Paper Science Exam 2

1/94

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

95 Terms

Chemical Pulping

Liberate fibers by removing lignin in middle lamellae, remove lignin from cell wall

Chemical Pulping Objectives

Object is to remove residual lignin, and have a final brightening step to brighten what chromophores remain

Mechanical Pulping Objectives

Object is to brighten (subject to brightness reversion)

Chemical Pulping Benefits

high strength, more flexible, denser

Pulping Methods

Alkaline (Soda & Kraft), Acid (Sulfite), and Neutral Sulfite Semichemical

Delignification

Breaking down the chemical structure of lignin, making it soluble in water

Delignification Selectivity

Removing lignin without degrading hemicelluloses

Dissolving Pulp

Low yield (30-35%) bleached chemical pulp with high cellulose content (95%), cellulose is degraded and only alpha cellulose remains (which is insoluble in NaOH)

Kappa Number (K)

Measure of lignin content in pulp to monitor the amount of delignification, K = lignin % * 5

Pulp Viscosity

Measure of average chain length of cellulose in pulp (degree of polymerization DP, which is the # of glucose units in the chain)

Soda Process

Developed by Burgess & Watts in 1861, the approach used NaOH which degrades cellulose too much, but cold soda pulping is good for straw, grasses, and other non-woods because it dissolves the middle lamella

Kraft Process

NaOH + Na2S + H2O → 2NaOH + NaHS, hydrosulfide protects cellulose from hydrolysis (NaOH) by enhancing selectivity while slowing condensation (reformation) of lignin

Delignification of Kraft Process

Reduces lignin to about 3-5%

White Liquor

NaOH + Na2S (the reagents)

Black Liquor

waste liquor that contains reactants, extractives, lignin, and some hemicellulose

Green Liquor

Partially recovered liquor, mostly Na2CO3 and Na2S (react with Ca(OH)2 to recausticize)

Bleaching

Reduces lignin to less than 1%

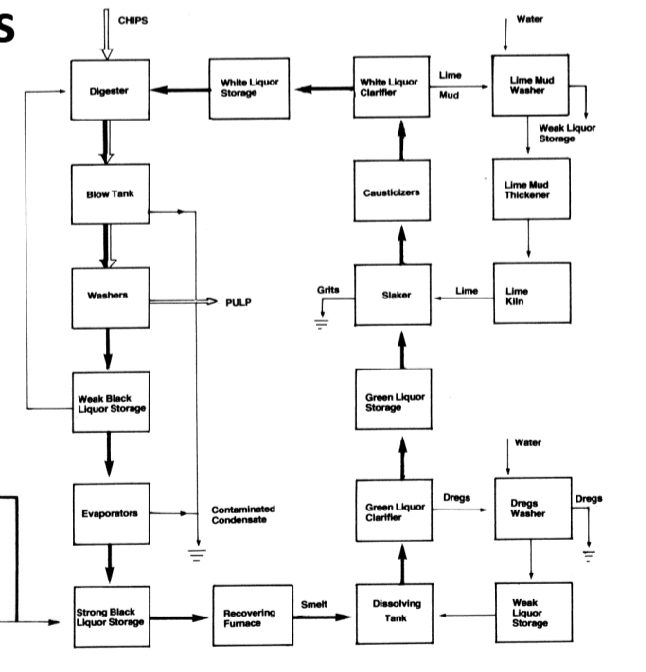

Chemical Recovery

Evaporation (of spent liquor to increase consistency), Combustion (heat is recovered for use in processes), Recaustisizing (react green liquor with Ca(OH)2)

Kraft Process Variables

Wood Species (HW, SW, Eucalyptus), Cooking Liquor Chemistry (liquor to wood ratio, sulfidity), Cooking Conditions (temperature at 170 degrees C for 1.5 - 3 hours), H-factor

H-factor

Area under curve (reaction rate vs. time) indicates extent of reaction

Lignin in Digester

Lignin is replaced by water in the digester

Draw Kraft Process Diagram

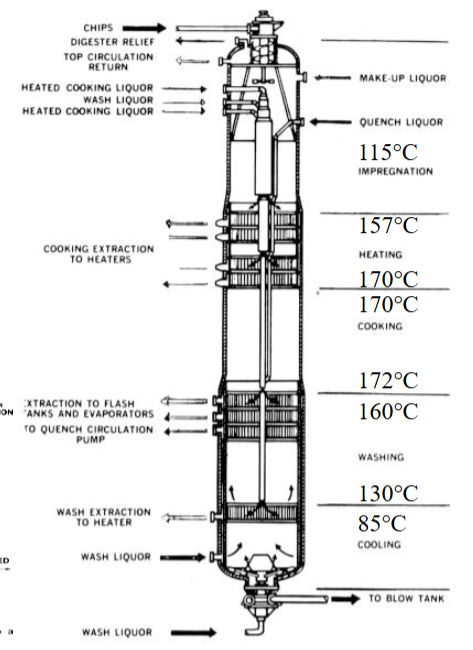

Kamyr Continuous Digester

Impregnation (115 degrees C), Heating (157 → 170 degrees C), Cooking (170 → 172 degrees C), Washing (160 → 130 degrees C), Cooling (85 degrees C) —— identify zones and draw digester

