Unit 5B - Timber

0.0(0)

Card Sorting

1/109

Earn XP

Description and Tags

Last updated 5:36 PM on 12/20/22

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

110 Terms

1

New cards

2 types of timber finishes

1. Rough sawn

2. Planed all round (PAR)

2

New cards

Uses of rough sawn timber

1. Exterior tasks

2. Where finish doesn’t matter

3

New cards

Uses of PAR

1. Furniture

2. Internal features

1. Windows

2. Doors

4

New cards

Seasoning

Reduction of moisture content in timber

5

New cards

Common moisture contents

1. Green timber: >50%

2. Exterior use:

6

New cards

Air-drying

Timber is stacked so that air can circulate

7

New cards

Air-drying time

\~25mm/year (plank thickness that seasons)

8

New cards

Air-drying results

Moisture content reduces to 18% (in the UK)

9

New cards

Kiln-drying

Heat and pressure is used to reduce moisture content

10

New cards

Kiln-drying advantages

1. Lower moisture content

2. Less prone to faults

3. Kills bacteria/insects that might attack wood

4. Faster process - can be sold sooner

5. No land needed for storage whilst seasoning takes place

11

New cards

Kiln-drying disadvantages

1. More expensive

2. Bad for the environment

12

New cards

Manufactured board

Natural timber is combined with adhesive

Waste, low-grade and recycled timber can be used

Usually a pale brown natural finish

Waste, low-grade and recycled timber can be used

Usually a pale brown natural finish

13

New cards

Methods of manufactured board production

1. Lamination

2. Compression

14

New cards

Lamination

Layers of wood are bonded together with adhesives

15

New cards

Compression

Wood is shredded/chipped/pulped → heated and compressed under high pressure

Normally adhesives bond the particles together

Normally adhesives bond the particles together

16

New cards

Laminated boards

1. Plywood

2. Blockboard

17

New cards

Compressed boards

1. OSB (oriented strand board)

2. MDF (medium density fibreboard)

3. Chipboard

4. Hardboard

18

New cards

Veneer

Thin slice of natural timber

19

New cards

Veneer uses

Manufactured boards are covered in them

Commonly seen on MDF and plywood

Commonly seen on MDF and plywood

20

New cards

Methods of veneer production

1. Rotary

2. Knife cut

21

New cards

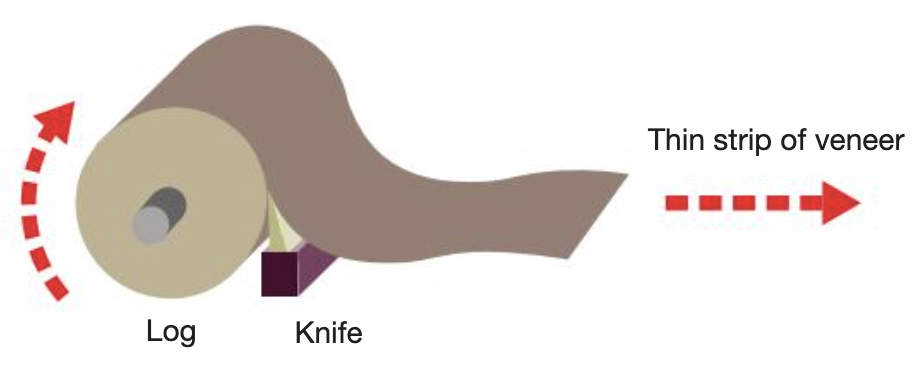

Rotary veneer production

22

New cards

Manufactured boards advantages

1. Available in large sheets & very stable - saves time joining narrow planks together

2. No defects/faults - less waste

3. No knots/resink pockets - avoids waste & protects tools that blunt easily

4. Smooth finish

5. Use low grade, recycled and waste wood

6. Many finishes, veneers and laminates

23

New cards

Manufactured boards disadvantages

1. Adhesives can contain hazardous particles or VOCs

2. Machining some (e.g. MDF) releases small particles - easily inhaled (even w/ mask)

3. Tools can blunt easily due to adhesive

4. Common wood joints are ineffective

5. Edges are hard to finish

6. Prone to absorb moisture

24

New cards

Wood is sustainable

We can grow new trees to replace those used for timber and fuel

25

New cards

Unsustainable timber supply

Often obtained illegally

Used much faster than it can be replaced

Used much faster than it can be replaced

26

New cards

Problems of unsustainable timber supply

Desertification - land degradation where an area becomes increasingly less fertile and changes itself to a desert by losing flora/fauna - caused by deforestation

