Fundamentals of Operations Management and Process Design

1/96

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

97 Terms

Operations management

The design, control, and coordination of resources and processes to provide customer and stakeholder value.

Input-transformation-output model

A framework that describes how input resources are transformed into outputs through processes.

Transformed resources

Input resources which undergo change in the process.

Transforming resources

Resources used to transform input resources.

Input-transformation-output model application to a coffee shop

A practical example of the input-transformation-output model in a coffee shop setting.

Inputs/transformed resources in a coffee shop

Coffee beans, Milk, Sugar, Customers.

Transforming resources in a coffee shop

Coffee machines, Personnel.

Outputs in a coffee shop

Prepared coffee, Satisfied customers, MONEEEEEEEEEEEEEY.

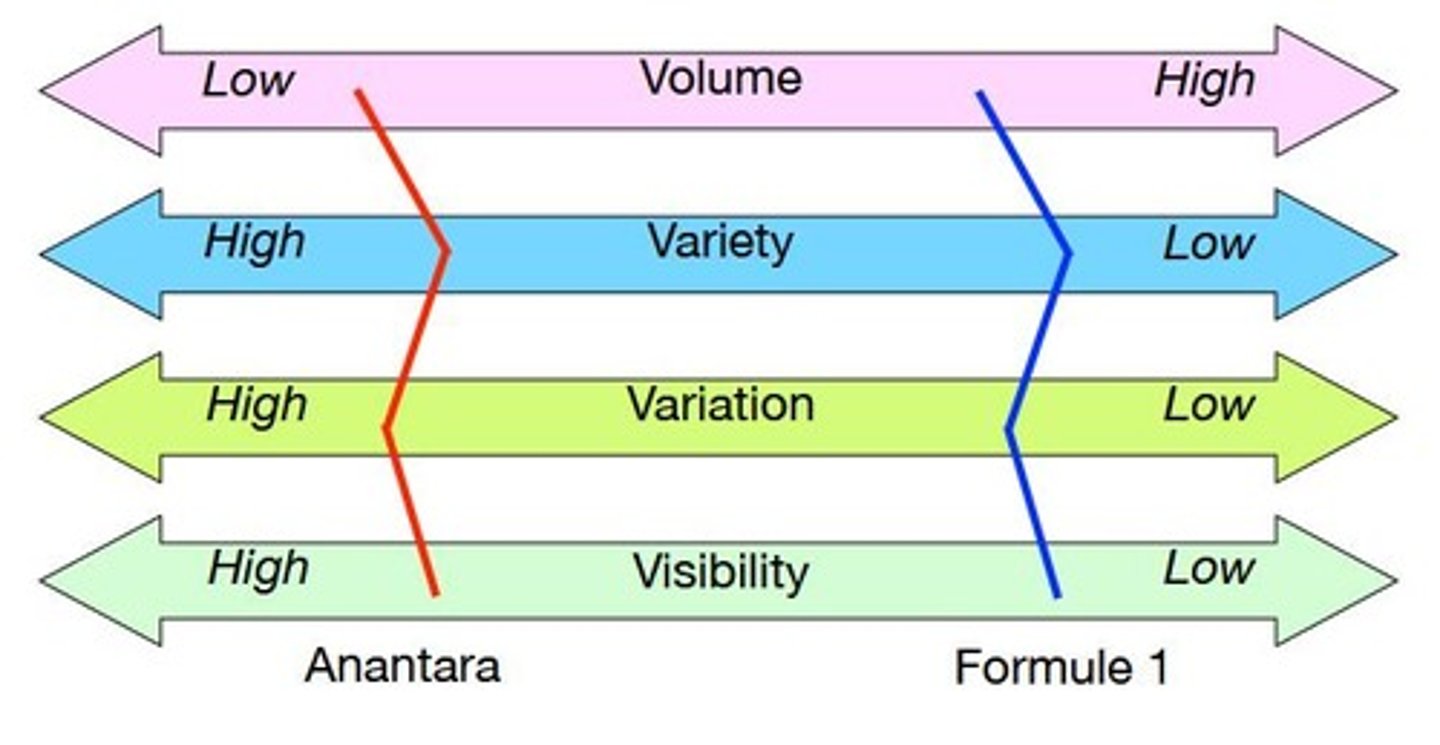

Operation characteristics (four V's)

Volume of output, Variety of output, Variation in demand for output, Visibility of creation of output to customers.

