BTECH LEGIT ATA PT 2

1/34

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

35 Terms

1. Light Wood Framing

2. Heavy Wood Framing of Beam and Girder Framing

What are the two types of Wood Framing?

Balloon Frame

- the lightest form of framing, studding and corner posts are set up in continuous lengths from first floor line or sill to roof plate

- this type of frame is lacking in rigidity and is liable to sway and tremble in heavy winds

Combination Frame

- A modification of the old braces frame which was of heavy timbers with every joist mortised and tenoned

- consists of lighter timbers and less mortising and pinning to save material and labor

Girts

these are framed into the corner posts at the second story level joists as well as to brace the whole frame

Drop Girts

Girts that support the floor joist

Raised or Flush Girts

Girts that are parallel to the joists

T

T or F

Combination Frame construction is more rigid than the balloon frame.

Platform Frame

- A system of framing for a building of wood construction several stories high, in which the studs are only one story high

- Also called Western Framing

Heavy Wood Framing of Beam and Girder Framing

This is the type of framing used in the Philippines in which the floor joists are carried by girders, and the roof trusses or rafters by girts which frame into the posts. Studs rest on floor sills and extend up the girder or girt in every floor.

Plain Joint (Lap Joint)

Type of Wood Joint

A type of wood joint used very hasty construction for temporary framing and is made by lapping one piece over the other and nailing them together. It is not a very strong joint

Butt or Square Joint (End Joint)

Type of Wood Joint

A type of wood joint used in placing full thickness of wood directly against the second piece. The end should be squared and the sides against which it butts smooth so that the pieces will be perpendicular to each other. The joint is toe-nailed.

Oblique Joint

Type of Wood Joint

This type of joint is made when the two pieces do not meet at right angles, e.g. bracings. One piece is cut at an angle to fit the other and the two pieces nailed securely together.

Spliced or Scabbed Joint

Type of Wood Joint

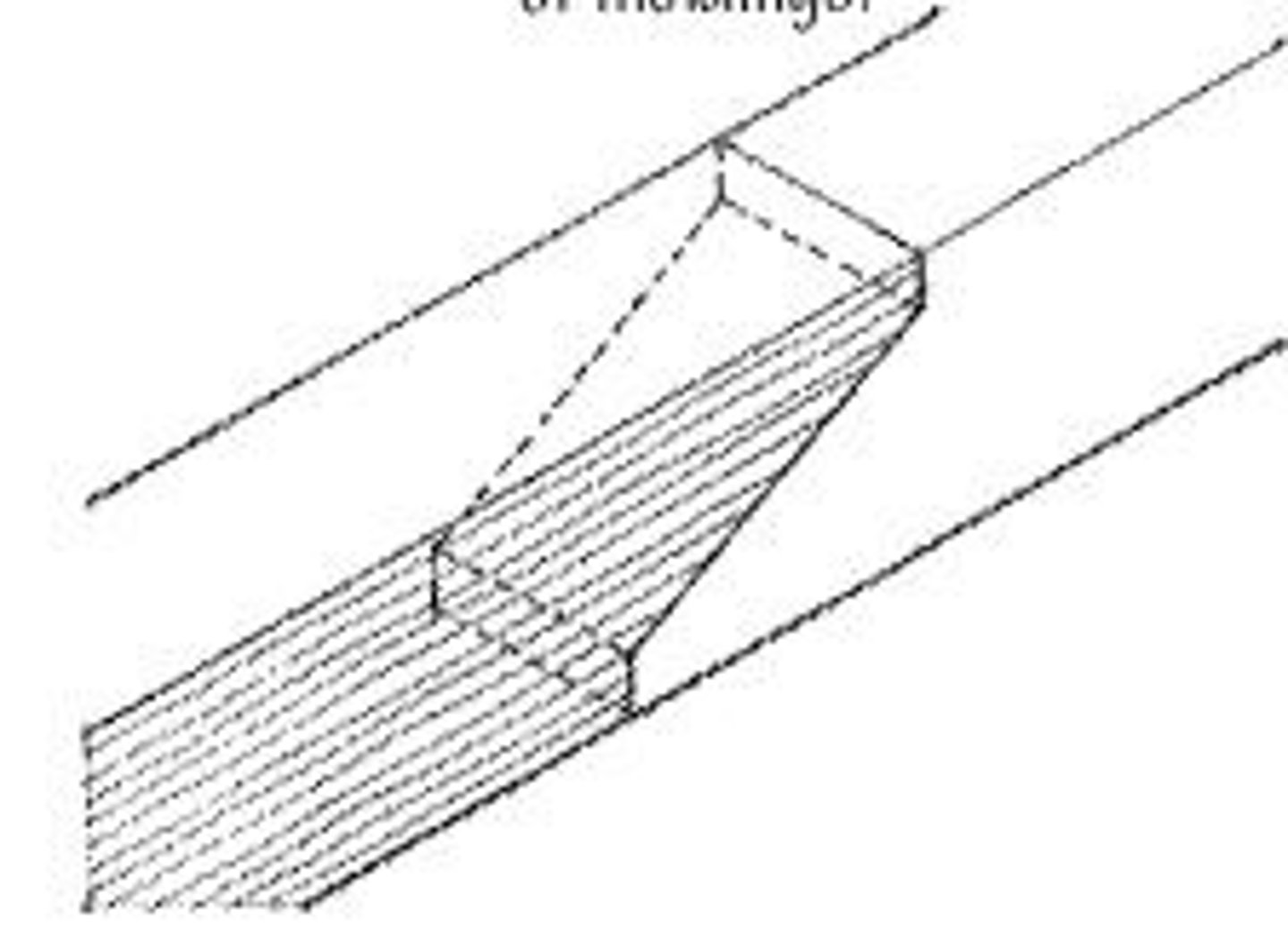

Scarf Joint

Type of Wood Joint

A joint by which the ends of two pieces of timber are united to form a continuous piece; the mating surface may be beveled, chamfered, notched, etc. before bolting, gluing, welding etc.

