Inventory managment W5

1/11

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

12 Terms

Inventory

the accumulation of things as they flow through a business or network. It forms whenever the rate of supply (stuff coming in) is different from the rate of demand (stuff going out).

physical inventory - stock

stock → accumulation of physical materials such as components, parts, finished goods, or paper information records.

why do you want to have stock?

is an insurance against uncertainty (in demand or supply)

can counteract a lack of flexibility

allows operations to take advantage of short-term opportunities

anticipate future demands

can reduce overall costs

can increase in value

fill the processing ‘pipeline’

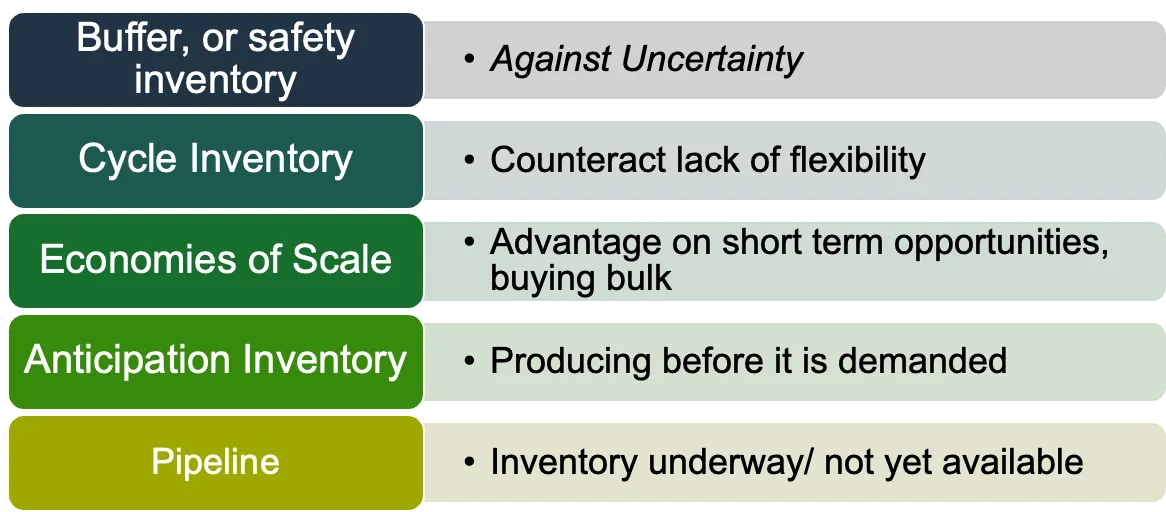

Types of stock

Insurance (Safety/Buffer Inventory) → It protects against the unexpected. If a supplier is late or demand suddenly spikes (like the COVID-19 PPE example or Swiss coffee stocks), safety stock prevents you from running out.

Cycle Inventory → You cannot make every product continuously. A baker makes bread in batches (e.g., White bread → Wholemeal → Grain). Inventory allows them to sell White bread while the oven is busy baking Wholemeal.

Economies of scale → This is a systematic strategy. You intentionally buy large quantities regularly to get a lower price per unit.

Anticipation Inventory → You build up stock before a known peak. (e.g., Making chocolate all year round to prepare for the Easter rush).

Pipeline → This is stock that is "on the move" (in a truck or warehouse). It exists because goods cannot teleport instantly from factory to store.

