Manufacturing 1 - Exam 3

1/155

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

156 Terms

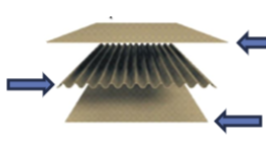

Corrugated board is essentially a paper sandwich consisting _____________ __________ layered between inside and outside ________________

corrugated medium, linerboard

What are the three arrows? (top to bottom)

outer liner

fluted medium

inner liner

_______________ is the most widely used kind of shipping container

corrugated

Corrugated is best known for its ________ _______ that offers _____________ to packaged products throughout the transportation cycle

structural strength, protection

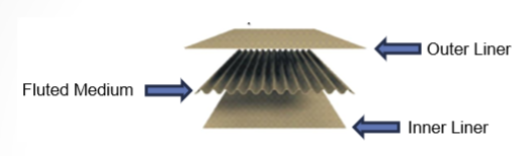

What is this?

Single Face

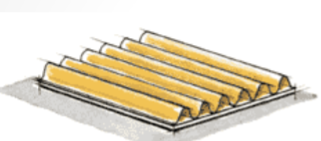

What is this?

Single Wall

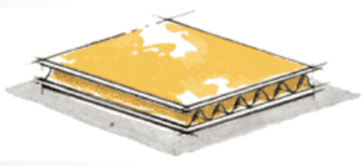

What is this?

Double Wall

What is this?

Triple Wall

What are the three typical substrates used for corrugate

kraft

mottled

bleach

What is the index for Kraft?

100 Index

What is the index for Mottled?

105 Index

What is the index for Bleach?

