Comprehensive Nanomaterials & Nanotechnology

1/136

Earn XP

Description and Tags

A comprehensive set of flashcards covering vocabulary and key concepts in nanomaterials and nanotechnology.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

137 Terms

Superparamagnetism

A magnetic state in single-domain ferromagnetic or ferrimagnetic nanoparticles where thermal energy is sufficient to randomly flip the particle’s magnetization direction.

kbT >= KV

kb = Boltzmann constant (J * K^-1)

T = temperature (K)

K = magnetic ansiotopy constant (J * m^-3)

V = particle volume (m³)

Typical materials

Fe₃O₄ (magnetite)

γ-Fe₂O₃ (maghemite)

Co, Ni nanoparticles

Blocking Temperature (T_B)

The temperature below which a nanoparticle’s magnetization appears “frozen” over the measurement timescale.

Tb = (KV) / (kb ln (τm/τ0)

where:

Tb = Blocking temperature (k)

K = Magnetic Ansiotropy constant (j*m³)

V = Particle volume (m³)

kb = Boltzmann constant

τm = Measurement time

τ0 = Attempt time (~10^-9 seconds)

Blocking temperature is NOT a fixed material constant.

It depends on particle size AND measurement time.

Critical Single-Domain Size

The maximum particle size at which a ferromagnetic particle remains a single magnetic domain.

Domain wall energy vs. magnetostatic energy

Below this size, forming a domain wall costs too much energy

Critical Diameter (D_c)

It determines the size at which a ferromagnetic material becomes a single magnetic domain. Given by scaling arguments involving exchange stiffness (A), anisotropy (K), and saturation magnetization (Mₛ)

Ferromagnetism to Superparamagnetism Transition

A transition characterized by a size-dependent change from multi-domain ferromagnetism to superparamagnetism.

multidomain → single-domain ferromagnet → superparamagnet

Energy Barrier (E_barrier)

The energy required to reverse the magnetization direction of a nanoparticle.

Ebarrier = KV

E = Energy barrier for magnetization reversal (J)

K = Magnetic Ansiotropy constant (J*m^-3)

V = particle volume (m³)

Larger particles → higher energy barrier

Smaller particles → easier thermal flipping

Curie Temperature (T_C)

The critical temperature above which a ferromagnetic material becomes paramagnetic.

Dendrimers

Highly branched, monodisperse macromolecules with a tree-like structure that encapsulate molecules.

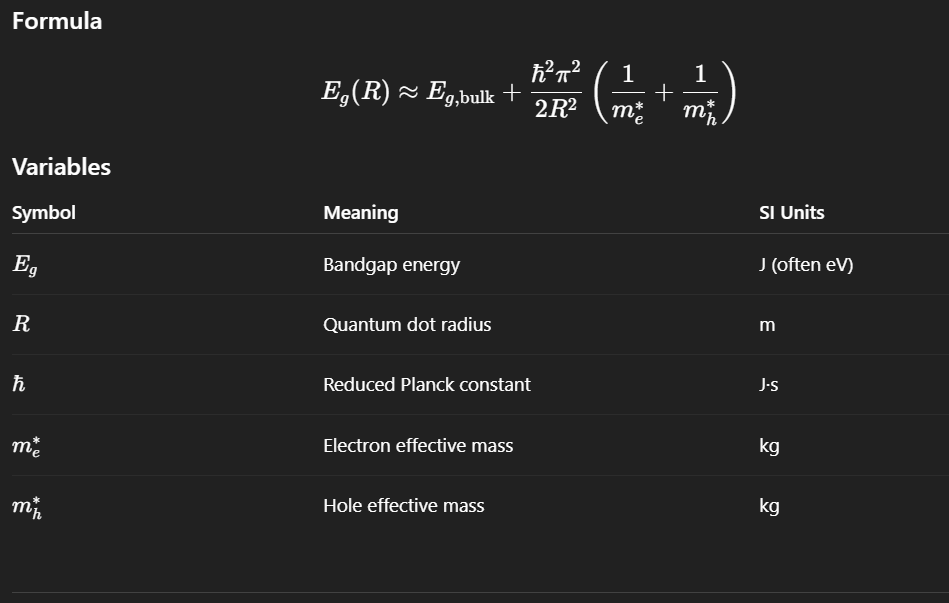

Quantum Confinement

The phenomenon where the electronic and optical properties of materials change as their size approaches the exciton Bohr radius

Confinement occurs when particle size ≲ exciton Bohr radius.

Size-dependent bandgap

Blue shift in optical absorption

Discrete density of states

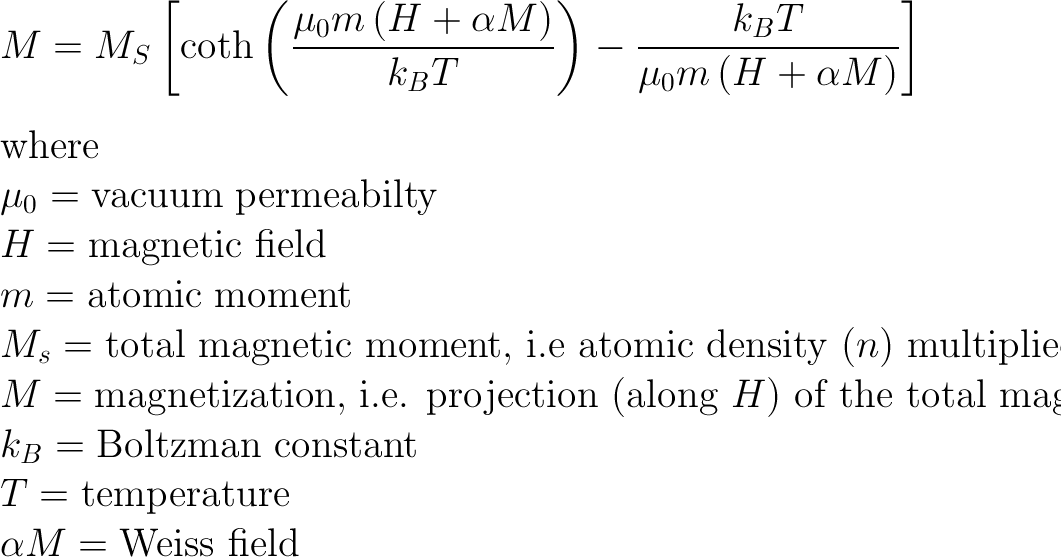

Langevin Magnetization

Shows that magnetization isn't perfectly linear with the field

At low fields/high temps, it follows Curie's Law (proportional to H/T)

At high fields/low temps, the dipoles fully align (saturate), and the function "bends over," balancing alignment forces (field) with randomizing forces (temperature)

Self-Assembly

A process by which components spontaneously organize into ordered structures through non-covalent interactions.

Types

Molecular Self-Assembly – e.g., lipids → bilayers, micelles.

Colloidal Self-Assembly – nanoparticles → crystals or clusters.

Supramolecular Self-Assembly – proteins, DNA structures.

Template-Assisted Self-Assembly – guided by pre-patterned surfaces.

Hydrodynamic Diameter (d_h)

The effective diameter of a particle in a fluid, including the particle itself plus the layer of solvent molecules that move with it. It represents how a particle “appears” when diffusing or moving through a liquid.

Measured through Dynamic Light Scattering (DLS). Use Stokes-Einstein Equation

Scanning Electron Microscopy (SEM)

Provides topography, composition, and sometimes crystallography of a sample.

Samples usually need to be conductive or coated with a thin conductive layer.

Used for:

Metals (Au, Cu, Al) – surface microstructure

Polymers – morphology of fibers or films

Nanoparticles – size and aggregation

Electron Beam:

A focused beam of high-energy electrons scans across the sample surface.

Interactions:

Electrons interact with the atoms in the sample and generate signals:

Secondary electrons → give surface topography (main imaging mode).