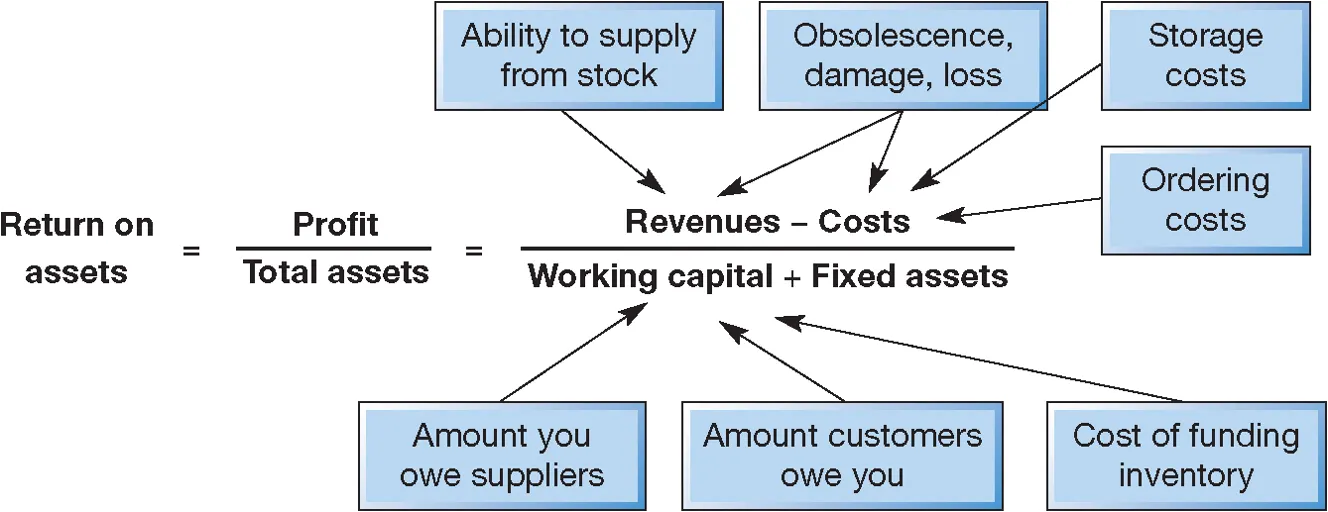

Consequences of having an inventory (picture)

Obsolete stock, or dead stock, refers to inventory that's no longer sellable or usable due to factors like expired shelf life, changing customer demand, or technological advancements, tying up capital and space.

Financial impact of stock

revenues - costs = cost of goods sold

Inventory costs

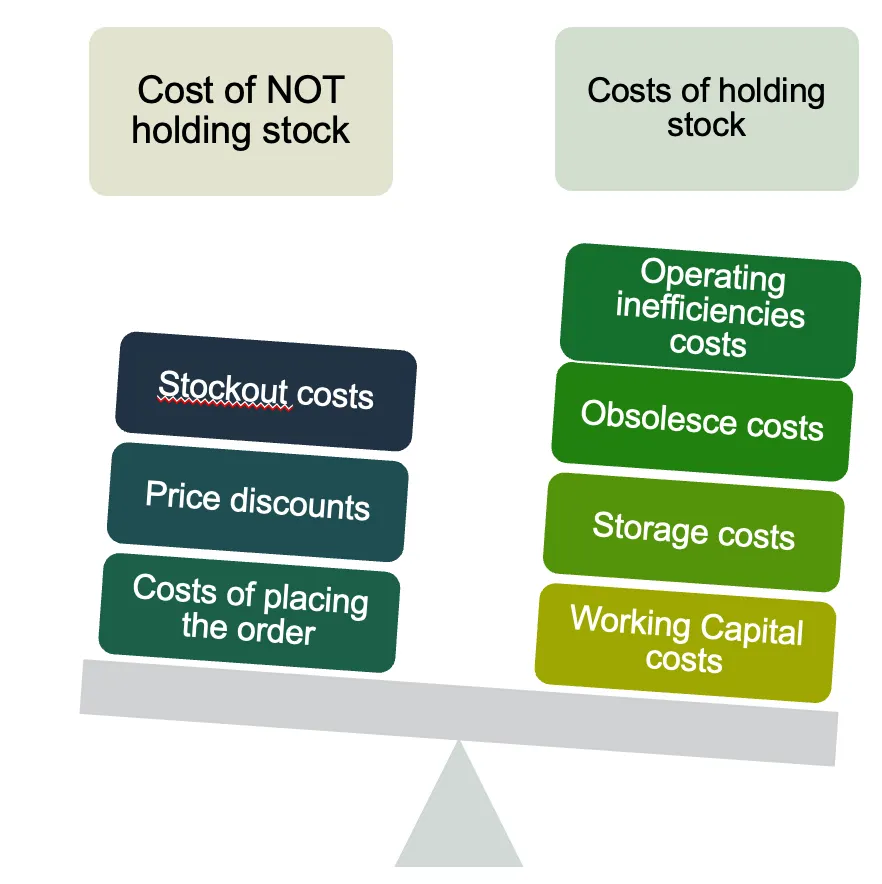

costs of NOT holding stock

stockout costs → the money you lose when you run out of a product, including lost sales, expensive emergency shipping, and disappointed customers.