Contributes to global warming

Contributes to global warming

27

New cards

Provenance of wood

Supplier should prove that wood is sustainably harvested

28

New cards

Organisations that ensure timber supply is regulated

1. FSC (Forest Stewardship Council)

2. PEFC (Programme for the Endorsement of Forest Certification)

29

New cards

Measurement format

*Length x width x thickness* - planks/boards

*Length x diameter* - rods/dowels

*Length x diameter* - rods/dowels

30

New cards

Manufactured boards sizes

Series of standard sizes

Thickness starts at 3 & 4mm, from 6mm goes up in threes - 9mm → 12mm etc.

Thickness starts at 3 & 4mm, from 6mm goes up in threes - 9mm → 12mm etc.

31

New cards

Single veneer thicknesses

Thicknesses range from 0.4 → 4.5mm - commonly 1.5mm

32

New cards

Manufactured board sheets

Full sheet is *2440 x 1220 mm* - based on old imperial standard of *8 x 4 feet*

Boards are usually available in half/quarter sheets and commonly smaller

Many DIY and timber stores offer cutting services for exact sizes

Boards are usually available in half/quarter sheets and commonly smaller

Many DIY and timber stores offer cutting services for exact sizes

33

New cards

Plank widths

Widths increase in 25mm stages - based on an imperial inch

Common size is *50 x 25 mm* - frame and carcass construction (rough sawn)

PAR would be \~ *45 x 20 mm* ∵ material removed on all sides for planing

PAR sizes always 2-3mm less per side in width & thickness - 5mm less width & thickness will be available

Reduction must be considered - inaccurate construction sizes

Common size is *50 x 25 mm* - frame and carcass construction (rough sawn)

PAR would be \~ *45 x 20 mm* ∵ material removed on all sides for planing

PAR sizes always 2-3mm less per side in width & thickness - 5mm less width & thickness will be available