Backscattered electrons → reveal composition contrast (heavier atoms appear brighter).

X-rays → give elemental composition (via EDS/EDX detector).

Detection & Imaging:

Detectors collect these signals to form a high-resolution image of the surface.

Resolution can reach ~1–10 nm, depending on instrument and sample.

Transmission Electron Microscopy (TEM)

TEM is a technique that images the internal structure of thin samples at atomic or nanometer resolution using electrons transmitted through the material.

Sample must be ultra-thin for electrons to transmit.

Materials

Metals (dislocations, edge boundaries)

Nanoparticles (shape, size, and crystal structure)

Electron Beam:

A high-energy electron beam passes through a very thin sample (<100 nm thick).

Interactions:

Electrons are scattered by atoms in the sample.

The pattern of transmitted and scattered electrons forms an image.

Can also produce electron diffraction patterns to study crystal structure.

Detection & Imaging:

Fluorescent screen, CCD camera, or detectors collect transmitted electrons.

Images reveal internal structure, not just surface like SEM.

Resolution can reach ~0.1–0.2 nm, allowing observation of individual atoms.

Dynamic Light Scattering (DLS)

DLS is a technique to measure the size (hydrodynamic diameter) and distribution of small particles or molecules in a liquid by analyzing their Brownian motion.

Non-destructive and commonly used for nanoparticles, proteins, and polymers.

How It Works:

Laser Illumination:

A laser beam passes through a colloidal solution of particles.

Scattering:

Particles scatter light in all directions.

Because particles are moving due to Brownian motion, the intensity of scattered light fluctuates over time.

Analysis:

Fluctuations are analyzed with an autocorrelation function to determine the diffusion coefficient DDD of the particles.

Using the Stokes–Einstein equation, the hydrodynamic diameter is calculated:

Scanning Tunneling Microscopy (STM)

Images surfaces at the atomic scale by measuring the quantum tunneling current between a sharp tip and the conductive sample.

Provides atomic-resolution surface topography and can also probe electronic properties.

How It Works / Measurement Principle:

Sharp Tip & Conductive Sample:

A very sharp metallic tip is brought extremely close (~0.5–1 nm) to the sample surface.

Quantum Tunneling:

When a voltage is applied, electrons tunnel through the vacuum between tip and sample.

The tunneling current III depends exponentially on the distance ddd:

I∝Ve-2κd

Where:

V = applied voltage

d = tip–sample distance

κ = decay constant depending on work function

Imaging:

The tip scans across the surface in a raster pattern.

A feedback loop keeps the tunneling current constant by adjusting the tip height.

The tip movement is mapped to create a high-resolution surface image at atomic scale.

X-ray Photoelectron Spectroscopy (XPS)

XPS is a technique to analyze the elemental composition and chemical states of a material’s surface (~1–10 nm) by measuring kinetic energy of electrons ejected by X-rays.

Surface-sensitive and widely used for metals, semiconductors, polymers, and coatings.

How It Works / Measurement Principle:

X-ray Irradiation:

The sample surface is irradiated with monoenergetic X-rays (commonly Al Kα: 1486.6 eV).

Photoelectron Emission (Photoelectric Effect):

X-ray photons eject core electrons from atoms.

The kinetic energy (KE) of the emitted electron is measured.

Binding Energy Calculation:

The binding energy (BE) of electrons is calculated using:

BE = hv - KE - ϕ

Where:

BE= binding energy (electronvolts, eV)

hν= photon energy (eV)

KE = kinetic energy of emitted electron (eV)

ϕ = work function of spectrometer (eV)

Interpretation:

Each element has characteristic binding energies → identify elements.

Small shifts in BE indicate chemical states / oxidation states.

X-ray Diffraction (XRD)

XRD is a technique to analyze the crystal structure, phase, and lattice spacing of materials by measuring the pattern of X-rays diffracted from the atomic planes.

Widely used for metals, ceramics, semiconductors, and nanomaterials.

How It Works / Measurement Principle:

X-ray Irradiation:

A beam of X-rays (typically Cu Kα, λ ≈ 1.54 Å) is directed at the crystalline sample.

Diffraction:

X-rays are scattered by the electron clouds of atoms in the crystal.

Constructive interference occurs when Bragg’s law is satisfied: 2λ = 2dsinθ

Detection & Analysis:

A detector measures the intensity of diffracted X-rays as a function of

The pattern of peaks is used to determine:

Crystal structure (cubic, tetragonal, etc.)

Crystallite size (via Scherrer equation)

Hall-Petch Relationship

Describes how a material’s strength (yield stress) increases as its crystal grain size decreases. Breaks down at very small grain sizes (inverse Hall–Petch)

σy=σ0+kd^(-1/2)

σy = (Yield Strength): The stress at which the material begins to deform permanently

σ0 = The baseline stress needed to move dislocations, independent of grain size, reflecting lattice resistance.

d = grain diameter

k = hall petch constant

Zirconium Oxide (ZrO₂)

A wide bandgap semiconductor known for its thermal stability and applications in optical coatings.

Plasmonic Nanostructures

Structures that exploit localized surface plasmon resonance for applications in sensing and photothermal therapy.

Localized Surface Plasmon Resonance (LSPR)

Collective oscillation of conduction electrons in metal nanoparticles, enhancing light interaction.

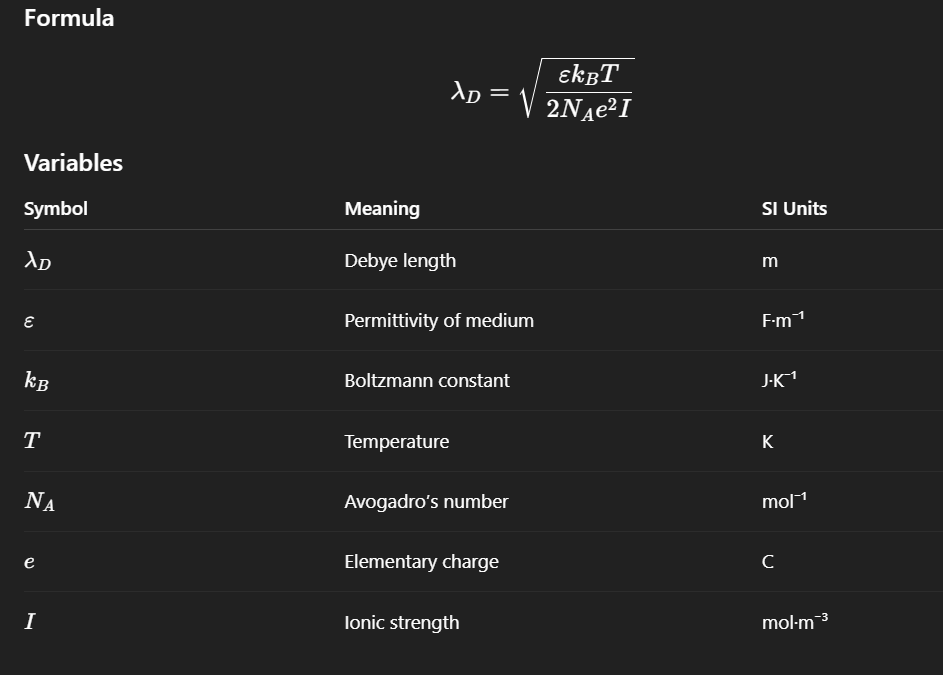

Debye Length (λ_D)

The characteristic length over which electric fields are screened by mobile charges in an electrolyte.

