ch 8 food safety (purchasing, storing, controls, HACCP, equiptment, sanitation, cleaning, waste

1/98

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

99 Terms

what is the ultimate goal of a food safety manager

assure that a safe food product is served to customers to protect them from foodborne illness

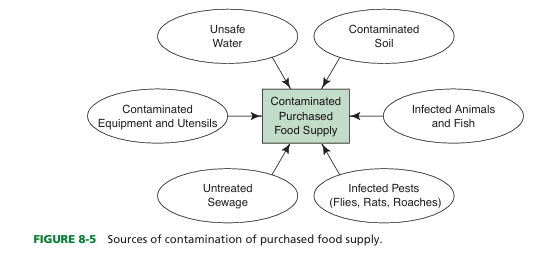

possibilities of food before it purchased include (5)

contaminated equipment, infected pests and animals, untreated sewage, unsafe water, and soil

after purchase, possible contamination exist in (3) of food

purchase, storage, and service of food

possible transmission routes from infected persons

respiratory tract discharges, open sores, cuts, and boils, or through hands soiled with feces into food being prepared.

food should be purchased from suppliers that are

approved and reputable

suppliers should be using (2)

using Good Manufacturing Practices (GMP) or Good Agricultural Practices (GAP)

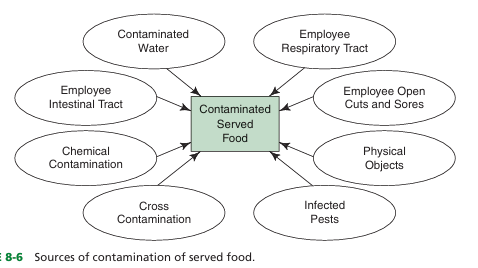

contaminated served food by (6)

contaminated water

employee respiratory tract

employee open cuts and sores

physical objects

infected pests

cross contamination

chemical contamination

employee intestinal trac

foodsafety starts in the _____ area of foodservice operation

receiving

meat food safety criteria

temp

color

texture

odor

packaging

41°F or below

bright red color

firm, nonslimy texture

no odor

intact and clean packaging

poultry food safety criteria

temp

color

texture

odor

packaging

41F or below

no discoloration

firm

no odor

frozen or packed in crushed, self draining ice

fish food safety criteria

temp

color

texture

odor

eyes

packaging

41°F or below

bright red gills and bright shiny skin

firm flesh; mild ocean or sea weed smell

bright, clear full eyes

frozen or packed in crushed, self-draining ice

shellfish food safety criteria

temp

odor

shells

packaging

Live on ice or at temperature of 45°F or below; shucked at internal temperature of 45°F or below

mild ocean or seaweed smell

unbroken shells; closed shells if alive

shellstock identification tags (packer’s name, address, and certification number) on container (manager must date when the last shellfish was served and then keep tags on file for 90 days from date)

shell eggs food safety criteria

temp

odor

packaging

Temperature of 45°F or below

no odor

clean and unbroken shells

liquid, frozen, dried food safety criteria

packaging

pausterization

Must be pasteurized

have a USDA inspection mark

dairy food safety criteria

temp

milk processes

cheese flavor, texture, color

Temperature of 41°F or below

milk must be pasteurized and comply with FDA Grade A standards

cheese with typical flavor, texture, and uniform color

canned goods food safety criteria

packaging

Can and seal in good condition (no swollen ends, leaks, dents)

dry goods food safety criteria

packaging

Intact packaging (no holes, tears, punctures, water stains

produce food safety criteria

temp

temperature of 41°F or below for fresh cut greens, melons, tomatoes, or other processed produce

define cold chain management

Temperature control throughout the supply chain delivery process of perishable foods.

focus is on maintaining a temperature-controlled environment throughout the distribution and storage stages of a food produce

Ex: for example, tracking the temperature of meat from the time it was initially processed at a meat packing plant through storage and transportation until it reached the foodservice operator to ensure that the temperature of the product was maintained at acceptable levels throughout the supply chain stages

define cross contamination

Transfer of microorganisms from one food product to another, by storing raw meat, poultry, and fish separate from cooked and ready-to-eat foods.

how should poultry, ground beef, meat, and RTE food and cooked meat be stored

Raw poultry should go on the lowest shelves

Raw ground meat should be placed on shelves above raw chicken but under raw whole meats and fish.