price discounts → the missed opportunity to get "bulk pricing" or volume discounts because you are ordering in small quantities rather than buying a lot at once to store.

costs of placing the order → These are the fixed administrative and processing fees you pay every single time you make a purchase, regardless of how many items you buy.

costs of holding stock

operating inefficiencies costs → Holding too much "safety stock" can hide deeper problems in your business, like slow production or quality issues, which prevents you from fixing them.

obsolesce costs → This is the financial loss that happens when your stored items become outdated, expire, or get damaged before you can sell them.

storage costs → This is the direct cost of the physical space needed for inventory, including rent for the warehouse, electricity, security, and insurance.

working capital costs → This represents the "opportunity cost" of having your cash tied up in unsold boxes on a shelf instead of using that money to grow the business or earn interest

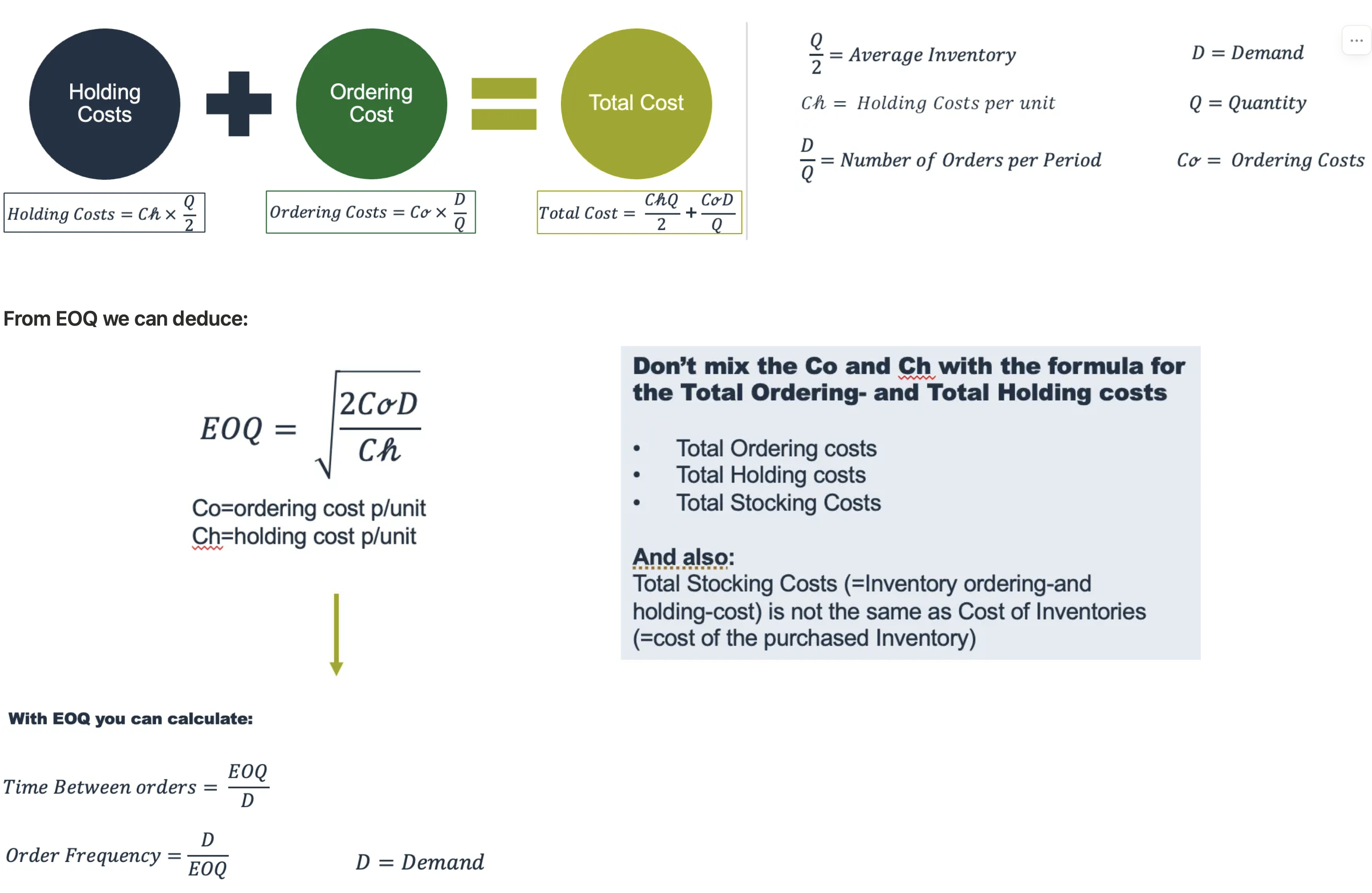

(calculate the Economic Order Quantity (EOQ)

