Formula sheet for inventory management

1/37

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

38 Terms

Average inventory

Average inventory is computed as the average of the beginning inventory and ending inventory of a time. Period such as a year or an inventory cycle.

Average inventory = (beginning inventory - ending in inventory)/2

iC/100 when given a %

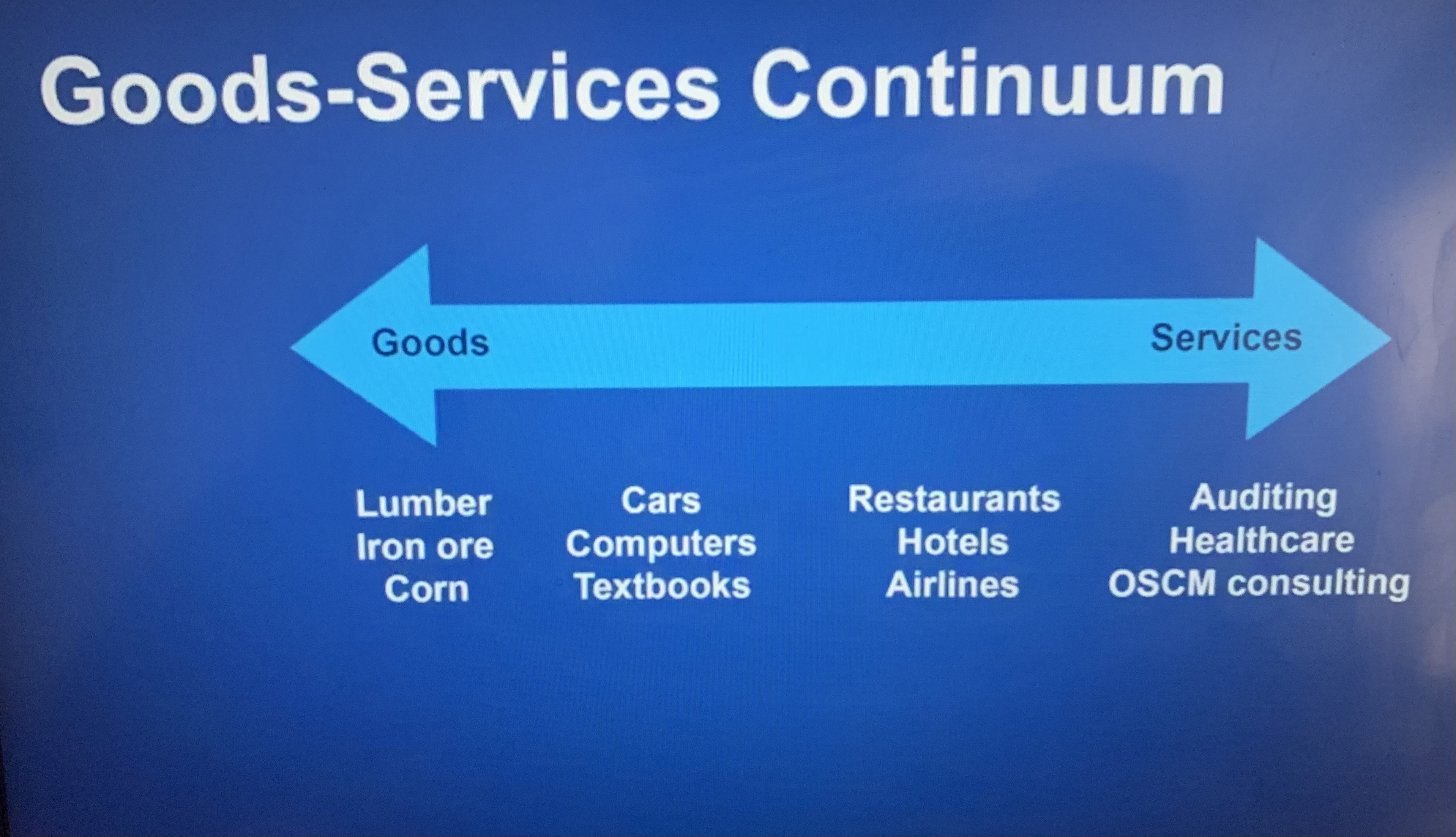

Goods: More tangible, Lower consumer contact, Quality easier to define, Can more often use inventories for uncertainty can store for future

Service: more intangible, high consumer contact, quality harder to, production and consumption mostly simultaneous

Q

Order quantity per order

Q*

Economic order quantity (EOQ)

D

Daily demand

S

Ordering cost per order

h

Holding cost per unit of inventory per day

T

Cycle time

TC

Total inventory cost

L

Leadtime of delivery

R

Re-order point

N(mean, Standard deviation²)

Normal distribution with mean and variance (Standard deviation)

di

Daily observed demand for day i for uncertain demand

Mean w. ^

Estimated mean demand for uncertain daily demand data

Standard deviation w. ^

Estimated standard deviation of demand from uncertain daily demand data

SS

Safety stock

Za

Safety stock factor for service level @

r

Inventory review period For periodic review policy

B

Base stock levels for periodic review policy

Cycle time (in EOQ equation)

Cycle time (T) is the number of days between two orders. For EOQ model, It is the same as the number of days one order quantity(Q) last at the fixed daily demand(D). Cycle time is measured as:

T=Q/D

Ordering cost per day

Ordering cost per day is the equivalent cost of ordering inventory measured on a daily basis. While the ordering cost is incurred once over an inventory cycle, the ordering cost per day is obtained by dividing the total ordering cost(S) by the cycle time(T)

Ordering cost per day (formula)

Ordering cost per day = S/T = SD/Q

Holding cost per day

The inventory holding cost per day, is the holding cost of the average inventory(Averaged over an inventory Cycle) for one day. It is obtained by multiplying the average inventory by the daily per unit holding cost(h).

Holding cost per day(Formula)

Average inventory = Q/2

Daily holding cost = (Q/2) * h

Daily total inventory cost

The daily total inventory cost (TC) is the sum total of the daily ordering cost and the daily holding cost for an order quantity Q.

Daily total inventory cost(Formula)

TC(Q) = SD/Q(Daily ordering cost) + (Q/2)*h(Daily holding cost)

Economic order quantity(EOQ)

The EOQ (Q*) is defined as the order quantity that minimizes the total inventory cost(TC) For a given daily demand (D), Ordering cost per order(S) and Daily unit holding cost (h).

EOQ(Q*) (Formula)

EOQ(Q*) = Square root of (2*S*D)/h

Daily holding cost, daily ordering cost, and daily total cost at EOQ

True or false: At the EOQ, the daily holding cost is equal to the daily ordering cost

True

Re-order point

Re-order point(R) Is the minimum level of inventory in stock at which point the next order needs to be issued in order to avoid any potential stockouts in the future. The re-order point for the EOQ model for a leadtime of delivery L and a daily demand D is given by:

R=L*D

Optimal order quantity

Optimal order quantity(Q*) = The square root of (2*S*Mean)/h

Where S is the ordering cost per order, and h is the holding cost per unit per day.

safety stock

The safety stock or buffer stock is the stock that is held as inventory to account for unexpected increases in demand during the leadtime period. The safety stock protects against possible stock out situations with a service level..

Expected demand during leadtime

Expected demand during leadtime = mean * L

Re-order point for continuous review policy

R= Expected demand during leadtime+ Safety stock

Expected cycle time of continuous review policy

Expected cycle time = Q/mean

Expected daily inventory in continuous review policy