HACCP Final Exam

1/77

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

78 Terms

What is HACCP?

Comprehensive, pro-active food-safety system

The idea is to critically examine the food production system and find possible hazards

Prevent, eliminate, or reduce the hazards

Three different types of hazards:

Physical: Foreign objects like glass, metal, or plastic

Chemical: Cleaning agents, pesticides, food allergens

Biological: Bacteria, viruses, parasites (e.g. Salmonella, E. coli)

The Jungle:

- when/who wrote it

- why was it written

- the 2 acts and who oversees them

1906; Upton Sinclair

To expose the appalling working conditions in the Chicago Meat Packing Industry

Meat Inspection Act - USDA; Food and Drug Act - FDA

Major events leading to the formation of the USDA

USDA (U.S. Department of Agriculture):

1862 – USDA Established

President Abraham Lincoln founded the USDA to support agriculture and rural development.1880s–1890s – Agricultural Growth

As farming expanded, the USDA began research, education, and food inspection programs.1906 – Meat Inspection Act

Sparked by Upton Sinclair’s novel The Jungle, this law gave USDA authority to inspect meat processing plants.

Major events leading to the formation of the FDA

FDA (Food and Drug Administration):

1906 – Pure Food and Drug Act

Passed due to concerns over unsafe food and false drug claims. It laid the foundation for FDA’s creation.1927 – Food, Drug, and Insecticide Administration Formed

A new agency to enforce the 1906 act.1930 – Renamed the FDA

Officially became the Food and Drug Administration.1938 – Federal Food, Drug, and Cosmetic Act

Expanded FDA powers after a deadly drug incident (Elixir Sulfanilamide tragedy).

What were two important laws passed on 1906?

Pure Food and Drug Act – Banned the sale of misbranded or contaminated food and drugs; led to the creation of the FDA.

Meat Inspection Act – Required sanitary conditions and federal inspection of meatpacking plants; enforced by the USDA.

What were the two NASA concerns?

1. Crumbs and water droplets - in zero gravity with electrical equipment. bite- sized foods and edible coatings to hold foods. Special packaging to minimize exposure of foods.

2. Microbiological safety: foods are free from pathogens, parasites, and biological toxins.

Who has the regulatory authority over meat and poultry products?

The USDA (United States Department of Agriculture), specifically its Food Safety and Inspection Service (FSIS), has regulatory authority over meat, poultry, and processed egg products.

3 Original Principles of HACCP

1. Identify and access hazards

2. Determine Critical control points (CCPS)

3. Establish systems to monitor all identified CCPs

Seven Principles of HACCP:

1) Conduct a Hazard Analysis

2) Determine the Critical Control Points (CCPs)

3) Establish Critical Limits

4) Establish Monitoring procedures

5) Establish Corrective Actions

6) Establish Verification procedures

7) Establish Record-Keeping and Documentation procedures

Where was the first meat application of HACCP?

Pillsbury Company in partnership with the U.S. Army and NASA in the 1960s, but the first offical use in thye meat industry came later.

Pillsbury worked w army to create space foods for NASA (1959)

What does Codex Alimentarius committee do?

Codex Alimentarius Committee sets international food standards to protect consumer health and ensure fair trade in food.

Develops guidelines and codes of practice for food safety and quality

Helps harmonize food regulations between countries

Supports global food trade by reducing barriers

Run jointly by the FAO (Food and Agriculture Organization) and WHO (World Health Organization)

9 Process Categories

1) Slaughter - All Species

2) Raw product - ground

3) Raw product - not ground

4) Thermally processed - commercially sterile

5) Not heat treated - shelf stable

6) Heat treated - shelf stable

7) Fully cooked - not shelf stable

8) Heat treated but not fully cooked - not shelf stable

9) Product with secondary inhibitors - not shelf stable

Benefits of HACCP

Reduces the amount of foodbourne illnesses and product waste

Builds on Quality Assurance and Control programs

Incorporates all levels of plant personnel: from maintenance to management

Increases operational efficiency, profits, and consumer confidence

Drawbacks of HACCP

Production companies’ responsibility: Shift from USDA monitoring to the plants needing to maintain records themselves

Employee participation: Requires effort from the entire team, from all shifts and departments

Costs: Remodeling, Replacing old equipment, Sampling materials, Validation, etc.

