3.) Principles of Design

1/21

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

22 Terms

Overview

• Explains the impact of design on efficiency & safety.

• Describes the basic principles of design for all food facilities

• Focuses on human engineering in design.

Impact of Design

◆ On Safety

◼ Design can support safe & sanitary food handling, thereby reducing the risk of food born illness.

◼ Design can prevent employee injuries by providing a safe work environment.

-

◆ On Efficiency

◼ Labor costs are between 25% & 40% of operating expenses.

◼ Design can reduce labor requirements, reducing expenses & providing competitive advantage.

◼ Design can reduce food costs, strengthening the bottom line.

◆ On Safety

◼ Design can support safe & sanitary food handling, thereby reducing the risk of food born illness.

◼ Design can prevent employee injuries by providing a safe work environment.

◆ On Efficiency

◼ Design can support safe & sanitary food handling, thereby reducing the risk of food born illness.

◼ Design can prevent employee injuries by providing a safe work environment.

Design Principles

• Principles that lead to efficiency & a pleasant environment for the worker & customer.

• Designers weigh these principles when locating functional areas within the building, laying out equipment, & designing custom fabricated items.

• A common misconception about design is that there is only one “right” way to lay out the equipment & arrange the space.

Design Principles

•Efficient & effective designs should:

1. Consider hazard analysis & critical control point.

2. Be flexible & modular.

3. Enhance the customer’s experience.

4. Show simplicity.

5. Create an efficient flow of materials & personnel.

6. Facilitate ease of sanitation & promote food safety.

7. Create ease of supervision.

8. Use space efficiently.

Hazard Analysis & Critical Control Point

• The U.S. Food & Drug Administration has adopted hazard analysis & critical control point as the basic standard by which food service facilities are evaluated.

• HACCP is the process by which food temperatures are monitored & corrected in a foodservice facility.

• This process includes the entire system from receiving through waste removal.

There are seven basic principles of HACCP:

• Analyze hazards.

• Identify critical control points.

• Establish preventive measures with critical limits for each control point.

• Establish procedures to monitor the critical control points.

• Establish corrective actions to be taken when monitoring shows that a critical limit has not been met.

• Establish procedures to verify that the system is working.

• Establish effective record keeping.

Design Principles: Flexibility & Modularity

•Flexibility to accommodate:

•New menu items.

•New methods of preparation.

•New equipment items.

•New methods of service.

-

• Achieved through Modularity:

•Standard sizes of equipment.

•Standard utility connections.

•Ease of removal & replacement.

•Flexibility to accommodate:

•New menu items.

•New methods of preparation.

•New equipment items.

•New methods of service.

• Achieved through Modularity:

•Standard sizes of equipment.

•Standard utility connections.

•Ease of removal & replacement.

Design Principles: Simplicity

◆ Food facilities invite clutter, clutter leads to poor sanitation, confusion, & inefficiency in the work areas.

◆ Examples of simplicity:

◼ Clean, uncluttered lines.

◼ Avoiding unnecessary accessories.

◼ Simplifying & reducing the number of menu items in order to simplify the kitchen & allow for greater consistency & quality of food items being prepared

◼ Convenient server stations

Design Principles: Flow of Materials & Personnel

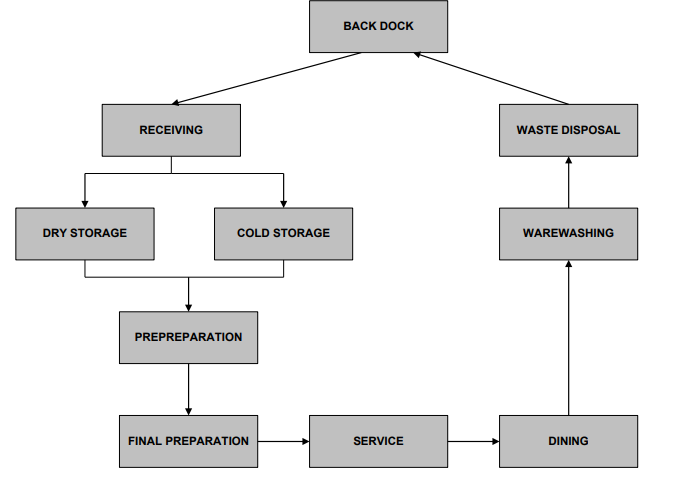

• Should follow a logical sequence beginning with receiving & ending with waste disposal.

• Some flow considerations in design are:

• Movement of employees from one functional area of the kitchen to another.

• Flow of raw food from the dock, to storage, to preparation, & to service.

• Flow of dishes through the dishwashing system & back to the service area.

• Flow of customers from the entry of the facility to the dining area.

• Some flow considerations in design are:

• Movement of employees from one functional area of the kitchen to another.

• Flow of raw food from the dock, to storage, to preparation, & to service.

• Flow of dishes through the dishwashing system & back to the service area.

• Flow of customers from the entry of the facility to the dining area.

Design Principles: Flow of Materials & Personnel

Design Principles: Ease of Sanitation

• A facility designed with sanitation in mind can be cleaned more quickly & easily & thus requires fewer labor hours.

• Some examples of sanitation design considerations:

• Building finishes (walls, floors, ceilings) that are easily cleaned & sanitized.

• Providing & arranging work area so that cross contamination between raw & cooked products is unlikely.

• Using wall-hung equipment & locating utility services in the walls, so that floors are free of clutter.

• Garbage disposals in preparation areas to simplify waste disposal.

• Some examples of sanitation design considerations:

• Building finishes (walls, floors, ceilings) that are easily cleaned & sanitized.

• Providing & arranging work area so that cross contamination between raw & cooked products is unlikely.

• Using wall-hung equipment & locating utility services in the walls, so that floors are free of clutter.

• Garbage disposals in preparation areas to simplify waste disposal.

Design Principles: Ease of Supervision

• Design examples:

• Locating the Production Office with lines of sight to the preparation areas (rather than the back door).

• Minimizing the number of walls & partitions between functional areas.

• Where interior walls are necessary, as between two banks of equipment, use half-height rather than full height walls.

• Avoid separating by floor (e.g. service areas on one floor, & preparation below).

Design Principles: Space Efficiency

• Providing these components will help ensure that each section of the kitchen has the necessary equipment & storage space to enable employees to work efficiently:

• A work surface

• A food prep sink

• A hand wash sink

• A cutting surface

• Storage for utensils

• Storage for pans

• Storage for raw ingredients

• Storage for the finished product

• Proper aisle space for movement

Design Principles: Lifetime Value

•The cost of a design solution or an item of equipment is not the purchase price, but the overall cost of ownership, including:

• Operational costs.

• Maintenance Costs.

• Labor costs to operate.

• Lifetime (how long it will last).

Design Principles: Compromise

• In the process of design, conflict is inevitable & compromise is necessary.

• Budget & space constraints are frequent causes of conflict.

• If the client insists on making choices that depart from principles of good design, the designer has three choices:

• Formally express the concern & give in to the client’s demand.

• Formally express the concern, then seek a design solution that will satisfy the client & will preserve the principles of good design.

• As a last resort, resign & bill the client for the work completed as of the day of the disagreement.

Design Principles

•Efficient & effective designs should:

1. Consider hazard analysis & critical control point.

2. Be flexible & modular.

3.Enhance the customer’s experience.

4. Show simplicity.

5. Create an efficient flow of materials & personnel.

6. Facilitate ease of sanitation & promote food safety.

7. Create ease of supervision.

8. Use space efficiently.