109 - 115 Index

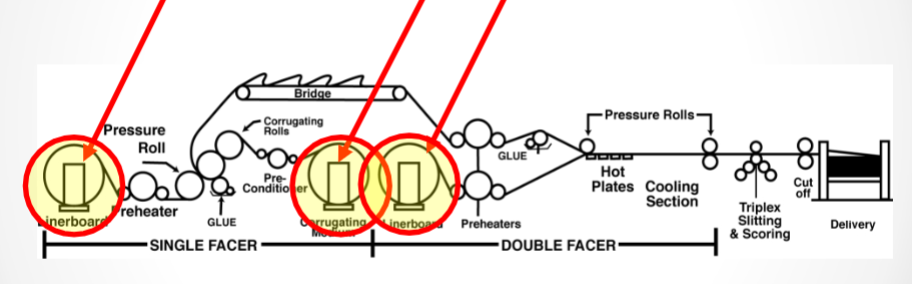

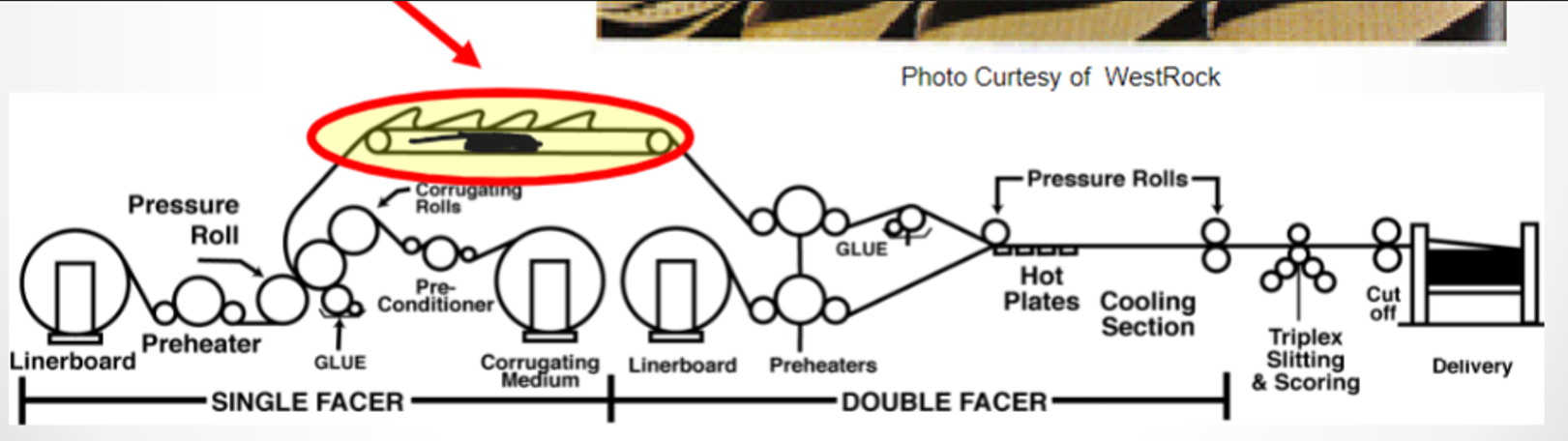

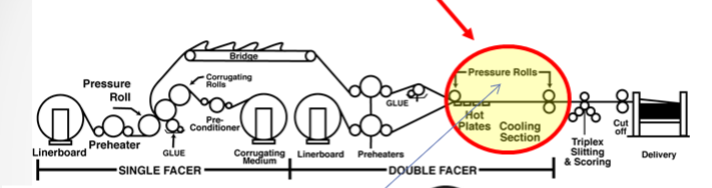

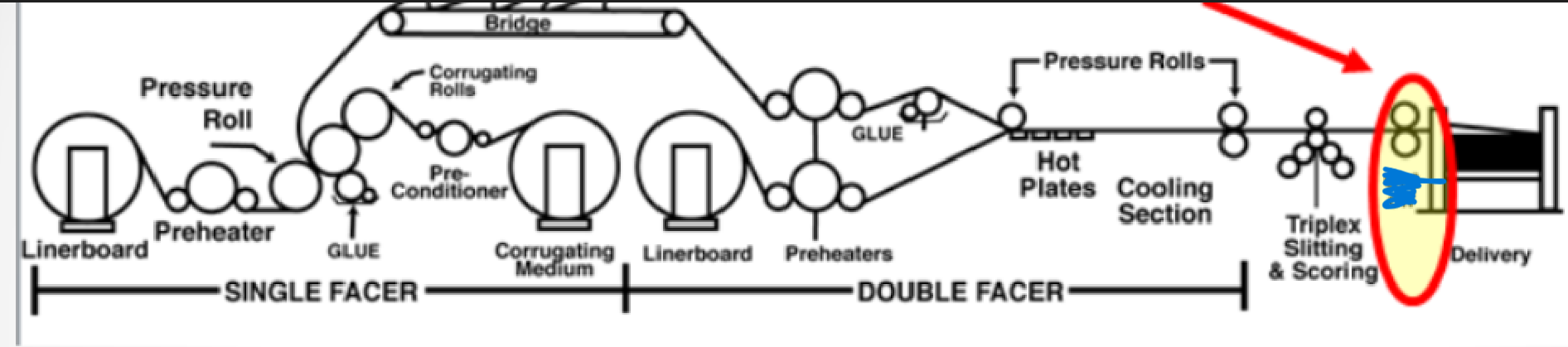

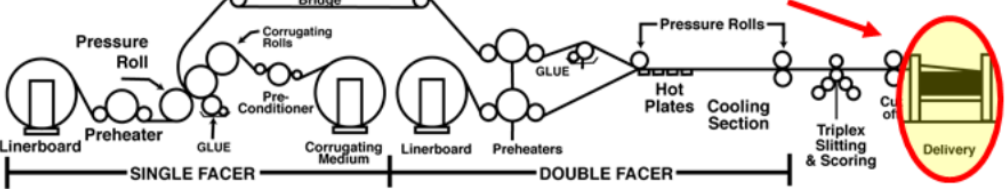

The ______ combines rolls of linerboard and medium into sheets of corrugated board

corrugator

The typical corrugator is equipped to run both _____ _____ and ____ ____ in a variety of flute heights

single wall, double wall

Modern corrugators can also be equipped with enhancements that offer a range of value added features such as:

functional coatings

color coating

tear tape or internal strings

water resistant adhesives

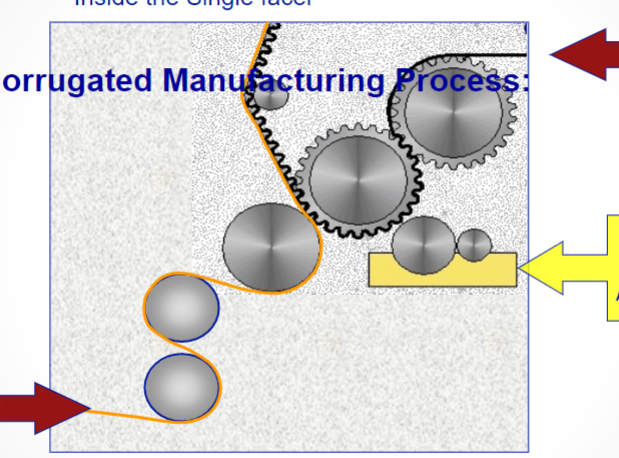

Which part of the corrugated manufacturing process is this?

