food credit 1

1/16

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

17 Terms

1. Milk sampling in primary milk production

the first stage

milking

handling

storage farm before being transported (so raw milk)

milk samplong: 2 types bulk and individual l

individual

-california - mastitis test

bulk

tank milk - redidus or medisine

test 2x a month and 1x a month

2x mnth - rediduse and total bak count

protein testing - 2,8%

fat testing - 3,5%

1 month

somatic cell count

frezing point

pathogen test - part of rutine - salmonela, ecoli, literia monocytogenes

transport test

temp less than 10

test aniboitisc

specific gravity and acidity

milk constitutens (fat, protein osv)

renetability

heat stability

antibiotic test - tank milk and individual

testing of pathogens - free of pathogents

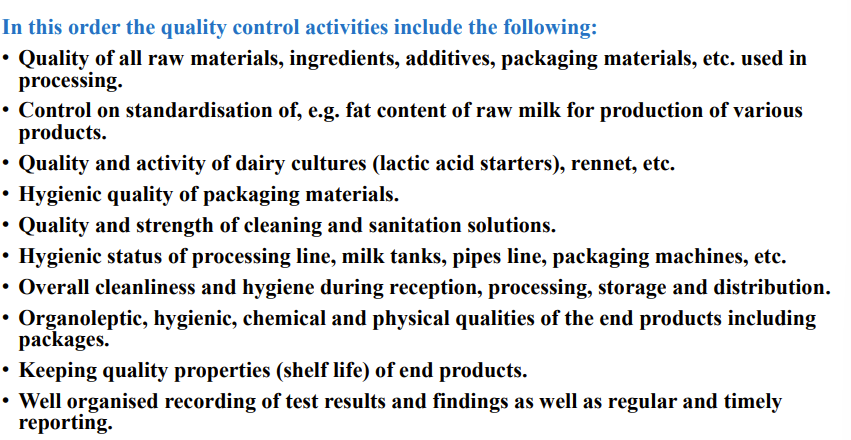

2. Types of controls in the dairy industry

control in dairy industry

1. Production holding (dairy farms): Individual milk samples: • visual testing for quality of first milk squirts, • mastitis California test • conductivity of milk, • antibiotic resisues

Bulk milk samples: Always before milk colection and transport of milk (residues of antibiotics) (1 a month somatic cell)

2. Processing establishment (dairy plant)

• Input control (raw milk)..

• Intermediate control (during manufacturing process).

• Output control (final products).

Milk reception

Milk testing – „transport sample“

Antibiotic residues: as well as composition of milk, appearence + acidity test

(quality control during manufacturing process)

• phosphatase test + peroxidase test (efficiency of heat treatment of milk),

salt content

fat

h2o

acidity

(final products):

• sensory evaluation

• physico-chemical properties,

• microbiology

If you send the sample out 3 layers of bags to ensure safe transport (2 bag + paper)

Temperature of milk during transport – less than 10 °C

Milk should be processed within 36 hours after arrival to a dairy plant.

Hygien control

the space and utensels

quality control (everithing milk control)

regulatory control

monitory control

microbiological control

document are in place

3. Determination of acidity of milk

pH and titratable acidity

pH of cow ´ s milk normally varies between 6.4 to 6.8

pH of milk varies slightly between species

at a pH of 4.6 to 4.7 lies the iso-electric point of cow ´ s milk

milk coagulates at room temperature

why would acidity change

pH of colostrum is slightly lower than pH (high acidity )of normal milk

mastitis milk may have a higher pH (low acidity)

0,16-0,18% lactic acid in fresh milk - if higher then spoild

why do we control: evaluate the fresh ness and bak

up - micriobial contamination and spolage

down - diluted milk

Method

Titration method Naoh -phenophalein

determination of milk acidity by orientational methods clot-on boiling test

indication papers- compared with standard strips

alcohol test - -if higher than 9sh sample will coagulate (milk + ethanol)

alisarin alcohol test - combination of ph and alcohol test

important for cheese cause can cordle defect

cheched every step of the way (from out of cow- transport - to finish product)

types of acidity

natural - form casind and phosphated (acidity important beaue regulate the whle milk and consistancy)

divelopment - by bakteria from lactose to lactig acid

natural is better than development

4. Determination of the specific gravity of milk and the freezing point of milk

Normal density of fresh cow milk is 29-33*L (lactodensimetric degrees).

