BMEN 207 CAD

1/61

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

62 Terms

Hand Fabrication

2D drawings are the key input

Can often be made quickly and functional under high loads

Maximize use of off-the-shelf components and machine tools

Computer Controlled Machining/Milling (CNC) and Laser Cutting

Generally, produces the highest fidelity and strong, functional parts

3D Printing

Often the quickest and lowest cost way to prototype custom parts

Types:

• Stereolithography (SLA)

• Fused Filament Fabrication (FFF)/Fused Deposition Modeling (FDM)

• Selective Laser Sintering (SLS) including Direct Metal Laser Sintering (DMLS)

• Polyjet

3D CAD Model is Necessary for…

3D Printing, CNC, Laser Cutting

Drill Press

better control of angle, position, and depth of holes

Table Saw

precise ripping and cross cutting wood and plastic

Bandsaw (Vertical)

precise cutting of metal (including steel), plastic, and wood

Horizontal Bandsaw

cross cutting of mostly metal (including steel) and plastic (better options for wood).

Unlike to vertical band saw you, can cut arbitrarily long pieces.

Mill

precise machining of metal (including steel) and plastic using changeable tools

Grinder

Grinding of ferrous metals (steel), for example, sharpening a drill bit.

No Aluminum!!

Combination Sander

Sanding smooth materials like wood, plastic, and metals

Miter saw

great for quick precise cross-cutting of wood, plastic and nonferrous metals (like extruded aluminum (with an appropriate blade)

Cordless drill

great for less precise hole drilling

Rotary tool

grinding, sanding, buffing small parts, cutting small steel pieces (cutting off a rusting bolt for example)

Fused Filament Fabrication (FFF)/Fused Deposition Modeling (FDM)

Heated filament is extruded into fine bead and used to build up layers that fuse and cool

Most common low-cost desktop system for printing plastic

Low resolution and poor surface characteristics but can be functional (for light duty)

SLA (stereolithography)

A laser or projected light (digital light processing) is used to solidify selected areas on a layer of photosensitive polymer

High resolution and good surface characteristics

Polyjet

Inkjet deposited photopolymers are solidified with UV light

Good resolution and surface finish

Good material selection

Selective Laser Sintering (SLS) including Direct Metal Laser Sintering (DMLS)

Heat (usually laser generated) is used to sinter selected volumes in the part

Potentially high resolution and mechanically robust and functional prototypes

SLA

Layer by layer

Smaller scale products

High resolution (Thinner layers)

FFF/FDM

Layer by layer

Larger scale products

Low resolution (Thicker layers)

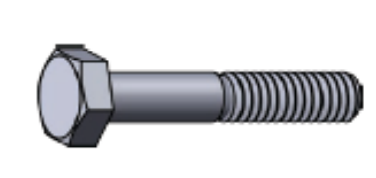

hext bolt

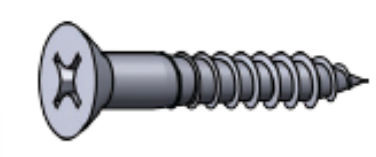

wood screw

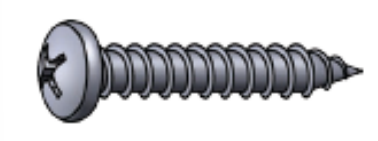

sheet metal screw

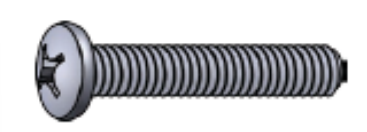

machine screw

socket screw

lag bolts

carriage bolt

zinc plated steel

low carbon, general use indoors/dry

hot-dipped galvanized steel

thicker zinc coating, outdoor use

stainless steel

good corrosion, but more expensive

phillips and slotted drives

combo drive

hex head

pan head

flat head

round head

oval head

truss head

socket head

button head

biotolerant

accepted by the body but not actively incorporated, resulting in the formation of a fibrous tissue capsule around them

bioinert

materials that, when placed into the human body, cause minimal or no immune response, toxicity, or interaction with surrounding tissues

bioactive

substances engineered to trigger specific, positive biological responses

M>6< × 1.0 × 10mm (Metric)

diameter (mm)

M6 × >1.0< × 10mm (Metric)

distance between threads (mm)

M6 × 1.0 × >10mm< (Metric)

length (mm)

>#4< - 40 × 1in (english)

diameter # (bigger number = bigger diameter)

#4 - >40< × 1in (english)

thread count (TPI)

#4 - 40 × >1in< (english)

length (in)

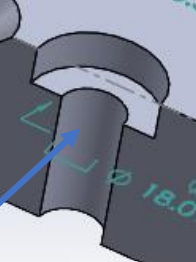

through hole

counter-sunk hole thru

counter bored hole thru

tapped hole thru

counter drilled hole thru

blind hole

>Ø< 500 ↧ 1.000

diameter

Ø >500< ↧ 1.000

diameter value

Ø.500 >↧< 1.000

depth symbol

Ø.500 ↧ >1.000<

depth value

Ø.500 x 82°

Ø [Countersink Diameter] x [Countersink Angle]

⌴ Ø.500 ↧ .313

⌴ Ø [Counterbore Diameter] ↧ [Counterbore Depth]

1/4-20 UNC - 2B ↧ .500

[Thread Size] - [Pitch] [Class] [Depth Symbol] [Thread Depth]