Agri 21 Theoretical lab last exam Jesus Christ part 3

1/24

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

25 Terms

Milk

Normal mammary secretion of

milking animals intended for

consumption as liquid milk,

or for further processing.

Milk composition

• Fat is the most variable and easily

influenced by:

- Feeding system

- Milking techniques

Bacterial count of milk

• Presence of microorganisms

causes the premature spoilage of

milk. Pathogenic organisms

contaminate milk due to careless milk

handling.

Chemicals

• Milk should be free from antibiotics,

pesticides, detergents, and

sanitizers.

Inspect the appearance and color of milk

• Color

-Cotton white: Carabao or goat

-Slightly yellowish: Cow

• Free from precipitates or floating fats

Taste (but do not swallow) a sample of milk

• High quality fresh milk should taste

slightly sweet and pleasant without

intense flavor.

Filter the milk through a clean white cloth into another clean container to check on impurities

• Good milk should be free from

impurities.

Clarification and filtration

• Done to remove extraneous materials and

body cells.

Mechanical centrifuge

CLARIFICATION AND FILTRATION

clarifies the milk

by removing dirt and somatic cells;

separates the fat

Passing milk through a cheesecloth

CLARIFICATION AND FILTRATION

serves as a filter

Cooling

• Storing of milk at 2 to 4°C

- to delay enzymatic and microbiological

changes in milk

Note: Milk freshly drawn from the cow’s udder is

warm, about 37°C

Separation

• Separation of cream from skim milk.

Gravity and Mechanical (centrifugation)

SEPARATION

based on the difference in

density between the cream and skim milk.

Standardization

• Provides products of uniform fat contents.

Pasteurization

• Process of heat treatment that aims to

destroy:

- microorganisms that can cause disease

- microorganisms and enzymes that may

shorten the shelf-life of the product.

• This is followed by rapid cooling to 4°C or

below to prevent surviving microorganisms

from multiplying.

Holding process

• Types of Pasteurization Method:

145°F (62.8°C) for 30 mins

Flash process

• Types of Pasteurization Method:

165 to 180°F (73.9 to 82.2°C)

for 15 seconds

Ultra High Temperature

• Types of Pasteurization Method:

140°C for 1 second

Vacuumization

• Involves the use of equipment that removes

volatile substances such as odors.

Homogenization

• Fat in milk exist in the form globules ranging

from 0.1 to 15 μm in diameter.

• Homogenization will render the globules

uniform in size of about 2 μm.

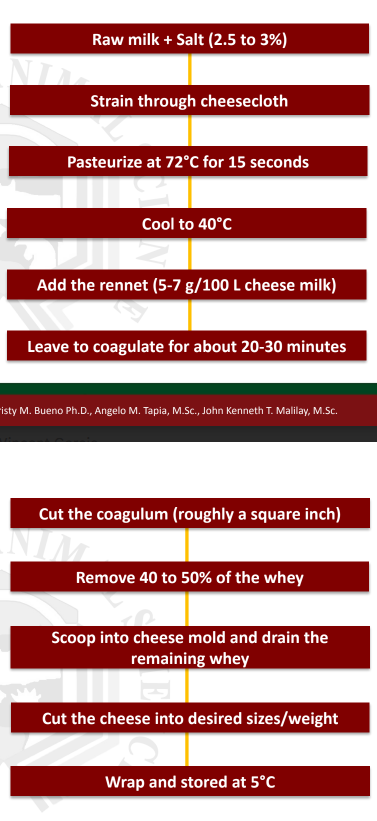

Cheese making

• Involves coagulating the casein protein in

milk then separating the milk into solid curds

and liquid whey. The liquid whey is drained

away.

microorganisms/starter cultures

Most type of cheeses use ______________cultures to determine the flavor and texture of the final cheese.

Process flow of manufacture of Kesong Puti

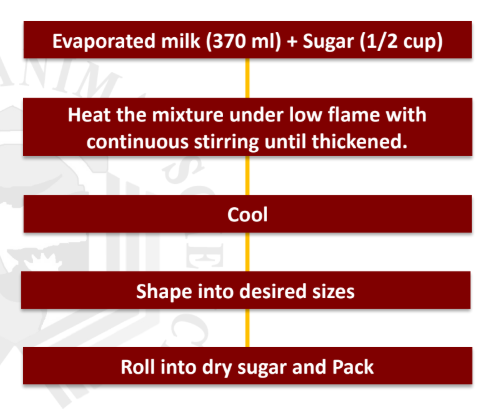

Pastillas

• Type of Filipino milk candy traditionally made

with carabao milk and sugar.

• Also known as Pastillas de Leche or

Pastiyema

Process of Manufacturing pastillas