EOQ (economic order quantity)

→ to find the perfect order size that minimizes your total costs.

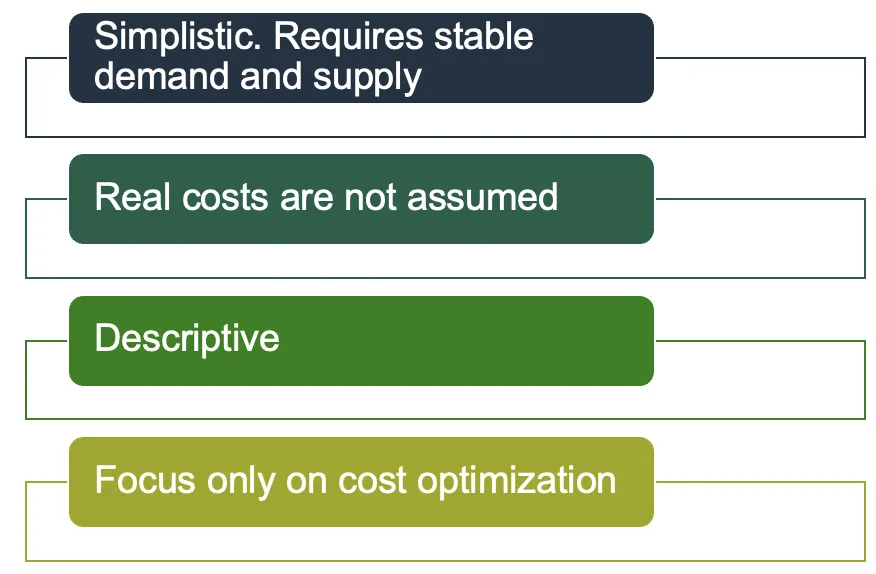

Disadvantages of EOQ

Simplistic / Requires stable demand and supply: The model unrealistically assumes that customer demand and supplier delivery times never change, which ignores real-world issues like seasonality or supply chain delays.

Real costs are not assumed: It relies on fixed theoretical estimates for holding and ordering costs, often failing to account for reality-based factors like bulk quantity discounts or fluctuating market prices.

Descriptive: It merely describes a static, theoretical ideal rather than providing a dynamic strategy that adapts to the constantly changing conditions of a real business environment.

Focus only on cost optimisation: By strictly prioritising the lowest possible inventory expense, the model overlooks other critical success factors like customer service levels, product quality, and responsiveness.