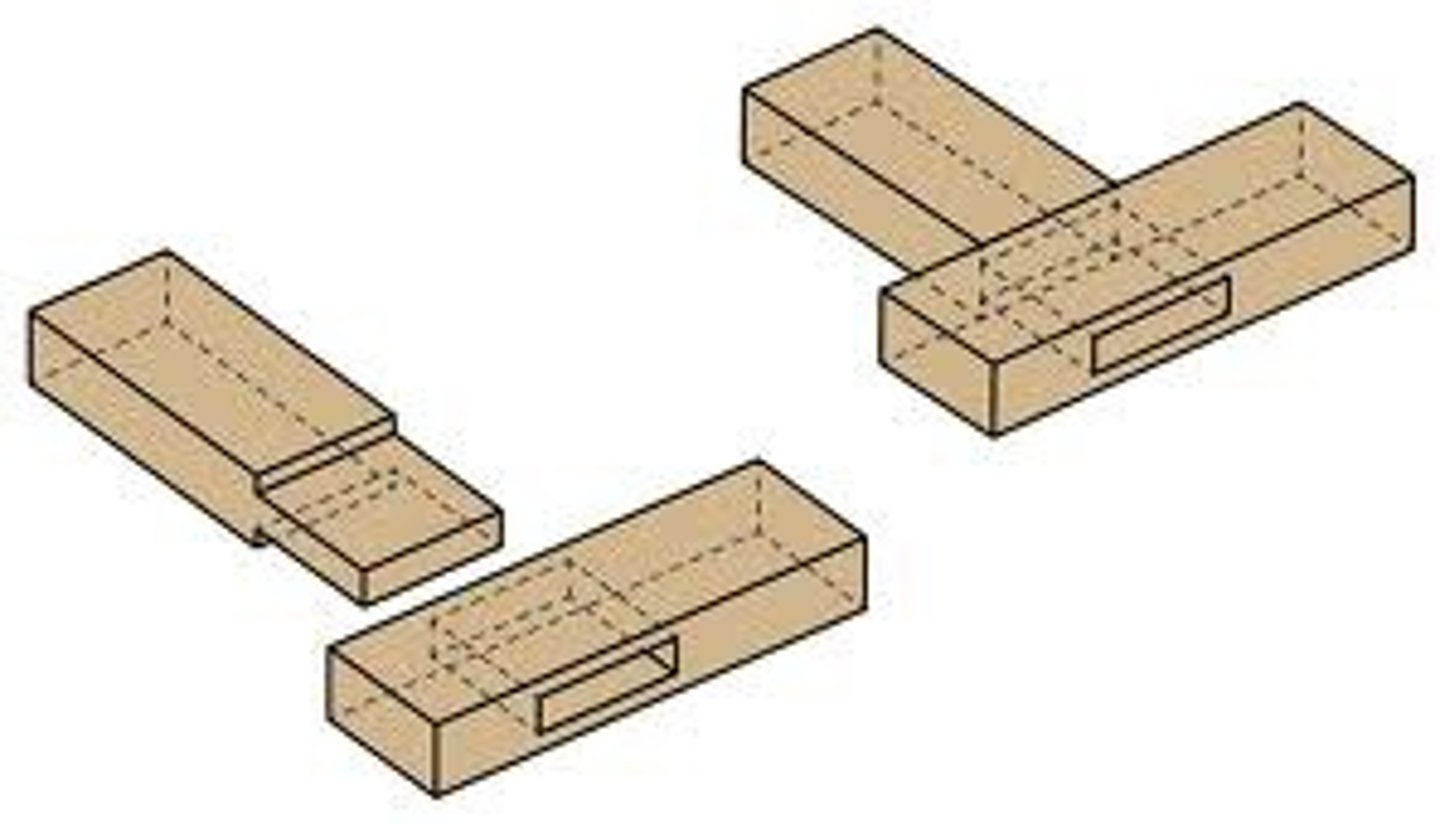

Mortise and Tenon Joint

Type of Wood Joint

This type of joint is used for building wooden framework where great strength and rigidity are all important. It is made by cutting a hole or mortise in one piece and a tenon or tongue in the second piece to fit the hole in the other. The tenon may extend fully through the other piece or only part of the way.

Halved Joint

Type of Wood Joint

this joint is made by cutting half the thickness of the wood from each piece at the ends to be joined so as to bring the sides flush. the purpose of this type of joint is to maintain a level surface at the joint

