A. WOOD: 5 Veneers and Grains

1/24

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

25 Terms

Inter-locked

A type of grain where grains are in successive layers and in opposite direction caused by each growth year

Diagonal grain

A type of grain when straight grained log is not sawn along its vertical axis

Spiral grain

A type of grain when trees grow twisted, spiral-grained logs and subsequent boards are produced. This twist happens either left or right-handed.

End grain

A type of grain when board is cut across the grain (perpendicular to the grain direction and the growth rings)

Quarter sawing

A type of sawing lumber when first, the sawyer cuts the log in quarters, then slices each quarter into boards, either by cutting boards from two flat sides alternately or by gang-sawing the quarter (parallel cuts)

Live saw

Sometimes called sawing through and through; produces much wider boards than other methods, and these boards show mostly mixed grain - flat grain near the centre of the face and quarter grain near the edges

veneer

A thin sheet of wood, rotary cut, sliced or sawn from a log or flitch.

stump veneer

Produced from the base of the tree. Here the grain pattern is always swirly twisted and often accompanied by cross fire and patches of burl. The sizes are normally small.

Crotch Veneer

Produced from the portion of the tree just below the point where it forks into two limbs. The grain is twisted, creating a variety of flame figures.

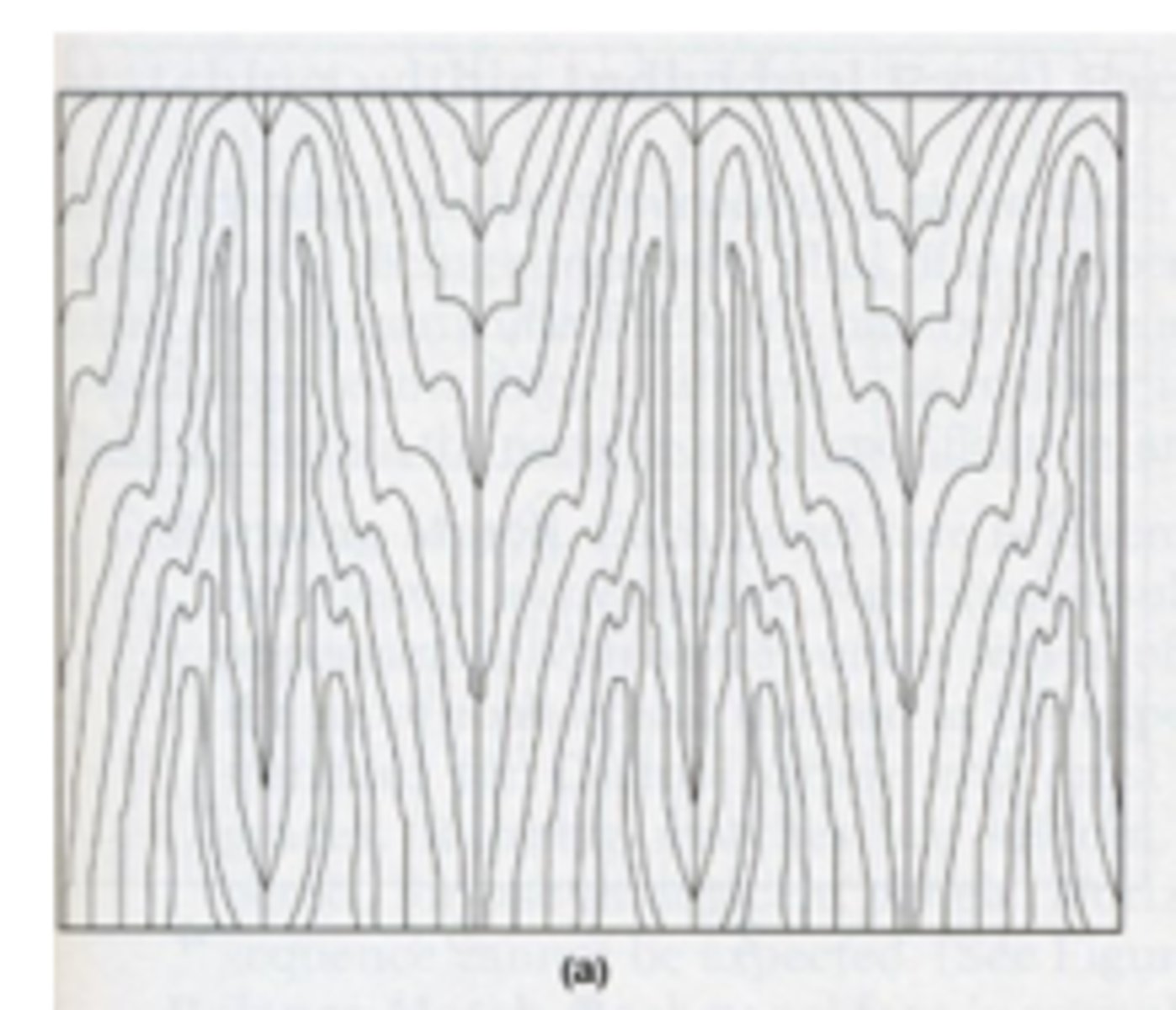

cathedral pattern

A grain appearance characterized by a series of stacked "V" and inverted "V". Pattern common in plain-sliced (flat-cut) veneer.

