Chapter 4 Section A (Unit 3)

1/12

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

13 Terms

4-1. AMA101

In Gas Tungsten Arc (GTA) welding, a stream of inert gas is used to

A. concentrate the heat of the arc and prevent its dissipation.

B. prevent the formation of oxides in the puddle.

C. lower the temperature required to properly fuse the metal.

Answer B. JSAT 4A

A stream of inert gas such as argon or helium flows out of the torch and envelopes the arc to exclude oxygen from the area and prevent the formation of oxides.

4-2. AMA101

Why is it necessary to use flux in all silver soldering operations?

A. To chemically clean the base metal of oxide film.

B. To prevent overheating of the base metal.

C. To increase heat conductivity.

Answer A. JSAT 4A, FAH

It is necessary to use flux in all silver soldering operations because of the necessity for having the base metal chemically clean without the slightest film of oxide to prevent the silver solder from coming into intimate contact with the base metal.

4-3. AMA101

Which statement concerning soldering is correct?

A. Joints in electric wire to be soldered should be mechanically secure prior to soldering.

B. Changeable shades of blue can be observed on the surface of a copper soldering tip when the proper temperature for soldering has been reached.

C. If the soldering temperature is too high, the solder will form in lumps and not produce a positive bond.

Answer A. JSAT 4A, FAH

Joints must be mechanically secure before soldering. If a soldered joint is subject to vibration, it can fail.

4-4. AMA101

A resurfaced soldering iron cannot be used effectively until after the working face has been

A. tinned.

B. fluxed.

C. polished.

Answer A. JSAT 4A, FAH

Without being tinned, heat cannot readily transfer from the iron to the work.

4-5. AMA101

Which of the following can normally be welded without adversely affecting strength?

Aircraft bolts

SAE 4130 chrome/molybdenum tubing

Spring steel struts

Most heat-treated steel/nickel alloy components

A. 2

B. 2 and 4

C. 1 and 3

Answer A. AC 43.13-1B

You must be very careful about using welding as a repair procedure. Generally materials, or weldments, which have been heat treated after fabrication are not candidates for field welded repairs. 4130 steel tubing is commonly used both during fabrication and repair.

4-6. AMA101

A very thin and pointed tip on a soldering copper is undesirable because it will

A. transfer too much heat to the work.

B. have a tendency to overheat and become brittle.

C. cool too rapidly.

Answer C. FAH

The tip on a soldering copper should be blunt and the entire head should be fairly wide. These features allow the soldering copper to retain its heat for a long enough period of time to perform its intended function.

4-7. AMA101

Filing or grinding a weld bead

A. may be performed to achieve a smoother surface.

B. reduces the strength of the joint.

C. may be necessary to avoid adding excess weight or to achieve uniform material thickness.

Answer B. AC 43.13-1B

A weld derives part of its strength from the proportions of the bead. Filing or grinding the bead of a weld will reduce its strength.

4-8. AMA101

Which statement concerning a welding process is true?

A. The inert arc welding process uses an inert gas to protect the weld zone from the atmosphere.

B. In the oxyacetylene welding process, the filler rod used for steel is covered with a thin coating of flux.

C. In the metallic arc welding process, filler material, if needed, is provided by a separate metal rod of the proper material held in the arc.

Answer A. JSAT 4A, FAH

In gas-shielded arc welding, a gas is used as a covering shield around the arc to prevent the atmosphere from contaminating the weld.

4-9. AMA101

What purpose does flux serve in welding aluminum?

A. Removes dirt, grease, and oil.

B. Minimizes or prevents oxidation.

C. Ensures proper distribution of the filler rod.

Answer B. JSAT 4A, FAH

Using the proper flux when welding aluminum is extremely important. Aluminum welding flux is designed to remove the aluminum oxide by chemically combining with it.

4-10. AMA101

Oxides form very rapidly when alloys or metals are hot. It is important, therefore, when welding aluminum to use a

A. filler.

B. solvent.

C. flux.

Answer C. JSAT 4A, FAH

Using the proper flux when welding is extremely important. Aluminum welding flux is designed to remove the aluminum oxide by chemically combining with it.

4-11. AMA101

When a butt welded joint is visually inspected for penetration,

A. look for evidence of excessive heat in the form of a very high bead.

B. the penetration should be 100 percent of the thickness of the base metal.

C. the penetration should be 25 to 50 percent of the thickness of the base metal.

Answer B. JSAT 4A, FGH

If it is properly done, the penetration in a butt weld should be 100% of the thickness of the base metal.

4-12. AMA101

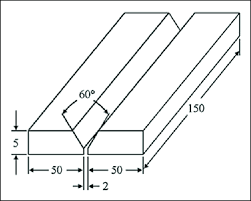

Edge notching is generally recommended in butt welding above a certain thickness of aluminum because it

A. aids in getting full penetration of the metal and prevents local distortion.

B. helps hold the metal in alignment during welding.

C. aids in the removal or penetration of oxides on the metal surface.

Answer A. JSAT 4A, FAH

Edge notching aids in getting full penetration and also prevents local distortion. All butt welds in material over .135 thick are generally notched in some manner to achieve full penetration of the weld.

4-13. AMA101

The shielding gases generally used in the Gas Tungsten Arc (GTA) welding of aluminum consist of

A. a mixture of nitrogen and carbon dioxide.

B. helium or argon, or a mixture of helium and argon.

C. nitrogen or hydrogen, or a mixture of nitrogen and hydrogen.

Answer B. JSAT 4A

Argon or helium are used to exclude oxygen from the area of the molten metal to prevent oxidation.