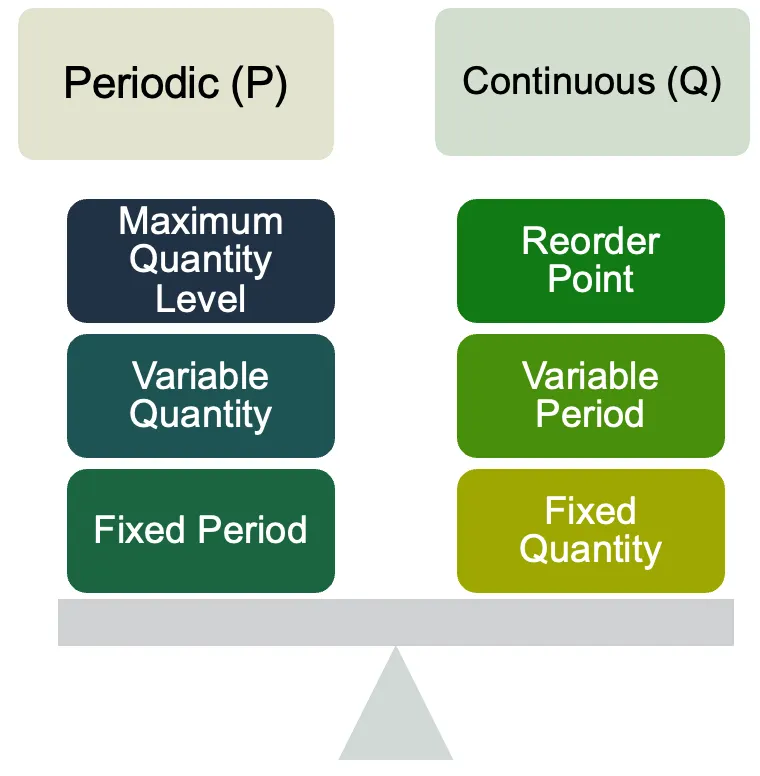

periodic x continuous review

Periodic Review (P-System)

Order always the same quantity whenever a minimum set stock level is reached

How it works: Inventory is checked at fixed time intervals (e.g., weekly, monthly).

Order trigger: An order is placed to bring stock up to a predetermined maximum (target) level.

Pros: Simplified scheduling, lower monitoring effort, easy to coordinate with other tasks (e.g., supplier deliveries).

Cons: Higher risk of stockouts between review periods because demand isn't tracked constantly; requires more safety stock.

Best for: Lower-value items, predictable demand, consolidated shipments.

Continuous Review (Q-System or Reorder Point System)

Order always the same quantity whenever a minimum set stock level is reached

How it works: Inventory levels are monitored constantly (in real-time).

Order trigger: An order is placed immediately when stock reaches a specific reorder point.

Pros: Lower safety stock needed, better responsiveness to demand changes.

Cons: Higher monitoring costs, more administrative effort.

Best for: High-value items, variable demand, items where stockouts are costly.

