process analysis and improve.

1/5

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

6 Terms

process chart

easy and fast to understand for comms and training purposes

can quickly see where improve. needed

symbols

rectangle

task or process

upside down triangle

queues where stuff is in waiting or storage

too much = issue

diamond

have multiple arrows

to show the multiple choices to pick from

arrows

connects one step to the next

can add other details

time

cost

ex.

multiple points where a patient is rejected

bring to the front of process

less labor and costs

process improvement

find where need to change

benchmarking

tinker or tear-down

need for change

warnings signs

leading = immediate effects

lagging = delayed effect

2 types

internal

leading

too many

delays

inv.

employee frustrations

idle staff/equip.

lagging

too much

OT

turnover

low KPI

external

leading

too many

complaints

return of product

bad media

lagging

lower

market shares

fnce perform.

benchmarking

compare org. to another

types

internal

best for org. w/ multiple locations

competitive

hard to get info

functional

order entry

service parts logistics

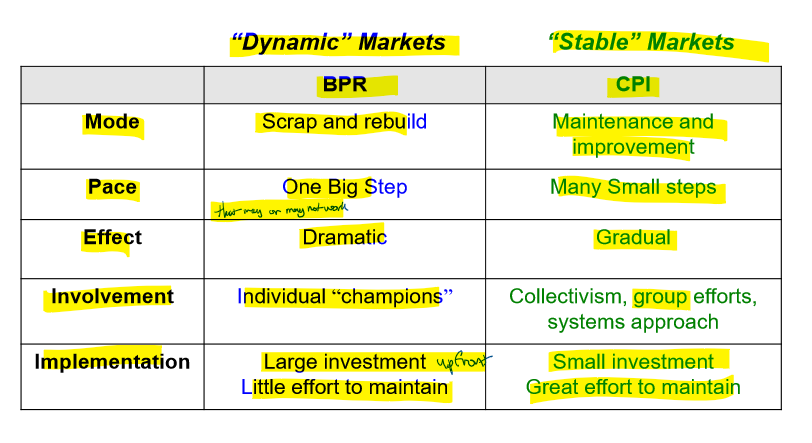

tinker v. tear-down

tinker = CPI (continuous process improvement)

never-ending process of small improvements

through employee involv.

teams that are trained to find and solve issues

need to be given time and ability to be creative that can be incorp. into business

tear-down = BPR (business process rengg.)

one time big improvement

scrapping and re-working

causes layoffs

occurs if not enough CPI

forced on you

discont. thinking

start from a clean sheet

need when

tech advanc. that a competitor adopts and sees drastic improve. as a result

customer now desires this thing

throuhg disruptive tech.

radically diff.

overtakes dominant tech.

usually performs badly at the start

ex.

telephone → cellphone

cd → spotify

just-in-time

lean production approach

lowers waste and betters quality

pull system

find issues and bottleneck to streamline production

only works if stable env. where production is linear and high volume

wont work for seasonal products

kanban

flow of material

worker only does their part when the bin ahead is empty

reduces excess inv. that can acc.