Mini Roll Stands

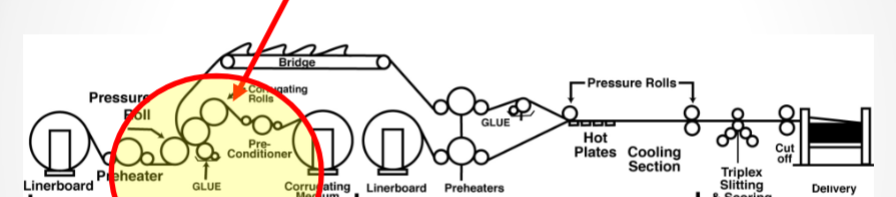

Which part of the corrugated manufacturing process is this?

Single Facer

This is the inside the single facer, what do the arrows point to? (Top to bottom)

Medium

Adhesive

Liner

Typically the glue used to make corrugated fiberboard is ______ ______

starch based

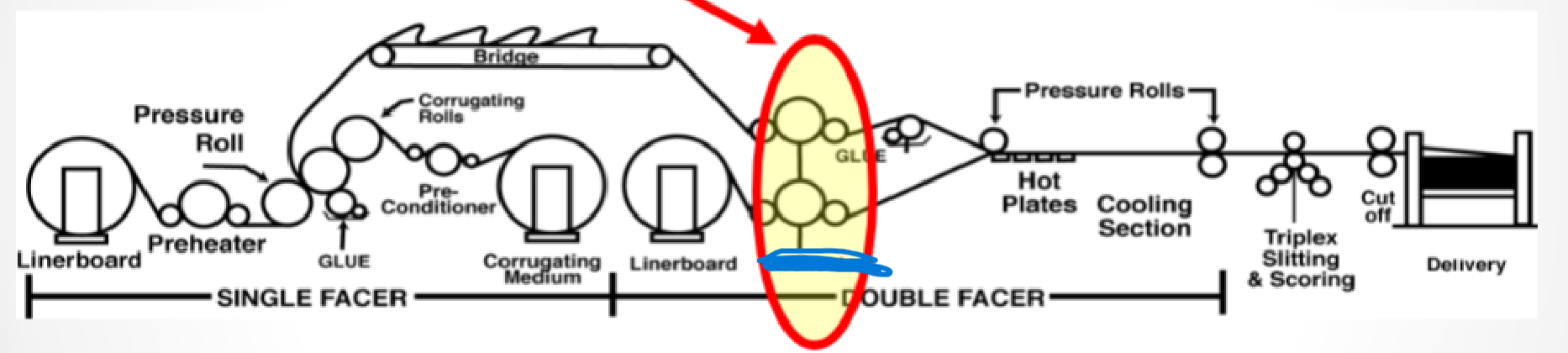

What does this show?