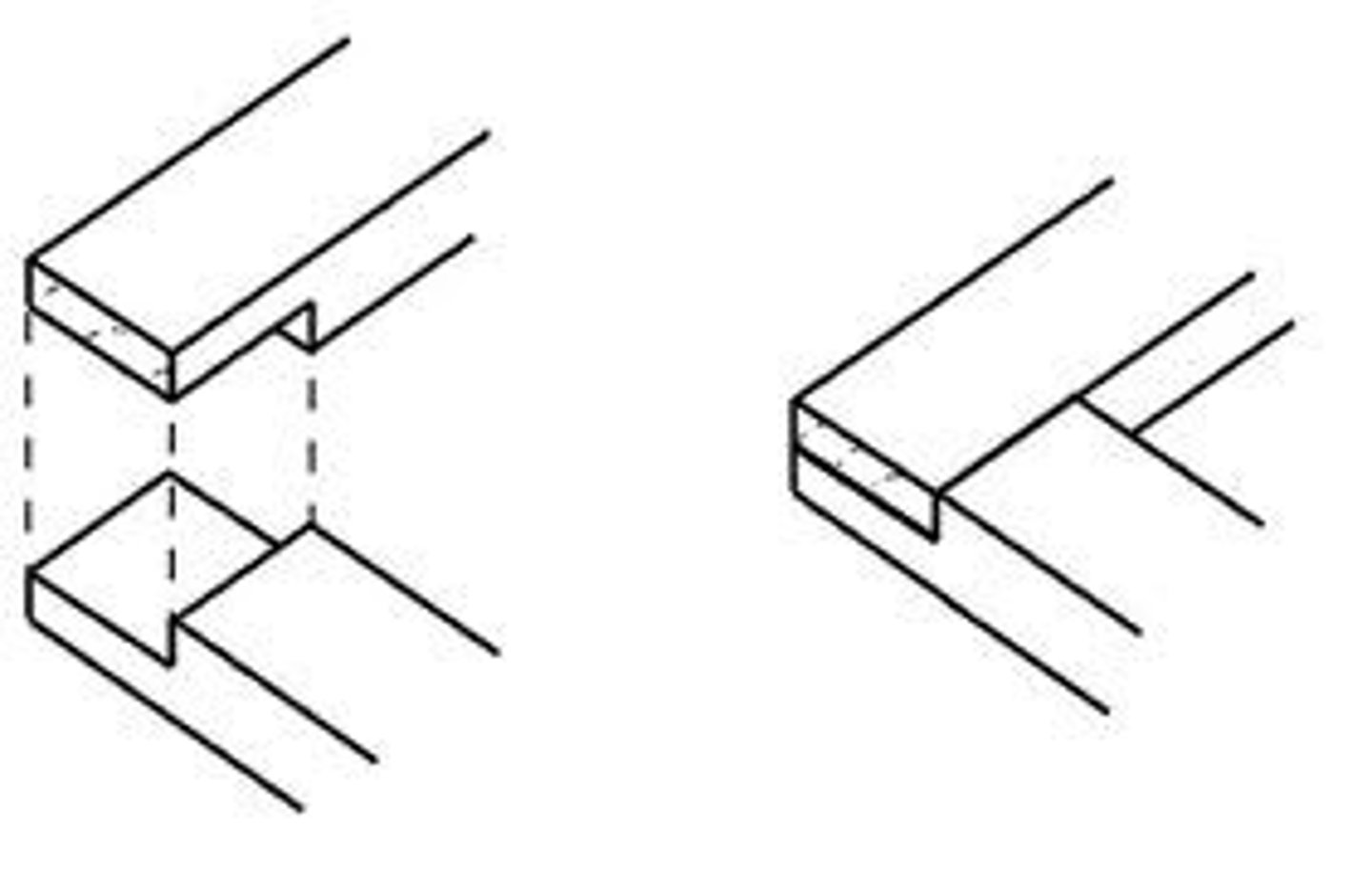

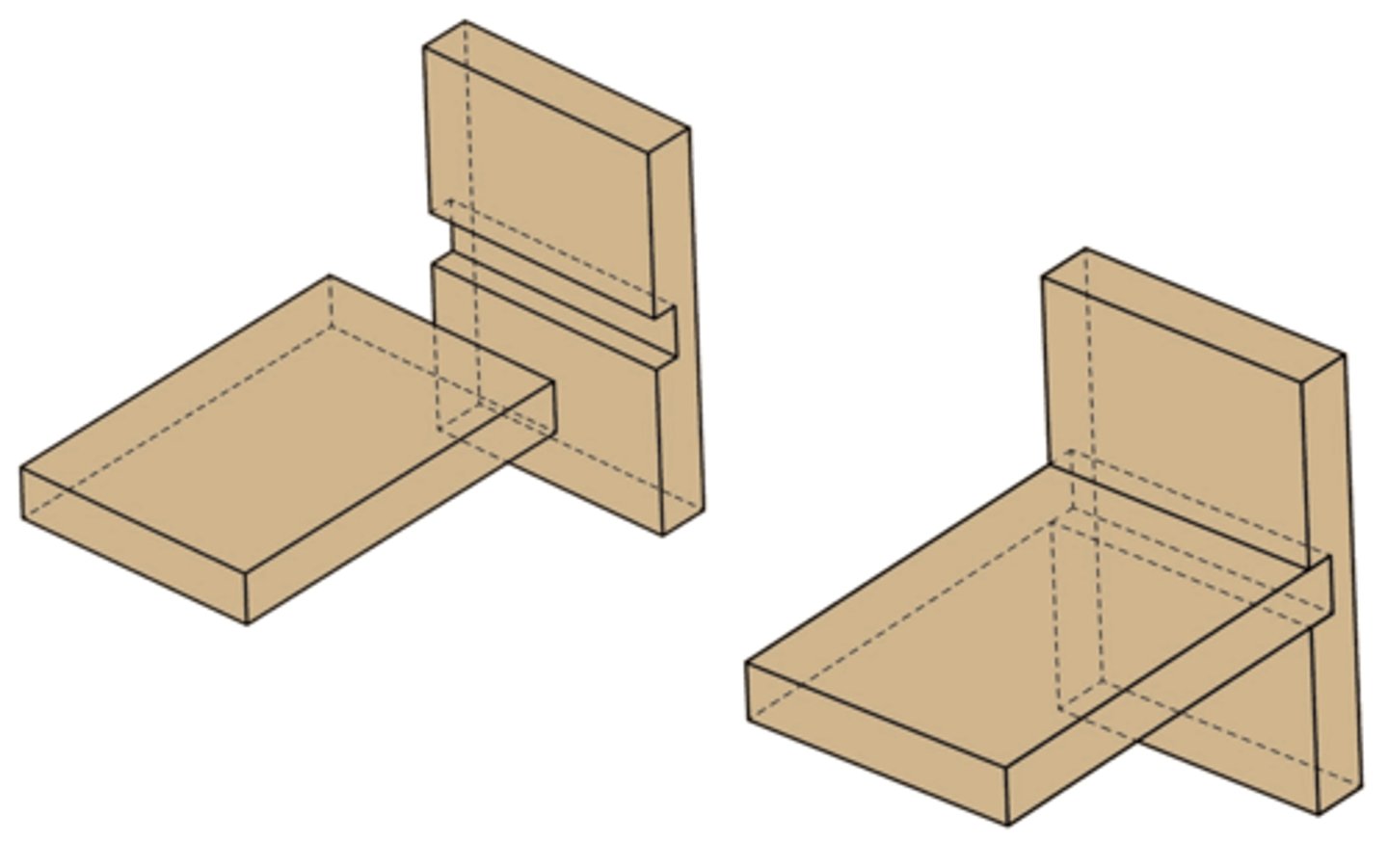

Rabbet Joint

Type of Wood Joint

This joint is made by cutting a shoulder or edge from one piece to receive the other piece. It is used in window or door frames, or in shelf and drawer construction.

Dado Joint

Type of Wood Joint

This is similar in shape and purpose of the rabbet joint. A groove is made in one piece at right angles to the grain of the other board.

Miter Joint

Type of Wood Joint

is a joint between 2 pieces which come together at a corner. it is a finish joint and should not be used where strength is an important requirement. it is made by cutting the 2 ends at angles complementary to each other, usually 45 degrees, and then butting them together. the joint is secured by clamp nails or finishing nails, corrugated fasteners or dowels, or by gluing.

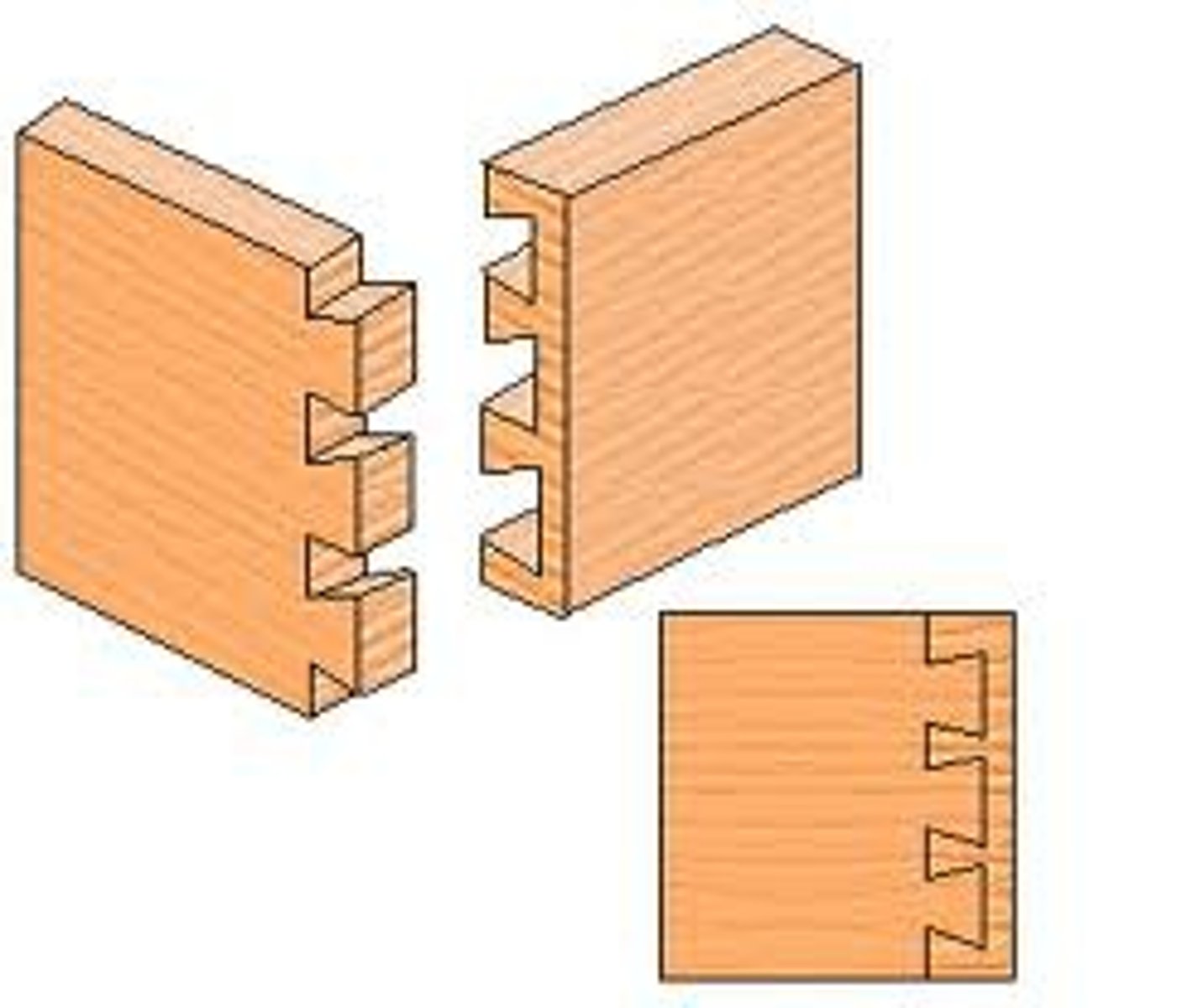

Dovetail Joint

Type of Wood Joint

This type of joint, used for cabinet work and furniture work, is strong and durable. It is made by cutting a pin in the shape of a dovetail in one piece to fit a groove similarly shaped in the other piece.