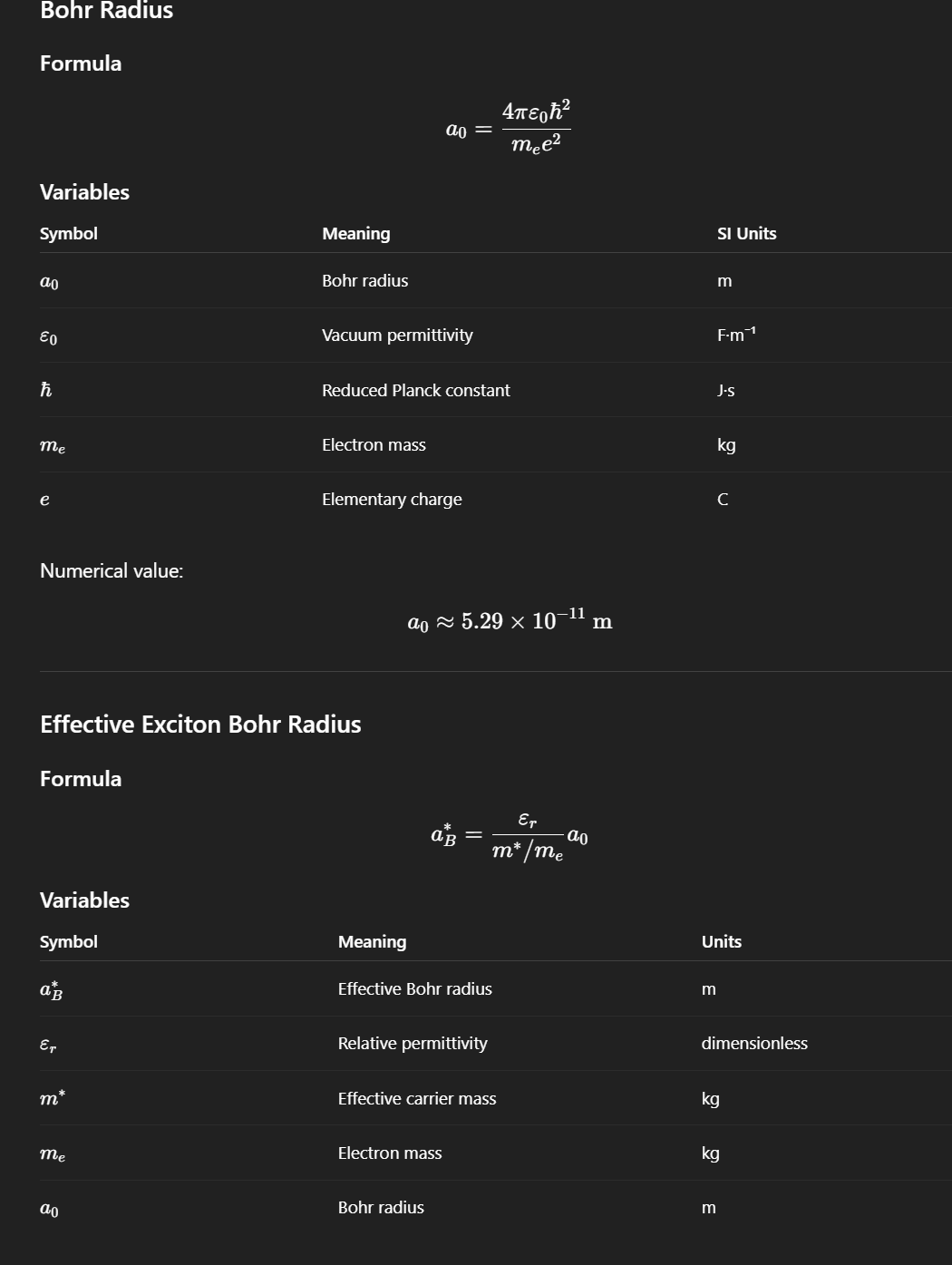

Bohr Radius (a₀)

The scale of the electron wavefunction in hydrogen, approximately 0.529 Å.

Nanoparticle

A three-dimensional confined structure with all dimensions on the nanoscale (< 100 nm).

Nanocrystal

A crystalline nanoparticle that has a well-defined crystal lattice and is characterized by techniques like XRD.

Quantum Dot (QD)

A 0D semiconductor nanocrystal with confinement in all three dimensions.

Materials

CdSe, CdS, PbS

InP (biocompatible alternative)

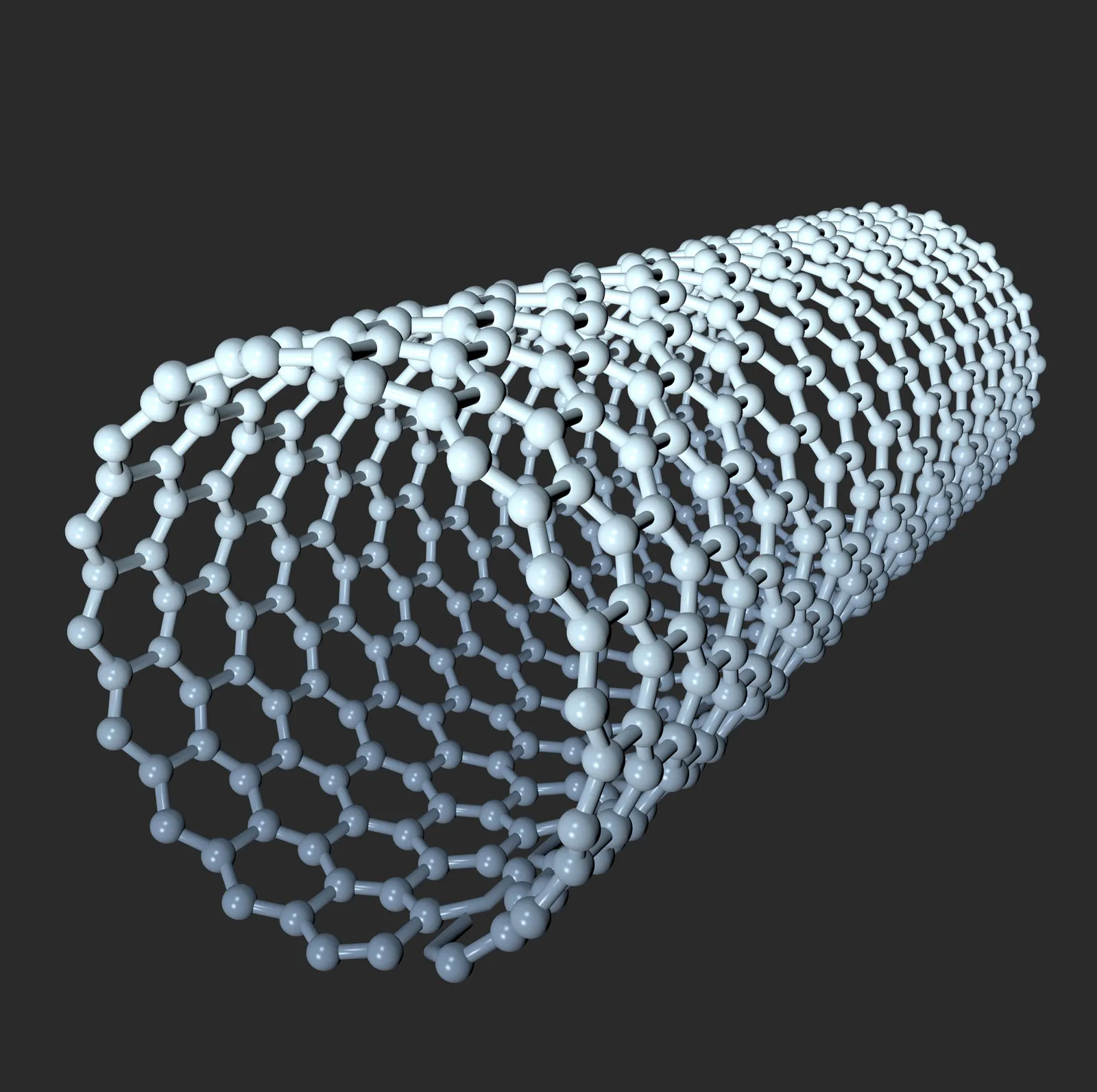

Nanotubes

Cylindrical structures of nanomaterials, particularly carbon-based, which exhibit unique electrical properties.

