formulations -hard capsules

1/68

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

69 Terms

what may be included in a hard capsule

owders

granules

pellets

mini-tablets

capsulets

semi-solids

liquids

what might the coating of a hard tablet be

the capsule may have different levels of coating,this may allow a pateint to take one tablet with different length of duration

are the sizes of hard capsules metric

no

what are the most common hard capsule sizes

1,2,3

what is important when you fill the capsule

What is important is when you fill a capsule you try get as much material into the capsule as possibles as the patient usually like to eat the smaller capsule

what do hard gelatin capsules consist of

You have a prefabricated body / cap

what is the water content of a gelatin hard capsule

10-12 %

how is the hard capsule made

steel dipping pins are dipped inot the solution

what is in the gelatin dipping solution for the hard capsules

gelatin-30%

water 65%

surfactants

colouring agents

opacifiers

what do surfactants in the dipping solution do

enhance the wetting of the pins

what are opacidfiers used for

-mostly metal oxides that have some added benefits as they lower the elctrostatic charges

easier detection of the faulty shell

what is meant by the easier detection of faulty shells

-a non-opiake shell makes it easier to notice cracks compared to a translucent shell

how do the opacifiers blunt the ceramic knives

Use a cicularting knife made of ceramic knives

-they blunt faster

what is the principle of the production of hard capsule shells made of gelatin

there is a thermo reversible solution to gel transition of gelatin ant 50-60 degrees

-if you lower the temperature gelatin will not dissolve

-if the temp is to high then the gelatin will melt

why is a vaccum used in the production of hard shell capsules

prevent the formation of air bubbles

what is done in the production of the gelatin hard shells

a heated dip pan is connected to a storage hopper containing the gealtin solution

how many lines are there in the production of the hard shell gelatin capsules

Normally there are 2 lines running in parrralel one is forming the body and one is forming the cap

many capsules can be made per hour

-how long does this tae

40,000

45 minutes for a complete cycle

what are feature of the coni-snap capsules

-tapered rim

-air vents

-dimples

-locking rings

-hemisphereical ends

what is the purpose of the tapered rim

engages easilt with the cap for easy closure

what is the point of the dimples

maintain a precise round capsule diameter which imporves the filling presformance

what is the point of the round hemi-spherical ends

makes the capsule mechanically stronger and reisitant to deformation

what is the point of the locking rings

full circumference leak-free closure

what is the purpose of the air vents

allow the air to escape from the cap

-the cap is pushed down very quickly and the air is trapped in the capule,if this aor cant escape it may cause the capsule to explode

what is a bonus of a capsule

they require fewer exipients

what do you need in a capsule

For a capsule you will need the capsule the drug and a bulking agent

list the exipients you need in a fast release hard capsule

diluents

lubricants

flow regulating agents

what are the diluents

the bulking agents

what are examples of diluents

mannitol

lactose

starch

microcrystalline cellulose

what are lubricants used for

-in parma technology you usually internal lubriaction

-you add ils/fats which are fatty acids

-this allows lubriation of the maciene without needing to lubricate the machiene and stop production

examples of lubricants used

-magnesium stearate

stearic acid

glycerol mono-sterate

wha are the flow regulating agents

-allow the powdered mitures to flow better into the capsuke

examples of flow regulating agents

aerosil

talc

what are the steps required to make a capsule

-weight the individual exipients

-sieve the materials to get a certain particle size

-bring the exipients together and blend them

-fill the capsule

When you want to fill the capsule with gransuoles you must do granulation

-dry or wet

give a general overview of the filling process

1-feeding

2-orientation

3-opening

4-ejection of non-seperated

5-dosing

6-closure

7-ejection

what are the 3 mechanisims used to fill a capsule

hand filling

semi-automatic

automatic

output of hand filling machienes

3,000 an hour

main use of the hand filling machienes

pharmacies

universities

output of the semi-automatic machienes

10,000-25,000 capsules an hour

what are the main useres of the semi-automatic machienes

start up companies

clinical trials

small industry volume

automatic machiene output

60,000-250,000 capsules and hour

main use of automactic machines

industry

added bonus of automatic machines

-they are like a dishwasher and they clean themselves

why are capsules used in liquid encapsulation

-enhance bioavailability

-drugs with low melting points

-sustained release of the drug

-critical stability

-low dose with high potency active substance

solubility of the drug in liquid encapsulation tablets

the chemists come up with high affinity liqands which often have poor aqueous solubilitu