Coped Joint

Type of Wood Joint

is used when fitting 1 piece of moulding at right angles to the second piece.

Tongue and Groove Joint

Type of Wood Joint

A joint formed by the insertion of the tongue of one member into the corresponding groove of another.

- Mortised Joint

- Housed Joint

- Bridled Joint

- Dovetailed Joint

What are the 4 common wood joints for furniture?

splice

The function of a ____ is to connect two or more pieces of timber in such a way that the joint will be as strong as a single timber of equivalent size.

- compression

- tension

- bending

What are the 3 types of splices?

1. Scabbed or Fished Splice

2. Halved Splice

What are the 2 splices for compression?

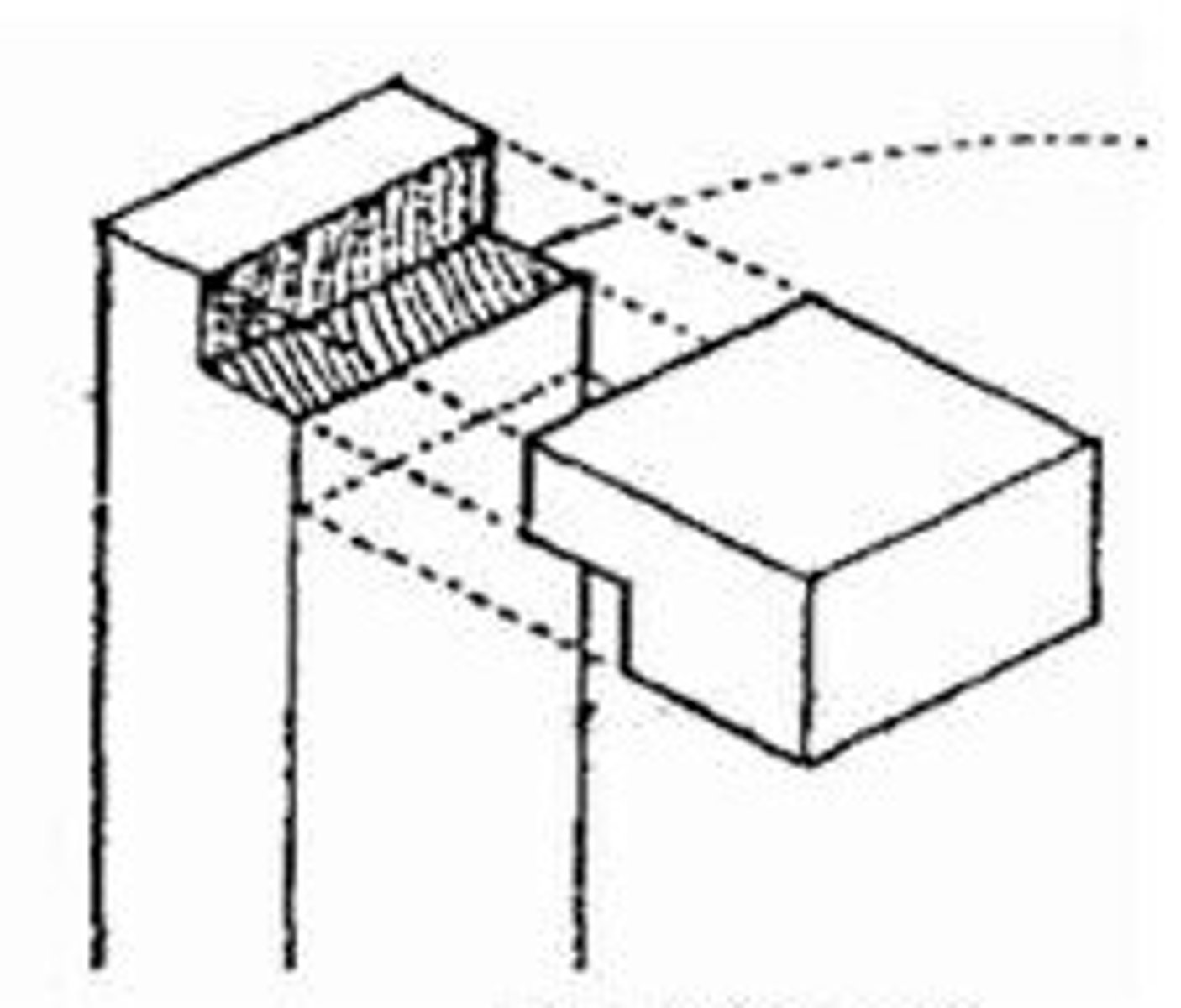

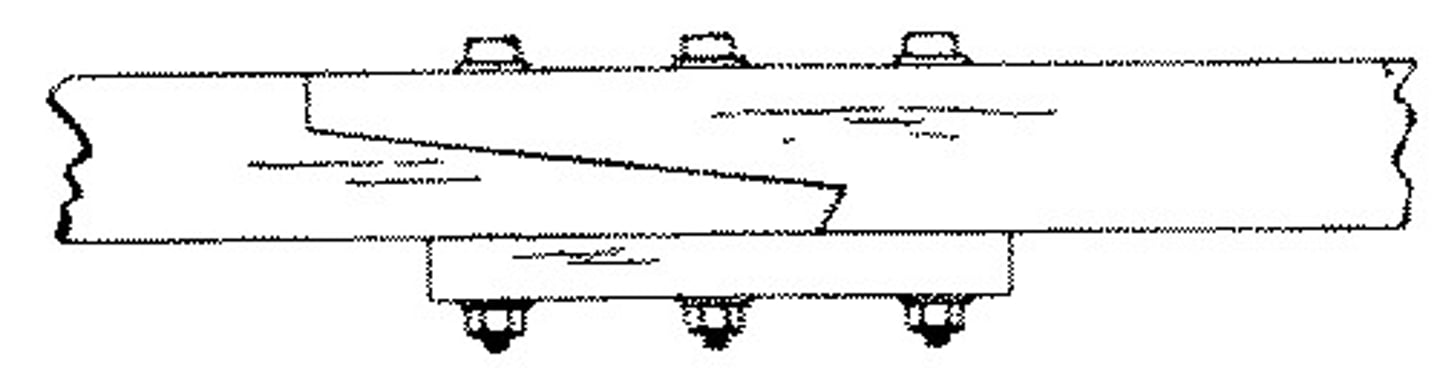

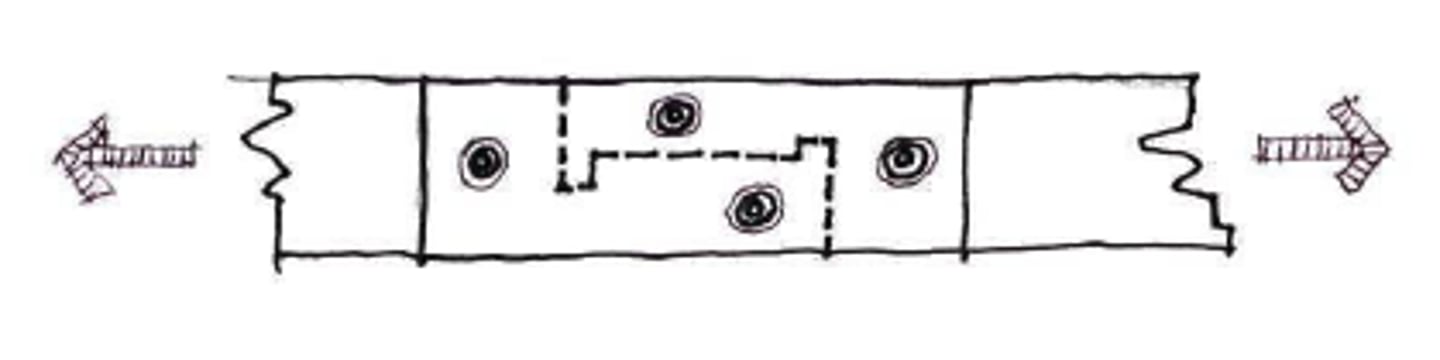

Scabbed or Fished Splice

SPLICE

Two pieces of timber are squared at their ends and fitted together. Two short wood pieces called scabs or metal plates called fishplates are fastened on either side of the pieces to be joined