Volume of output

How much output is created through the process.

Variety of output

How varied are the outputs of a process.

Variation in demand for output

How elastic or conditions-related is demand.

Visibility of creation of output to customers

How visible the process of creating output is to customers.

Dabbawallas

A successful food delivery system in Mumbai that aligns operations with the local culture and environment.

Four V-profile

A model that outlines the volume, variety, variation, and visibility of operations.

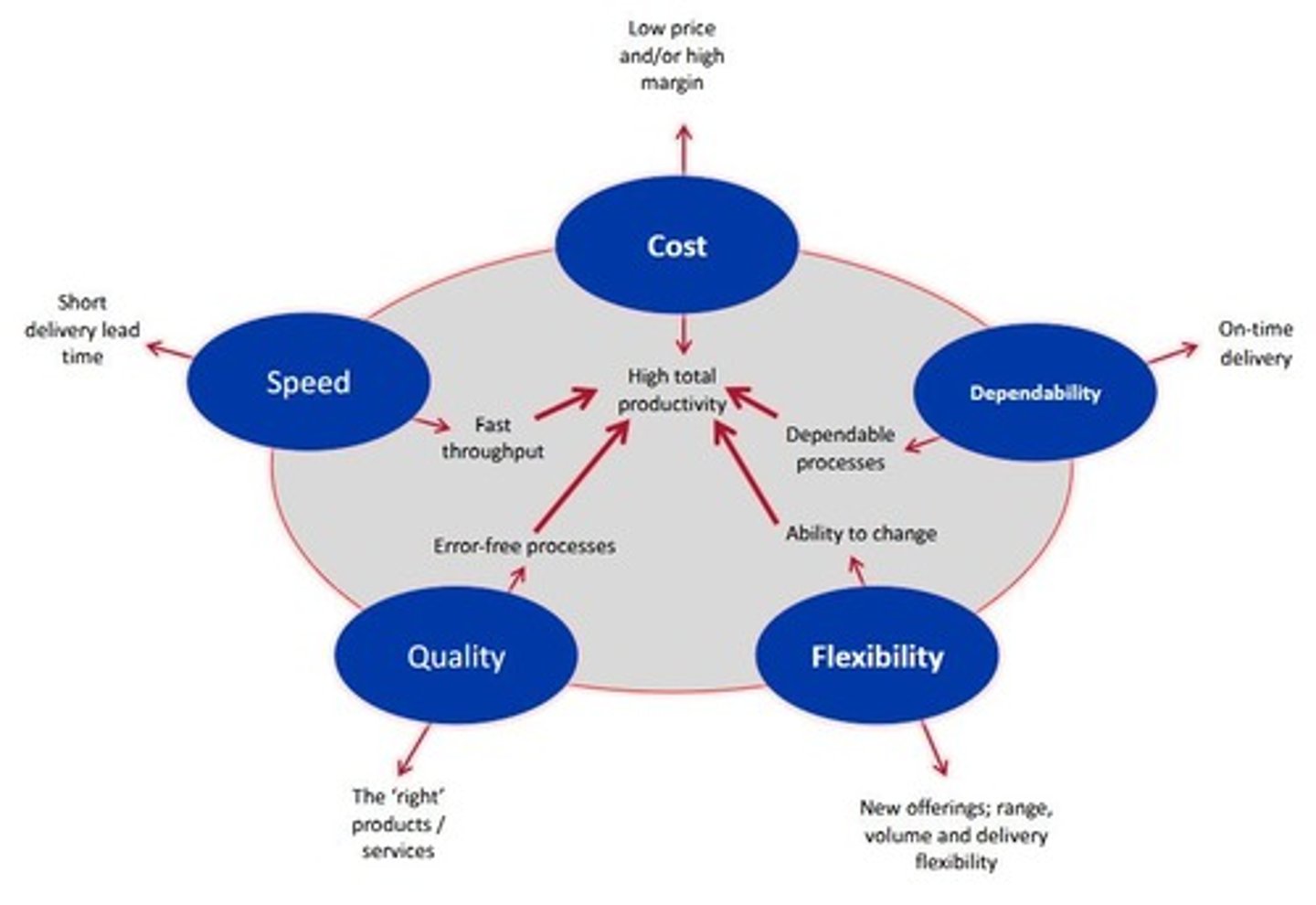

Performance objectives of operations

Five objectives: quality of output, cost reduction, increased dependability, improved customer satisfaction, and speed of production and delivery.

Quality of output

The degree to which the output meets the required standards and specifications.

Cost reduction

The process of minimizing expenses to improve profitability.

Increased dependability

The ability to deliver products or services consistently and reliably.

Improved customer satisfaction

Enhancing the experience and fulfillment of customer needs.

Speed of production and delivery

The rate at which products are produced and delivered to customers.

Flexibility of operations

The capability to adapt to changes in customer demand and operational conditions.

Cost of production

The total expenses incurred in the manufacturing of a product.

Types of quality

Includes conformance to basic requirements and specification which adds custom value.

Types of flexibility

Includes product/service flexibility, mix of products and services, volume flexibility, and delivery flexibility.

Polar diagram of performance objectives

A visual representation showing internal and external traits of performance objectives.

Case study - Concept Design Services

An analysis of a design firm facing challenges and advantages in operations.

Challenges in Concept Design Services

Issues include subcontracting difficulties, communication gaps, and unpredictable sales forecasts.

Advice for CDS

Recommendations include hiring consultants, improving communication, and better sales forecasting.

Process design

The planning and organization of processes to achieve specific operational goals.

