FPQC: SEMI-SOLID DOSAGE FORMS, LIQUID DOSAGE FORMS (Solutions, Emulsions, Suspensions)

1/76

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

77 Terms

Minimum Fill

SEMI-SOLID DOSAGE FORM

-Determination of the weight or volume of filled container.

-For preparations with labelled amount of not more than 150 g or 150 mL.

ACCEPTANCE CRITERIA OF MINIMUM FILL

SEMI-SOLID DOSAGE FORM

-Average of 10 containers is not less than the labelled amount.

-Individual content not less than 90% ( if label <60mL or < 60 g) or not less than 95% (if label = 60-150g or 60-150mL) of the labelled amount.

-If criteria is not met, test additional 20 containers.

Appearance

SOLUTIONS

Visual inspection to check for the presence impurities of and floating matter.

Physical Attributes

Viscosity, Clarity, Color, Odor, Taste

Emulsions

It is a two-phase liquid system combining 2 immiscible liquids.

-Dispersion Medium/External/Continuous Phase

-Dispersed/Internal/Discontinuous Phase

-Emulsifying Agents

Enumerate the general components of emulsions

Dispersion Medium/External/Continuous Phase

GENERAL COMPONENTS OF EMULSIONS

A solvent on which the dispersed phase is distributed; can be a liquid or semisolid (e.g., creams, lotions)

Dispersed/Internal/Discontinuous Phase

GENERAL COMPONENTS OF EMULSIONS

The substance distributed in the dispersion medium (API)

Emulsifying Agents

GENERAL COMPONENTS OF EMULSIONS

-Stabilizer of the droplet forms (globules) of the internal phase.

-Acts as a bridge between the 2 phases while at the same time providing a protective film around the globules and retards coalescence.

-Dye Solubility Test

-Dilution Test

-Conductivity Test

-Cobaltous Chloride in Filter Paper Test

-Fluorescence Test

Enumerate the types of emulsions

Dye Solubility Test

TYPE OF EMULSIONS

-Water soluble dye will dissolve in the aqueous phase

Methyl red

Methylene blue

Methyl orange

Malachite green

Crystal violet

Examples of water soluble dye in dye solubility test

Sudan red

Examples of oil soluble dye in dye solubility test

Water

DILUTION TEST

-o/w emulsion can be diluted with?

Oil

DILUTION TEST

-w/o emulsion can be diluted with

O/W: +

W/O: -

TESTS FOR EMULSIONS

Conductivity Test

O/W: Spotty Fluorescence

W/O: Continuous Fluorescence

TESTS FOR EMULSIONS

Fluorescence Test

O/W: Pink

W/O: Pink Spots

TESTS FOR EMULSIONS

Cobaltous Chloride in Filter Paper

Breaking

Coalescence

Sedimentation

Flocculation

Creaming

Phase Inversion

What are the common problems that always encountered in emulsions?

Breaking (completely irreversible)

Phase Inversion (partially irreversible)

What are the problems of emulsion that is irreversible?

Coalescence

Creaming

Flocculation

Sedimentation

What are the problems of emulsion that is reversible?

Ideal Characteristics of Suspensions

-Should not settle rapidly & should be readily redispersed upon gentle shaking of the container.

-Particle size of suspensoid should remain fairly constant throughout long periods of undisturbed standing.

-Should pour readily and evenly from its container.

Flocculated Suspension

Deflocculated Suspension

What are the two types of suspensions?

Flocculated Suspension

-A flocculated suspension is a suspension in which particles have undergone flocculation

-Has floccules

-The rate of sedimentation is high

-The volume of sediment is high

-Form porous sediments

-The re-dispersion of a sediment can easily be done by agitation

Deflocculated Suspension

-A deflocculated suspension is a suspension where no flocculation has taken place

-Has no floccules

-The rate of sedimentation is low

-The volume of sediment is low

-Form non-porous sediments

-The re-dispersion of a sediment is difficult by agitation

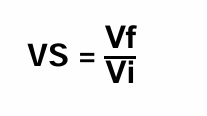

Sedimentation Volume (VS)

SUSPENSIONS

-Checking if the suspension settles rapidly

-Ratio of height of sediment settled after standard condition (Vf) and the initial height/volume of the suspension (Vi).

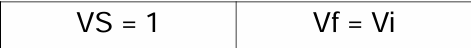

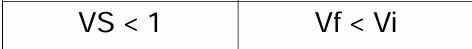

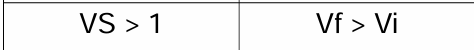

Ideal

SUSPENSIONS

Always

SUSPENSIONS

Not Possible

SUSPENSIONS

Deliverable Volume

FOR ALL LIQUID DOSAGE FORMS

-Provides assurance that liquids will, when transferred from the original container, deliver the volume of dosage form that is declared on the label of the article.