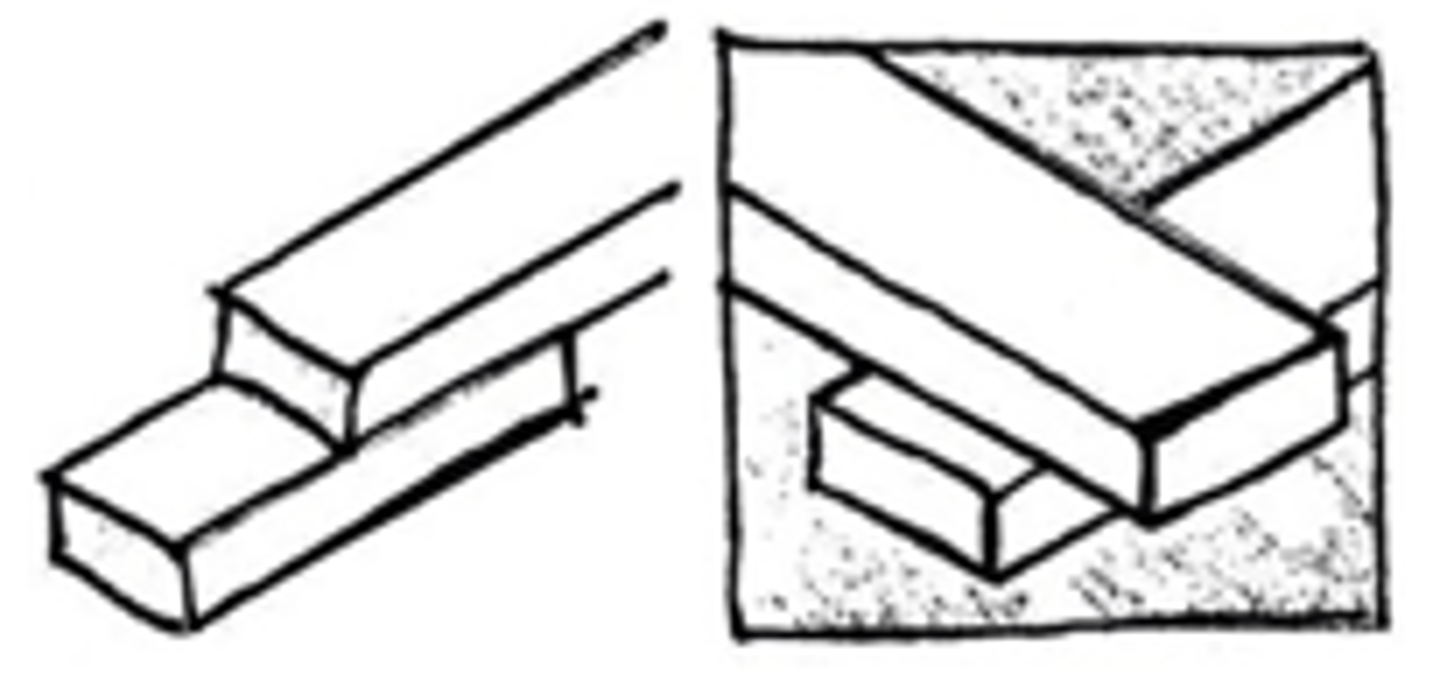

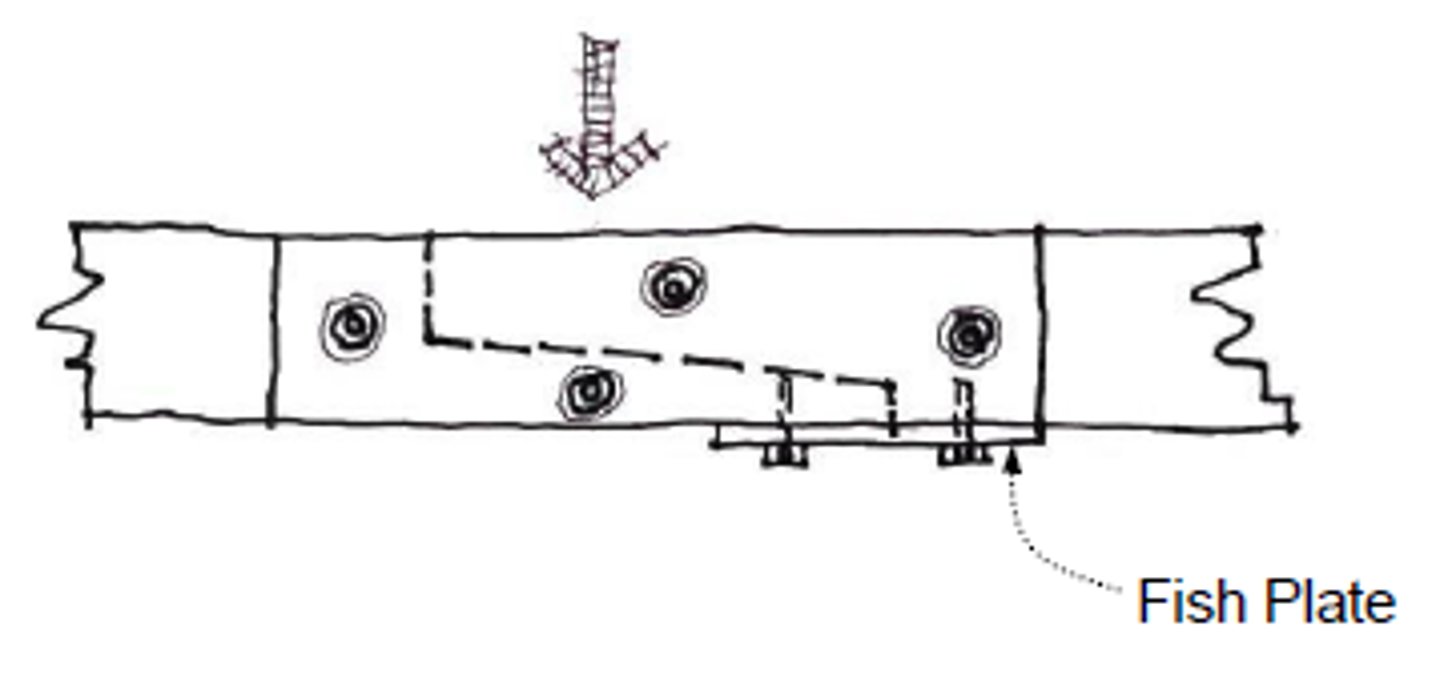

Halved Splice

SPLICE

This splice is better for direct compression, and when combined with scabs or fishplates, may be used where there is some tension. This splice is made by cutting half the thickness of each piece to the required length and putting the halved sections together.

