strength (improper curing).

Increased plastic shrinkage cracking.

Premature stiffening if >21 °C → more water needed, lower later strength.

✅ Procedures

Keep surroundings cool.

Cool concrete & ingredients (e.g. ice, liquid nitrogen, shaded aggregates).

Work rapidly → avoid delays.

Adjust mix proportions.

Delay pours → night shifts / cooler times.

Cool formwork, reinforcement, subgrade with water before placing.

Spray surfaces after placing; wet-cure tops of walls & columns.

Schedule ready-mix trucks efficiently → avoid slump loss.

Use light-coloured trucks to reduce heating.

Finishing & curing are critical → curing compounds, spraying, ponding.

Postpone pour if extreme hot weather predicted.

Cold weather’s affects?

🥶 Cold Weather Concrete

Keep concrete >4 °C to allow hydration.

Protection from early freezing is most critical.

At 10 °C, concrete usually gains enough early strength after 24–48 hrs.

Low temps = slow setting, delayed strength.

Insulating blankets only retain heat, don’t raise temperature without external source.

✅ Procedures

Heat water & materials.

Heat placement area.

Use extra cement or high-early-strength cement.

Add accelerating admixtures (faster hydration, but reduces working time).

Don’t place on frozen subgrade → thaw & recompact if needed.

Protect massive pours (piers, dams, foundations) by insulating formwork & surfaces.

Preheat formwork in very cold conditions.

🧰 Insulation Options

Polystyrene / polyurethane sheets.

Sprayed urethane foam (continuous layer).

Mineral wool or cellulose fibre.

Do precast & prestressed members have accelerated curing procedures? What requirements need to be met as per AS3600?

Yes. Saturated Steam or dry heat, which requires concrete member to be sealed to prevent loss of mixing water.

AS3600 - min curing times are critical for compressive strength targets prior to formwork stripping

If table below is not adhered to, severe defects or even collapse of members may occur

Minimum strength and curing requirements in accordance with AS 3600:

Exposure classification | Minimum fc (MPa) | Minimum initial curing requirement (see Clause 1.7.1.5.1) | Minimum average compressive strength at the time of stripping of forms or removal from moulds (MPa) |

A1 A2 | 20 25 | Cure continuously for at least three days | 15 |

B1 B2 | 32 40 | Cure continuously for at least seven days | 20 25 |

C1 C2 | 50 50 | 32 |

Consolidation = Compaction

Yes

What is the amplitude of a vibration?

The deviation in mm from the point of rest

Is this true?: In general, high amplitude and low frequency of vibration are preferred for stiffer concrete mixes, and low amplitude and high frequency typically work better with more plastic mixtures.

Yes

List the 3 common vibrators

Internal vibrators are vibrating elements that can be inserted into the fresh concrete at selected locations and are generally applicable to construction sites.

External vibrators employ vibrating devices attached at strategic positions on the formwork. External (or formwork) vibration is mostly applicable to the manufacture of precast concrete items, and for vibration of tunnel-lining forms.

Surface vibrators employ portable horizontal platforms on which a vibrating element is mounted.

How to Internal Vibrate properly

Immersed vertically full depth & at least 150mm into preceding layer

Put in quickly and taken out slowly

Spacing is 1.5 times the radius of the vibrator

Tell me about Roller Compacted concrete

0 Slump

Dams & Pavements

Consolidation by smooth drum rollers weighing 1500 - 5000 kg/m3

VPM

Vibrations per Minute

Give a form of manual consolidation

Rodding - repetitive poking or tamping of a steel rod into the fresh concrete. The rod should be long enough to penetrate the full depth of the layer being placed, and thin enough to pass between the reinforcing steel and the formwork.

Heavy Flat Faced Tools - For dry concrete with very low slumps, the surfaces can be rammed with heavy flat-faced tools until a film of mortar or cement paste appears at the surface. This film indicates that the voids within have been sufficiently filled. Please note that over-ramming should be avoided.

What is a Tremie? When is it used?

Underwater

What is dry-mix and wt-mix in Shotcrete?

Dry-Mix: cementious materials and aggregates are mixed w/o water. Then transported by compressed air into a nozzle with compressed water to spray

Wet-Mix: Everything is mixed but chemical admixtures as they are applied at the end.

Should concrete testing be done at the end of the pump? Not at the truck dispatch.

Yes. Can reduce the slumpb by up to half the desired amount.

The 90-minute limitation may be waived by mutual agreement between the customer and the supplier if, after that period, the….