Is there any FDA applications of HACCP? Some examples.

Yes, the FDA applies HACCP in several food industries

Seafood HACCP –

Required since 1997 for all seafood processors (e.g., shrimp, tuna) to prevent hazards like parasites or histamine.Juice HACCP –

Required since 2001 for juice processors (e.g., orange juice, apple juice) to control pathogens like E. coli and Salmonella.Voluntary HACCP in other foods –

Used in dairy, bottled water, and some processed foods, although not legally required in all cases.

Food Safety Modernization Act

January 2011; Final Rule by Pres. Obama

Created to ensure the U.S food supply is safe. Purpose is to proactively prevent contamination. Similar to HACCP program. Includes foods for Humans and Animal Consumption

The 4 preliminary tasks to develop HACCP

1. Assemble HACCP team

2. Product description: ID intended use and consumers of food

3. Develop flow diagram

4. Verify flow diagram

What should constitute a HACCP team?

A HACCP team should include people with knowledge and experience in the specific food operation.

Production staff – Understand the day-to-day processes.

Quality assurance/food safety personnel – Know food safety principles and regulations.

Maintenance or engineering staff – Understand equipment and facility design.

Sanitation team – Know cleaning procedures and hygiene practices.

Management – Provide support and resources.

What is the Purpose of conducting a hazard analysis?

Identify potential biological, chemical, and physical hazards in the food production process.

Evaluate the risk and severity of each hazard.

Determine which hazards must be controlled to ensure food safety.

What is a CCP? And purpose of doing a CCP assessment?

A CCP (Critical Control Point) is a step in the food process where a specific hazard can be prevented, eliminated, or reduced to a safe level.

Temperature Danger Zone: the range where bacteria grow fastest

40°F to 140°F (or 4°C to 60°C)

In this zone, bacteria like Salmonella and E. coli can multiply rapidly.

Food should not stay in this range for more than 2 hours.

Keep cold foods below 40F

Keep hot foods above 140F

Minimize time food spends in the danger zone

Cooking temperatures for beef, chicken, pork, eggs, and vegetables

Beef (steaks, roasts):

145°F (63°C) with a 3-minute rest timeGround beef:

160°F (71°C)Chicken (whole or ground):

165°F (74°C)Pork (chops, roasts):

145°F (63°C) with a 3-minute rest timeEggs:

Cook until yolks and whites are firm or to 160°F (71°C) if used in a recipeVegetables (for hot holding):

135°F (57°C)

These temperatures help prevent foodborne illness by killing harmful pathogens.

What are monitoring procedures? Purpose?

A monitoring procedure in HACCP is the routine observation or measurement of a Critical Control Point (CCP) to ensure it stays within safe limits.

It helps keep food safe by checking if things are working as planned.

Purpose:

To ensure control of identified hazards at CCPs

To detect any deviation from critical limits

To provide records for verification and corrective actions

To allow quick response before unsafe food is produced

Continuous Monitoring:

Happens constantly during the process.

Uses tools like thermometers, pH meters, or automated sensors.

More reliable and preferred when possible.

Example: A thermometer that constantly records cooking temperature.

Noncontinuous (or Intermittent) Monitoring:

Happens at regular intervals (not constantly).

Involves manual checks like visual inspection or periodic testing.

Used when continuous monitoring isn't practical.

Example: Checking refrigerator temperature twice a day.

What are Corrective Actions? Purpose?

Corrective actions are steps taken when a critical limit is not met at a Critical Control Point (CCP).

Purpose:

To correct the problem and bring the process back under control

To prevent unsafe food from reaching consumers

To identify and fix the cause of the deviation

To document what went wrong and how it was handled

What are the differences between verification, validation, and calibration procedures?