Nanotubes are usually made of rolled-up sheets of atoms:

Carbon Nanotubes (CNTs):

Formed from graphene sheets rolled into cylinders.

Can be Single-Walled (SWCNT) or Multi-Walled (MWCNT).

Properties arise from structure:

Electrical: Metallic or semiconducting depending on chirality (rolling angle).

Mechanical: Extremely strong and stiff due to sp² carbon bonds.

Thermal: Excellent thermal conductivity along the tube axis.

Atomic Layer Deposition (ALD)

Sequential Exposure:

The substrate is alternately exposed to two or more precursor gases.

Each precursor reacts chemically with the surface in a self-limiting reaction, depositing one monolayer per cycle.

Self-Limiting Reactions:

Only available reactive sites on the surface participate → prevents overgrowth.

Cycle Repetition:

Repeating cycles increases film thickness linearly:

3. Relevant Materials / Examples:

Oxides: Al₂O₃, TiO₂, HfO₂

Nitrides: TiN, AlN

Metals: Pt, Ru

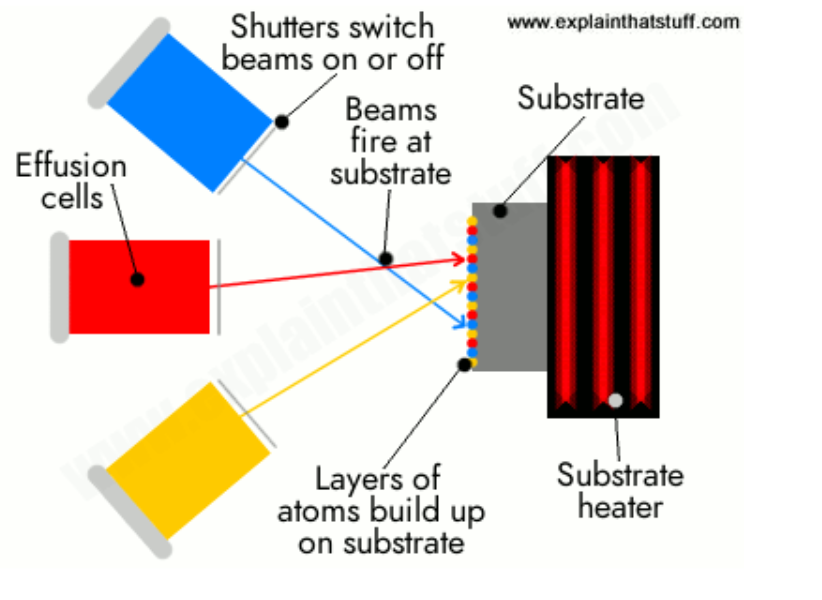

Molecular Beam Epitaxy (MBE)

A method for growing thin crystals by using molecular beams of high purity.

Ultra-High Vacuum Chamber:

Reduces contamination and allows long mean free path for atoms.

Molecular Beams:

Pure elemental sources (like Ga, Al, As) are heated to evaporate atoms.

Atoms travel as molecular beams toward the substrate.

Epitaxial Growth:

Atoms adsorb on the substrate surface, diffuse, and arrange themselves according to the crystal lattice of the substrate.

Layer-by-layer growth enables atomic-scale control of thickness and composition.

Monitoring:

Reflection High-Energy Electron Diffraction (RHEED) is often used in-situ to monitor surface structure and growth rate.

3. Key Materials / Examples:

Semiconductors: GaAs, AlGaAs, InP, SiGe

Heterostructures: Quantum wells, superlattices

Oxides and metals can also be grown with modified MBE systems

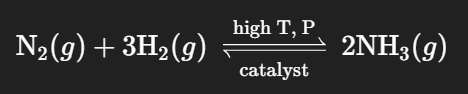

Haber-Bosch Process

An industrial method for synthesizing ammonia from nitrogen and hydrogen gases.

Epitaxial Growth

The deposition of a crystalline overlayer on a crystalline substrate maintaining the orientation of the substrate.

Key Materials / Examples:

Semiconductors: GaAs on GaAs, Si on Si

Heterostructures: GaAs/AlGaAs, InGaAs/GaAs

Oxides: SrTiO₃ on perovskite substrates

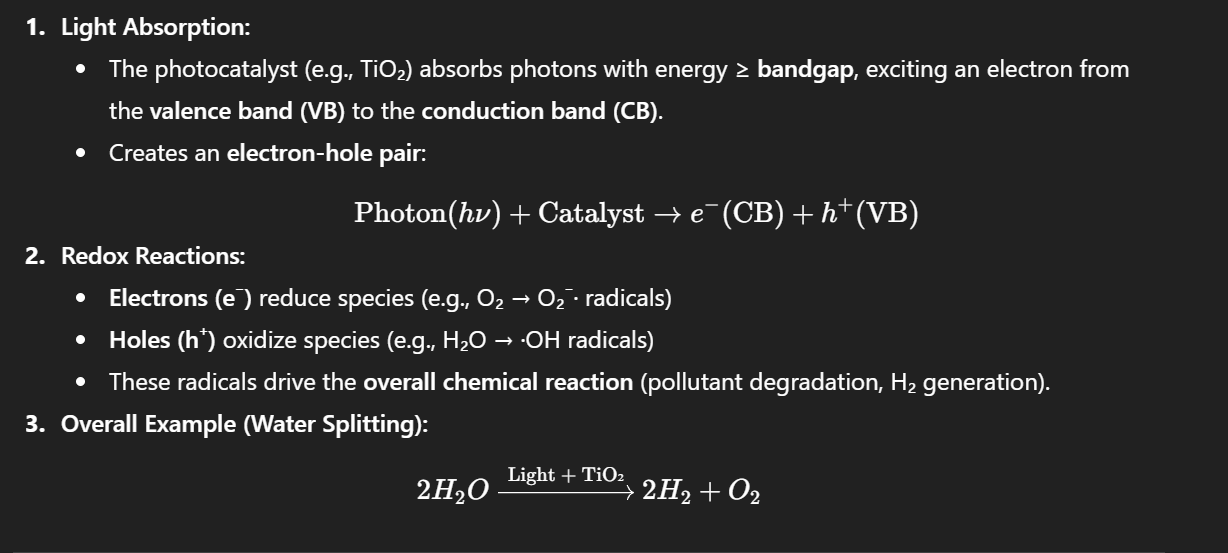

Photocatalysis

A process that uses light to accelerate a photoreaction in the presence of a catalyst.

Relevant Materials / Examples:

Semiconductors: TiO₂ (most common), ZnO, CdS

Doped materials: N-doped TiO₂ (visible light activity)

Nanomaterial

Any material with at least one dimension on the nanoscale, typically defined as ranging from 1 to 100 nm.

Polymer Nanocomposite

Polymer nanocomposites are polymers reinforced with nanoscale fillers to enhance mechanical, thermal, electrical, or barrier properties beyond conventional composites.