…consistency of the concrete is such that it can be properly placed and compacted without the addition of any more water to the mixer

Temperature limits of concrete

Not less than 5C nor greater than 35C. If ambient temp is not 10-30C, measures may need to be adopted to comply with those requirements

Does stiffening occur in hot dry weather?

Yes

In hot dry weather can the limit be reduced on the time from the commencement of mixing to the initial set from 90 mins? Can this time be extended in the cold?

Yes

Name the 15 items to be listed on the concrete document

Name of supplier and place of concrete plant

Serial number of the record/certificate

Date of supply

Name of customer

Project name and location

Delivery vehicle identification, if applicable

Quantity of concrete covered by the certificate

Specified class and strength grade, or other mix identification

Specified slump, if applicable

Maximum nominal size of aggregate

Time of commencement of mixing

For concrete specified by water-cement ratio, the estimate of the quantity of water, if 13any, added after completion of batching and whether the addition occurred before, or after, the commencement of discharge

For concrete specified by slump, the estimate of the quantity of water added after commencement of discharge

Any other detail that may be agreed between the customer and the supplier.

What are the 3 “Do’s” of for concrete production

Wash and clean concrete mixers after use to ensure sufficient mixing will be maintained for future works.

Fill out delivery dockets in accordance with AS 1379 and your requirements.

Calibrate weighting and batching facilities regularly.

What are the 5 “Don’ts” of for concrete production

Add water beyond the allowable amount as per the relevant mix design to make the concrete more fluid—it generally lowers the strength of the hardened concrete.

Carry out batching by volume, but always by mass (exceptions might be acceptable for small size DYI or low-risk projects if approved by the engineer).

Accept concrete that was batched 90 minutes prior to arrival on site, unless sufficient slump retention is provided.

Can you place a layer of concrete more than 500mm thick?

No! The concrete must be compacted before continuing

List 4 tools used to pour in concrete to formwork

Drop chutes

Lay flat

Tremie

Placement pipes

Concrete trucks in Australia have typical transport capacities from __ m3 to more than __ m3. The most common truck sizes in Australia are __ m3 and __ m3 trucks

1

12

6

8

Discharge of concrete in a batch should be completed within ______ mins from commencement of mixing or _____________. To what code?