Bridge

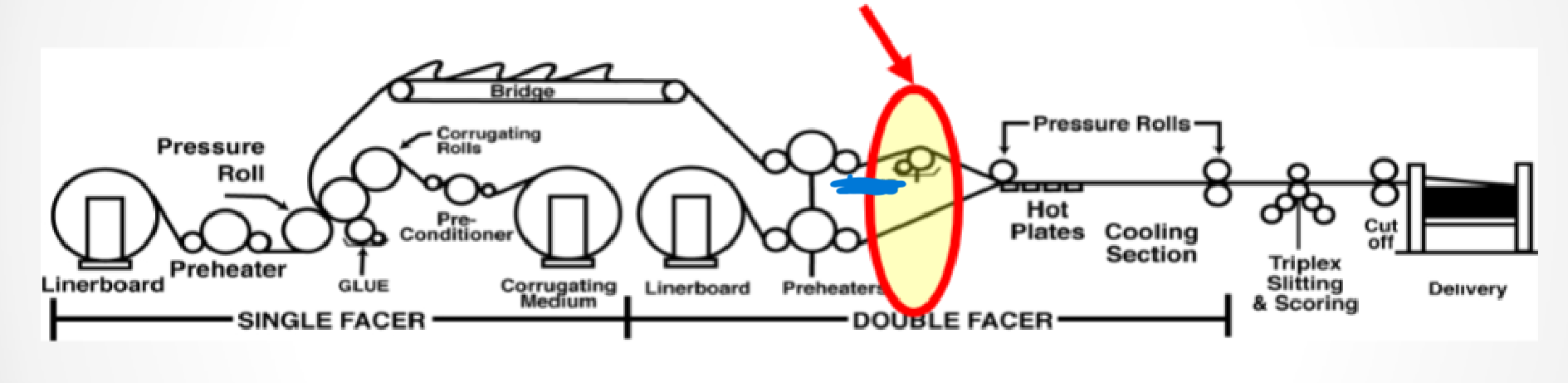

What does this show?

Preheaters

What does this show

Glue (starch) machine

What does this show

Double backer

What is this showing?

Slitter/scorer

Scoring, slitting, and trim removal take place in the _______ ______ and ________ section in the combining process

Triplex slitting and scoring section

What does this show

cut off

What does this show?

Downstacker

What are some package design considerations?

What type of product will the package contain?

Orientation of the product to the shipping case

How many products will the package contain including is size and weight?

Package environmental needs

Handing and distribution needs

Will the product be packed by hand or machine filled and closed?

What are some equipment considerations

box erecting system

loading considerations

palletization

use of manual to robotics

What is the distribution methodology?

Distribution center

Retail

E-commerce

Direct to consumer

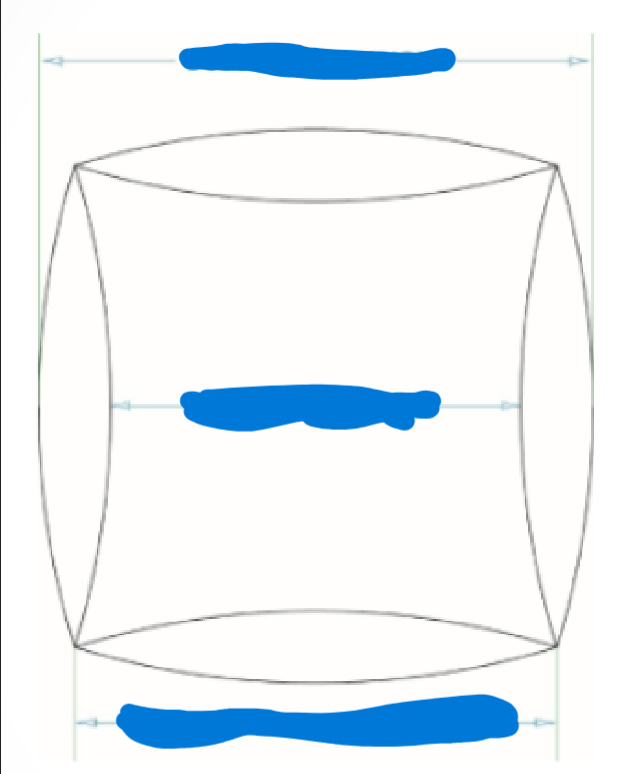

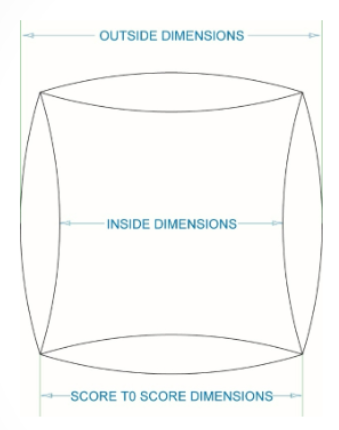

What are the three sets of dimensions?

Inside Dimensions

Outside Dimensions

Score to Score Dimensions

Size is typically given as ________ ________

inside dimensions

Inside dimensions are determined by the ______ of the item you wish to fit in the box

size

Outside dimensions are determined by the inside dimensions required plus the _____ _____ selected

board grade

Some customers give size in outside dimensions based on ______ allotted by the retailer or a desired _____ footprint

space, pallet

Score to score dimensions are determined by the ______ of the box and the _____ _____ selected

style, board grade

What type of dimension is shown? (top to bottom)

Outside Dimension

Inside Dimension

Score to Score Dimension

Length is ____ to _______

left to right

Width is _____ to ______

front to back

Depth is _____ to _____

top to bottom

E flute is used for what?