-For products with labelled amount not exceeding 250mL.

-Gently drain liquid contents from bottle for a period not to exceed 30 minutes for Multiple Unit Containers and 5 seconds for Single-unit containers.

ACCEPTANCE CRITERIA (Multiple Unit Containers)

-Average volume obtained from 10 containers is NLT 100%.

-No individual container is less than 95% of labelled amount.

-If criteria is not met, test to another 20 containers.

ACCEPTANCE CRITERIA (Single Unit Containers)

-Average volume obtained from 10 containers is NLT 100%.

-Each individual container is within the range of 95-110% of the volume declared in the label.

-If criteria is not met, test to another 20 containers.

Sterility Test

STERILE PRODUCTS

Test which confirms that the products are free from the presence of microorganisms.

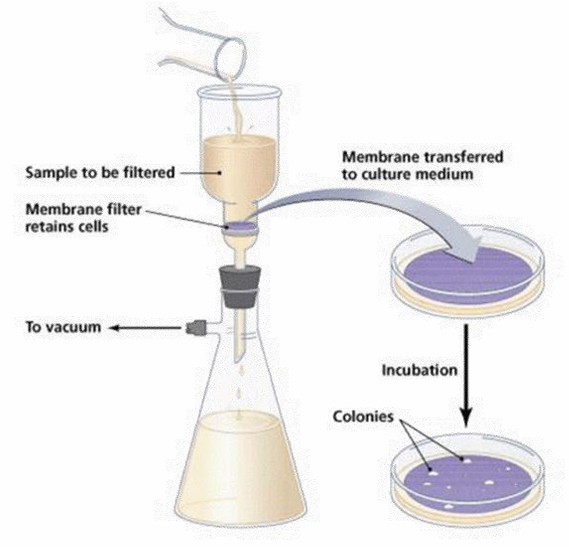

-Membrane Filtration

-Direct Inoculation

Enumerate the test performed in the sterility test:

Membrane Filtration

Direct Inoculation

ANAEROBIC BACTERIA

-Clostridium sporogenes

-Pseudomonas aeruginosa

-Staphylococcus aureus

STERILE PRODUCTS

Use of Fluid Thioglycolate Medium

14 days

STERILE PRODUCTS

Incubation period of Fluid Thioglycolate Medium and Soybean-Casein Digest Medium

30-35 degree Celsius

STERILE PRODUCTS

Temperature of Fluid Thioglycolate Medium

Fungi and Aerobic Bacteria

-Aspergillus brasiliensis

-Bacillus subtilis

-Candida albicans

STERILE PRODUCTS

Use of soybean-casein digest

20-25 degree Celsius

STERILE PRODUCTS

Temperature of Soybean-Casein Medium

Pyrogen Test

STERILE PRODUCTS

-Pyrogen- fever producing substances.

-Based on the response of human leukocytes which release inflammatory mediators in response to pyrogen contamination.

-Endotoxins = lipopolysaccharides found in the cell membrane of Gram-negative bacteria.

-In not more than 30 minutes before the injection of the test dose, determine the “control temperature” of each rabbit.

-The test solution is warmed to 37± 0.2°C prior to injection.

-Inject to the vein of the ear of each of 3 rabbits 10 ml of the test solution per kg body weight. Record the temperature at 30 minute intervals between 1 and 3 hours after the injection.

Pyrogen

Fever producing substances.

Endotoxins

Lipopolysaccharides found in the cell membrane of Gram-negative bacteria.

Rabbit Pyrogen Test

Test Animals: Healthy, Mature Rabbits

-Use only those rabbits whose control temperatures between them is ≤ 1°C

-Do not also use any rabbit having a temperature exceeding 39.8 ⁰C.

-Stage 1: 3 rabbits

-Stage 2: Additional 5 rabbits

Sample Size of Rabbit Pyrogen Test

Apparatus and Diluents

PYROGEN TEST

Depyrogenated at 250°C for NLT 30 minutes; treatment of diluents and solutions used for washing and rinsing

Temperature Recording

PYROGEN TEST

Use an accurate temperature-sensing device such as clinical thermometer or thermistor probes.

Stage 1

PYROGEN TEST

-Rise in temperature ≥ 0.5 degree Celsius any of the rabbits

If YES: Continue test using additional 5 rabbits

If NO: Passed the Pyrogen test

Stage 2

PYROGEN TEST

-The rise in temperature ≥ 0.5 degree Celsius in not more than 3 of the rabbits

-Sum of individual rise in temperature not exceed 3.3 degree Celsius

If YES: Passed

If NO: Failed

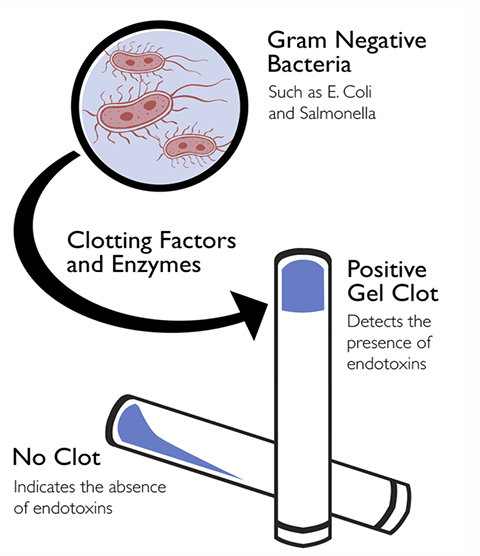

Limulus Amoebocyte Lysate (LAL) Test

Bacterial Endotoxin Test is also known as?