Continuous Digester

Presteaming, chip chute, high pressure feeder, heaters (heat exchangers), condenser for extractives, recirculation of liquor, heating zones

Breaking bonds in cellulose to break off lignin

1) Alkaline hydrolysis: drops strength (decreases chain length & viscosity); 2) Peeling reaction: stops bond breaking with NaS, drops yield (loses some money); both should limit temperature to prevent cellulose degradation

Sulfite Pulping (<5% of market)

Acid hydrolysis via NaHSO3: acid tears apart lignin and Na makes lignin negative and therefore soluble (to be washed out)

Condensation of Lignin

Lignin reforms back into an insoluble polymer that is impossible to remove, and is called a burned cook because the pulp becomes black

Sulfite Pulping Cooking Liquor

SO2 + H2O → H2SO3, forms bisulfite (pH 3 - 5)

Calcium Salts in Cooking Liquor (abandoned due to insoluble salts)

CaCO3 + 2H2SO3 → Ca(HSO3)2 + CO2 + H2O

Ca(HSO3)2 → H2SO3 (FREE) + CaSO3 (COMBINED)

Sodium Salts in Cooking Liquor

Na2CO3 (SODA ASH) + H2SO3 → 2NaHSO3 + CO2 + H2O

Ammonium Salts in Cooking Liquor

NH4OH (AMMONIA)+ H2SO3 → NH4HSO3 + H2O

Magnesium Salts in Cooking Liquor

Mg(OH)2 + 2H2SO3 → Mg(HSO3)2 + H2O

Mg(HSO3)2 → H2SO3 (FREE) + MgSO3 (COMBINED)

Neutral Sulfite Semi-Chemical Pulping (NSSC, 7% of market)

Na2SO3 + Na2CO3, high yield (80%) similar to CTMP, only removes middle lamella, usually made from hardwood, has good compressibility for liner medium due to stiffer fibers

Strength Comparison of Pulping Methods

CTMP > TMP > RMP > PGW > SGW

Solid % Before Multiple-Effect Evaporators

15%

Solid % in Concentrated Black Liquor Storage

70%

Clarifier

Takes out solids

Dregs Washer

Non-dissolving solids removed, washes out Na2S so it doesn’t combust in the atmosphere

Smelt out of recovery boiler

Na2CO3, Na2S, dregs

Steam from recovery boiler

Runs through multiple-effect evaporators

Recovery Boiler

100m tall, biggest building on site, bottleneck of the process

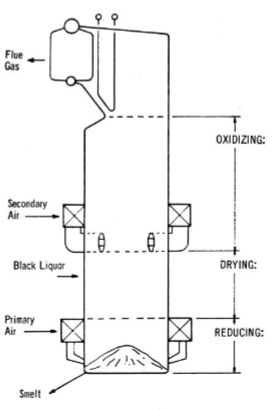

Recovery Boiler Zones

Drying, oxidizing, reducing. Black liquor goes into the drying section, some organics rise into the oxidizing section before dropping down to the reducing section

Draw Recovery Boiler

Slaking

CaO is introduced into green liquor, CaO (lime) + H2O → Ca(OH)2 (slaked lime/milk of lime)

Recaustisizing

Ca(OH)2 + Na2CO3 → CaCO3 + 2NaOH

Lime Kiln

Rotating kiln going from 200 to 1200 degrees Celsius to turn CaCO3 into CaO

Brownstock Washer

Separates black liquor from wood pulp fibers after cooking

1980s

Mechanical Pulping → Chemical Pulping

Acid process → Alkaline process

Bleaching in Europe

Total Chlorine Free (Peroxides → Oxygen)

Bleaching in U.S.