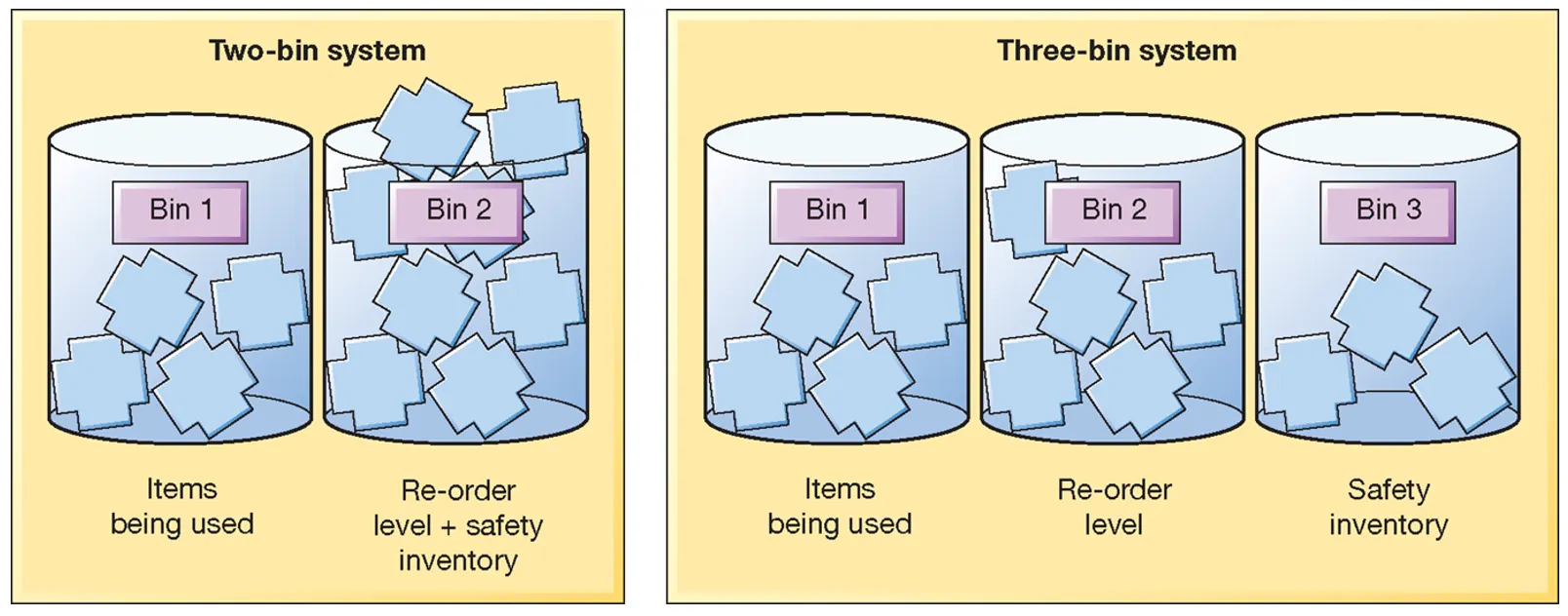

two-bin & three-bin system

two-bin system → you use stock from the first bin until it runs out, at which point you switch to the second bin, which automatically signals that it is time to place a new order while providing enough supply to last until that delivery arrives.

three-bin system → this system adds an extra layer of security by keeping a third, separate container strictly for emergencies, ensuring you have a dedicated safety buffer (Bin 3) even if your reorder stock (Bin 2) runs out before the new shipment gets there.

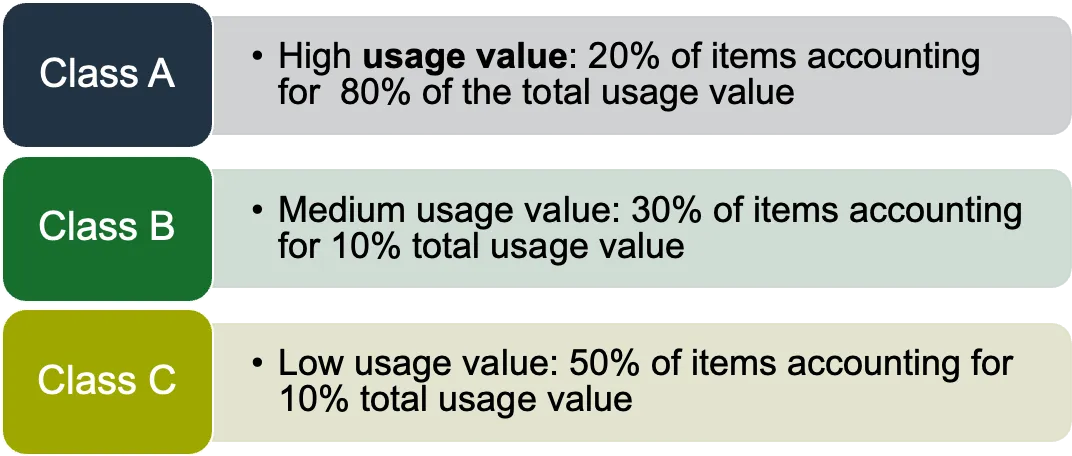

use ABC inventory analysis

Usage Value=usage rate × item individual value

QUIZ

Inventories exist because → there is a difference in the timing or rate of supply and demand

A queue of people is an accumulation of customers, and, in the example of people waiting on a phone to speak to a customer adviser from a service helpline, can be considered as inventory → TRUE

Which of the following is NOT a common disadvantage of holding physical inventory? → it counteracts inflexibility

Which of the following is NOT a common advantage of having queues of customers? → queues utilise space efficiently

Which of the following costs generally increase as order size is increased? → insurance costs

The re-order point is → the point at which stock will fall to zero minus lead-time

What is a two-bin system? → a system in which orders are placed when only one complete bin of stock is remaining

Stock cover, stock turn

Stock Cover = nr of weeks or days of supply, before stock becomes zero and needs to be refilled

Days of Supply = inventory on hand / average daily usage

Example: a company as 9000 units on hand and the annual usage is 48000 units. There are

240 working days in the year. What is the days of supply?

Answer: avg daily usage = 48000/240 = 200 units

days of supply = inv on hand/avg daily usage = 9000/200 = 45 days

Stock Turn = nr of times the stock turns a year

Stock Turn = Cost of goods sold/Average inventory value

Example (see Annual report on next slide): Apple has as Sept 2023 a twelve month sales of

USD 383 billion. Cost of the sales (or cost of goods sold) were USD 189 billion.

Average Inventory value was USD 5,6 (=(4,9+6,3)/2). What is the stock turn?

Answer: cost of goods sold (or cost of sales) / avg inventory value = 189 / 5,6 = 34 times

or in other words Apple turns its inventory every 11 days! (365 days /34 times = 11 days).