- Density decreases when water is added,

- Increases if cream is added.

Normal freezing point of milk is -0.54 to -0.57*C:

- If water is added, the freezing point is higher (closer to 0*C)

5. Evidence of heat treatment of milk, describe the scheme of heat treatment of milk

Milk is heat treated before processing with these objectives:

To kill all bacteria and viruses that may be harmful to human health (pathogens),

To kill other microorganisms (and their possible spores), especially those that can cause spoilage of milk and milk products,

To inactivate milk enzymes and enzymes produced by microorganisms,

To affect the milks physical and chemical properties in order to improve its suitability for further processing.

Pasteurization, where the milk is heated to temperatures below 100*C, which kills the pathogens and a large number of other microorganisms,

Sterilization, where the milk is heated to above 100*C. This kills all microorganisms, spores and viruses.

Pasteurization can be done using batch method or continuous method. In the batch method, a vat pasteurizer which consists of a jacketed vat surrounded by either circulating water, steam or heating coils of water or steam, is used. Most commonly used is the continuous method, which usually uses high temperature short time (HTST) pasteurization. It consists of a stack of stainless-steel plates clamped together. The heating medium can be vacuum steamor hot water. The milk enters at 5*C and leaves the pasteurizer at 4-6*

vat past - low temp + long time

continous - high - short

Heat treatments:

-Terminization of final products: min 50*C max 75*C, min 20 sec.-Low pasteurization:72*C for 15 sec.

-Normal HTST: 81-85*C for 3-5 sec.

-UHT processing (ultra-hightemperature sterilization): 135*C for 1 second

Tests to determine proper pasteurization:

Phosphatase test:-Test of pasteurization above 70*C,-Normal HTST pasteurization inactivates the alkaline phosphatase in milk,

presence (yellow color )

White color is proper pasteurization.

Peroxidase test: -Test of pasteurization above 80*C,

Peroxidase enzyme is inactivated in a few seconds at temperature of 80*C,

Its presence(blue color)

White color is proper pasteurization.

Catalase test:-Catalase is destroyed by heating at75*C for 60 seconds

6. Laboratory examination of the basic comnstituents of milk

1. water content: dry method - 130 for 6min 80-90% in fresh milk

2. Determination of protein content:

-Caseins and whey proteins, 2-8-3.7%,

-Content depends on nutrition, stage of lactation, season, breed, mastitis etc.,

-Kjeldahl determination of nitrogen content

3. Determination of fat content and quality:

-Average content 3.3%,

Gerber method: separation of fat in a butyrometer, determination of its volume and calculations of percentage fat content

very important energy content - taste and value.

4. Determination of lactose:

-inortant for energy+ fermentaion

-4-5%

-Disaccharide composed of D-galactose and D-glucose,

-Titration method, chloramine-T method, lactoscan

7. Laboratory examination of milk from mastitis dairy cows

Inflammation of the mammary gland caused by:

bacterial infection

trauma or

injury to the udder.

Most mamma: • streptococci, • staphylococci,

Easy sigh to see

blood in milk or coagulation

california mastitis test

negative 200.000 (ish 400.000)

positive: over but worsst 500.000

somatic cell count

healthy: 300.000

sick: 1.000.000

Mastitis reduses milk yield by 10 – 25 % per cow:

pH in milk will increase (7,2)

we can register a lowering of vitamins C and A and an increase of vitamin B

increasing electrical conductivity lowering refraction of milk´s whey

Microorganisms with the exception of Mycoplasma, are usually controlled quite easily by: •Good udder hygiene. •Corect use of good milking machines. •Dipping teats after milking. •Treatment of all quarters of all cows at drying-off

high count of somatic cells

N mastitis test

california mastitis test

Fosomatic

increased of chloride ions and decrease of lactose

chlorine sugar number

chloride content

changes of pH: the bromthymol test

8. Microbiological examination of milk, counting the total bacteria count

Cow milk

4% fat

4% protein

4,5% lactose

Sheep

7,5 fat

5% protein

5% lactose

Microorganisms in the dairy industry can be divided into desirable (bacteria, molds, yeasts, viruses and bacteriophages) and undesirable (fermentative bacteria, psychrotrophs, thermoresistant microorganisms, spore-forming aerobic and anaerobic bacteria and coliforms).