Square Splice

SPLICE

This is a modification of the compression halved splice. It has an extra notch to keep it from slipping and is usually used in combination with scabs or fishplates. A splice for tension.

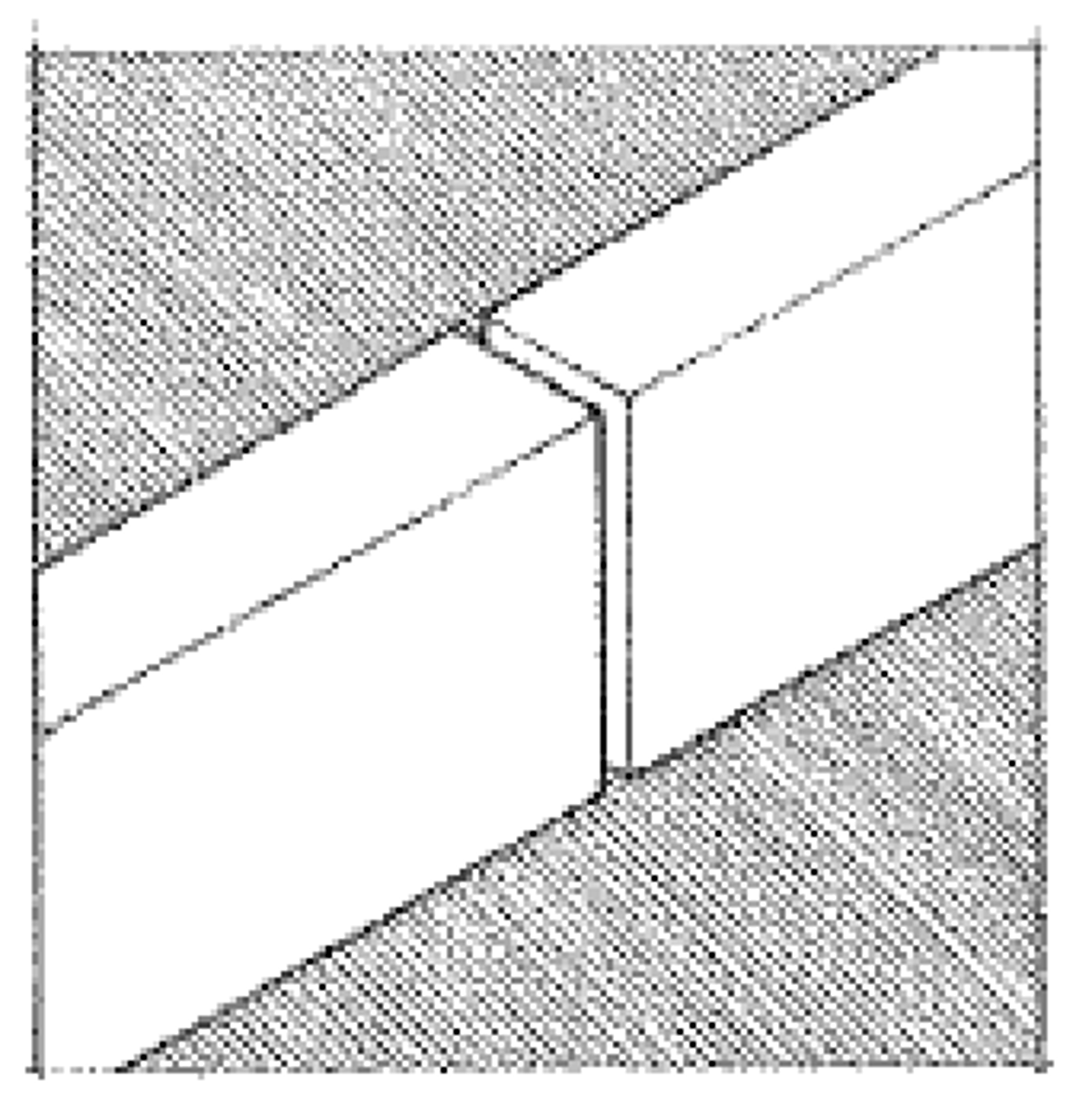

Scarfed Splice

SPLICE

When a piece of timber is subjected to bending as in a horizontal piece supporting a weight, the upper part is subjected to compression while the lower half is under tension. Combine the features of the tension and compression splice. A splice for bending.

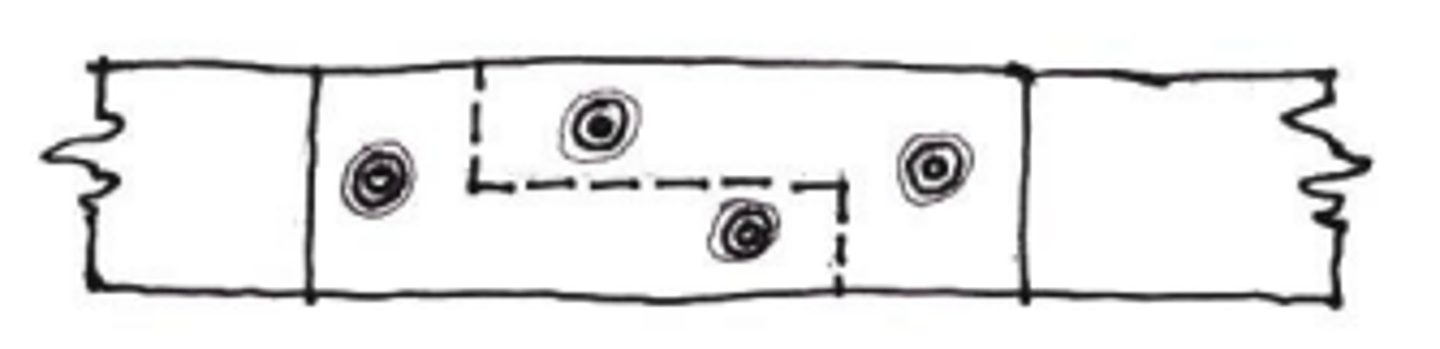

Timber connectors

Are metal devices used to provide added strength at bolted joints. They eliminate complicated framing of joints; simplify the design of heavy construction, and save much time and labor