-if you process the drugs as powders the biolavailability is low

-if you place the drug in oil the drug may have good solubility

-these liquid base formualtions have the drug in the solution

drugs with low melting point and encapsulation

-they may be solid at room temperature

When you are processing the drug the temperaryre may increase and the drug may crystalise

powder formation and liquid preparation dosahge forms

-something may go wrong as the pateint could over dose

-the solution contains the same amount of drug in each formulation as the drug is in a solution

-oily solution = no dust generation and is much safer

what is done to a hard capsule to enusure that no liquid comes out

micro-spray sealing

explain micro-spray sealing

1-spray fluid onto join between the 2 capsule halves

2-the capillary action draws fluid up between the cap and the body

3-the capsule is then gently heated to melt the 2 gelatin layers

4-the 2 gelatin layers fuse together to form an impervious seal

5-the gelatin then sets and hardens at room temperature

what are the liquids that can be used for hard gelatin capsule filling

Many oils can be used as the material

-natural compounds or little chain triglycerides which are the same chemically as the natural oils

YOU MUST HAVE A LIPOHILLIC SYSTEM

What substances are incompatable with a hard capsule shell

-ethanol

-glycerin

-glycofurol 75

MCM

what drugs cannot be used in the hard shell gelatin campsules

drugs with reactive aldehyde groups

-these drugs can cause/under go the maillard reaction and cause cross linking

what cannot be in the environment with gelatin capsules

high temperatures

humidity

light

what should the dose of a drug be in a hard gelatin capsule and why

100-600mg

what should the paticles be (shape and size ) when used for a hard capsule gelatin capsule

isometric particles as they have better flow properties

size

10-150 micrometeres

what is the issue with hydroscopic drugs and harrd shell gelatin capsules

Do not want a hydroscopic drug as they will draw water from the shell and the shell will become brittle

what size should the capsule be

small

why should you colour the capsule

help with identification

added psychological effect

what temp and humidity should gelatin capsules be stored

15-25 degrees

35-65 humidity

what must the packaging protect from

mechanical effects

high atmospheric humidity

what are some of the materials included in the packaging

PVC

PVDC

aluminium

polyethylene

polypropylene

what are the types of combination products you can have

combinations of single active dose with various coatings

-combinations of multiple actives

what are the combinations of single active dose with various coatings

one extended relase capsule contains 4 small tablets each with a various degree of coating

what occurs in relation to coating and pellets

-each of the are coated with a coating -modified release

Small pellets are not held back in the stomach you get similar release kinetics

Capsule dissolves in the stomach and the pellets are released and emptied

what are contolled release formulations with 2 incompatible druga

combination of 2 drugs which are incompatible with eachother and they require differnent release profiles

what are the benefits to workers of using capsules with cytotoxic high poent drugs

