PreQ ESD - 2.13 Sand Casting

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

18 Terms

Sand casting definition

pouring molten metal into a shaped hole made in damp sand and letting it cool

Draft

Tapering of the pattern that prevents sand being dislodged

Reason to put fillet in the pattern

To stop cracks from appearing during cooling

When to split a pattern

when the shape would dislodge sand. So locating dowels can be made to keep the halves in line

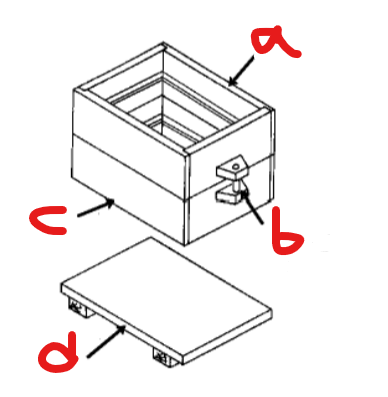

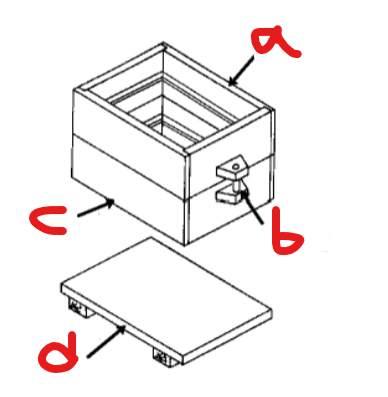

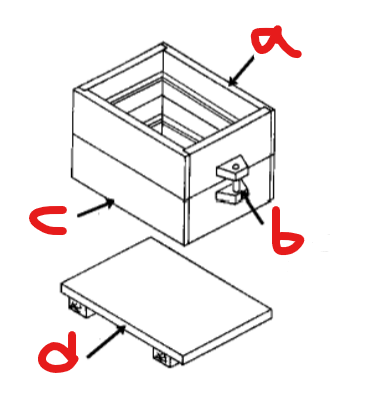

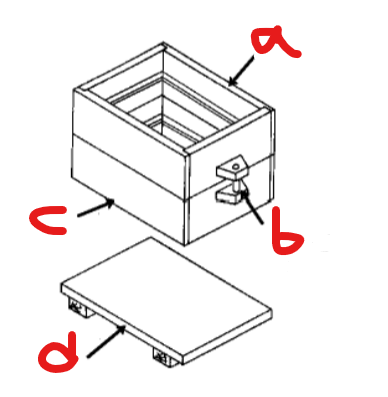

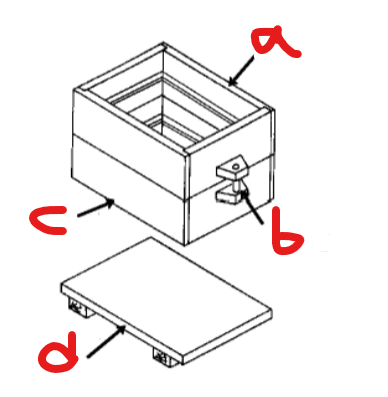

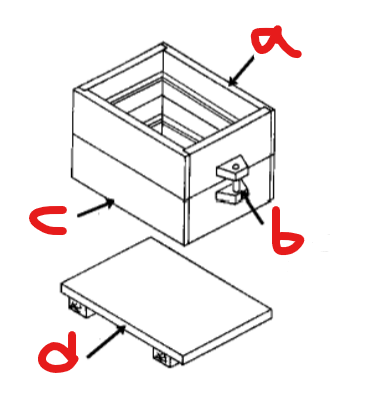

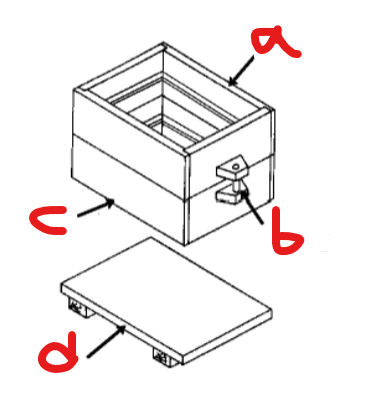

What is A

Cope

What is B

Locating pin

What is C

Locating pin

What is D

loose

Preparing pattern

Making the pattern in wood and must be drafted

The drag is turned upside down and put on the base board.

Moulding

The pattern is placed in the middle. Moulding sand, made damp with oil or water, is sieved over the pattern until the pattern is covered.

sand is shoveled in and then rammed with a rammer until packed tightly

Excess in removed by strickling with a metal strip to level the excess

he drag is turned the right way up and the cope is then placed on top. The top half of the pattern is added and also the sprue pins are positioned. Sand is then added and rammed to fill the cope

Spruce pin

Spruce pin is hammered into the sand to create holes where molten metal can enter.

Removing the pattern

The cope is now lifted off and the top half of the pattern and the sprue pins are removed. Channels called gates are cut between the sprue pin holes and the pattern to allow the molten metal to flow into the mould cavity.

Wood screw is screwed into the patterned to lift the pattern out.