Validation:

Proves the HACCP plan works to control hazards. Done BEFORE implementation or when changes are made

→ Does the plan work?

Verification:

Confirms the HACCP plan is being followed correctly. Done REGULARLY during operations.

→ Is the plan being followed?

Calibration:

Ensures instruments give accurate measurements. Done on a scheduled basis or if equipment seems off.

→ Are the tools measuring correctly?

What are prerequisite/support programs?

Must be written, functional, and in place in the plant BEFORE HACCP can be implemented. HACCP uses this as a foundation.

What are some examples of prerequisite programs?

Pest control, Glass control, Receiving, Personal Equipment, Facilities Design

Product Specifications, Traceability/recall, Food Safety Training, Labeling

Storage, Distribution, Chemical Control, Allergen, QA/QC, Temperature Control, Complaint Investigation

Why is it important to have a sound foundation of prerequisite programs prior to implementing the HACCP?

1. They control general food safety risks:

Prerequisite programs (like sanitation, pest control, employee hygiene) handle basic environmental and operational hazards.

2. HACCP focuses on specific hazards:

With prerequisite programs in place, HACCP can focus on critical process points rather than everyday cleanliness or facility issues.

3. They support consistent operations:

They create a stable and controlled environment, making it easier to apply and maintain HACCP.

4. They reduce the number of CCPs:

By controlling many risks in advance, fewer critical control points may be needed in the HACCP plan.

Prerequisite programs lay the groundwork for a successful, focused, and efficient HACCP system.

Prerequisites vs HACCP

- Deviation: unlikely to result in injurious products vs serious consequences

- Generally managed in quality programs vs food safety only

- Broad programs and multiple lines vs Specific product and line

- Difficult to associate a failure with a particular lot vs easy to point out a failure with a particular lot

Five steps to Establishing Prequisite Program

1. Commitment from management

2. Documentation for compliance (Include standard operating procedures (SOP's))

3. Employee training

4. Verification

5. Resources

What are the general Sanitation practices?

Clean and sanitize all equipment and surfaces

Use proper cleaners and sanitizers on tools, machines, and workspaces.

Personal hygiene

Wash hands regularly

Wear clean uniforms, gloves, and hair restraints

Stay home when sick

Pest control

Seal entry points, remove food sources, and use traps or professional services.

Proper waste disposal

Remove trash often and use covered, labeled containers.

Safe water and ice supply

Ensure all water and ice used in food production is clean and safe.

Cleaning schedules and checklists

Follow regular cleaning routines and keep records.

Facility maintenance

Fix leaks, cracks, and equipment issues that could cause contamination.

How FDA and USDA regulate sanitation requirement?

FDA focuses on general food products using cGMPs.

USDA-FSIS strictly monitors meat, poultry, and eggs with detailed SSOPs and daily inspections.

Both ensure sanitation to prevent foodborne illness and protect public health.

What is the record keeping requirement for meat and poultry SSOPs document?

Daily, signed records of all sanitation actions, corrections, and verifications are required and must be retained for 6 months.

Pre-Operational Sanitation

Ensures that facilities, equipment and utensils are free from soil, tissue debris, chemicals and other hazards before starting.

Develop detailed written procedures for daily cleaning of product contact surfaces, equipment and facilities

Describe equipment disassembly and re-assembly after cleaning / sanitizing

Sanitizer approved for the intended use and prepared according to manufacturer

Use acceptable cleaning techniques

Operational Sanitation

Written procedures for maintaining sanitation during product preparation, storage and handling

Prevent direct product contamination and adulteration during operations

Develop procedures for cleaning, sanitizing and disinfecting equipment and utensils during production, breaks, between shifts and at mid-shift cleaning

Cleaners Used in the Industry

Chlorine containing compounds

→ Na or Ca-hypochlorite; Gaseous Cl

Aldehydes

→ Formaldehyde; Phenols; Alcohols; Acids

Quaternary ammonium compounds (QUATS)

→ Not corrosive but low efficient on spores

Oxygen releasing substances

→ Peroxide compounds; Per-acetic acid

Procedures for assessing SSOP effectiveness

Organoleptic/sensory: sight, feel, smell

Chemical: sanitizer level

Microbial: swabbing, culturing for pathogens or indicator organisms

Major foodbourne Pathogens: Norovirus

Where found: Human feces/vomit; spreads via dirty hands, surfaces, contaminated water/food (like salads, shellfish).