Raw meats should be placed above raw poultry and raw ground meat but under cooked and ready-to-eat foods

Ready-to-eat foods and cooked food items should be placed on upper shelves above any raw meat, fish, or poultry.

define temperature danger zone

Temperature range (41°F to 135°F) in which bacteria multiply rapidly

how quickly should TCS food be cooled

time/temperature control for safety (TCS) food, should be cooled within 2 hours from 135°F to 70°F; and within 6 hours from 135°F to 41°F or less

Safe temperatures are below 41F and 135F and above

when can cross contamination occur (like why)

Cross-contamination can occur in production and service when improper food-handling practices are used

Cutting board to cut raw meat and then using same uncleaned to cut produce

Handling raw meat or poultry and not washing hands well before handling RTE foods

why is employee hygiene and practices important

Employee personal hygiene and good food-handling practices are basics of a food safety program in a foodservice facility.

One major risk is that unsanitary employees can contaminate, or infect by bacteria, food products in production and service

A foodservice employee personal hygiene program should include three major components:

maintaining personal cleanliness

wearing proper work attire

following hygienic hand practices

basic rules for employee dress and rules

Proper attire (pulled back hair, closed toed shoes, proper clothes, no jewelry)

Proper handwashing

Nails short and clean, no false nails, no nail polish

Cuts and wounds on hands need be covered

No eating, chewing, drinking

how often to clean room temp food contact services

at least every 4 hours

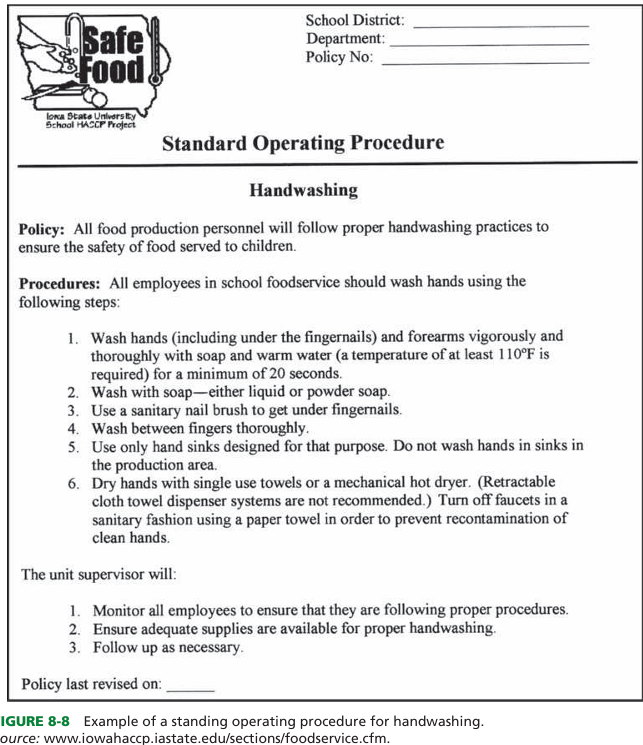

for a food safety program, what 3 things must be put in place/ identified

critical control points (CCP) identified

standard operating procedure put in place

hazard critical control point (HACCP) model selected

define hazard analysis critical control points

systematic analysis of all process steps in the foodservice subsystems, starting with food products from suppliers and ending consumption of menu items by customers.

what are the critical points

those steps in production processing In which loss of control would result in a unacceptable safety risk

HACCP was crated as a what, for what

HACCP uses a preventive approach to quality control

HACCP was developed in 1971 for NASA to be sure food fed to astronauts in outer space is absolutely safe

3 phases of HACCP

Selection of control points

Identification of critical control points

Establishment of monitors for control

what are the 7 HACCP principles

Created in 1992 by NACMCF

Principle 1: conduct a hazard analysis

Principle 2: determine the critical control points

Principle 3: establish control limits

Principle 4: Establish monitoring procedures.

Principle 5: establish corrective actions

Principle 6: establish verification procedures

Principle 7: establish recordkeeping and documentation procedures

define hazard

Unacceptable contamination of food

define critical control points

Locations in the food product flow where mishandling of food is likely to occur

basis for a strong HACCP program is having the necessary prerequisite programs in place. What programs? (11)

Sanitation standard operating procedures

Quality management

Employee education and training

Personal hygiene

Safe food handling and storage practices

Temperature monitoring

Specifications and suppliers

Food recalls and disaster plans

Equipment monitoring and calibration

Preventive maintenance programs

Integrated pest management

define standard operating procedure (SOPs)

written, step-by-step instructions for routine tasks

what types of thermometers are need in foodservice operations (4 types)—> not specific names but like location and type

bimetallic stemmed or digital pocket test, refrigerator/freezer/dry storage, hot holding, and meat thermometers

what is the HACCP manager (type of thermometer)

is an electronic device for recording and transmitting temperature, time, and location for any food preparation process that requires accurate record keeping

infrared thermometer

not inserted into food; rather they use infrared technology to measure the temperature of the food on the surface

most commonly used thermometer

bimetallic stemmed thermometer

define calibrate

Process to assure temperature testing equipment is providing an accurate temperature reading.