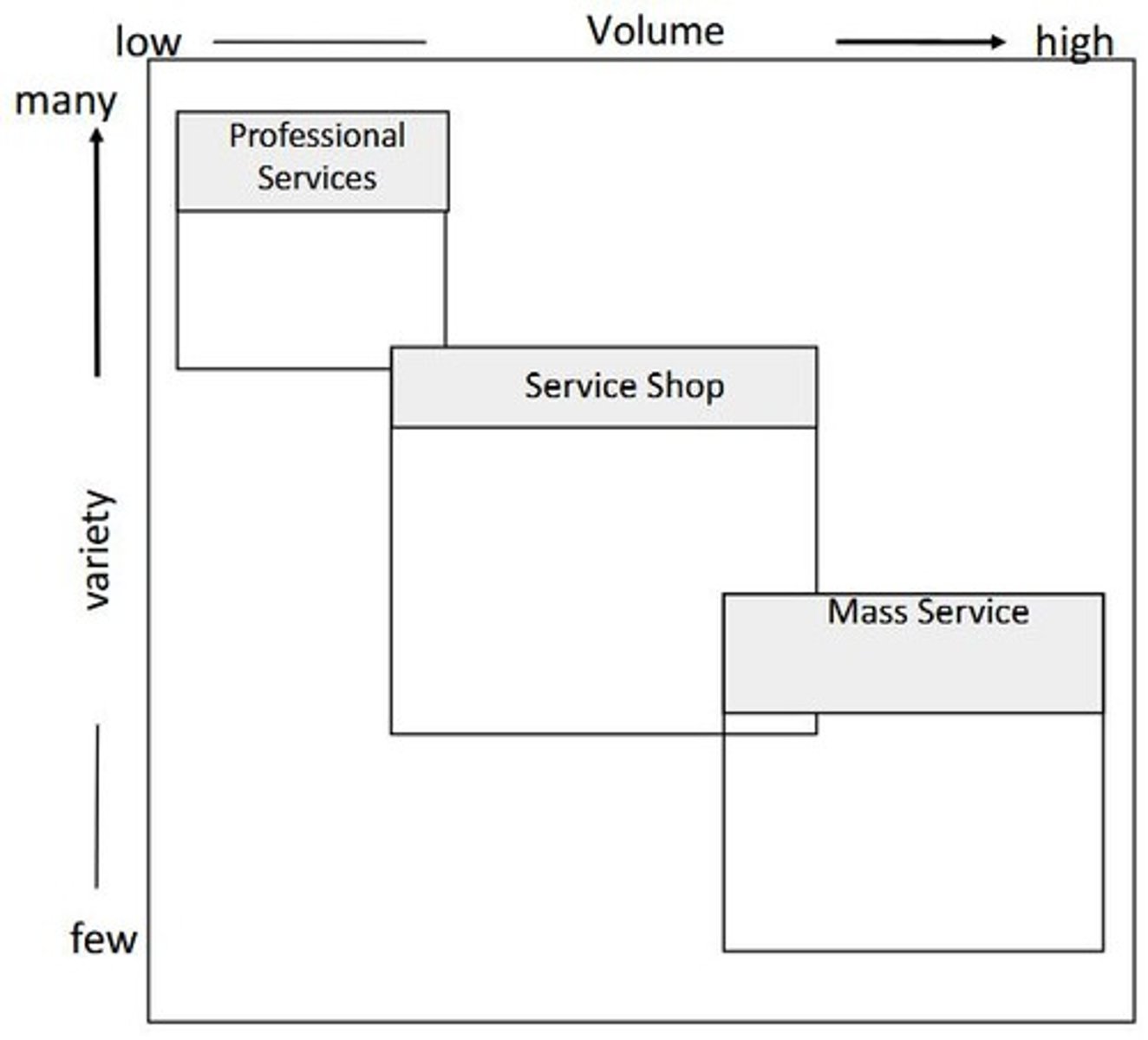

Process types

Includes project, jobbing, batch, mass, and continuous processes.