Growth: Doesn’t grow in food, but survives well on surfaces and hands.

Survival: Very resistant; survives freezing, and even mild heating.

Effect: Causes vomiting and diarrhea; highly contagious.

Major foodbourne Pathogens: Salmonella

Where found: Raw poultry, eggs, meat, unpasteurized milk, fruits, and vegetables.

Growth: Grows between 40°F–115°F, especially in warm, moist foods.

Survival: Killed by cooking to proper temps (e.g., 165°F for poultry).

Effect: Causes fever, diarrhea, cramps.

Major foodbourne Pathogens: Shiga toxin-producing E.coli (E.coli o157:H7/ STEC)

Where found: Undercooked ground beef, raw milk, contaminated produce or water.

Growth: Grows in intestines; survives freezing and some acid conditions.

Survival: Killed by cooking beef to 160°F.

Effect: Can cause severe bloody diarrhea and kidney failure (HUS).

Major foodbourne Pathogens: Scombrotoxin (Histamine poisoning)

Where found: Time-temperature abused fish (tuna, mackerel, mahi-mahi).

Growth: Caused by bacterial breakdown of fish proteins forming histamine.

Survival: Not destroyed by cooking or freezing.

Effect: Causes allergic-like symptoms: flushing, headache, nausea.

Major foodbourne Pathogens: Clostridium perfringens

Where found: Cooked meat, poultry, gravies held at unsafe temps.

Growth: Grows fast in the danger zone (40°F–140°F), especially in large batches.

Survival: Forms heat-resistant spores; some survive cooking.

Effect: Causes diarrhea and cramps (not vomiting), usually within 6–24 hrs.

Major foodbourne Pathogens: Staphylococcus aureus (produces enterotoxin)

Where found: On skin, nose, and hands of humans; also in improperly stored foods like salads, pastries.

Growth: Grows fast at room temp; toxin produced is heat-stable.

Survival: Toxin not destroyed by cooking.

Effect: Rapid onset (1–6 hrs) of nausea, vomiting, cramps.

Major foodbourne Pathogens: Ciguatoxin (Ciguatera fish poisoning)

Where found: Tropical reef fish (e.g., barracuda, grouper, snapper).

Growth: Natural marine toxin from algae eaten by fish—not bacterial.

Survival: Not destroyed by cooking or freezing.

Effect: Neurological symptoms: tingling, reversal of hot/cold sensation, nausea.

Major foodbourne Pathogens: Campylobacter jejuni

Where found: Raw poultry, unpasteurized milk, contaminated water.

Growth: Prefers microaerophilic conditions (low oxygen); grows well at 42°C (chicken body temp).

Survival: Killed by cooking and pasteurization; can survive in refrigerated raw meat.

Effect: Causes diarrhea (sometimes bloody), fever, and cramps.

Incidents/illness caused by:

Physical Hazards: 2%

Chemical Hazards: 4%

Biological Hazards: 94%

Examples of each types of hazards

Biological: These are microorganisms that can cause illness.

Salmonella in raw poultry

E. coli O157:H7 in undercooked ground beef

Listeria monocytogenes in deli meats

Norovirus in ready-to-eat salads

Chemical: These include natural toxins, allergens, or chemical contaminants.

Allergens like peanuts in baked goods (undeclared on label)

Cleaning chemicals residue left on equipment

Pesticides on fruits and vegetables

Histamine (scombrotoxin) in spoiled tuna

Physical: These are foreign objects that can cause injury.