Bacterial Endotoxin Test

This test depends on the gelling property of the limulus amoebocyte lysate (LAL) obtained from the aqueous extract of circulating amoebocytes of Limulus polyphemus or Limulus Tachypleus tridentatus (horseshoe crab).

Advantages over Rabbit Pyrogen

BACTERIAL ENDOTOXIN TEST

-Greater sensitivity and simplicity

-Can quantify the amount of endotoxin in the sample

Gel Clot Technique

BACTERIAL ENDOTOXIN TEST

-This is to detect based on clotting of the LAL reagent in the presence of endotoxin

-To test the integrity of the gel, take each tube in turn directly from the incubator and invert it through about 180° in one smooth motion.

Positive: a firm gel forms upon inversion

Negative: no gel is formed

Turbidimetric Method

Chromogenic Method

Enumerate the methods of bacterial endotoxin test

Turbidimetric Method

BACTERIAL ENDOTOXIN TEST

It is based on the development of turbidity after cleavage of an endogenous substrate.

Chromogenic Method

BACTERIAL ENDOTOXIN TEST

It is based on the development of color after cleavage of a synthetic peptide-chromogen complex.

Leaker Test

This test usually is performed by producing a negative pressure within an incompletely sealed ampoule while the ampoule is submerged entirely in a deeply colored dye solution (0.5-1% Methylene Blue)

Blister Packs

The leaker test is also used in leak test for?

Test for particulate matter

Limits the presence of particulate matter

Mobile

Randomly-sourced

Extraneous substances

Other than gas bubbles.

The particulate matter is consists of?

Electronic Particle Counters/ Light Obscuration Test

Microscopic Particle Count Test

Enumerate the two methods that are used in the test for particulate matter:

-Extrinsic

-Intrinsic

-Inherent

Enumerate the types of particulate matter

External to the process

TYPES OF PARTICULATE MATTER

Origin of Extrinsic

Extrinsic

TYPES OF PARTICULATE MATTER

Material that is not part of the formulation, package or assembly process

-Glass and Stopper fragments

-Metals

-Silicone Oil

-Filter and Process particles

-Fibers form clothing and hair

-Skin Flakes and Dirt particles

TYPES OF PARTICULATE MATTER

Examples of Extrinsic

Part of the process or products

TYPES OF PARTICULATE MATTER

Origin of Intrinsic

Intrinsic

TYPES OF PARTICULATE MATTER

Material from sources related to the formulation, package or assembly process

-Active ingredients

-Ingredient degradation

-Protein aggregation

-Ingredient anomalies

-Immiscible droplets

-Any other process related to particle

TYPES OF PARTICULATE MATTER

Examples for Intrinsic

Part of the formulation

TYPES OF PARTICULATE MATTER

Origin of Inherent

Inherent

TYPES OF PARTICULATE MATTER

-Material expected from drug substance and formulation components

-Adjuvant material in suspension products

-Certain excipients

-Mannitol crystallization

-Proteinaceous aggregates

TYPES OF PARTICULATE MATTER

-Examples for Inherent

Electronic Particle Counters/Light Obscuration Test

TEST FOR PARTICULATE MATTER

It uses an electronic instrument designed to count and measure the size of particles by means of a shadow cast by the particle as it passes through a high intensity light beam.

Advantages and Disadvantages for Electronic Particle Counters/Light Obscuration Test

• Constant in process measurement

• Quickly identify size and number of particles

• Cannot identify source of particle

• Requires routine preventive maintenance and calibration

• Air bubbles cannot be differentiated

Microscopic Particle Count Test

TEST FOR PARTICULATE MATTER

-Enumerates subvisible, essentially solid particulate matter after collection on microporous membrane filter.

Stereomicroscope

TEST FOR PARTICULATE MATTER

-Apparatus that is used in the Microscopic Particle Count Test

-Composed of filter assembly for retaining particulate matter

Advantages and Disadvantages for Microscopic Particle Count Test

• Allows collection of particles larger than rated pore size.

• Microscope identification of particle types and materials.

• Slow counting and sizing on the membrane surface.

• Requires top and bottom lighting to distinguish particles.