Relevant Materials / Examples:

Carbon-based: Carbon nanotubes (CNTs), graphene, carbon black

Clay-based: Montmorillonite (MMT) nanosheets

Metal oxides: TiO₂, SiO₂, ZnO nanoparticles

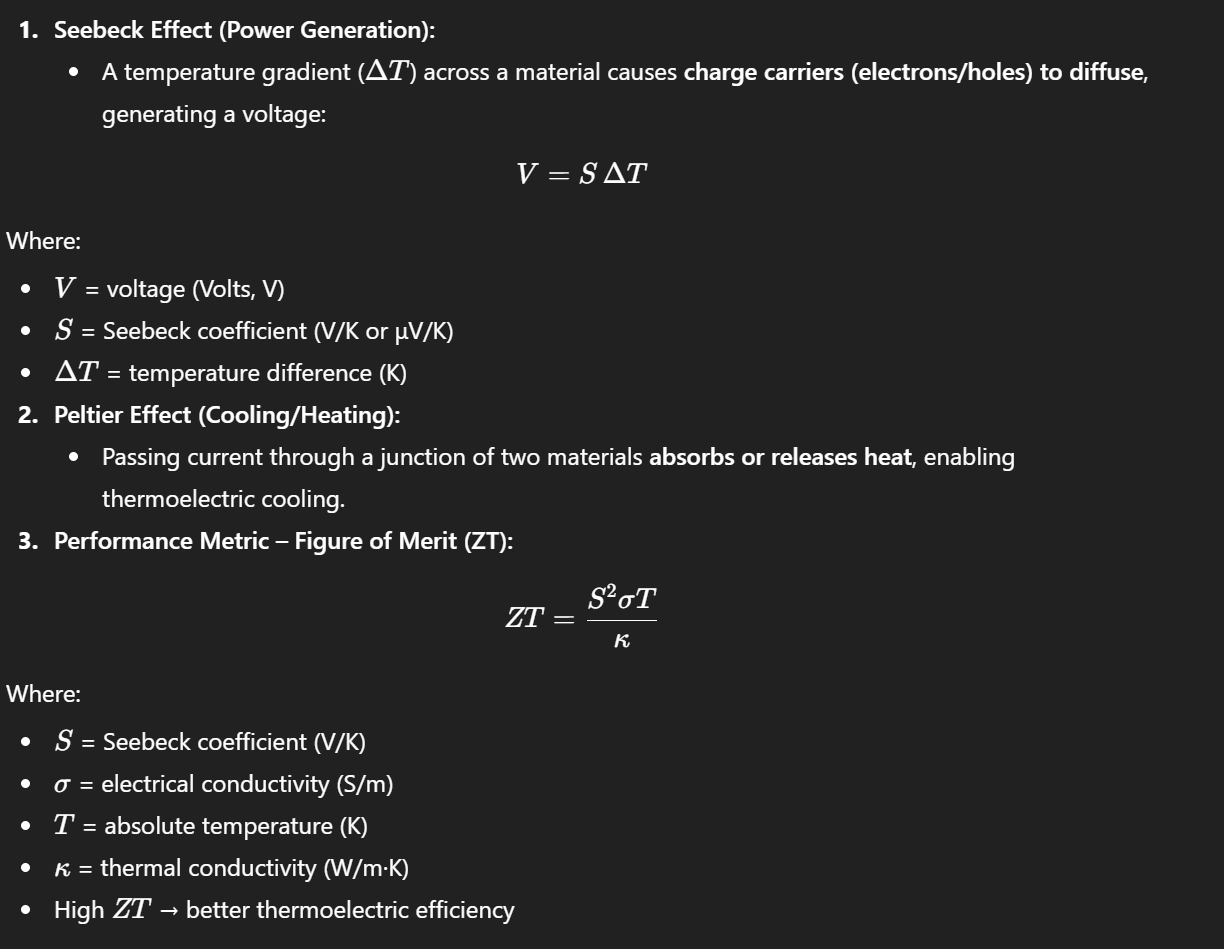

Thermoelectric Materials

Thermoelectric materials convert temperature differences directly into electrical voltage (Seebeck effect) or vice versa (Peltier effect).

Efficiency depends on the material’s electrical conductivity, thermal conductivity, and Seebeck coefficient.

Key Materials / Examples:

Bismuth telluride (Bi₂Te₃) – room-temperature applications

Lead telluride (PbTe) – high-temperature power generation

Silicon-germanium (SiGe) – space thermoelectrics

Skutterudites, Half-Heusler alloys – advanced thermoelectric materials

Acoustic Imaging

A form of imaging; can use nanoscale contrast agents, but spatial resolution is typically microscale

Sound Wave Generation:

A transducer emits high-frequency sound waves (typically 1–15 MHz for medical imaging).

Wave Propagation & Reflection:

Sound waves travel through the medium and are partially reflected at interfaces where acoustic impedance changes:

Z=ρc

Where:

Z = acoustic impedance (kg/m²·s)

ρ = density of the medium (kg/m³)

c = speed of sound in medium (m/s)

Resolution:

Axial resolution: Δz = c/(2f)

Where:

f = frequency of ultrasound (Hz)

c = speed of sound in medium (m/s)

Carbon Nanotubes (CNTs)

Mechanical Properties

Extremely high tensile strength: ~50–200 GPa (stronger than steel by weight)

High Young’s modulus: ~1 TPa (stiff, very resistant to stretching)

Lightweight: density ~1.3–1.4 g/cm³ (much lighter than metals)

Flexibility: can bend without breaking and recover shape

Electrical Properties

Metallic or semiconducting depending on chirality (n,m)(n, m)(n,m)

High electrical conductivity: up to 10⁶–10⁷ S/m for metallic CNTs

Thermal Properties

High thermal conductivity: up to 3000–3500 W/m·K along the tube axis (better than copper)

Good thermal stability: can withstand >600 °C in air, ~2800 °C in vacuum

Chemical Properties

Chemically stable due to sp² carbon bonding

Can be functionalized to attach chemical groups → improves solubility or adds new functionality

Optical Properties

CNTs can absorb light in UV–NIR range

Exhibit photoluminescence in semiconducting CNTs → useful for bioimaging and sensors

Metal Oxide Nanoparticles

Nanoparticles formed from metal oxides, which exhibit unique electrical properties and stability.

Relevant Materials / Examples:

TiO₂: photocatalysis, sunscreens, self-cleaning surfaces

ZnO: UV-blocking, antibacterial, electronics

Fe₃O₄ / Fe₂O₃: magnetic nanoparticles for MRI, drug delivery

CeO₂: redox catalyst, antioxidant in biomedical applications

CuO, Co₃O₄, NiO: catalysis, sensors, energy storage

Nanowires

Structure:

Diameter: 1–100 nm

Length: up to several microns → very high aspect ratio (length/diameter)

Quantum Effects:

Electron motion is confined in the transverse direction → quantum confinement

Leads to size-dependent optical and electronic properties

Conductivity and Carrier Transport:

High surface-to-volume ratio → surface scattering affects electron mobility

Can exhibit ballistic transport over short distances

Relevant Materials / Examples:

Semiconductors: Si, GaAs, InP

Metals: Au, Ag, Cu

Oxides: ZnO, TiO₂

Nanofilms

Thin films of nanostructured materials, often used for coatings.

Electron motion is restricted perpendicular to the film → quantum confinement

High surface area → surface interactions dominate properties

Relevant Materials / Examples:

Metals: Au, Ag, Pt → plasmonics, electrodes

Semiconductors: Si, GaAs → electronic devices

Oxides: TiO₂, ZnO → photocatalysis, sensors

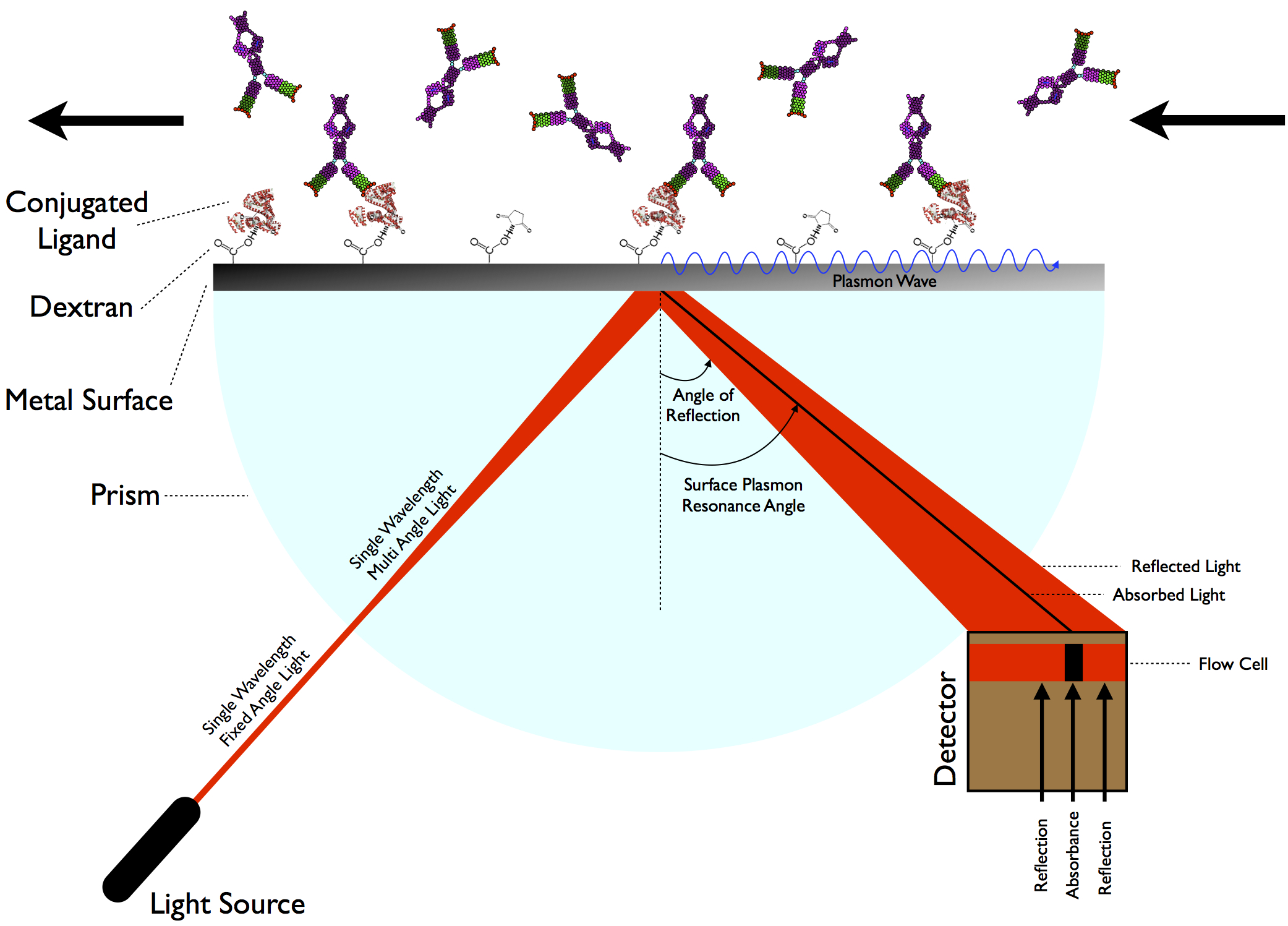

Plasmonic Sensors

Plasmonic sensors use surface plasmon resonance on metallic nanostructures to detect tiny changes in refractive index near the surface.

Quantum Wells

A quantum well is a thin layer of a low-bandgap semiconductor sandwiched between higher-bandgap semiconductors, creating confinement of charge carriers (electrons and holes) in one dimension.

Semiconductors: GaAs/AlGaAs, InGaAs/InP

Quantum Wires

Nanostructures confined in two dimensions, allowing charge carriers to move freely in one dimension.

Quantum Dots

Quantum dots are zero-dimensional semiconductor nanostructures where electrons and holes are confined in all three spatial dimensions, leading to discrete, atom-like energy levels.

When nanoparticles get to a certain size, shit starts to hit the fan and nothing works the same

This usually occurs at ~2-10nm or 10-15 atoms. Some are the size of molecules.

Quantum mechanical effects (confinement) messes everything up

Small QDs are blue and larger ones are red

When illuminated by a certain wavelength, QDs electrons can be excited

Commonly used in displays

Used in solar cells to capture a broader spectrum of light

Called tunable photoluminescence

Used in biology as a dye

Thermal Conductivity

A measure of a material's ability to conduct heat.

k = (1/3) Cvl

C = heat capacity

v = phonon velocity

l = mean free path

Phonon Mean Free Path

Average distance a phonon travels before scattering.

l = vτ

l = Mean free path (m)

v = phonon velocity

τ = Relaxation time

Zirconium dioxide

A widely used ceramic material known for its hardness and thermal stability.

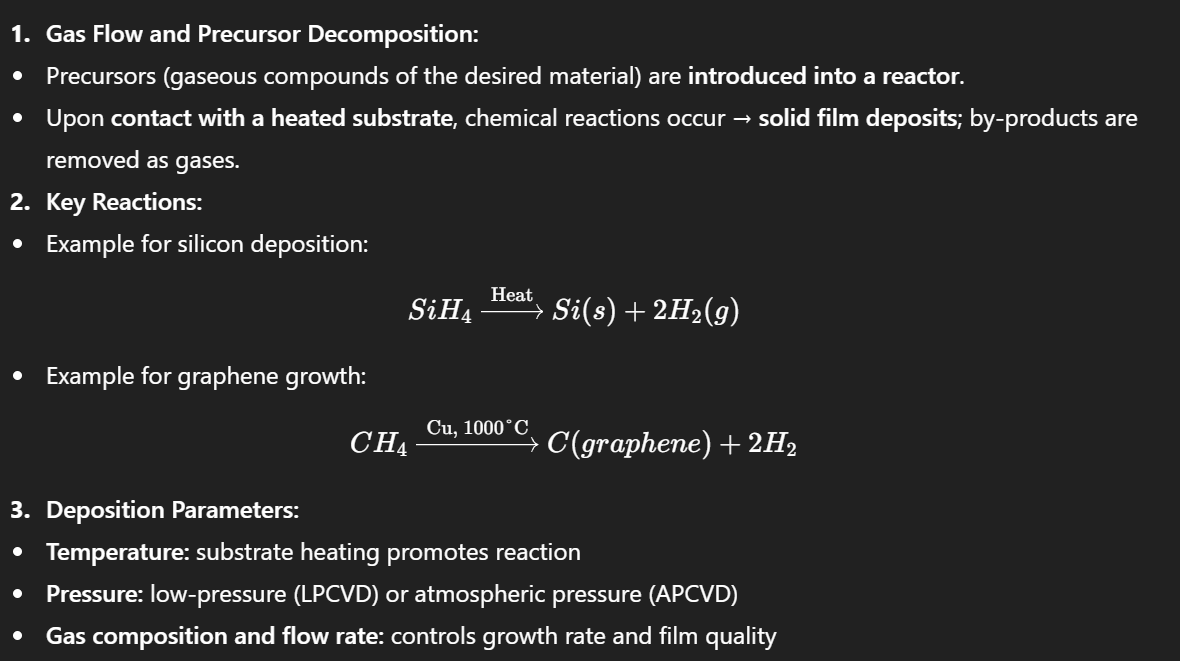

Chemical Vapor Deposition (CVD)

Chemical vapor deposition (CVD) - involves using gaseous precursors that react of decompose onto a substrate, creating the desire material.

Usually done by filling a heated chamber with chemical precursors that react and fall onto the substrate.