reduces exposure risk as the in-process tablets do not nee to be handeled

what is the advantage of using semi-solid or liquid formulations into a capsule

-minimise airborne dust risk

-minimise cross contamination

-reduces the cost of having dedictaed facilites amd

capsules and dry powder inhalers

-advantage

convienent to handle

-high pulmonary availability

-pateints can chack the consumption

-

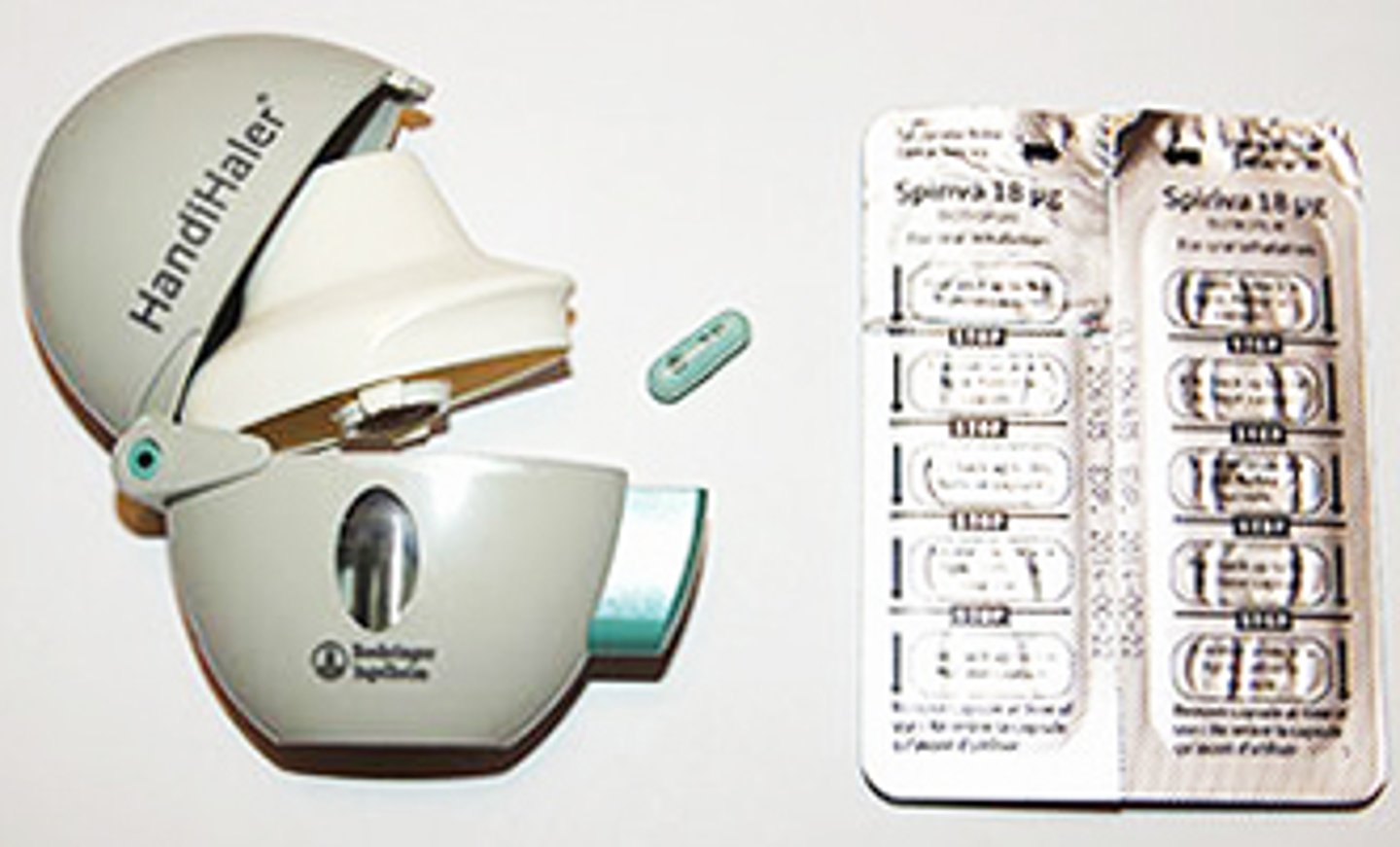

explain what spriva is

it is an inhaler used fort COPD treatment

-consits of a dry powder formulation

--you can place a capsule in an inhaler which pierces the capsule and the api is released when the pateint inhales