Cosmetics and high end small items

B flute is used for what?

High end and heavier items such as wine and liquor

C flute is used for what?

More protection for shipping

B/C Double Wall flute is used for what?

Very heavy items (industrial/sporting goods)

What are the factors for choice of fluting?

size of product

weight of product

environmental

shipping requirements

stacking requirements

What are the corrugated box styles?

RSC - Regular Slotted Container

HSC - Half Slitted Container

FOL - Full Overlap

Die Cuts - Specialized Designs/Use

What is the most common style of box utilized?

RSC - Regular Slotted Carton

In the design of an RSC the outer top and bottom flaps meet in the ______ of the _____ dimension of the container

middle, width

In the design of an HSC the outer flaps meet in the ______ of the _____ dimension of the container

middle, width

Typically, two HSC containers will be sized to allow for placement over each other to create a _______ case

telescoping

In the design of an FOL the outer top and bottom flaps ____ ____ each other in the ____ dimension of the container allowing for the major and minor flaps to fold over each other

fold over, width

In the design of a straight tuck top and bottom corrugated container the tuck top and bottom panels are ____ _____ with each other

in line

In the design of a _____ _____ corrugated container the bottom panels lock into each other to form a non-glued bottom

Tuck Top

______ _____ packaging refers to a box, tray, sleeve, bin, or other display that product is shipped in that can be set on the shelf upon arrival at a store

Retail ready

What are things to keep in mind for display manufacturing?

Will the display design be able to fit on the converter’s machinery?

Can it be glued?

Will it require manual folding and stitching or special gluing?

What are things to keep in mind for display assembly?

Will the display be prone to tearing in the assembly to loading process?

Can the loaded display it be lifted?

Will the retailer be able to put the display together properly?

What are the types of corrugated display types?

Counter Unit

Power wing (sidekick)

Floor Display

¼ Pallet to ½ Pallet

Full Pallet 40 × 48

Pull Pallet 48 × 48

Once an order has been placed, the _______ ________ ______ can create an instruction sheet to be packed with the display

Corrugated display vendor

This will allow the retail location on how to assemble to ________ ______ correctly

Corrugated Display

What are the main corrugated printing methods?

Flexo

Flexo preprint

Flexo lamination

Offset lamination

Digital

Describe the flexo printing process:

Flexible printing plates are mounted to a cylinder and pick up a fast drying water based ink from an anilox cylinder that is metered by a rubber roll or doctor blade system

In flexo printing sheets are fed through the ______ and _______ are transferred to the corrugated board

cylinders, grapics

What are the two ways that litho quality graphics can be incorporated into corrugated packaging?

Single Face Laminating

Labeling the combined board

With ______ ______ _______ a printed “top sheet” can be laminated directly to the medium as the outside liner

single face laminating

Which tyle of printing uses solvent based inks?

Litho Liner Printing

______ _______ is the most recently developed printing technology

digital printing

Graphics from a digital computer file are transmitting ______ to a printer that plots the graphics onto the corrugated board which eliminates the need for _______ ______

directly, printing plates

What is used in secondary labeling and coding?

Non contact ink jet printing

Pressure sensitive on demand label printing and application equipment from manual to auto print and apply