Often creates volatile by-products which are removed by a gas flow/purging process

Commonly used to make thin films

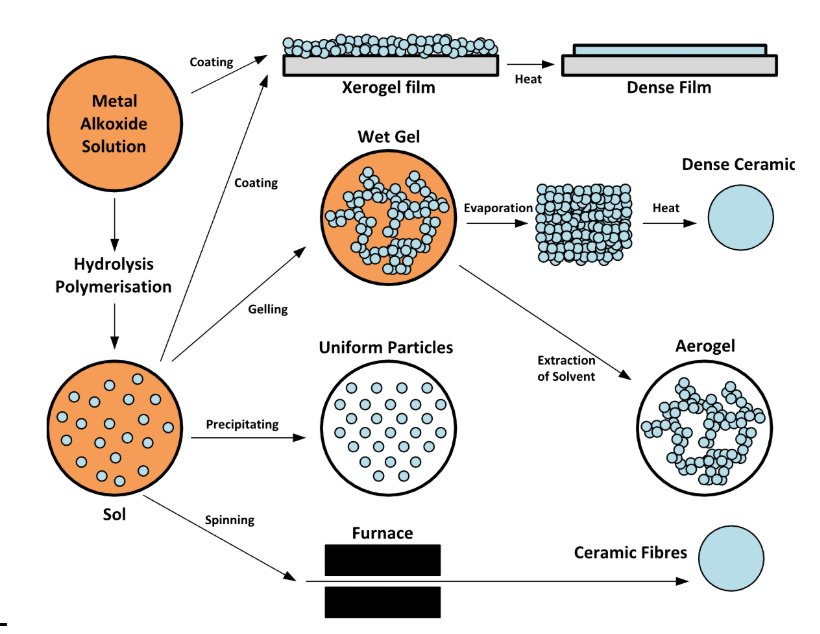

Sol-Gel Process

A method for producing solid materials from small molecules, usually involving the transition from a liquid solution to a solid gel.

Nanostructured Supercapacitors

Nanostructured supercapacitors are high-surface-area energy storage devices that store charge via double-layer formation or pseudocapacitive redox reactions, offering fast charge/discharge and high power density.

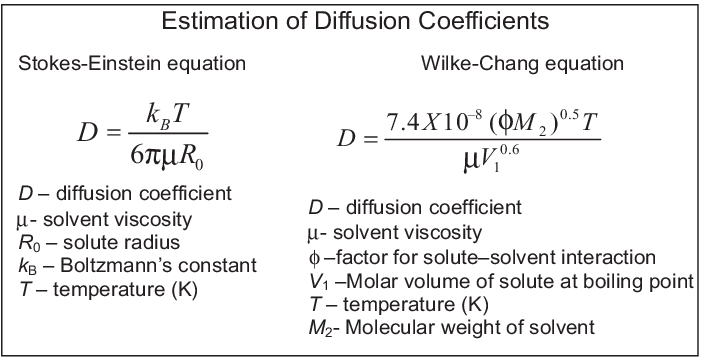

Stokes-Einstein and Wilke-Chang

Stokes-Einstein: Used for nanoparticles like Au

Wilke-Chang - Small molecules (solutes) like Ethanol

Van der Waals

Weak electric forces

Weak bonds

Strongest:

Repulsive force from Pauli Exclusion Principle

Keesome Force

Repulsive/attractive force between permanent charges

Debye Force (Induction, polarizability)

Permanent pole and an induced pole

London Dispersion Force

Temporary Instantaneous induced poles on each other.

Semiconductors

N-type

Electrons are the charge carriers

P-type

Holes are the charge carriers

Metallic Ionic

Metal donates electron density to a more electronegative element.

Some electrons remain in partially filled bands → metallic conductivity.

Covalent Ionic

Electron density is shared but shifted toward the more electronegative atom.

Produces polar covalent bonds.