90

before proper placement

AS1379

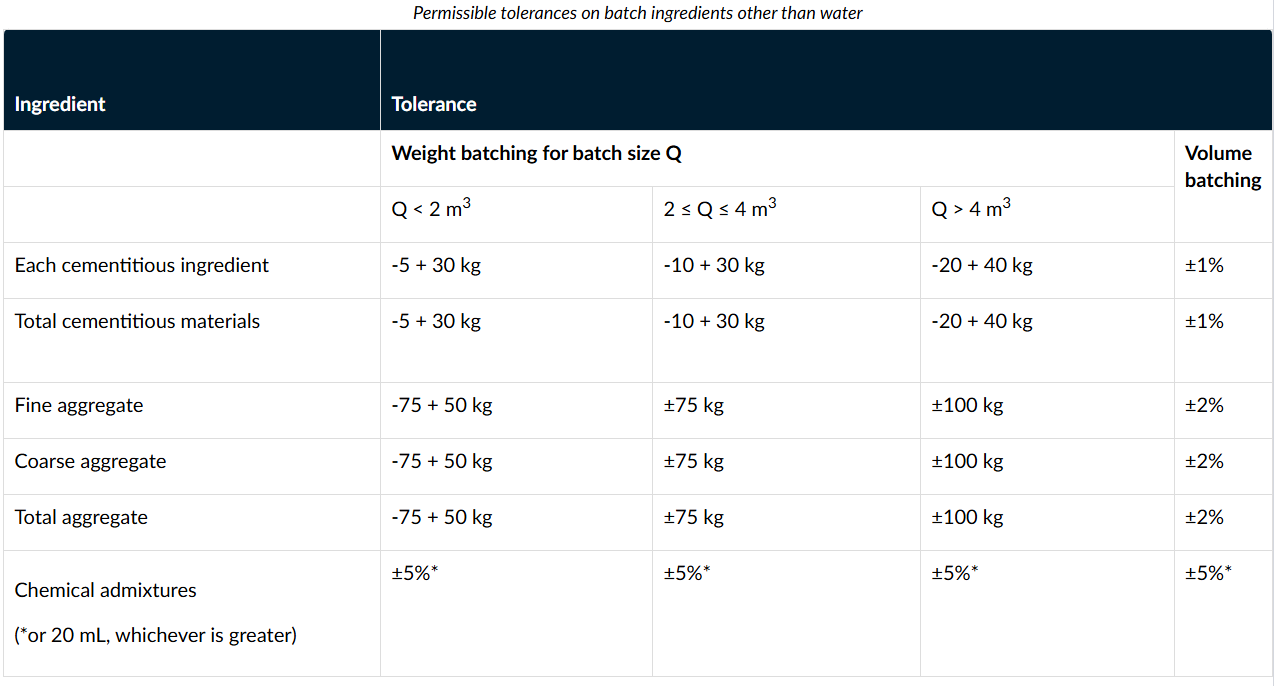

2 batch ingredients with different tolerances

Aggregates & Cement

Water

The quantity of each ingredient in a batch shall be measured and controlled within the tolerances given for each ingredient in _____?

AS1379-2007

Tolerance for Q<2 m3 of total cementious material?

-5 +30 kg

The quantity of water added to a batch is achieved by _______________, and by maintaining the specified __________

accomplishing the specified slump

design water-cement ratio

Tolerance of w/c ratio?

+10%

Where the w/c ratio is specified, regular moisture content checks of aggregate in accordance with _________ shall be taken

AS 2758.1

The rated mixing capacity of a batch mixer must be not more than % of the gross internal volume of the mixing chamber. If a batch mixer is operated as an agitator, for this purpose only, the rated agitating capacity may be taken as up to __% of the gross internal volume of the mixing chamber.

65

80

What is an Agitator?

A concrete agitator looks like a truck with a large, revolving concrete drum at the back, which is the most distinctive feature.

Inside this drum are angled blades designed to mix and keep the concrete from setting during transport and before it's discharged.

The truck also has a hydraulically operated chute that swings out to pour the concrete where it's needed.

The minimum number of revolutions of the mixing mechanism should be as determined from the mixer manufacturer’s recommendations unless determined in accordance with _____.

Mixing should be carried out by either central mixing, mobile mixing, or staged mixing in compliance with _____. Select the following headings to find out more about each.

AS 1379

What is the % of each element (typically) in concrete?

Water = 14-21%

Cement = 7-15%

Aggregate (Sand/Gravel) = 65-80%

Air = <2%

3 types of mixing

Central Mixing - Stationary

Mobile Mixing - Truck-mounted drum mixer

Staged Mixing - Partially mixed centrally, and rest added later in mobile mixer

What is the chemical process of concrete hardening called?

Hydration

Does concrete have low thermal conductivity?

Yes

What environment does concrete make for the embedded steel reinforcement?

Alkaline (opposite of acidic on pH scale)

Concrete is a mix of what?

Cement, water, and aggregates (stone or sand), and sometimes other cementitious materials and chemical admixture

What is most concrete today made out of? What is an SCM?

Portland cement and supplementary cementitious materials (SCMs), which react with water to form the cement paste. Sand, gravel, and stones make up the largest fraction of concrete, and the cement paste is the ‘glue’ that sticks them together.

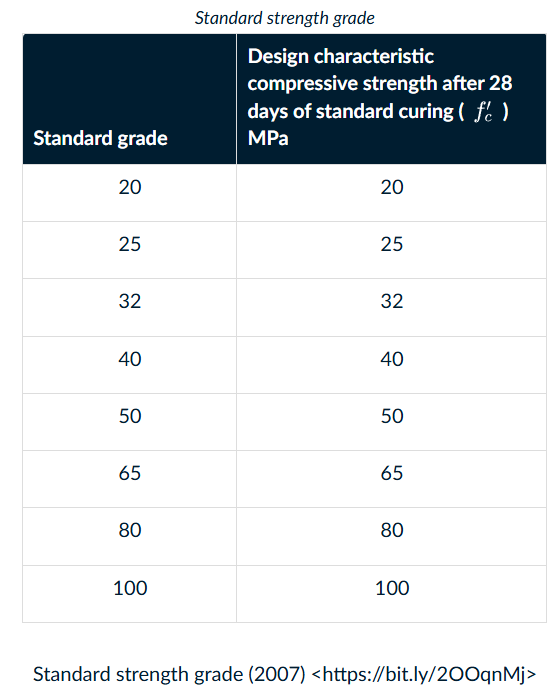

What is concrete grade?

Design characteristic compressive strength after 28 days (f’c) MPa

What standards ties to concrete?

AS1379 - Concrete Specification & Supply

AS1012.12.1 - Concrete Testing

What is MPa a measure of?

Metric unit of Pressure

What is the range of compressive strength for ‘Normal Class’ (Conventional) concrete?

20-50 MPa