Reduction must be considered - inaccurate construction sizes

34

New cards

Plank lengths

Lengths vary, often bought by metre

Commonly 1.2m, 1.5m, 1.8m, 2.4m, 3m, 3.6m, increasing to max 4.8m

Commonly 1.2m, 1.5m, 1.8m, 2.4m, 3m, 3.6m, increasing to max 4.8m

35

New cards

Moulding

Specially shaped section of wood

36

New cards

Architrave

Common type of moulding around door frames

37

New cards

Skirting board

Another form of moulding in older-style houses

38

New cards

Dowel rods

Circular sections of timber, can be ridged for use in wood joints

39

New cards

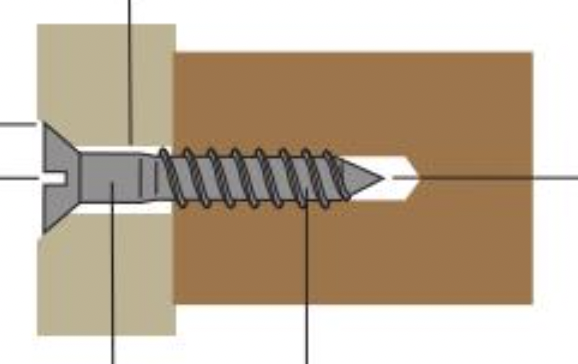

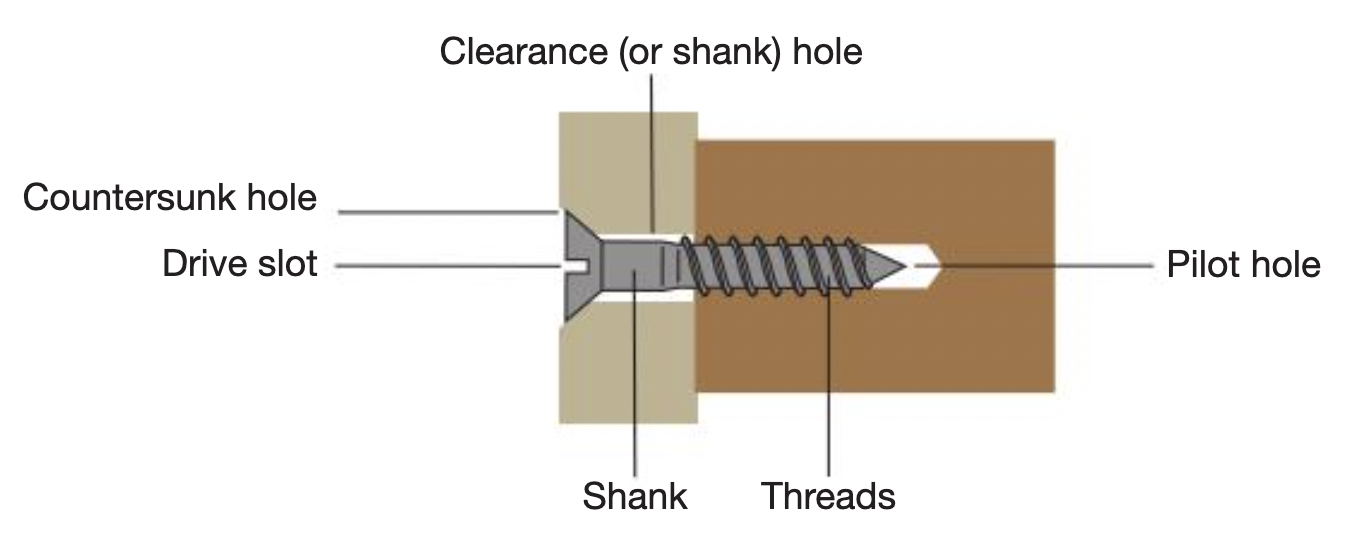

Woodscrews

Join 2 pieces of wood

Different lengths and diameters

Different driving methods - slotted/Phillips/Pozidriv most common

Allen & Torx becoming used more - more reliable connection with powered screwdrivers so fewer stripped heads

Different lengths and diameters

Different driving methods - slotted/Phillips/Pozidriv most common

Allen & Torx becoming used more - more reliable connection with powered screwdrivers so fewer stripped heads

40

New cards

41

New cards

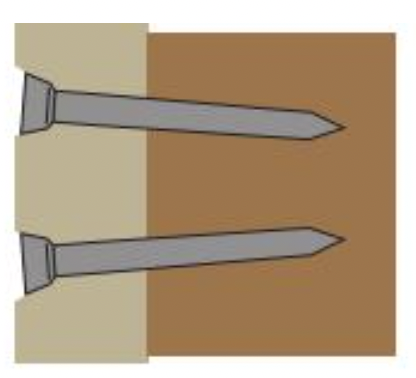

Dovetail nailing

Skewing nails or pins at an angle so that there is less chance that they come loose through force or vibrations

