cob 300c - test 1 study guide (ch. 1-7)

1/107

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

108 Terms

Service

Intangible

Can not be stored

Quality corrections may not be possible

Higher customer contact (experience matters)

Process may affect customer

Less uniformity in outputs

Supply Chain

a sequence of activities and organizations involved in producing and delivering a good/service

Suppliers → producer → distributor → customers

Process

one or more actions that transform inputs into outputs

Two factors that tend to have universal strategic operations importance.

Quality and time

Operations Function

set of activities in business that generate value by transforming inputs into outputs using efficient processes

Ex. Input = doctor → process = surgery

output = healthy patient

Product

Tangible

Can be stored

Quality corrections possible

Less customer contact

Process may not affect customer

Higher uniformity in outputs

Systems Design

Typically strategic decisions that require long-term commitment of resources and determines parameters of system operation

Ex. capacity, facility location & layout, product/service planning

Systems Operations

- Generally tactical and operational decisions

- Ex. scheduling employments, managing quality control and projects

- Where operations managers spend most of their time

Mass Production

Utilizes interchangeable parts and division of labor

Lean Production

- Get inventory just in time, simply when it is needed.

- More efficient, reduce waste

Mass customization

catering to high demand, but customers can put their specified request

Ex. dell computers, nike shoes

Order Loser

product/service characteristics that repel customers

Order qualifiers

basic characteristics of product/service for customers to consider

Order Winners

characteristics of product/service is perceived as better than competition

Ex. mcdonalds give free toys to kids

Cost Leadership

- Price lower than competitors (max value)

- Ex. walmart

Differentiation

- Distinguish organization (value add)

- Ex. apple

focus

Target specific segment of market

Upper management processes

govern the operation of entire organization

Operational processes

core processes that make up value stream

Supporting processes

support core processes

Supply > Demand

Too much investment, not a lot of return

- Wasteful + costly

Supply < Demand

Cannot cater to demand, losing potential to earn revenue

- Opportunity loss + customer dissatisfaction

Supply = Demand

ideal

Systems Approach

Emphasizes interrelationships among subsystems (the whole is greater than the sum of its parts)

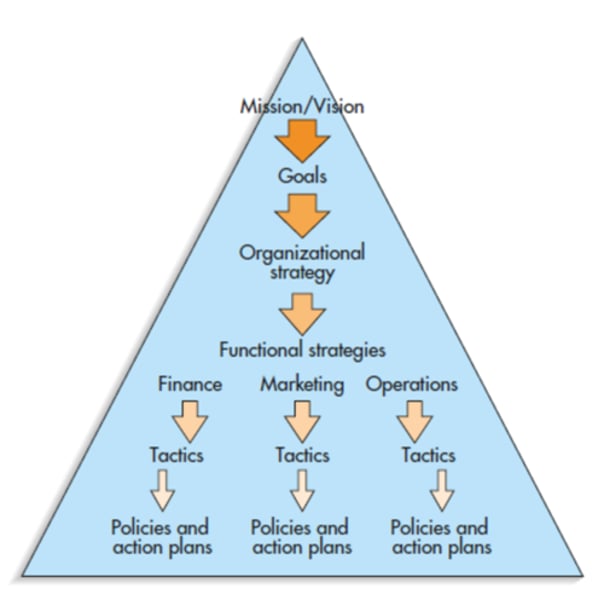

Strategy

action plan for how an organization expects to achieve its missions/goals

Organizational strategies

Higher level, org as a whole

Functional level strategies

- Slightly different focuses

- More detailed/specific

organizations implement strategies through:

- tactics : the "how to" part

- operating procedures : the actual "doing" part

Strategic Hierarchy

Mission -> Organizational goals-> organizational strategies ->

functional strategies -> operations strategies -> tactics -> operating procedures

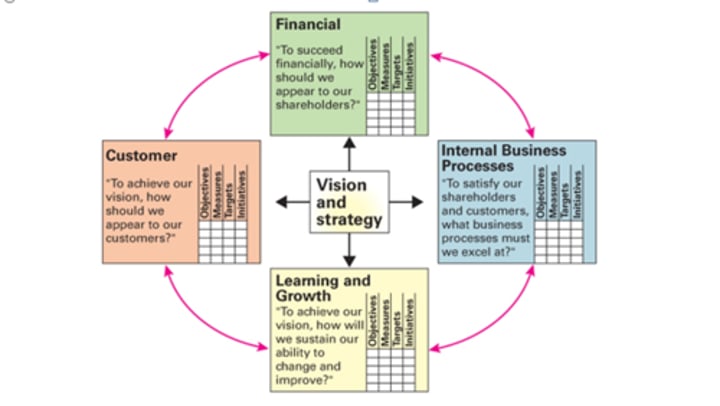

Balanced Scorecard

A top-down management system used to clarify vision/strategy and transform them into action

