OSH CHAPTER 5

1/25

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

26 Terms

What should employers ensure regarding work equipment?

Employers must ensure that work equipment is suitable, maintained, inspected if necessary, provided with adequate information and instruction, and used only by trained individuals.

What does 'CE' marking indicate about new equipment?

'CE' marking indicates that the manufacturer claims the equipment is safe and meets relevant supply law.

What is the hierarchy of controls in risk management?

The hierarchy includes eliminating risks, taking physical measures to control risks (like guards), and implementing safe systems of work if risks cannot be adequately controlled.

What are the types of maintenance for work equipment?

Types of maintenance include preventative planned maintenance, condition-based maintenance, and breakdown-based maintenance.

What are user responsibilities regarding work equipment?

Users must take reasonable care for themselves and others, cooperate with employers, use equipment properly according to instructions, and report dangerous situations.

What are common hazards associated with hand-held tools?

Common hazards include broken handles, incorrect use, slipping tools, dull blades, and flying particles.

What safety considerations should be taken when using hand tools?

Safety considerations include using well-designed high-quality tools, regular maintenance, and proper inspection before use.

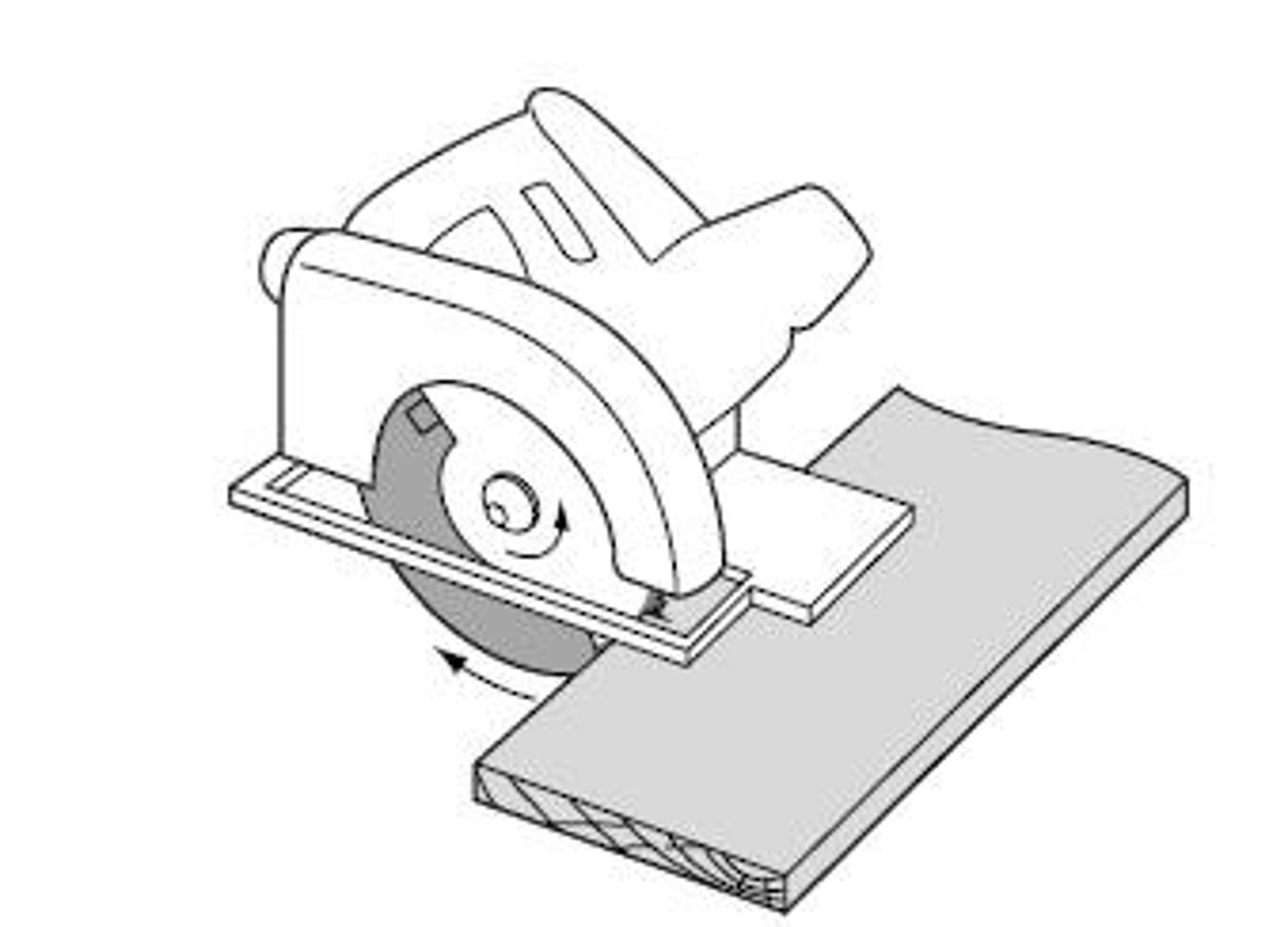

What are some general hazards of hand-held power tools?

Hazards include mechanical entanglement, manual handling injuries, hand-arm vibration, and electrocution from poorly maintained electrical cables.