42

New cards

Round wire nail

All-purpose, wide flat head, can galvanise it for exterior use

43

New cards

Panel pin

Thin diameter, discrete small head, pin punch used to set below surface

44

New cards

Clout pin

Very wide head, often galvanised, used in roofing felt and plasterboard

45

New cards

Oval wire nail

Shaped nail, small head, prevents splitting, best for interior use

46

New cards

Tack

Sharp, short wide head, used to attach material e.g. upholstery to wood

47

New cards

Lost head nail

Thicker panel pin, used where head shouldn’t be visible, pin punch used

48

New cards

Knock-down fittings

Temporary

Join 2/sometimes 3 pieces of wood usually with screws

Easily dismantled for storage/transportation

Flat pack furniture relies on them

Join 2/sometimes 3 pieces of wood usually with screws

Easily dismantled for storage/transportation

Flat pack furniture relies on them

49

New cards

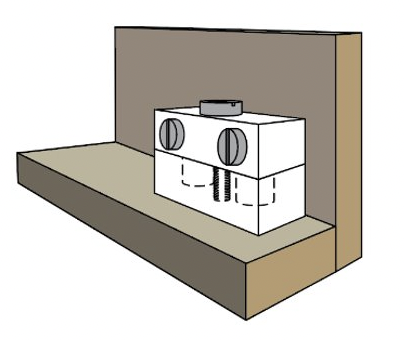

Connecting/block fitting

50

New cards

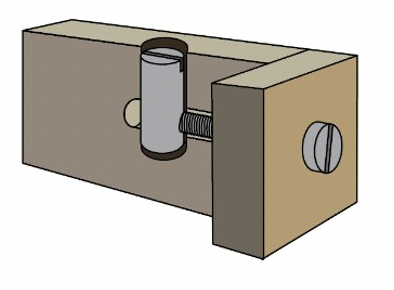

Cross dowel fitting

51

New cards

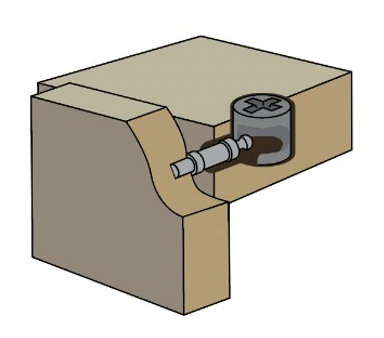

Cam lock fitting

52

New cards

Hinges

Attach door, windows etc. to frames/carcases

Usually metal, commonly polished brass or steel

Sold in pairs

Usually metal, commonly polished brass or steel

Sold in pairs

53

New cards

Rebating

Recessing the hinge to ensure flush fit

54

New cards

Butt hinge

Standard for doors/windows

Needs rebating

Needs rebating

55

New cards

Flush hinge

Less robust than butt hinge

No rebating

No rebating

56

New cards

Butterfly hinge

Decorative version of butt hinge

Used in cabinets

Used in cabinets

57

New cards

Piano hinge

Long, butt style hinge

Cut to required length

Fine, close join possible

Cut to required length

Fine, close join possible

58

New cards

Concealed hinge

Flat pack furniture

Specialist jig needed

Specialist jig needed

59

New cards

Tee hinge

Galvanised/painted/black japanned for outdoor use on sheds and gates

60

New cards

Factors in drilling

1. Drill bit type - correct amount of material removed

2. Speed - slower if bit is larger to avoid scorching wood

3. Depth - may not want to fully drill through

4. Feed rate - avoid excessive strain on drill bit

61

New cards

Pillar drill

Accurate

Can drill larger holes in thicker materials

Can drill larger holes in thicker materials

62

New cards

Cordless drill

Adaptable

Variable speeds for drill

Clutch can help avoid over-tightening

Variable speeds for drill

Clutch can help avoid over-tightening

63

New cards

Wood drill bit

Drill holes in wood

Flutes remove waste

Flutes remove waste

64

New cards

Twist drill bit

General purpose bit - also used on plastic and metal

65

New cards

Countersunk bit

Bit for countersunk screw holes - allows screw to be flush

66

New cards

Hole saw

Drills large holes

Easily overheats ∵ high peripheral speed

Easily overheats ∵ high peripheral speed

67

New cards

Flat bit

Efficiently makes large holes

Efficiently removes waste

Long shank for greater depth

Efficiently removes waste

Long shank for greater depth

68

New cards

Forstner bit

Accurate hole-cutting bit

Good for flat-bottomed/partial thickness holes

Good for flat-bottomed/partial thickness holes

69

New cards

Saws

Tenon, rip, cross-cut, coping and band

Cut material and joints to size

Cut material and joints to size

70

New cards

Saws for cutting straight lines

Tenon saw, rip saw, cross-cut saw

71

New cards

Saw for cutting joints

Tenon saw

72

New cards

Saw for cutting large panels

Rip and cross-cut saw

73

New cards

Saw for curved lines

Coping saw

74

New cards

Band saw

Powered saw

Straight cuts/gentle curves in thick/thin material

Straight cuts/gentle curves in thick/thin material

75

New cards

Scroll saw

Powered saw

Curves in thin material

Curves in thin material

76

New cards

Smoothing plane

Removes very thing layers

Smooths/flattens along grain

Smooths/flattens along grain

77

New cards

Chisel

Different versions

Used with mallets to form rebates/recesses

Used with mallets to form rebates/recesses

78

New cards

Rasp

Like a file

Very rough teeth - fast material removal

Different profiles

Very rough teeth - fast material removal

Different profiles

79

New cards

Surform

Fast material removal

Sharp but brittle grater-like blade

Different profiles

Sharp but brittle grater-like blade