Metal shavings from broken machinery

Glass fragments from light bulbs

Plastic pieces from packaging

Bone chips in ground meat

Biological Hazards - Prevention

Prevention Methods:

Cook foods to safe internal temperatures (e.g., 165°F for poultry)

Wash hands, surfaces, and equipment properly

Prevent cross-contamination (separate raw and ready-to-eat foods)

Maintain proper refrigeration (≤ 40°F) and hot holding (≥ 135°F)

Follow hygiene and sanitation programs

Use approved water sources and pasteurized products

Chemical Hazards - Prevention

Prevention Methods:

Store chemicals away from food and food-contact surfaces

Train staff on proper use and labeling of chemicals

Rinse equipment after cleaning to remove chemical residues

Use only food-grade lubricants and additives

Manage allergens through ingredient control, labeling, and clean-up procedures

Physical Hazards - Prevention

Prevention Methods:

Use metal detectors, X-ray machines, and sieves

Inspect raw materials for bones, stones, or debris

Maintain and inspect equipment to prevent loose parts

Use protective coverings (e.g., shatterproof lights)

Train employees to detect and report physical contaminants

9 Most Common Food Allergens

Milk/Dairy

Eggs

Fish

Shellfish

Tree nuts

Peanuts

Wheat

Soybeans

Sesame

Top 5 food-germ pairs

1. Norovirus – Leafy Greens

Spread by infected handlers or contaminated water

Causes vomiting, diarrhea, and stomach pain

2. Salmonella – Poultry

Found in raw or undercooked chicken and turkey

Can cause fever, diarrhea, and abdominal cramps

3. Clostridium perfringens – Beef

Grows in cooked meat left at unsafe temperatures

Causes diarrhea and abdominal cramps

4. Campylobacter – Unpasteurized Milk

Common in raw dairy products

Causes diarrhea (sometimes bloody), fever, and cramp

5. E. coli O157:H7 – Ground Beef

Found in undercooked or contaminated ground meat

Can cause severe diarrhea, kidney damage (HUS)

Foods Supporting Microbial Growth

Characteristics of the Food FATTOM

Food

Acidity - Can grow well between pH of 4.6-7.5

Time and Temperature - Temp danger zone

Oxygen Level

Moisture

→ Bacteria: 0.95-0.88

→ Yeast: 0.88-0.80

→ Mold: <0.80

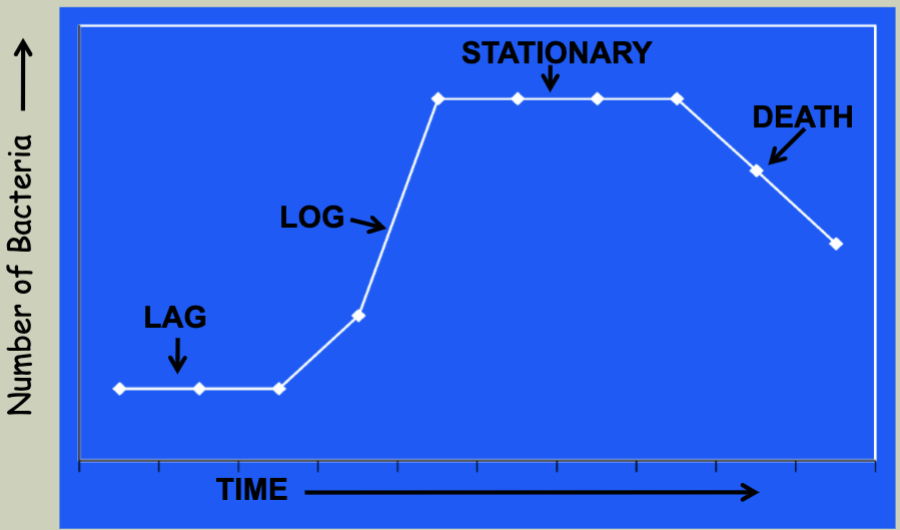

Growth Stages of Bacteria

Lag Phase

What happens: Bacteria are adjusting to their new environment.

Growth: Little to no increase in number.