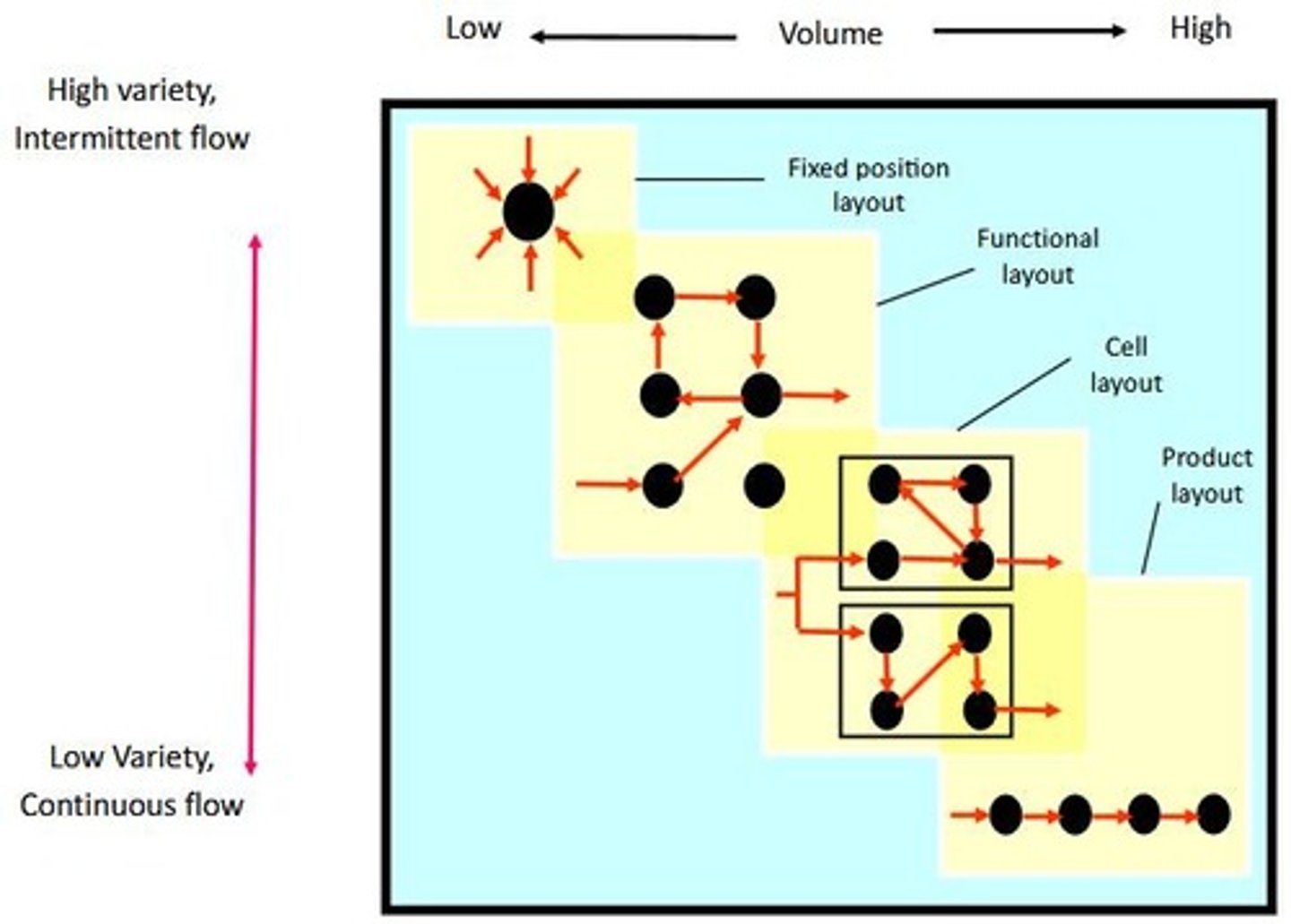

Layout types

Includes fixed position, functional, cell, and product layouts.

Line Balancing

The assignment of tasks to resources to optimize workflow and minimize idle time.

Case study - North West Bank

An examination of the consolidation of departments and the resulting operational challenges.

Organizational coherence

The alignment of teams and processes to create a unified operational strategy.

Process mapping

The visualization of processes to identify steps and improve efficiency.

Throughput time

The total time an item spends in the system from entry to exit.

Cycle time

The average time taken to complete a single cycle of a process.

Sales forecast

An estimate of future sales, crucial for planning and inventory management.

Market intelligence

The process of gathering and analyzing information about market trends and customer preferences.

Investment in operations

The allocation of resources to improve various operational objectives.

Specialist recruitment

Hiring individuals with specific skills and expertise for particular roles.

Generalist recruitment

Hiring individuals with a broad range of skills applicable to various roles.

Work-in-progress

Number of items within the process at any given time

Throughput efficiency

Work content / Throughput Time (x 100)

Little's Law

Throughput time = WIP x Cycle time

Work-in-progress (WIP)

Number of units waiting to be processed further

Number of transforming resources

Work content / Cycle Time

Inventories

Accumulations of transformed resources

Stock

Physical items

Ques

People

Databases

Information

Managing databases

More about organization of the data, its storage, security, and retrieval

Transforming resource

Information can often turn from a transformed resource into a transforming resource (e.g.: customer data being used to target ads for similar groups)

Buffer inventory

Can be used for unexpected fluctuations in demand, essentially protection against uncertainty

Cycle inventory

Countering lack of flexibility with demand-sufficient inventory of item A while production of item B takes up all product processes

Anticipation inventory

For large but mostly predictable demand fluctuations

Pipeline inventory

Inventory awaiting distribution or locked down from other customers by an order

Queues of customers

Enable prioritization (e.g.: hospital queues with separate emergency lines)