EU legislation 853/2004 rule for a - somatic cell count and total bacteria count for raw milk, Milk from healthy udder has 100-1000 cfu/ml. Also states that there can be no detectable antibiotic residues.

For goat and sheep milk, somatic cells are not counted, and total bacteria count can be 1,5million if the milk will be heat treated, and 500.000 if used as raw milk (in cheeses). No antibiotic residues are permitted.

Contamination can occur due to improper hygiene at milking, mastitis, dirty milking machine or equipment, bedding, feed, soil, feces, water, air etc.

Microbial

Dilution, spread plate technique, incubation, counting units, calculation

9. Laboratory examination of raw cow's milk: sensory evaluation / compilation of flow diagram / CCP / methods of laboratory examination of raw cow's milk / defects of raw cow's milk

Bactoscan• Approved rapid method for detection of total bacteria in raw milk

Fossomatic • Somatic cell counting for raw milk testing

Residue testing

• Copan milk test.

• Delvotest

Laboratory for raw milk – reception hall = INPUT CONTROL Immediately after arrival to a dairy plant, raw milk sample (so called „transport sample“ is tested for:

Temperature (less than 10 °C).

Antibiotic residues

screening test: - detectable = milk is rejected (cannot be processed), - not detectable = milk is processed and is tested next for:

titratable acidity or pH,

density (or freezing point) = adulteration of milk with water,

basic constituents (fat content, protein content),

rennetability (for cheese making),

heat stability, etc

phosphatase test : yellow unpastarized

white pasturized

peroxidase test; blue unpasturized

white paturized

Sensory analysis of raw milk includes evaluation of color, flavor and consistency:

-color: milk ranges from yellowish creamy white (cow milk) to creamy white (buffalo).Intensity of the yellow color depends on various factors (more yellow in summer whiter when fed beets, red when presence of blood or injury to mammary gland, blue caused by feed or microbial contamination

-Flavor: includes smell and taste. The flavor of milk is a blend of sweet taste of lactose and salty taste of minerals, both are dampened by proteins. Phospholipids, fatty acids and fat of milk also contribute to taste,

-Consistency: homogenous liquid without deposits, flakes and coarse dirt. Factors influencing organoleptic properties of milk are nutrition (flavors passed in feed or through digestive system-> blood-> milk, quality of feed, interval between feeding and milking), health status (metabolic disorders, microorganism), residues of cleaning products and improper storage (sunlight, metal, long-term storage)

10. Laboratory examination of consumer liquid milk: sensory evaluation / compilation of a flow diagram / CCP / methods of laboratory examination of drinking milk / defects of drinking milk

defects :

cookig aroma

lipolitic aroma

oxidation smell

proteolitic smell

Consumer liquid milk: processed . Sensory evaluation

color: white

consistency: homogenous liquid without deposits, slight fat look is okay for non-homogenized.

smell and taste: milky, bit sweet, free from foreign odor/flavor. sensory changes + defects: cooking aroma, lipolytic aroma, proteolytic smell, oxidation smell

Flow diagram

fix the sensation

deodorization → centrifugation → homogenization → standardization → pasteurization → cooling → packing + shipping

receiving raw milk: need to get it at under 10 degrees heat treatment - microbes can survive - control temp. + time storage - at 3-5 degrees

ccp

temperature

storage

package

Methods of Laboratory

milk constituents - by lactoscan (protein, fat, lactose, freezing point)

titratable acidity of milk pH of milk

control of heat treatment by storch microbiological testing: pathogen testing, total bacterial count.

defects abnormal color (pink/yellow/blue), smell taste (sour, bitter, fruity), physical defects like coagulation due to fermentation by yeast

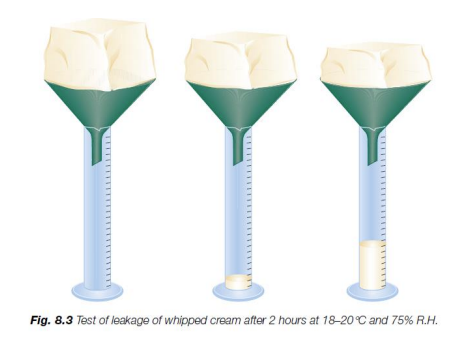

11. Laboratory examination of cream: sensory evaluation / compilation of flow diagram / CCP / methods of laboratory examination of cream / cream defects

rich in fat

The cream must be treated by one of the following methods of heat treatment: • a) pasteurization,

According to the fat content, divided into:

10% by weight; and less than 35% of milk fat,

more than 28% and less than 35% of milk fat,

more than 35% fat.