Elemental Chlorine Free (Chlorine dioxide, ClO2)

Reductive Bleaching

Brightens remaining materials (Mechanical Pulping)

Oxidative Bleaching

Removes remaining lignin (alkali is used to remove oxidized lignin) (Chemical Pulping)

Chlorine (C)

ECF (primarily used, chlorine and hypochlorite are eliminated) and TCF; Not used because of dioxin

Chlorine dioxide (D)

Used in all bleached paper, unstable/explosive when 12-15% is in gas phase so use upflow towers to prevent gas accumulation, good selectivity towards lignin

Alkaline Extraction (E)

NaOH deprotonates lignin fragments so they are negatively charged which dissolves lignin from previous stage

Hypochlorite (H)

NaOCl

Oxygen delignification (O)

O2

Peroxide (P)

H2O2

PO

Oxygen-peroxide

Peracetic acid (Pa)

CH3CO3H

N

Neutralization

Enzymes (X)

Xylanase attacks xylans, which are hemicellulose attached to lignin

Ozone (Z)

O3

Bleaching Sequence

OD(EOP)D - O reduces lignin, D0 oxidizes to remove lignin, D1 reduces remaining chromophores

Jordan Conical Refiner

An old refiner meant for secondary (tickler) refining

HC Refining

For mechanical pulping

LC Refining

For almost every pulp

Disk Refining

Not designed to shorten fibers; rids S1 layer to liberate microfibrils (some fines are created in the process)

Acids and Bases

Used to control pH; high pH (alkaline) deprotonates fibers while low pH us bad because it can react with CaCO3 to make salt and gas which causes foam

Alum

pH and retention: attracted to negative fibers and attaches filler to fibers

Retention aids

Keep fines and fillers in paper (long positively charged polymers)

Drainage aids

Water removal on the wire

Pitch control chemicals

Prevents deposits/accumulation of pitch (which comes from extractives in mechanical pulp)

Stickies control chemicals

Prevents accumulation of adhesives/stickies from recycled pulp

Biocides

Microorganism control

Process Chemicals

Added to improve process

Functional Chemicals

Added to change paper properties

Sizing agents

Control penetration of liquids, control the rate of wetting in paper

Dry strength agents

Make dry paper stronger (cationic starch)

Wet strength agents

Make wet paper stronger

Optical Brightening Agents (Colorants)

Dumps UV back into 457 nm to increase brightness

Clay (filler)

Flat platy structure, used to create glossy surfaces, inert, has a slight cream color (lowers brightness)

Calcium Carbonate (filler)

PCC shape versus ground

Titanium Dioxide (filler)

expensive but scatters light very well

Talc (filler)

similar to clay, flat platy structure, hydrophobic, used in Asia

Stock prep

Blend chest (everything is blended) which goes to the machine chest (feeds paper machine)

Stock approach system

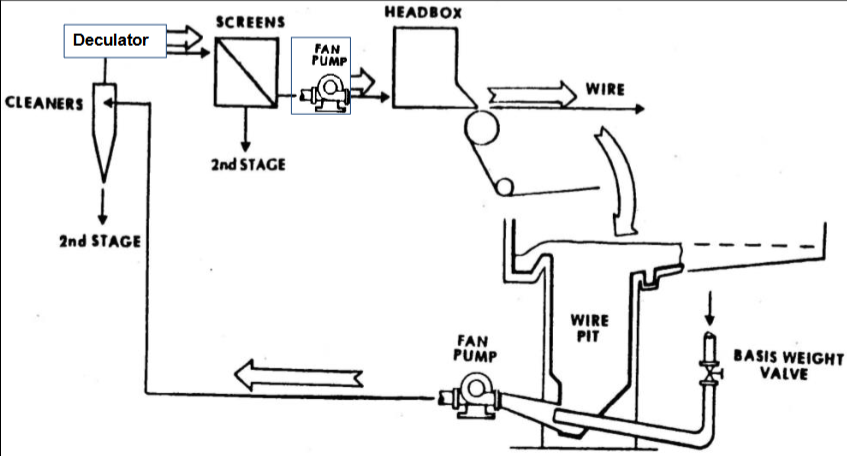

Basis weight control/valve, fan pump 1, hydrocyclones, deculator, fan pump 2, pressure screens, headbox (in this order)

Draw Stock Approach System Diagram

*2nd fan pump should come before the pressure screens

Solid % coming out of pulp mill

10%

Solid % coming out of machine chest

3%

Solid % coming onto paper machine from headbox

0.5%

Stuff Box

On top of building connected to basis weight control valve creating an almost constant pressure; has a Weir which is a dam inside to maintain pulp level to keep constant pressure

Hydrocyclones/Centricleaner

spins to separate light and heavy particles (removes sand/dirt/grit from pulp)

Deculator

Removes air after hydrocyclones

Pressure Screens

Doesn’t plug, has hydrofoils, has many designs