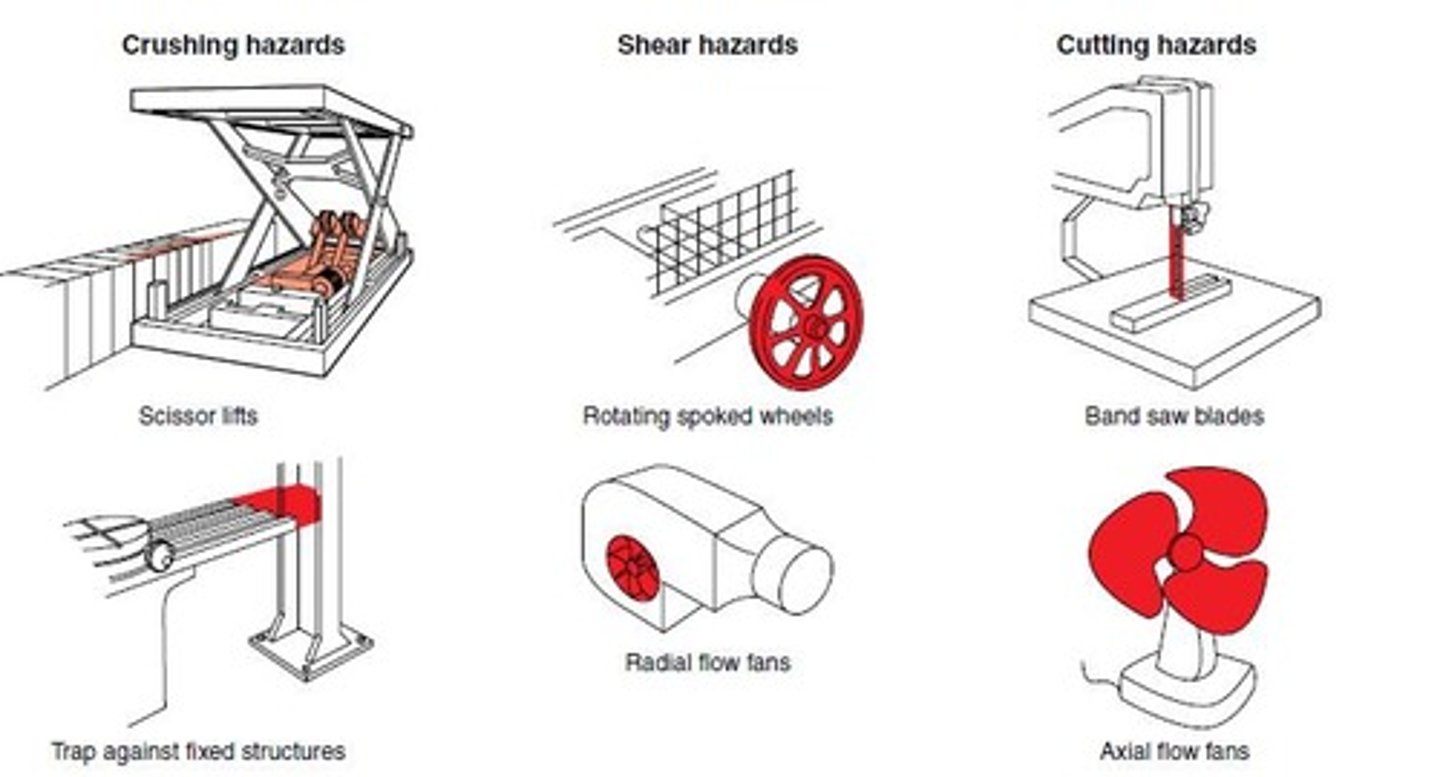

What are the classifications of machinery hazards?

Classifications include crushing, shearing, cutting, entanglement, drawing-in, impact, stabbing, friction/abrasion, and high-pressure fluid injection hazards.

What are practical safeguards for machinery hazards?

Practical safeguards include fixed enclosing guarding, interlocked guards, pressure-sensitive mats, and providing information, instruction, training, and supervision.

What is the purpose of adjustable guards on machinery?

Adjustable guards are used to provide safety while allowing access for operations that require varying clearance, such as during different cutting sizes.

What is the role of interlocking guards in machinery safety?

Interlocking guards allow safe access for operation and maintenance without dismantling safety devices and are connected to the machine's power or control system.

What should be considered when assessing risks from manual handling activities?

Hazard factors should be considered to suggest ways of minimizing manual handling risks.

What responsibilities do workers have when handling work equipment?

Workers are responsible for ensuring proper maintenance and safety when handling work equipment to avoid accidents.

What is the importance of maintaining work equipment?

Proper maintenance ensures that work equipment continues to operate safely and as designed.

What must be done if equipment is found to be damaged?

Damaged equipment must not be used and should be examined for safety before use.

What is the significance of markings on work equipment?

Markings must be clearly visible and durable to ensure safety and compliance.

What are the risks associated with using poorly insulated tools?

Poorly insulated tools can lead to electrocution or burns, especially in hot work environments.

What is the impact of using dull tools?

Dull tools can cause more hazards than sharp ones, as they may slip and cause injuries.

What should be done with cracked saw blades?

Cracked saw blades must be removed from service immediately.

What is the role of training in equipment use?

Training is essential to ensure that users can operate equipment safely and effectively.

What is the purpose of providing adequate information and instruction for work equipment?

Adequate information and instruction help ensure that equipment is used safely and correctly.

What should be done if risks cannot be eliminated?

If risks cannot be eliminated, physical measures or safe systems of work should be implemented to control them.

What is the significance of the working environment in relation to equipment use?

The working environment affects how equipment is used and maintained, influencing safety and operational effectiveness.

What are the consequences of not complying with safety standards for work equipment?

Noncompliance can lead to accidents, injuries, and legal repercussions for employers.

What is the importance of inspecting work equipment?

Inspection ensures that equipment remains safe to use and meets operational standards.