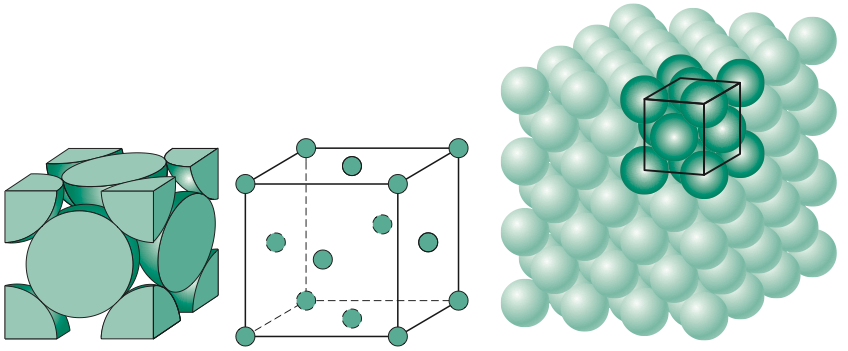

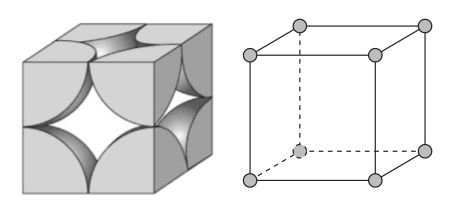

Face Centered Cubic / cubic packed

ABCABC close packing pattern

Atomic packing factor of .74

Unit cell has 4 atoms

Side length = 4Rsqrt2

Coordination number = 12

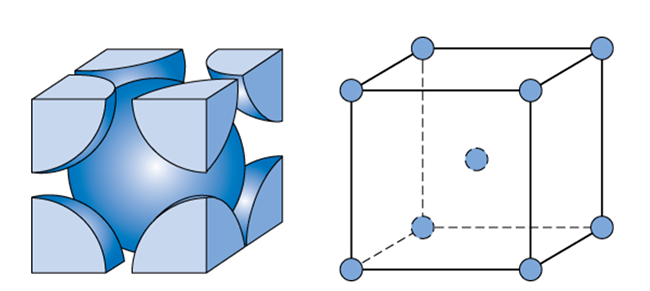

Body centered cubic

Atomic packing factor of .68

Unit cell contains 2 atoms

Side length = 4Rsqrt3

Coordination number of 8

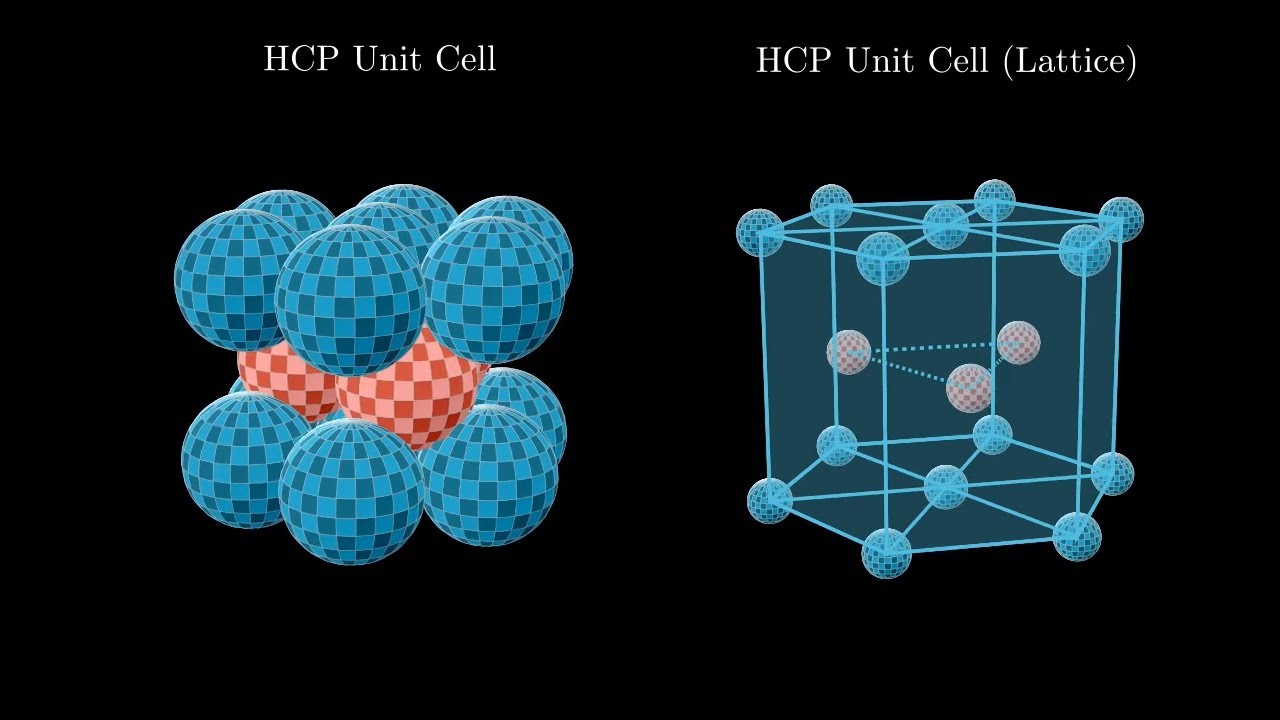

Hexagonal Close packing

ABAB packing pattern - 2 repeating layers

Atomic packing factor of .74

Unit cell has 6 atoms

Coordination number of 12

Simple Cubic

Atomic packing factor of .52

Unit cell has 1 atom

Side length = 2R

Coordination = 6

Atomic Packing factor

How efficiently atoms are packed within a unit cell

APF = (volume of atoms in a unit cell) / (total unit cell volume)

Coordination number

Number of nearest-neighbor atoms around a given atom

Point Defects

Localized disruptions in a crystal lattice involving only 1 or 2 atomic positions.

Linear Defects

One-dimensional (1-D) disruptions in the regular arrangement of atoms within a crystal.

Interfacial Defects

Two-dimensional (2-D) boundaries, such as grain boundaries or surfaces, that separate regions of different crystallographic orientations or structures.

Stoichiometric vs. Non-Stoichiometric Defects

Stoichiometric Defects: Do not change the overall ratio of cations to anions in the compound.

Non-Stoichiometric Defects: Result in a change in the ratio of cations to anions.

Vacancies

A point defect characterized by an atom missing from its normal lattice site.

Can be caused by thermal vibrations or non-stoichiometric conditions.

Interstitial Cations

Cations that occupy normally unoccupied interstitial sites in the lattice, causing local distortions.

Impurities

Foreign atoms within a crystal that either substitute for host atoms (substitutional) or occupy interstitial sites (interstitial).

Frenkel Defect

A point defect in ionic solids where a cation leaves its normal lattice position and occupies a nearby interstitial site.

Schottky Defect

A point defect in ionic solids where an equal number of cations and anions are missing from the lattice, maintaining charge neutrality.

Edge Dislocation

A linear defect caused by an extra half-plane of atoms inserted into the crystal structure.

Screw Dislocation

A linear defect where the lattice atoms are displaced in a spiral or helical pattern around the dislocation line.

Grain Boundaries

The interface where two grains of different crystallographic orientations meet within a polycrystalline ceramic or metal.

Twin Boundaries

A specific type of interfacial defect where there is a mirror symmetry in the arrangement of atoms across the boundary.

Porostiy

Void spaces within a material, percentage of total volume

Higher porosity, higher absorption

Porosity (%) = (Volume of Voids / Total Volume) x 100

Open porosity

Pores are interconnected and accessible to the surface

Higher absorption

Higher permeability

Closed pores

Isolated pores that are not connected to the surface

Lower absorption

Lower permeability

Unary phase change

Single compound vs temperature or pressure

Binary phase change

You have a material composed of elements A and B. Y axis is temperature or pressure, and X axis is the percent of element B in the compound

Engineering stress and strain

σ = F/A

ε = ΔL / L0

Used when area barely changes

True stress and strain

σ = F/A

ε = ln(L / L0)

Relationship between engineering and true stress/strain

Used during uniform deformation

σtrue = σeng(1+εeng)

εtrue = ln(1+εeng)

Ductility

(A0-Af)/A0 * 100%

Stress σ vs Strain graph ε

Elastic region

Follows Hooke’s Law σ = Eε

Young’s (Elastic) Modulus is slope: E= σ/ε

Yield Strength

Plastic deformation

Dislocations happen in bulk

Atomic planes slip past each other

Upper yield strength

Caused by a temporary build-up of resistance to plastic deformation from interstitial atoms (like carbon and nitrogen) that lock dislocations within the material

Afterwards they slide past each other

Lower Yield strength

Once the dislocations are free, the applied stress needed to keep them moving is significantly lower.

Plastic region

σ = Kεn

K is strength coefficient

n is strain-hardening component (0-1) for most metals)

Strain hardening

Continued plastic deformation creates many more dislocations.

These dislocations interact, tangle, and block each other.

Because motion is harder, the material needs more stress to continue deforming

Necking

Reaches ultimate tensile strength

Maximum engineering stress

Local region becomes thinner than the rest and experiences a higher stress

Considère criterion

(dσtrue)/(dεtrue) = σtrue

Flexural Strength

Strength under bending

3 point bending σf = (3FL)/(2bd^2)

4 point bending σf = (FL)/(bd^2)

F = load at fracture, L = support span, d = specimen length, d = specimen thickness

Compressive Strength

Maximum stress before failing in compression

σ = Fmax / A

Fracture Toughness (K_IC)

How well a material can handle cracks

KIC = Yσ sqrt(πa)

a is crack length

Y is geometry factor

Brittle Fracture

If a crack of length a already exists, how much tensile stress will break the material? Applies to brittle materials ONLY.

σc = sqrt((2Eγ)/πa)

Bragg’s Law

nλ = 2d sin θ

n: diffraction order (integer, dimensionless)

λ: wavelength of incident radiation (length, meters or Å)

d: distance between crystal planes (meters or Å)

θ: Bragg angle (degrees or radians)

Thermal Expansion

ΔL = a L0 ΔT

Higher a means more expansion per degree

Thermal Conductivity

q = -k(dT/dx)

Rate at which heat flows through material

q: heat flux (W/m^2)

k: thermal conductivity (W/(m*k))

dT/dx: temperature gradient

Larger k is a good conductor

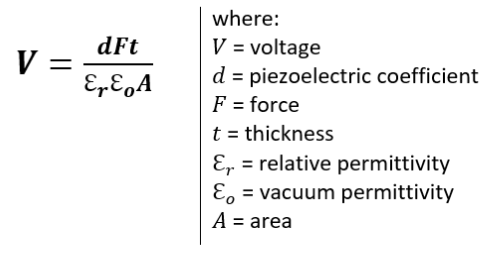

Piezoelectricity

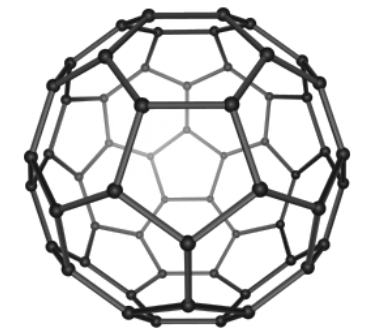

Fullernes

Resembles a hollow cage-like structure. Can take a spherical, ellipsoid, or tube-like shapes

Denoted by Cn where n indicates the number of carbon molecules

The most famous fullerene, buckminsterfullerene is denoted by C60 and can be found naturally. Image of buckminsterfullerene below.

Fullerenes with less than 60 carbon atoms are called ‘lower fullerenes’ and those with greater than 70 are called ‘upper fullerenes’

Applications include MRI & X-ray contrasting agents, drug & gene delivery, and tumor treatment

Graphene

Visible to the naked eye, graphene is 2D nanomaterial at the atomic scale. It is a sheet of carbon molecules.

Carbon atoms interlock in hexagons to form a honeycomb like structure

Multiple layers of graphene is called graphite

First discovered by scientists who used scotch tape to lift an atom thick layer off of a graphite block

Strongest material at the microscopic scale

Applications include as a lubricant (in powdered form), as a protective coating, in electronics, and in biosensors