Easiest way to calibrate is to place thermometer in glass of ice water for at least 30 seconds

what are T sticks

Many foodservice operations have supplemented the use of thermometers with a disposable product called T-Sticks.

T-Sticks are multipurpose sensor sticks used to monitor food temperatures and the temperature in the dishwasher’s final rinse section

define bioterrorism

Intentional use of biological agents or germs to cause illness.

Became a thing due to the sept 11 terrorist attacks

Food and water became a potential target for terrorist attacks

Strategic Partnership Program Agroterrorism (SPPA) Initiative

-what is

-formed by what agencies

Designed to protect nation's food supply

Is a DHS, USDA, FDA, and FBI collaboration

what is ALERT

FDA Center for Food Safety and Applied Nutrition developed food security preventive measures guidance for food processors and retailers

what does ALERT stand for

A- Assure products received are from safe sources,

L- Look (monitor) the security of productions in the operation

E- Employees know who should or should not be in the area

R- Report and keep information related to food defense accessible and

T- Threat

suggestions for food protection (7)

-awareness

-procurement

-access

-personnel management

-monitoring

-planning

-education

awareness

Awareness—be alert to unusual activity in and around your operation

procurement

Procurement—use reputable suppliers and inspect deliveries carefully

access

Access—control access to foodservice operation

personnel management

Personnel Management—screen applicants carefully and document, post, and enforce employee schedules

monitoring

Monitoring—observe employees and customers and check less used areas

planning

Planning—have detailed response plans in place that include call lists

education

Education—educate employees on the role they need to play in helping monitor and report unusual occurrences

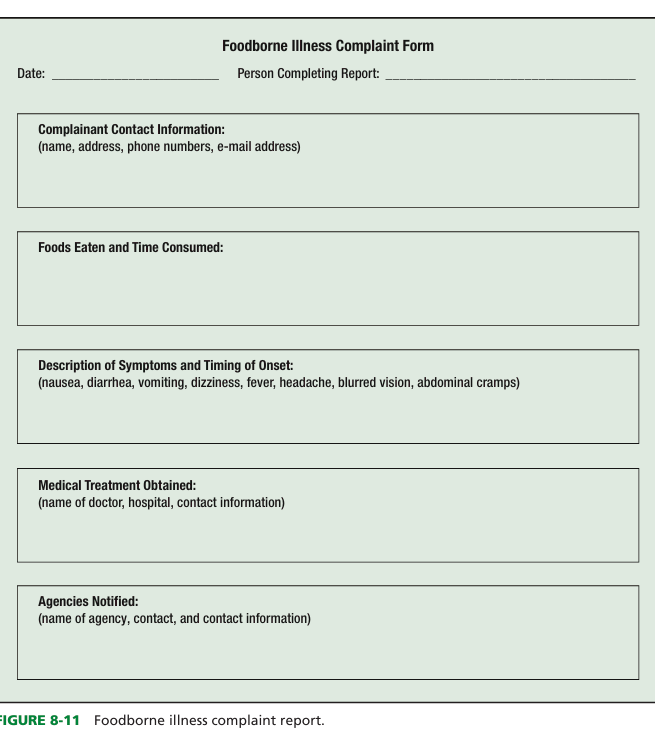

procedure for complaints

have person complete a complaint report

Obtain all the pertinent information including names and addresses of all party members, the employee who served the meal, the date and time of customer's visit, and suspect meal

Remain concerned and polite, but do not admit liability of offer to pay medical bills

Never suggest symptoms, but let the complainant tell their own story

Record the time the symptoms started, which will help in identifying the disease

The first requirement for a sanitary design is

cleanability

which means the facility has been arranged so that it can be cleaned easily

define clean

Free of physical soil and with an outwardly pleasing appearance.

define sanitary

Free of disease-causing organisms and other contaminants

what 6 factors effect cleaning process

Type and condition of dirt—certain types of dirt require special cleaning methods

Water hardness—cleaning is more difficult with hard water as the minerals in the water react with the cleaning detergent and decrease its effectiveness

Water temperature—hot water aids in dissolving detergent and loosening dirt

Surface to be cleaned—some surfaces require special cleaning supplies and techniques