Whipping cream with 40% milk fat is usually easy to whip - if it drop so does the whipp abillity (best results at 6°C )

CREAM

Two principal requirements production of cream

good coffee stability

flocculate when poured into hot coffee.

coffee stability of cream can be improved to a certain extent by adding sodium bicarbonate if allowed (0,02%)

Coffee stability, involving several factors:

The temperature of the coffee; the hotter the coffee, the more easily the cream will flocculate.

The type of coffee, more acid-the more flocculate

Flow diagram:

milk

-centrifugation and standarizaton - ceparation (50 temp)

-homogenezation

-pasterization

-cooling

-packing

CCP:-Residues in raw milk,-Heat treatment of raw milk

LABRATORY

Determination of phosphatase and peroxidase activity

Both enzymes present and active in fresh milk and are completely destroyed by the heat treatments

phosphatase - inactivated at 40°C

peroxidase - 75- 80°C

Acidity test: Tiltratable acidity test - phenophalein as an indicator

soxhlet henkel degrees - used in cental europ

Fat content: Gerber method - by centrifugation (sulphuric acid + alcohol)

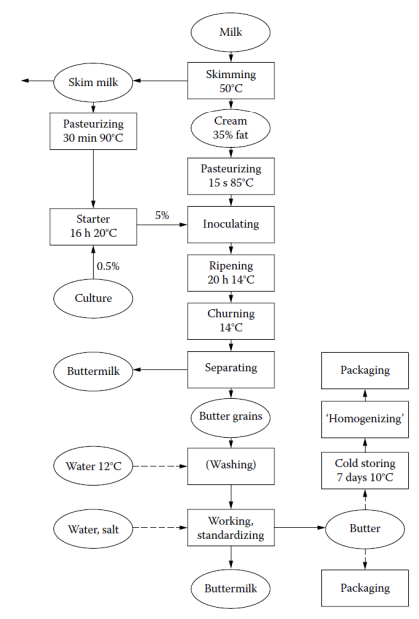

12. Laboratory examination of butter - sensory evaluation / compilation of flow diagram / CCP / methods of laboratory examination of butter / butter defects

Butter is generally made from cream

Divided into 2 main categories:

sweet cream butter;

cultured & sour cream butter made from soured cream

can also be classified according to salt content:

unsalted,

salted

extra salted

flow diagram: photo

fat + high iodine value will produce greasy butter

cream must be of good microbial quality, without taste or aroma defects.,

Cream is pasteurised at a high temperature, usually 95C

If necessary, any undesirable flavouring substances can be removed by vacuum treatment

bak count inportant it can effect diacetyl formation as well as which bak because it can effect consistancy - end up with yogurt consistancy

temp for butter chrurning 10 beat out the air - washing remove buttermilk

sensory evaluation

‘Appearance’ - colour, visible purity, absence of physical contamination, absence of mould growth

‘Consistency’- Body, texture and firmness, spreadness

body

flavour

aroma

lab

Determination of water: by burning

Fat determination: thiobarbituric acid - lipid oxidation

Acid determination: Naoh + phenophalein

peroxida value

sodium chloride

1-2% salt ish

13. Laboratory examination of sour milk products -sensory evaluation / compilation of flow diagram / CCP / methods of laboratory examination of sour milk products / defects in milk products

Sensory evaluation:

-Packaging evaluation,

-White to creamish color,

-Homogenous, smooth texture,no gas bubbles,

-Solid to creamy consistency,

-Pleasant fresh aromatic yoghurt-likeflavor

Flow diagram:

-Raw milk,

-Centrifugation,

-Pasteurization (CCP–85*C for 1-2 sec),

-Homogenization (10-20 MPa),

-Cooling (40-43*C),

-Addition of milk powder (40-60g/L)

-Inoculation with starter culture,-Packaging,

-Fermentation (42-45*C for 2.5-3.5h, 35*C over night),

-Cooling

CCP:

-Raw milk,

-Pasteurization,

-After fermentation?