burl veneer

Produced from a large, wartlike growth on the trunk of the tree. The grain pattern typically resembles a series of eyes laid side by side. Obviously the veneers leaf sizes are generally small and additionally are defective

random match

The veeers are placed in a random order and orientation. This provides a completely random and unmatched look.

center match

where the leaves are all the same width and the grain pattern is centered on the panel. This is the most labor intensive and, therefore, is most expensive

book match

practice of matching two surfaces, so that two adjoining surfaces mirror each other

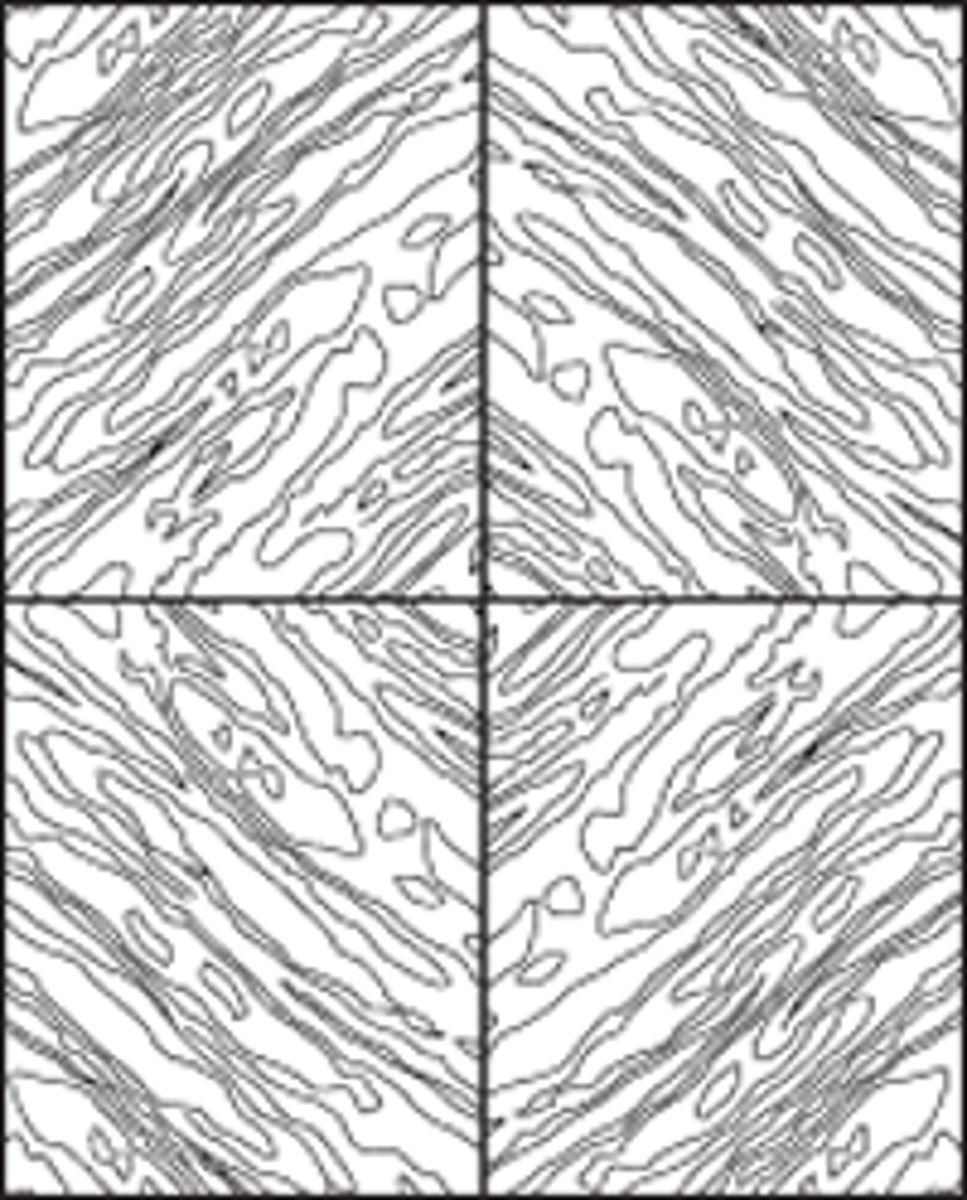

diamond match

Leaves of veneer are oriented at an angle in a mirror image that forms a concentric diamond pattern.