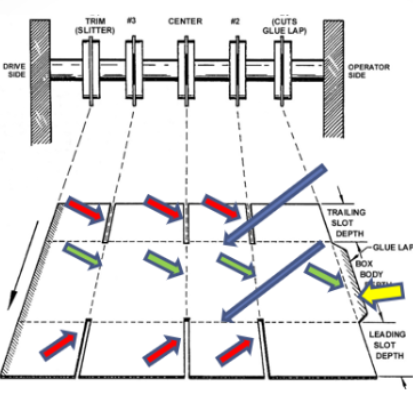

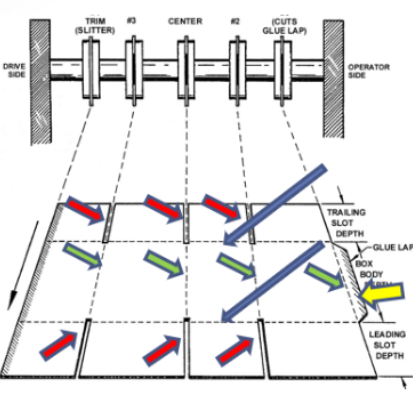

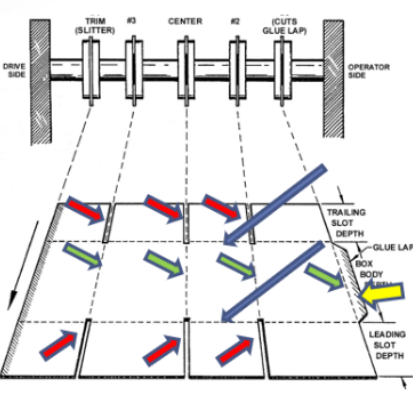

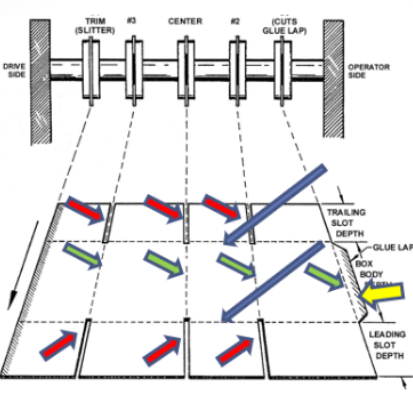

The horizontal scores shown by the BLUE arrows are typically accomplished on what?

corrugator/combiner

The vertical scores shown by the green arrows are typically accomplished on what?

flexo, folder & gluing machine

The slots shown by the red arrows are typically accomplished on what?

flexo, folder & gluing machine

The glue lap shown by the yellow arrows are typically accomplished on what?

flexo, folder & gluing machine

An RSC can also be run utilizing ______ ______ to allow for further accurate finished corrugated container

die cutting

_______ _____ systems provide random length pattern control and simplifies the glue lap bonding process in the corrugated box manufacturing process

cold adhesive

What are the two methods of corrugated die cutting?

Rotary

Platen (flat bed)

What tests are completed on the delivered containers before the corrugated containers are released to manufacturing?

Dimensional Quality

Squaring and Folding Qualities

Print Accuracy & Quality

Board and Glute Specifications

_____ _____ is a multiplier used to convert a known dead weight storage load to a compression requirement

safety factor

What determines safety factor?

time

humidity

abuse

What are other factors to consider in safety factor?

the number of times the package is handled

product support

case alignment

environment

stretch wrap

printing

The area within ____ ____ of each corner of an RSC contributes to approx 65% of its stacking strength

3 inches

_______ _______ testing tells us the weights of the liner and medium components used to make corrugated board

basis weight

Basis weights are in __________

lb./MSF - pounds per thousand square feet

______ testing is a compression test on a sample of board that is directly related to the compression strength of a corrugated case

ECT

ECT units are in _______

lb./in

The ______ ________ of a corrugated case is directly related to the edgewise compression strength (ECT) of the corrugated board used to construct the case

stacking strength

_______ _______ measures the amount of force that it takes to puncture through corrugated board with a rubber diaphragm

Mullen Burst

_______ _______ measures resistance to flexing of corrugated board

Bending stiffness

______ _______ is directly related to corrugated case compression strength

Bending stiffness

Bending Stiffness results are given in _______

lbf/in

________ relates to the compression strength of a case

caliper

Increased board caliper yields ________ case compression strength

increased

If flutes of corrugated board are crushed significantly during manufacture, ECT, Bending Stiffness, and Box Compression are _________ affected

negatively

______ _______ measures the amount of force required to pull the corrugated medium away from the linerboard on a sheet of corrugated board

Pin adhesion

_______ _______n testing measures the amount of resistance the flutes provide to crushing force applied perpendicular to the surface of the sheet of board

flat crush

________ _______ is the water absorptiveness of sized paper, paperboard, and corrugated fiberboard

Cobb Test

What are the two methods of liner and medium compression strength testing are used to predict the ECT of combined board?

Ring Crush Test

Short Span Compression Strength

________ is a compression test on a short span (.0276”) of a strip of linerboard or medium

STFI

STFI strength of liners and mediums ________ to ECT strength of corrugated board

correlates

_________ _________ testing is a compression test on a strip of linerboard or medium formed into a circle

ring crush

Ring crush strength of liners and mediums _______ to ECT strength of corrugated board

correlates