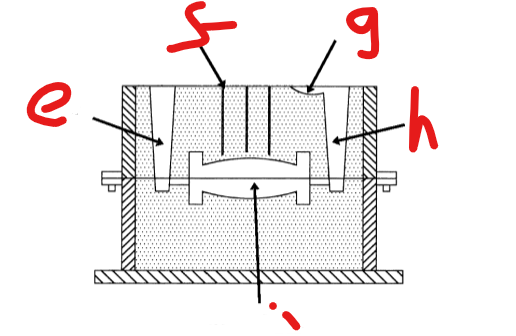

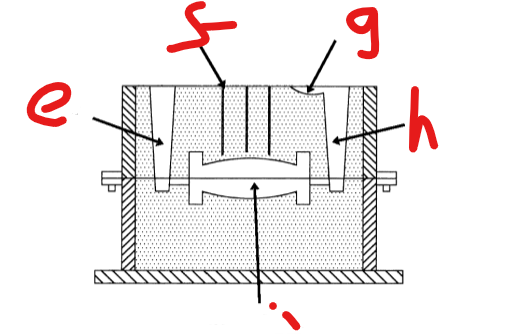

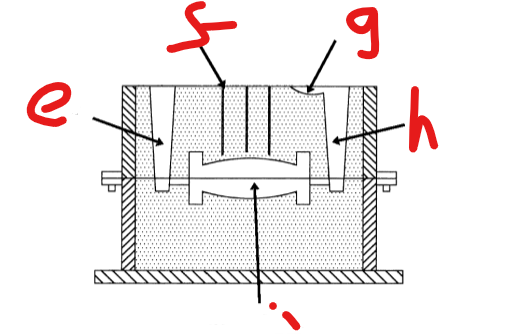

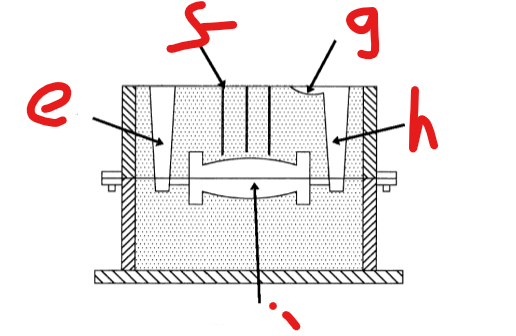

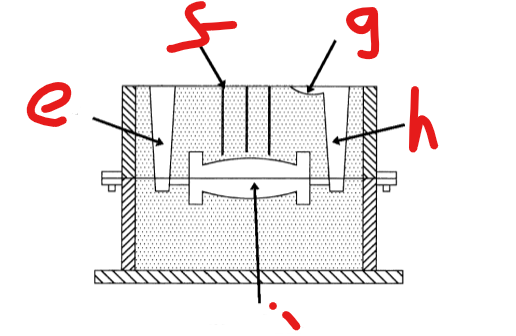

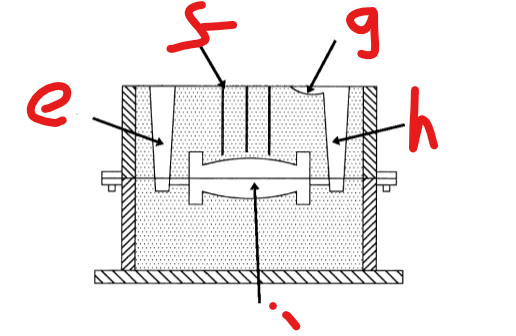

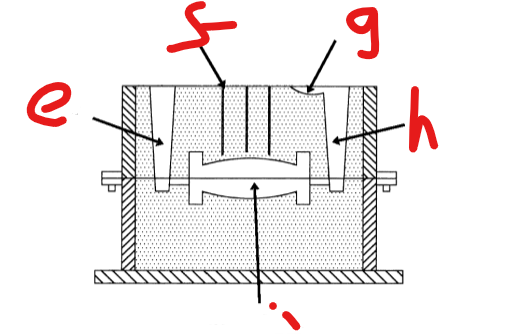

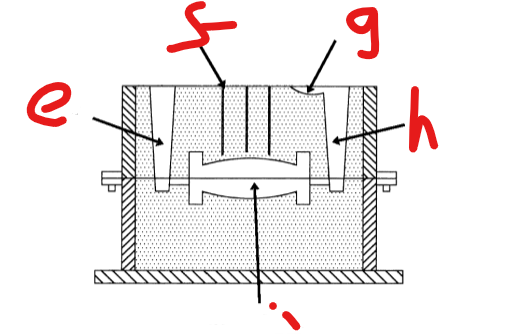

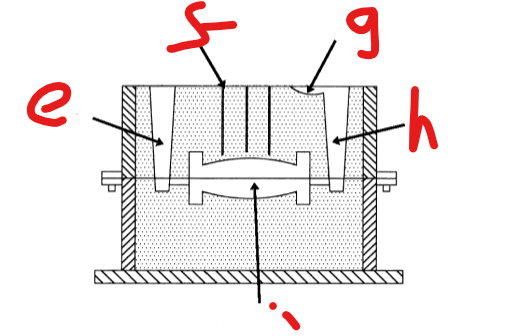

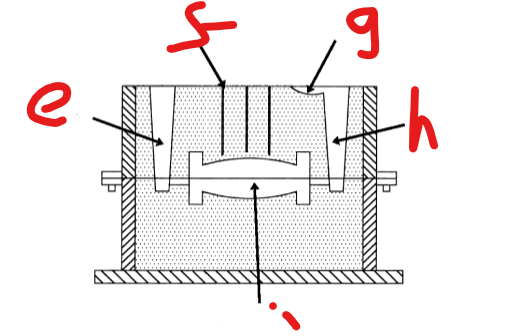

What is E

Riser - hole that allows excess metal to come out

What is F

Vents - Holes to allow trapped air to escape

What is G

Pouring basin - place to pour molten metal

What is H

Runner

What is I

Mould cavity

Cores use

To create a core made from half cores in a core box into where the mould cavity is