Laboratory examination:

-Fat content,

-pH,

-Titratable acidity

Defects:

-Thin consistency: insufficient fermentation, unsuitable milk etc.,

-Gasbubbles: contamination by coliform bacteria,

-Defects of color, taste and aroma: linked to raw materials and production,

-Same flavor defects as cream (bitter, unclean, rancid, cooked,oxidized/tallow/metallic, low/high acid etc.)

14. Laboratory examination of cheeses (general) - sensory evaluation / compilation of flow diagram / CCP / methods of laboratory examination of cheeses / cheese defects

1.classification according to the method of processing in general

natural cheeses

sweet cheeses

acid cheeses

processed cheeses

2.Classification according to the species

3.Classification according to consistency hard semi hard soft

4.Classification according to the fat content

high fat or fat more than 60%

full cream 45 – 60%

half fat 25 – 45%

low fat 10 – 25%

skimmed fat less than 10%

5.water in fat free

6.lactose

milk wil have to be coagulated / calcium plays an important role + ph of milk adjusted by 1.5-2% starter lactic culture (Lactococcus lactis, Streptococcus thermophilus)(reduces ph in milk) (heat treatment 60 pasturization 70 15min)m 70% coagulated by rennet

Acid-coagulated cheeses - are produced from milk or cream by acidification to pH 4.6 - a high-moisture

ph 5-6 in general

The Evaluation of the Quality of the Cheese

organoleptic examination (appearance, colour, consistency, structure, flavour)

physico-chemical examination ( fat, NaCl, titrable and active acidity)

Microbial examination

sensory analysis - appearance, flavour and texture attributes smell tast

serious defects in the cheese may be caused by

bad quality of the milk

not keeping up the technological procedures

the bad quality of the ingredients

not keeping up the hygienic conditions

surface defects in the cheese

Laboratory investigation of cheese samples

Dry matter determination - by drying with sand at a temperature

Fat content in cheese by the Gerber method - temp 60 alcholoh to separate layers (centrifuation method)

Sodium chloride in cheese according to Mohr

Determination of pH

15. Laboratory examination of sheep's milk - sensory evaluation / compilation of a flow diagram / CCP / methods of laboratory examination of sheep's milk / defects in sheep's milk

Sensory evaluation:

-White, weak yellow-ish color,

-Pure milky without string smelling materials,

-Fat content and protein content is higher in sheep ́s milk (doubled fat 7.4 and 4.5 protein),

-Titratable acidity is higher (8-12.5SH),

-pH is similar (6.3-6.8).

Flow diagram:

CCP:

Laboratory examination:

-Total bacteria count(max 1500000 if being pasteurized, max 500000 if being usedraw)’

-Somatic cell count is not used,

-Phosphatase test,

-Peroxidase test,

-Verification of sheep ́s milk (no addition of cow or goat milk) = qualitativeimmunochemical test

Lacaune + east friesian - dairy breed - 300-600 litres

Milk products made from sheep milk are divided into the following groups:

a) modified sheep milk, flavoured sheep milk and liquid sheep milk products,

b) fermented sheep milk products,

c) cheese.

Sheep's milk has a delicate, slightly sweet taste, it has non transpared white colour with a characteristic sheep's aroma.

18-25% of produced sheep's milk is used for cheese production

81,6 % water,

18,45 % dry matter:

6,9 % fat,

4,45 % casein

4,55 % lactose

main protein in milk casein (whey protein 20%) - less lactose

Calcium and zinc higher

high vitamin C

sensory evaluation

color - white yellowish

smell - pure milky without strong odour

for raw COW milk critiria: Plate count at 30 °C (per ml) 100 000 maximum

Somatic cell count (per ml) 400 000 maximum,

LABRATORY

Determination effectiveness of pasteurization by Fosfatest

phosphatase test - detect inadequate pasteurisation and possible raw milk contamination (yellow unpasturized/ white pastrurized)

IDF method for determination of phosphatase activity

Determination of peroxidase activity in milk

storch test (blue unpasturized/ white pasturized

To verify the presence of raw cow's milk in sheep milk,

a qualitative immunochemical test)

16. Laboratory examination of bryndza - sensory evaluation / compilation of flow diagram / CCP / methods of laboratory examination of bryndza / defects of bryndza

From what: from ewe´s milk lump cheese (fresh or pasteurized milk)

How does it look: white, mature, spreadable cheese in granular form

Made by: milling a lump of matured sheep's cheese or by milling a mixture of lump cheese and lump cow's cheese.