Why: Cells are metabolically active, preparing to divide—synthesizing enzymes and nutrients.

Log Phase (Exponential Phase)

What happens: Rapid bacterial multiplication.

Growth: Exponential (doubling at a constant rate).

Why: Conditions are ideal—ample nutrients, low waste, no limiting factors.

Important for food safety: This is when pathogens multiply fastest in the temperature danger zone (40°F–140°F or 5°C–60°C).

Stationary Phase

What happens: Growth rate slows and stabilizes.

Growth: Number of new cells = number of dying cells.

Why: Nutrients deplete, and waste products build up.

Death Phase

What happens: Bacteria begin to die off faster than they grow.

Growth: Sharp decline in population.

Why: Toxic environment and lack of nutrients make survival difficult.

Organisms of Concern: Beef & Pork

Beef:

Salmonella

E. coli O157:H7

C. perfringens

L. monocytogenes

Pork:

Salmonella

C. perfringens

T. spiralis

Y. enterocolitica

Organisms of Concern: Poultry & Fish and Seafood

Poultry:

Salmonella

Campylobacter

C. perfringens

T. gondil

Fish and Seafood

Vibrio spp.

C. botulinum

Viruses

Helminths

Norovirus

Organisms of Concern: Vegetables & Fruits

Vegetables:

Salmonella

E. coli O157:H7

L. monocytogenes

C. botulinum

Norovirus

Fruits:

Salmonella

E. coli O157:H7

L. monocytogenes

Cyclospora

Norovirus

Organisms of Concerns: Milk/Dairy

Salmonella

Campylobacter

L. monocytogenes

Y. enterocolitica

Foodborne Infection: Pathogens grows in your body

Cause: Eating food containing live harmful microorganisms (like bacteria, viruses, or parasites)

What happens: The pathogens grow and multiply inside your body, causing illness

Onset time: Slower (usually 12+ hours to days)

Examples:

Salmonella (from raw poultry or eggs)

Norovirus (from contaminated salads or shellfish)

Campylobacter (from undercooked poultry)

Foodborne Intoxication: Toxin is already in the food

Cause: Eating food that already contains toxins produced by bacteria or other organisms

What happens: The toxin makes you sick directly, even if the bacteria are dead

Onset time: Rapid (often within a few hours)

Examples:

Staphylococcus aureus enterotoxin (from improper food handling)

Clostridium botulinum (from canned foods)

Scombrotoxin (from spoiled tuna or mackerel)

How to Kill/Injure Biological Hazards

Heat

→ Hot water, steam vacumming, steam pasteurization

pH

→ Low pH (Acidic): Use of an organic acid application (Acetic acid, lactic acid, mixtures)

→ High pH (Basic): Use of a basic application (Trisodium phosphate)

Oxidation (Chlorox, Purex, chlorine based products)

Others (Irradiation, ultraviolet light, high pressure)

What are prions?

Prions are infectious proteins that cause abnormal folding of normal proteins in the brain and other nervous tissue. Unlike bacteria, viruses, or parasites, prions contain no DNA or RNA—just protein

Prions are extremely resistant to heat, disinfectants, and radiation, making them a unique and serious public health risk.

Hurdle Technology

A food preservation method that uses multiple techniques (or "hurdles") together to prevent the growth of pathogens and spoilage organisms.

Hurdle technology is widely used in ready-to-eat foods, fermented products, and meat preservation.

Goal:

Improve food safety

Extend shelf life

Maintain sensory quality (taste, texture, appearance)

Sources of Biological Hazards

Bacteria (e.g., Salmonella, E. coli, Listeria)

Viruses (e.g., Norovirus, Hepatitis A)

Parasites (e.g., Giardia, Trichinella)

Fungi (e.g., molds producing mycotoxins)

Raw Animal Products

Food Handlers

Contaminated Equipment or Surfaces

Contaminated Water

Soil or Animal Feces

Shellfish and Seafood

What is a bacterial ‘log reduction’?

