exam 2 operations management

1/66

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

67 Terms

The Taguchi Loss Function indicates that:

Inconsistency in a products dimensions is expected to cost money

Concurrent engineering benefits?

Product design time reduced

What is the reliability of a four-component product, with components in series, and component reliabilities of .80, .95, .98, and .79?

0.59

I discussed an example where the engine design of automobiles changed from "points and condenser distributors" to "electronic ignition." What design concept is this an example of?

Robust design engineering

If an assembly line yields a percentage of parts that are of unacceptable size or reliability (product won't work) what is the best way to improve reliability (quality)?

Add another person/station to the least reliable process

What is the main advantage of a pull system over a push system?

Pull system coincides with actual customer demand

Anna works on an assembly line where it takes her 20 minutes to produce 40 units of a product needed to fill a Kanban container. It takes her an additional 5 minutes to transport the container to Josh, who works at the next station. The company uses a safety stock of 15%. The current assembly line uses 5 kanban containers between Anna's and Josh's stations. What is the demand for Josh?

418

In JIT or lean applications use of what helps to minimize work between processes?

Kanban containers

A bakery uses 9 kanban containers between two work stations that each hold 4 cakes. If safety stock is 9% and lead time is 11 days, determine daily demand.

3 cakes

Which one of the following is not a benefit of JIT implementation?

Variability in products or service delivery

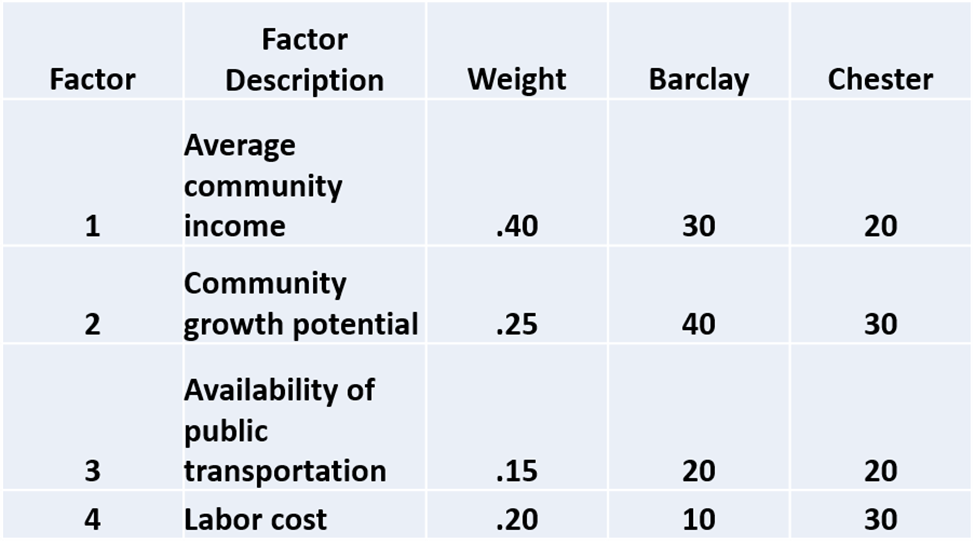

A clothing chain is considering two different locations for a new retail outlet. They have identified the four factors listed in the following table as the basis for evaluation, and have assigned weights as shown. The manager has rated each location on each factor, on a 100-point basis, as shown under the respective columns for Barclay and Chester.

What is the best location based on these success factors

Barclay, 27

How has the Lubbock Economic Development Alliance been able to attract 249 companies to Lubbock since 2004?

Offered incentives

Why do so many global companies choose to have facilities in China?

China artificially maintains a low value currency

What has changed in warehousing as a result of Industry 4.0 (technological advances)?

Reduction in warehouse space required

Alogistics Co. has just signed a contract to deliver products to three locations, and they are trying to decide where to put their new warehouse. The three delivery locations are Dallas, Kansas City, and Memphis. Which town would be the best place to put the warehouse to minimize transportation costs?

Location X Coordinate Y Coordinate

Dallas 42 64

Kansas City 60 45

Memphis 90 60

Loads/Trips

Dallas 700

Kansas City 150

Memphis 220

Last Mile 55, 59

What type of layout has the most product flexibility?