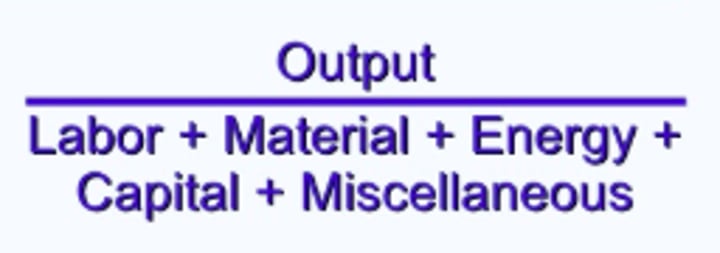

Productivity

- A measure of the effective use of resources

- Usually expressed as the ratio of output to input

- Operations Manager's responsibility is to increase productivity

Single-factor productivity

= output/(single input)

Multifactor productivity

=output/(multiple inputs)

Life cycle and its implications

- Selling something at maturity phase, relatively stable (Efficiency)

- Growth phase, focus on speed

The six phases of the generic development process are:

Phase 0: Planning

Phase 1: Concept development

Phase 2: System-level design

Phase 3: Design detail

Phase 4: Testing and refinement

Phase 5: Production ramp-up

In which variant of the generic product development process, does concept development assume a proven technology?

Platform products

Variants of product development

- technology push products

- platform products

- process-intensive products

- customized products

- quick-build products

- complex systems

- generic (market pull products)

- High-risk Products

technology push products

firm begins with new technology and looks for a market

ex. tyvex envelopes, gore-tex rainwear

platform products

built around a preexisting technological subsystem

-EX: consumer electronics, computers, printers

process-intensive products

-production process has an impact on the properties of the product

-Product design cannot be separated from process design

- characteristics are highly constrained by the production process

-ex. snack foods, breakfast cereals, chemicals

customized products

new products are slight variations of existing configurations

- highly structured development process

- ex. motors, switches, batteries, containers

quick-build products

rapid modeling and prototyping enables many design-build-test cycles

- testing phases are repeated

- ex. software, cellular phones

complex systems

systems must be decomposed into several subsystems and many components

- system integration and validation

- airplanes, jet engines, automobiles

generic (market pull products)

The team begins with a market opportunity and selects appropriate technologies to meet customer needs

- distinct planning, process design, etc.

- sporting goods, furniture, tools

High-risk Products

Technical or market uncertainties create high risks of failure

- ex. pharmaceuticals, space systems

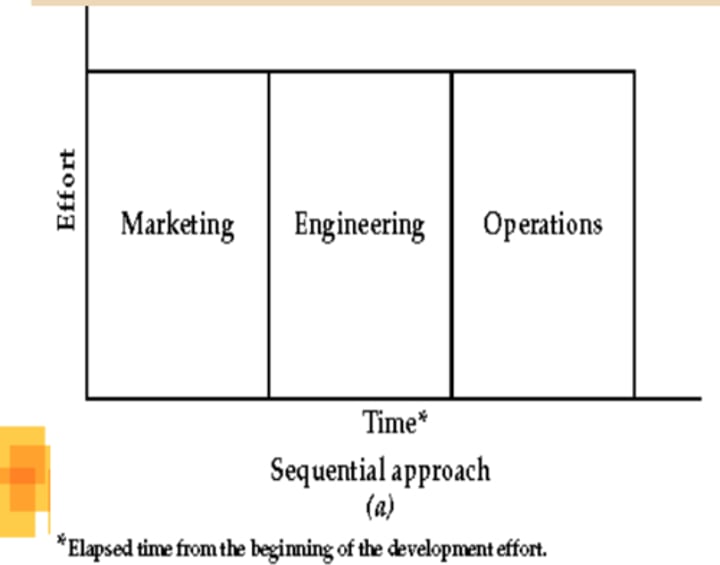

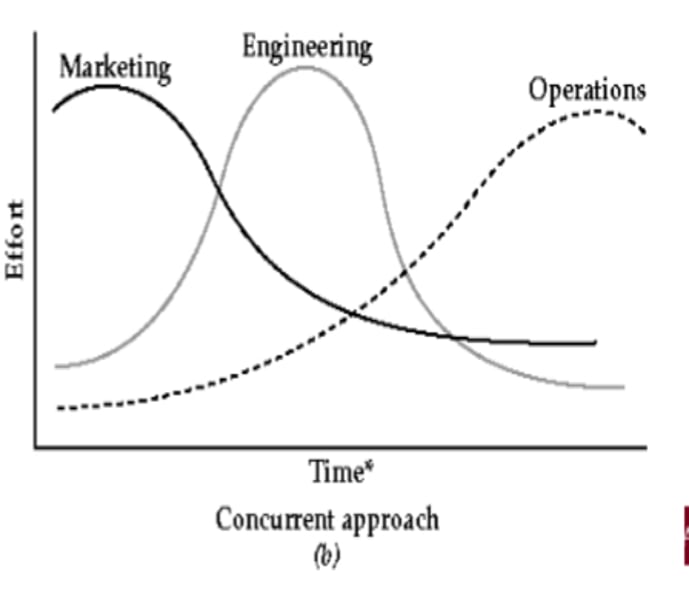

sequential approach

stakeholders getting involved in stages, one at a time

concurrent approach

stakeholders getting involved around the same times

- More agreement on services, faster and less mistakes

- Bring product faster to the market

House of Quality

a matrix that helps translate customer requirements into concrete operating or engineering goals. However, the most important benefit of the house of quality is that it helps focus on building a product that satisfies customers.