A bacterial log reduction is a way to measure how much bacteria is killed. It's used to show how effective a cleaning, cooking, or sanitizing process is at reducing germs.

1-log reduction = 90% of bacteria killed

2-log reduction = 99% killed

3-log reduction = 99.9% killed

4-log reduction = 99.99% killed

5-log reduction = 99.999% killed (reduction for food safety standards)

→ reduces number of microorganisms 100,000 fold

Control Point (CP) – Any step at which a biological, physical, or chemical factors can be controlled.

Critical Control Points (CCP) – A step at which control can be applied and is essential to prevent or eliminate a food safety hazard, or reduce it to an acceptable level.

FDA and USDAs regulation for number of CCPs that are needed in the food processing industry

The FDA and USDA do not require a specific number of CCPs (Critical Control Points) in a food processing facility.

The number of CCPs must be based on a thorough hazard analysis of your specific food process.

You must identify all significant hazards and apply a CCP where control is essential for food safety.

Guidelines

USDA-FSIS (for meat & poultry): Requires a validated HACCP plan with CCPs tailored to the process.

FDA (for juice, seafood, etc.): Follows HACCP principles and expects appropriate CCPs based on risk.

Critical Limits

The maximum or minimum values that must be met at a Critical Control Point (CCP) to ensure food safety.

A critical limit is a safety boundary—if crossed, the food may be unsafe.

Parameters that May Be Critical Limits

Temperature; pH; Moisture Level; Line Speed; Product visual defects

Time; Flow Rate; Water Activity; Salt concentration; Physical dimensions

Water; Viscosity; Sanitizer concentration; Operation of a metal detector

Steps in Setting Critical Limits

• Determine food safety parameter (time, temperature, pH, flow rate, etc.) that must be met at each CCP

• Determine proper standard that will prevent eliminate or reduce the occurrence of the food safety hazard to an acceptable level

Critical Limit

A required safety boundary at a Critical Control Point (CCP)

If not met, food may be unsafe and must trigger corrective action

Set by regulations, scientific data, or validation

Critical Limit = safety rule

Operating Limit

A stricter, internal target used to stay safely within the critical limit

Not required by law but helps avoid getting close to the critical limit

Provides an extra safety cushion

Operating Limit = safety buffer

Four Steps in Establishing Monitoring Procedures

1. What attribute will be monitored at the CCP to control the identified hazard

2. How will the attribute be monitored (Procedures)

3. When will it be monitored? (frequency)

4. Who will perform the monitoring procedures

Accuracy

How close a measured value is to the actual (true) value?

Precision

How close the measured values are to each other?

Three Elements of Corrective Action

Determine and correct the cause of non-compliance

Determine the disposition of the non-compliant product that poses a food safety risk

Record the corrective action

When is revalidation done and specific points to be looked at?

Revalidation is the process of reviewing and confirming that your HACCP plan still works effectively to control food safety hazards.

When to Revalidate:

Ingredient, equipment, or process changes

New products or formulations

Updated regulations or science

Recurring deviations or incidents

As part of routine review (e.g., yearly)

To ensure the HACCP plan is still accurate, effective, and up to date in preventing food safety risks.

When is verification of prerequisite programs done?

Verification ensures that prerequisite programs (PRPs)—like sanitation, pest control, or employee hygiene—are being followed and are effective.

On a regular schedule

Before or during HACCP implementation

When there are changes

After a deviation or contamination issue

During internal audits or inspections

When preparing for third-party or regulatory audits

What are some of the types of independent checks?

Internal Audits

Supervisor or QA Reviews

Third-Party Audits

Calibration Checks

Laboratory Testing

Environmental Monitoring

Product Sampling and Testing

Independent checks provide unbiased confirmation that controls are working and food safety is maintained.

What are 4 different types of HACCP records?

Monitoring Records: Document routine checks at Critical Control Points (CCPs).

Corrective Action Records: Show what was done if a critical limit was not met.

Verification Records: Confirm that the HACCP system is working as intended.

Validation Records: Provide scientific or technical proof that your control measures are effective.