Different profiles

80

New cards

Disc/Belt Sander

Sand easy to reach sections

Material safely held

Material safely held

81

New cards

Bobbin sanders

Cylindrical - sand internal curves

82

New cards

Glasspaper

Best for hard-to-reach areas

Apply different amount of force

Different grades measured in grit density

Lower grits are coarse and scratch, higher grits are smooth and polish

Apply different amount of force

Different grades measured in grit density

Lower grits are coarse and scratch, higher grits are smooth and polish

83

New cards

Wood lathes

Turn bowls/spindles

Slower speed for larger diameter

Special chisels - scraper, gouge, parting tool

Slower speed for larger diameter

Special chisels - scraper, gouge, parting tool

84

New cards

Former/Jig

Used in laminating

Object held against them, pressure applied with clamps/vacuum

Curves can be quite complex

Object held against them, pressure applied with clamps/vacuum

Curves can be quite complex

85

New cards

Bending wood

Can make ornate shapes and curves

Soaking in water - increases moisture content and makes wood more flexible

Soaking in water - increases moisture content and makes wood more flexible

86

New cards

Steaming

1hr/25mm of thickness - steamer box is faster

Thinner wood = tighter radius

Wood bent around former, clamped (same as laminating), dry for 1 hour

Few days to dry

Thinner wood = tighter radius

Wood bent around former, clamped (same as laminating), dry for 1 hour

Few days to dry

87

New cards

Best/Worst woods for bending

Best - oak, hickory, elm, walnut and ash

Softwoods/tropical hardwoods generally don’t bend as well

Softwoods/tropical hardwoods generally don’t bend as well

88

New cards

Butt join

Weak - little surface area for adhesive

Pins/nails common

Pins/nails common

89

New cards

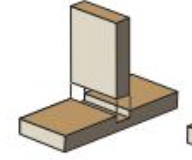

Dowelled joint

Wooden dowels add strength and rigidity

Dowels glued for strength

Dowels glued for strength

90

New cards

Mitre joint

Ends cut to 45°

More attractive than butt joint - used in picture frames/surrounds

Weak - little surface area

Metal splines can strengthen

More attractive than butt joint - used in picture frames/surrounds

Weak - little surface area

Metal splines can strengthen

91

New cards

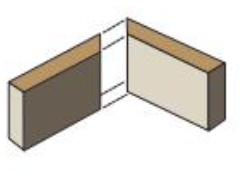

Housing joint

Stronger joint - larger surface are for adhesives

Physical advantage - wood supported on 3 sides

Physical advantage - wood supported on 3 sides

92

New cards

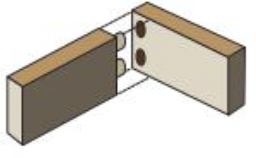

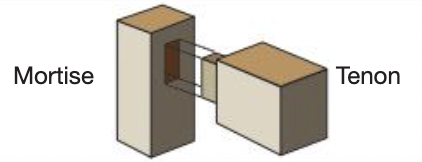

Mortise and tenon joint

Used in tables/chairs

Strong - very large surface area for glue

Physical advantage - tenon

Strong - very large surface area for glue

Physical advantage - tenon

93

New cards

Advantages of flat-pack furniture

1. Compact - easy to transport

2. Low cost

3. Many styles & finishes

4. Easy to assemble

5. Can disassemble for storage/moving

94

New cards

Disadvantages of flat-pack furniture

1. Needs to be constructed - additional cost?

2. Less robust than traditional furniture

3. Can be complex to build

4. Weak to moisture

5. Chips/breaks more easily

95

New cards

CNC (Computer Numerical Control) routers (flat) & lathes (cylindrical)

Great repetitive accuracy

Very high level of detail

Available in large formats

Can make ornate shapes

Can work with large panels

Work quickly - screw holes/slots/patterns cut in 1 process

Can save/reuse templates - save minimise waste

Can produce large quantities of identical items

Very high level of detail

Available in large formats

Can make ornate shapes

Can work with large panels

Work quickly - screw holes/slots/patterns cut in 1 process

Can save/reuse templates - save minimise waste

Can produce large quantities of identical items

96

New cards

QC (Quality Control)

Checking product is made correctly - ensure dimensionally accurate, safe

97

New cards

Tolerance

Allowed range/variation of measurements in a product

98

New cards

Go/no go gauge

Set to min/max tolerance - allowed variation in measurement of a product

Place gauge onto product part - easily rejected if size is wrong

Place gauge onto product part - easily rejected if size is wrong

99

New cards

Reasons for finishes

Aesthetics & Protection

100

New cards

Aesthetics finishes

1. Match/contrast with existing materials

2. Enhance natural grain

3. Give a shine/sheen or matt finish