Process layout

A hospital's layout has advantages in what area?

Service flexibility

Which of the following workers is the most productive?

$11 wages, 3 parts produced

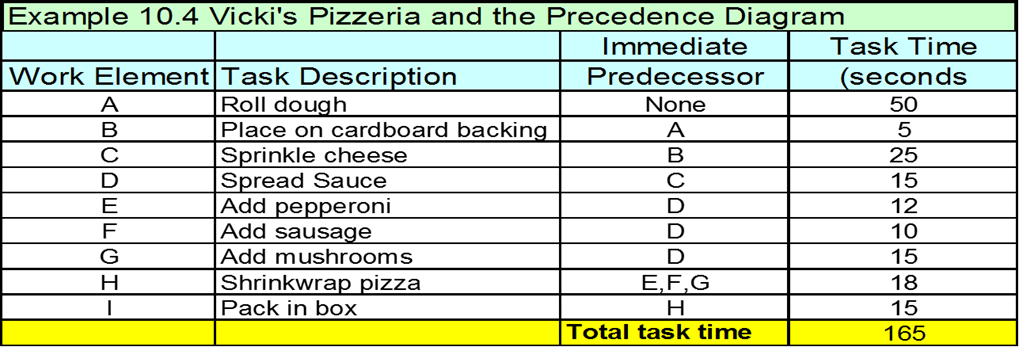

What would be the through-put in this pizza making operation if it took 59 seconds to shrink-wrap one pizza?

61 pizzas per hour

Why is a U-shaped assembly line potentially mor efficient?

Stations are closer together

Taguchi Loss Function

Area of good, Try to minimize loss

Reliability of Processes

.90 * .80 * .99 = 71.3%

Processes in Parallel

Someone to check the work at each station to get higher reliability

Kanban Containers

Stores x number of products for WIP

Demand(Process Time + Delivery Time)(1 + Safety Stock)/Capacity

Number of Kanbn Containers

Factor Rating

Factor weight * Factor Score

Center of Gravity

Sum of all x * Shipped out per month / Sum of shipped per month

Same thing for y but swap out x

Process Layout

Transportation, Figure out ways to have less walking

Block Layout

Load Distance score, lower # means less walking

Output per hour

Available time / bottleneck

Minimum # of work stations

Sum of task time / Cycle time

Layout Calculations

Sum of task times / (# of stations)(New cycle time)

Balance Delay

1 - % from Layout calc

Service design bad

went out of business

Robust Design

Less likely to fail (less tune ups)

Outcome of taguchi loss function

If out of range, high cost, lose customers, more repairs

Concurrent Engineering

Walls broken down, need to address issues immediately

JIT, Lean

Operation with minimum amount of people and processes that you can

Direct Labor cost

Unions make labor cost more than asian companies

Warehouse help

Gravity slides, closer in warehouse, less people

Methods analysis

Move things closer

Puch system

Makes products based on forecasted demand

Pull system

Makes products based on demand directly

Process Layout

Hospital (Cutsom layout)

Product Layout

Assembly line

Quality at the source

Person who checks quality at every step of assembly line

Jidoka

Workers stop system when they see bad quality

Decision makers from bottom up

Person who works the process knows best

Suppliers JIT

Co-locate facilities, less space taken

Location

Needs to add value in customers eyes

China Dollar

Artificially maintained, keeps labor down

Total Preventative Matinence (TPM)

Schedule downtime

Toyota SA

Vendors located close by (smallest plant with 2000)

Clustering

Resturants close by together creates traffic, creates business

LEDA

Offers incentives to come to lubbock

Infrastructure assistance

Bought HR Licence but city would not give assistance

Center of gravity benefit

Minimize transportation

Office Layout

Have someone at the door to monitor traffic and also have a private room for conversations

Retail store Layout

Optimize revenue per sqft, high margin items close to register

Warehouse layout

Industry 4.0, more robotics, less space required

Cross docking

Less handling when loading, unloading

Process layout attributes

Same resources in 1 place, Flexible

Product layout benefits

Higher paying, more WIP

U shaped assembly line

Less people, closer together

Cycle time

Determined by bottleneck

Most productive

Lowest cost per part

Efficiemcy

Lowest cost, less production