It has a delicate odour and taste and has a pleasantly sour sheep's cheese taste that is slightly spicy and salty.

divided into group by material

a) made from 100% sheep lump cheese

b) from a mixture (50:50) of sheep lump cheese with lump cow cheese from pasteurized milk,

c)from a mixture (50:50) of barrel sheep lump cheese with lump cow cheese from pasteurized milk,

removal of whein in it

labratory evaluation

Dry matter

Detemrmined by drying the sample with sand at a temperature of 102 ± 2 ° C to constant weight

Fat

The non-fat solids are dissolved in concentrated sulphuric acid H2SO4 and the resulting mixture is centrifuged. The percentage of fat is read on a graduated scale on the centrifuge tubes (butyrometers) at a temperature of 65°C. Amyl alcohol is used to facilitate the separation of fat and aqueous phases.

Sodium chloride

Sodium chloride present in cheese is transferred into aqueous extract, and then is determined by titration with 0.1 mol.l -1 of silver nitrate. Potassium chromate is used an indicator

Titrable acidity

The titratable acidity is given by the volume of sodium hydroxide solution NaOH, which is consumed in the titration of 100 g of cheese using phenolphthalein as indicator and is given in degrees Soxhlet - Henkel (° SH). § Titrate to a light pink color, which lasts at least one minute

ph

The principle is that the active acidity (pH) of the cheeses and curds is determined potentiometrically with a pH meter according to the instructions of the apparatus, mostly using a glass and calomel electrode.

17. Laboratory examination of dried milk products - sensory evaluation / compilation of flow diagram / CCP / methods of laboratory examination of dried milk products / defects of dried milk products.

Obtained by the removal of water

spray dried milk powder - milk powder for direct consumption

roller dried milk powder - milk powder for industrial processing

Whole milk or whole cream milk powder: 26-40% fat, water content 5%,

Partially skimmed or half full cream milk powder: 1.5-26% fat, water content 5%,

Skimmed milk powder: 1.5% fat, water content 5%.

Milk powder must be packaged in materials that are impermeable to moisture and odours

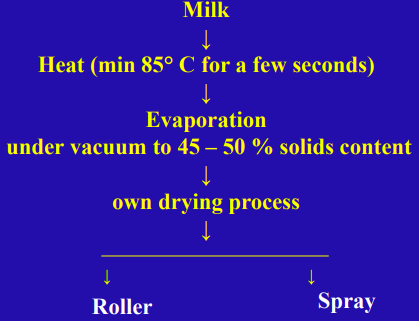

There are 2 ways to create milk powder, by roller drying process and by spray drying process. They have some initial steps in common:

Milk,

Heat (min 85*C for a few seconds),

Evaporation under vacuum to 45-50% solids content,

Own drying process,

Roller or spray.

Roller drying method:

Milk is spread in a thin film on the surface of a drum and dried in one rotation,

The dried film is removed by scraper knives,

Drum is heated by steam internally,

Film of dried milk is pulverized.

Spray drying method:

-A mist of small milk droplets is sprayed into a steam of hot air of 200*C that is forced through a suitably designed drying chamber,

Defects:

Spray milk that has a high moisture content due to insufficient drying or exposure to water during storage will have lower solubility, darker color and an unpleasant stale flavor,

Spray milk powders containing milk fat will easily show defects caused by oxidation of the fat.

Sensory evaluation:

White to creamy color, homogenous,

Powdery, homogenous, minimal amount of easily disintegrated lumps,

Clean flavor and odor, characteristic of milk powder, with a pasteurized taste or weak cooked flavor.

Laboratory examination:

Titratable acidity,- 0.10-0.15, sodium hydroxide (NaOH)

Water content (5%) - by drying techniques