Efficient multi-level access to data

Use for databases

Inventory management

Affects return on assets

Obsolescence costs

With large orders, some items will inevitably sit in storage longer than others, potentially losing value

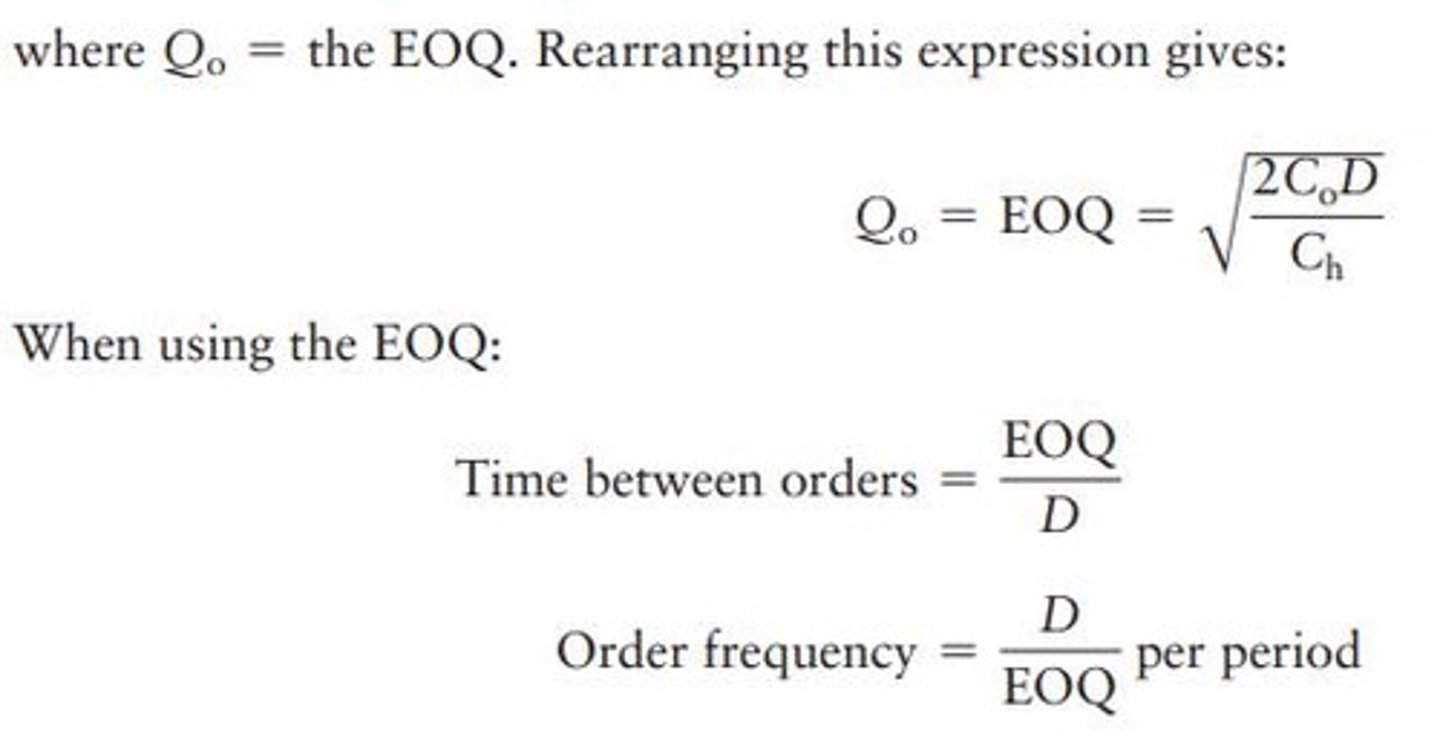

Economic Order Quantity (EOQ)

Formula for how much of a specific item to order

Q

Items ordered

D

Demand rate (units demanded per month)