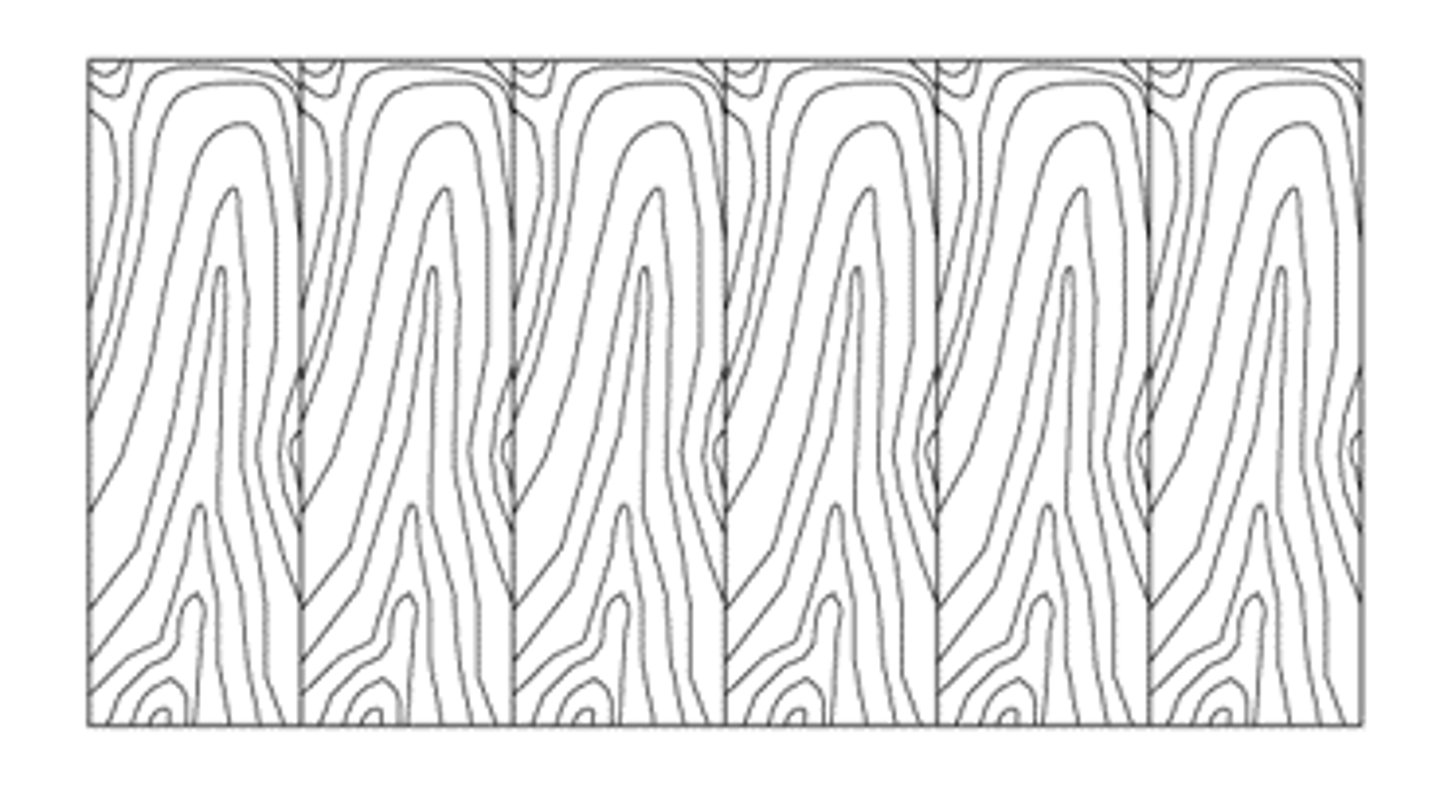

slip match

The joining together of individual wood flitches, side by side, so as to provide a repetitive decorative pattern in the arrangement, but not necessarily continuous or symmetrical in the overall visual effect.

saw cutting

method of cutting veneer used for thick cut veneers that are 1/8" thick. These are cut using circular saws

rotary cutting

method of cutting veneer widely used for constructional and some decorative veneers such as bird's eye maple

off center cutting

method of cutting veneer with a combination of rotary cutting and flat slicing that produces a figure similar to a flat sliced veneer

half round cutting

method of cutting veneer similar to off center cutting and produces also a flat sliced veneer.

back cutting

method of cutting veneer where a rotary method is used for cutting decorative butt and crotch veneers

flat slicing

method of cutting veneer common for producing traditional crown cut veneer

book match veneer

slip match veneer

diamond match veneer