- Customer requirements + design requirements meet at the middle in relationships

Which of the following is primarily used to help design products that will connect product attributes with customer desires?

The house of quality matrix

Value analysis / value engineering

used to simplify products with the goal of achieving better performance at a lower cost.

Design for Manufacturing and Assembly (DFMA)

Oriented toward the engineering of the product with an emphasis on reducing production cost

- simplification of the product by reducing the number of separate parts.

Cycle Time

the average time between completion of successive units

Utilization

the ratio of the time that a resource is actually used/activated relative to the time that it is available for use

Process Flowcharting

use of a diagram to present the major elements of a process

flowchart symbols

tasks/operations : rectangle

decision points : diamond

storage areas/queues(waiting lines) : triangle

flows of material/customers : arrow

Stage

used to indicate that multiple activities have been pulled together for analysis purposes

- Single-stage process

- Multi-stage process

Buffering

a storage area between stages where the output of a stage is placed prior to being used in a downstream stage

Blocking

occurs when the activities in a stage must stop because there is no place to deposit the item

Starving

occurs when the activities in a stage must stop because there is no work

Bottleneck

stage that limits the capacity of the process

Make to Stock (MTS)

process activated to meet expected or forecast demand

- Serve customers from finished goods inventory

Make to Order (MTO)

process activated in response to an actual order

- Make the customer's product from raw materials, parts, and components

Assemble to Order (ATO) / Hybrid

quicker response than MTO and more flexible than MTS

- Combine a number of preassembled modules to meet a customer's specifications

engineer to order

Firm will work with the customer to design the product , and then make it from purchased materials, parts, and components

Total average value of inventory

The total average investment in raw material, work-in-process, and finished goods inventory

Inventory turns

cost of goods sold divided by the average inventory value

Days-of-supply

inverse of inventory turns scaled to days

Little's Law

inventory = throughput rate x flow time

Efficiency

A ratio of the actual output of a process relative to some standard

actual output/standard output

Operation Time

The sum of the setup time and the run time for a batch of parts that are run on a machine

set up time + run time

Flow Time

The average time that it takes to move through an entire system

Throughput Rate

The output rate that the process is expected to produce over a period of time

1/ cycle time

Process Velocity (Throughput Ratio)

Ratio of value added time to flow time;

value added time/flow time

Value-added Time

The time in which useful work is actually being done on the unit

Run time

The time required to produce a batch of parts.

Calculated by multiplying the time required to produce each unit by the batch size.

Lead Time

The time needed to respond to a customers order

Customer Order Decoupling Point

Where inventory is positioned in the supply chain to allow processes or entities in the supply chain to operate independently

Product-Process Matrix

a model that describes the alignment of process choice with the characteristics of the manufactured good

Project Layout

For large or massive products produced in a specific location, labor, material, and equipment are moved to the product rather than vice versa

- Ex. airplane

Workcenter (Job Shop)

A process with great flexibility to produce a variety of products, typically at lover volume levels

Batch

a process in which goods or services are produced in groups (batches) and not in a continuous stream

Assembly Line

An item is produced through a fixed sequence of workstations, designed to achieve a specific production rate

Continuous Process

A process that converts raw materials into finished product in one contiguous process

Service Package

A bundle of goods and services that is provided in some environment

Bundles consist of five features:

1. Supporting facility

2. Facilitating goods

3. Information

4. Explicit Services

5. Implicit Services

High Degree of Customer Contact

More difficult to control and more difficult to rationalize than low degree of customer contact

Service System Design Matrix

1. Mail contact

2. Internet and on-site technology

3. Phone contact

4. Face-to-face tight specs

5. Face-to-face loose specs

6. Face-to-face total customization

Service System Design Matrix characteristics

high contact reduces efficiency, but has high sales potential

Production line approach

service delivery is treated much like manufacturing (McDonald's)

Self-Service Approach

customer takes a greater role in the production of the service (ATM machines)

Personal Attention Approach

Ritz-Carlton Hotel Company

Service Blueprint

The flowchart of a service process, emphasizing what is visible and what is not visible to customers

Poka-yokes

Procedures that prevent mistakes from becoming defects. They are commonly found in manufacturing but also can be used in service processes

How should services accommodate the variation introduced by the customer?

more accommodation → more cost

less accommodation → less satisfaction

Five Types of Variability

1. arrival variability

2. request variability

3. capability variability

4. effort variability

5. subjective preference variability

arrival variability

customers arrive at times when there are not enough service providers

request variability

travelers requesting a room with a view

capability variability

A patient being unable to explain symptoms to doctor

effort variability

shoppers not putting back their carts

subjective preference variability

interpreting service action differently

strategies for managing customer-introduced variability

- classic accommodation (employees on hand)

- low cost accommodation (low-cost labor, outsource, self service)

- classic reduction (require reservations)

- uncompromised reduction (target customers)