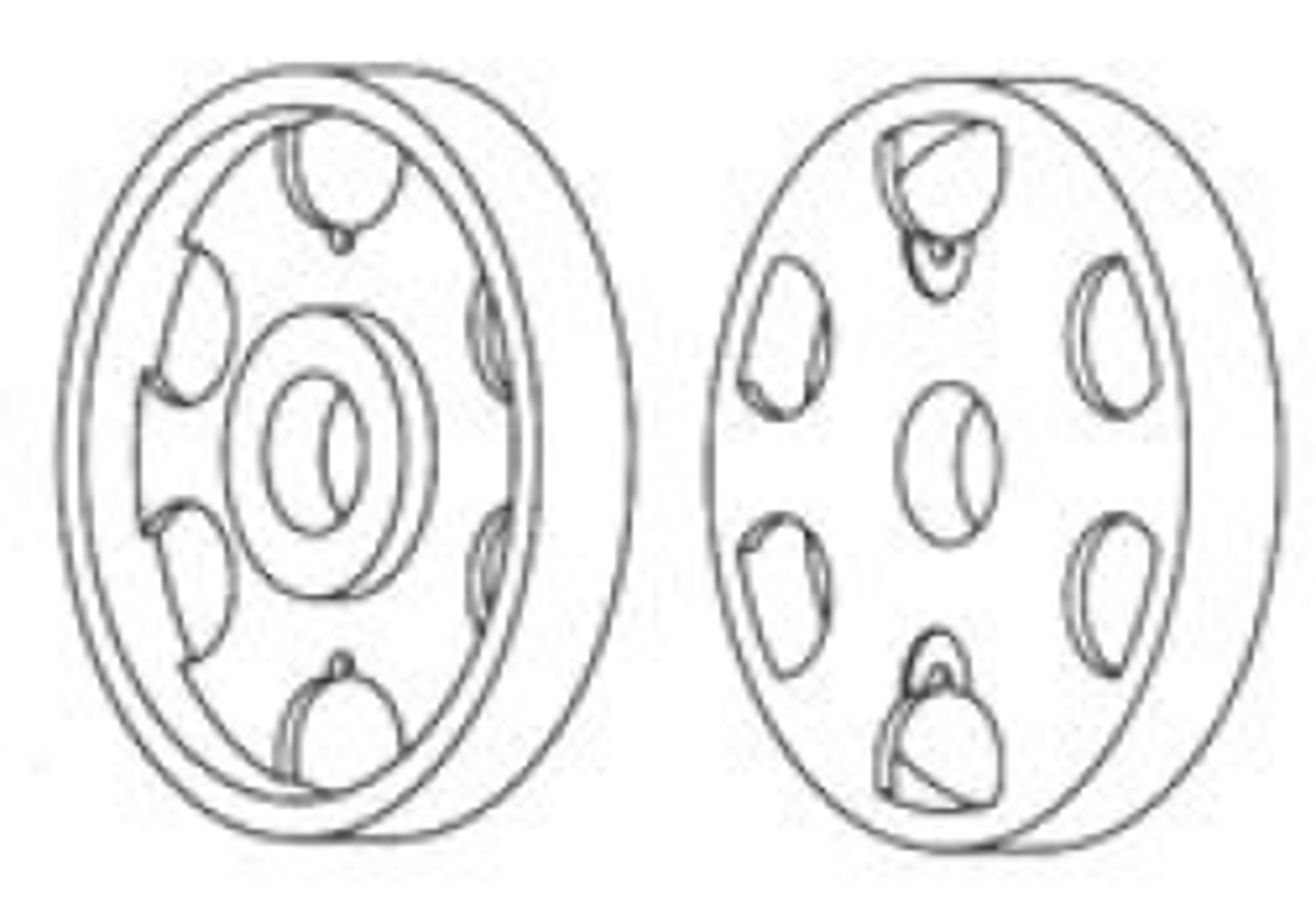

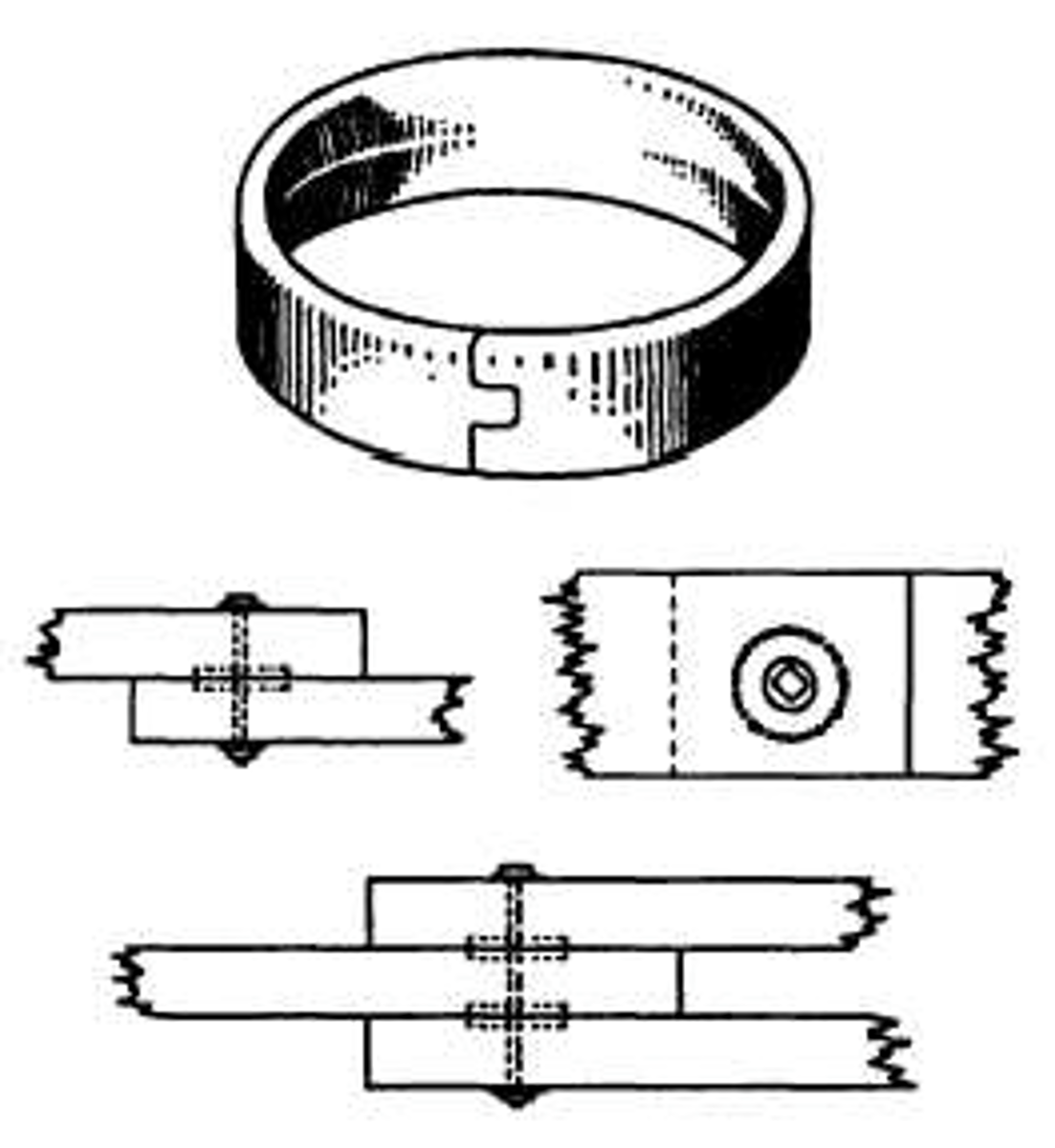

Split Rings

Timber Connector

These are made in sizes of 2-1/2, 4 and 6 in. in diameter. They used for heavy construction.