Ch

Total cost of holding one unit in stock for a period of time

CO

Total cost of placing an order

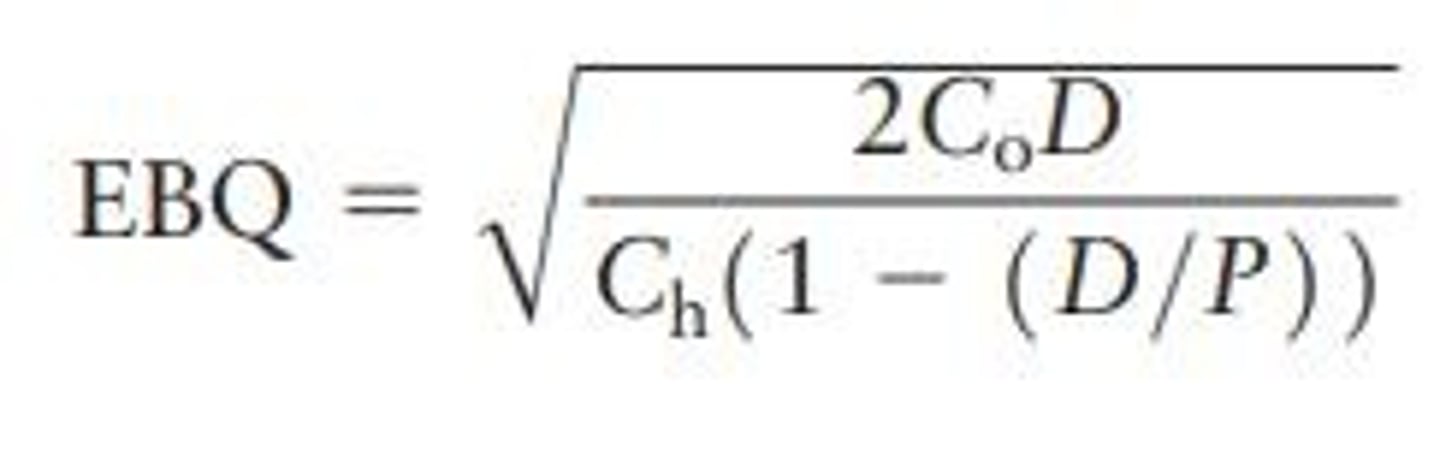

Economic Batch Quantity (EBQ)

Takes into account that even when produced in batches, items are added to and sold from the inventory continuously

P

Rate at which items are made and put into inventory

Lean philosophies

Argue for different methods to reduce costs

Order placement timing

When should the order be placed?

Lead time

The time between ordering a product and it arriving

Re-order point

Point at which stock will fall to zero minus the order lead time

Re-order level

The level of inventory when a replenishment order needs to be made

Safety / Buffer stock

The stock that is still in inventory the moment the replenishment order arrives

Lead-time usage

How many products are taken out of the inventory during order lead time (d1 and d2 in the picture)

Continuous review

Orders placed at re-order level and the order quantity is constant

Periodic review

Orders placed at regular intervals and at quantities that help reach a certain point every time

Maximum quantity Qm

Set higher to compensate for uncertain demand and lead time

Usage value

Usage rate X Individual value

Pareto law (or 80/20 law)

A relatively small proportion of the total range of items in an inventory will account for a large proportion of the total usage value

ABC Inventory control

Controlling stock according to the Pareto law

Class A items

The 20% of items that contribute 80% of usage value

Class B items

The next 30% of items that contribute 10% of usage value

Class C items

The last 50% of items that contribute 10% of usage value

Consequence of stock-out

One of the criteria for classifications of items

Uncertainty of supply

One of the criteria for classifications of items

High obsolescence or deterioration risk

One of the criteria for classifications of items

Cover of the stock

Calculate how long the inventory would last without replenishment

Perpetual inventory principle

The principle followed by computerized inventory management systems

Dependent demand

Dependent on other products or variables (e.g.: car tires in an automobile plant are dependent on cars)

Independent demand

Dependent on random factors that are very difficult to predict

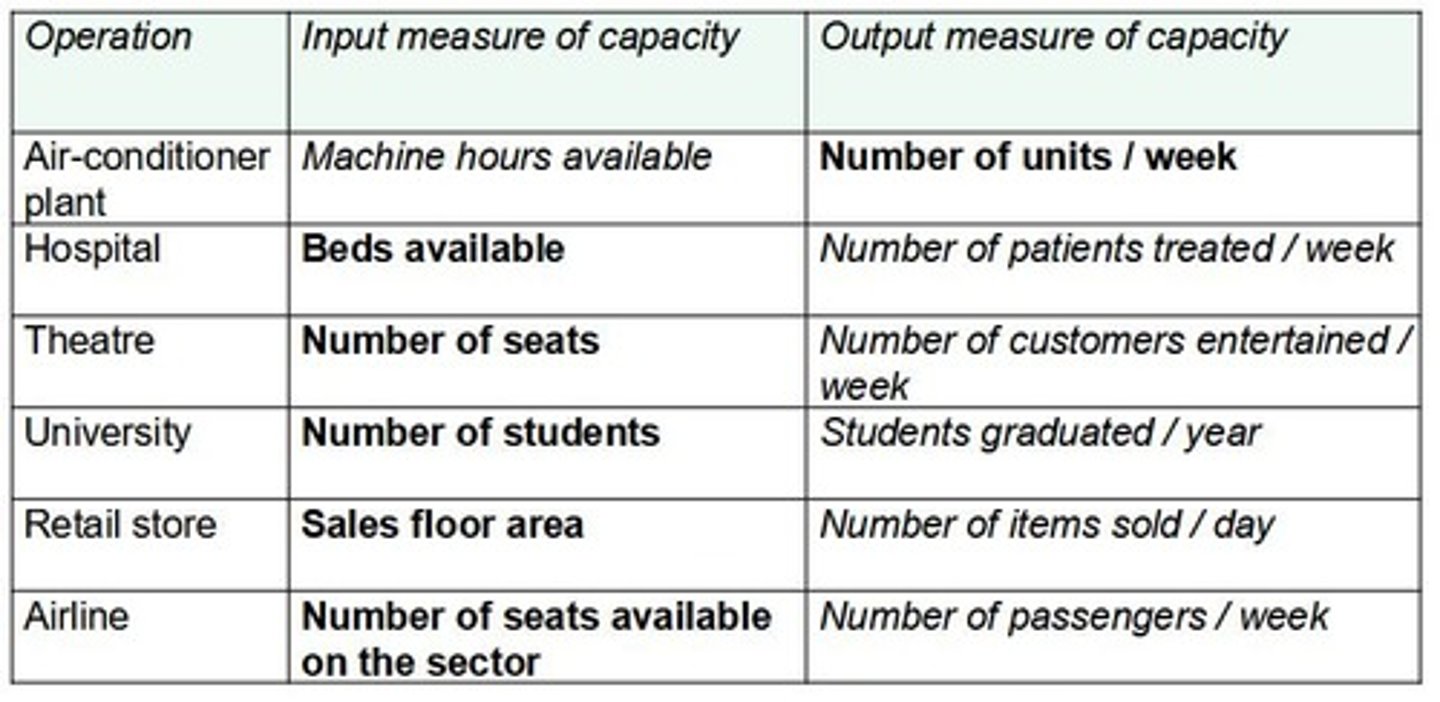

Capacity

Scale of an operation, not necessarily reflective of processing capability

Capacity management

The purpose is to determine an appropriate amount of capacity for an operation

Chase demand plan

Adapting to demand and trying to stay above it

Manage demand plan

Affecting demand with marketing efforts

Level capacity demand

Keep capacity at a constant level despite of demand (e.g.: luxury products or petrochemical [capacity hard to change])