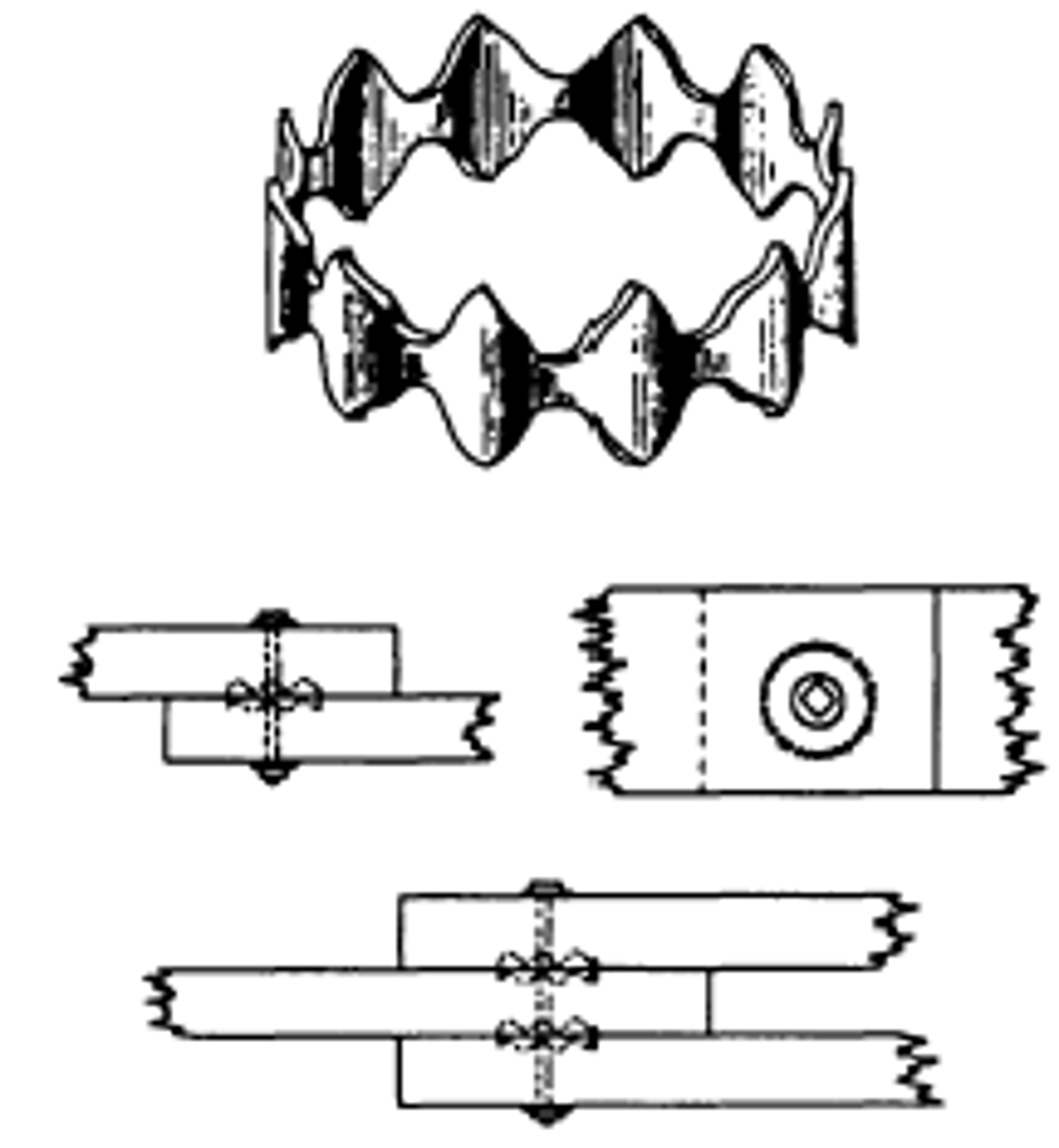

Toothed Rings

Timber Connector

These are toothed and corrugated. They are made in 2, 2-5/8, and 4 4 in. dia. They are used between two timber frames for comparatively light construction.

Claw Plates

Timber Connector

One side is clawed and other smooth and they are used either singly, in timber to metal connections, or in pairs in timber to timber connections.

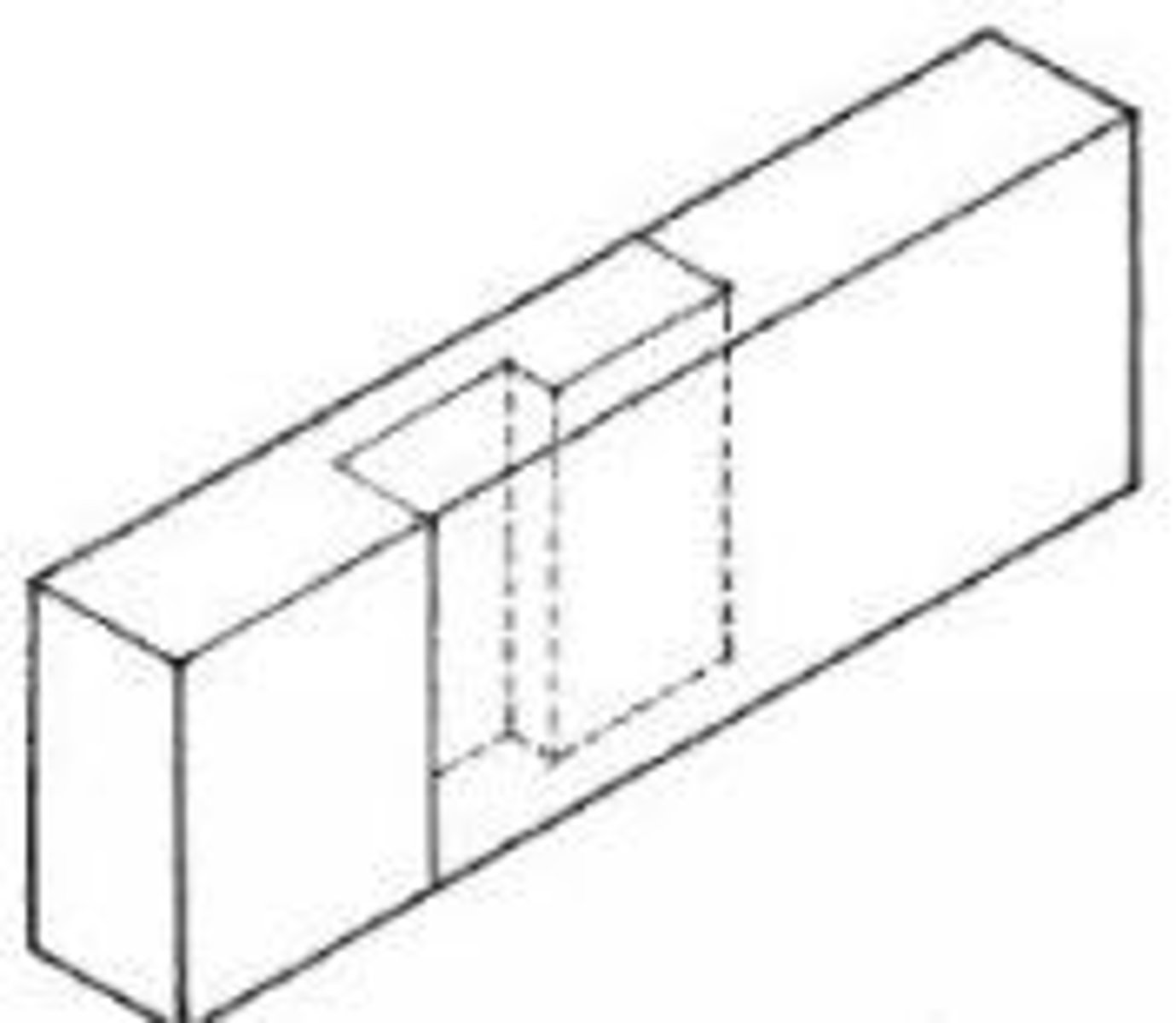

Shear Plates

Timber Connector

When installed these lie flush with the timber surface. They are used singly or in pairs. In timber to metal connections the plate is placed with its back towards the metal.