Agitation or pressure—additional pressure may be needed to remove dirt

Length of treatment—longer exposure to detergent makes cleaning easier

what are the 4 types of cleaners

detergents, abrasive cleaners, degreasers, delimers

detergents

detergents- used to remove dirt from surfaces (floors, walls, counters, equipment)

abrasive cleaners

Abrasive cleaners- contain abrasive agent(s) to help more difficult to remove dirt

degreasers

Degreasers- used to remove grease from surfaces (ovens, grills, hoods)

delimers

Delimers- used to remove mineral deposits (dishmachines, steam wells)

____________ is critical for any surface that comes in contact with food, which includes, of course, all dishes, utensils, pots, and pans

sanitation

most common chemicals used in sanitation

Chlorine

Iodine

quaternary ammonia

effective of sanitation agent is impacted by (5)

concentration of the sanitizer, the hardness, temperature, and pH of the water, and the contact time on a surface

define material safety data sheet (MSDS)

Sheet with use and safety information about a chemical.

how should receiving and storage area be designed

for easy cleaning

dry storage area design

Slip resistant floors, insulated walls and subfloors, insect and rodent proof, light colored walls, products never stored on floor--> dry storage area

fridge and freezer storage area design

Hard surfaces, easy clean floors, walls, fixtures, nonabsorbent material, drains, uniform ventilation and adequate lighting--> fridge and freezer storage

define ware washing machine

Process of washing and sanitizing dishes, glassware, flatware, and pots and pans either manually or mechanically.

dishmachine process consist of (5)

scrapping, prewashing, washing, sanitizing, and air drying

single tank dish machine (for what, has what)

For plates, cups, silverware, or glasses.

two doors that can be manually opened and one combined wash-and rinse tank. It holds a rack of dishes that does not move.

rack coveyor dishmachine (works how)

Dishes are still racked to be cleaned in the rack conveyor dishmachine. After dishes are scrapped and sorted, they are placed in racks and the racks with soiled dishes are put on a conveyor that moves the racks through the dishmachine.

Rack conveyor dishmachines have one, two, or three tanks.

2 tank vs 3 tank rack conveyor machine

The two-tank machine has prewash and power-wash tanks

the three-tank machine has a heavy-duty power prewash, power-wash, and power-rinse

flight type continous conveyor

This dishmachine is typically used in high-volume operations

rather than being placed in racks, plates and trays are placed between rows of plastic pegs on a conveyor; smaller items such as glasses, cups, and flatware are racked before sending them through the machine.

pot washing is done how

with power soak

Pot washing is quite different from dishwashing because pressurized hot water is sprayed directly on the soiled surface.

define power soak, what is it

Pot- and pan-washing equipment that capitalizes on the natural scouring abilities of high-turbulence, heated water

considered the easiest way to clean pots and pans

Maintaining an optimum cleaning temperature of 115°F loosens soil while powerful jets blast clinging particles away

proper plumbing is important to prevent mixing of what 2 things

potable and nonpotable water

potable water

water that is safe for human consumption

sanitation of kitchen and dining areas (plan)

-need regularly scheduled programs on proper cleaning procedures

-plan must be started when facility is being planned

procedure for cleaning floors

Spills should be wiped up promptly to avoid tracking and to eliminate a safety hazard.

Regular schedules for cleaning floors should be established. Floors subjected to heavy traffic and food spills, such as in the production areas, must be scrubbed at least daily and hosed, stripped, and steamed periodically for more thorough cleaning.

Floor care equipment, including brooms, mops, and vacuums, should be cleaned regularly.

dish storage

All dishes and utensils must be stored dry and in clean, dust-free areas above the floor and protected from dust, mop splashes, and other forms of contamination

Mobile equipment designed for various things is ideal

general rules to trash and garbage handling (5)

Garbage and trash containers must be leakproof, easily cleanable, pest-proof, and durable with tight-fitting lids. Today, plastic bags frequently are used for lining containers to facilitate disposal.

Garbage and trash should not be allowed to accumulate anywhere but in containers

Garbage and trash should be removed from production areas on a frequent basis for appropriate disposal.

Garbage storage areas should be easily cleanable and pest-proof. If long holding times for garbage are required, these areas should be refrigerated to prevent decomposition, odor, and infestation by vermin.

A garbage can washing area with hot water and a floor drain should be located away from food production and storage areas.

define pulper

Water-filled tank in which solid waste is broken down into a slurry by a shred ding device and then water is pressed out of it (water is then reused)

replacing garbage disposal units

require daily cleaning

define solid waste

Solid and semisolid products, such as foodwaste, paper, cardboard, metal, and plastic, that are being discarded from a foodservice

goal is what when it comes to food waste

prevent pollution before it occurs

An integrated solid waste management program includes the following:

Menu design and planning

Purchase specifications

Food production practices

Service methods

Portion control

Waste-product disposal methods

Consumer education

Employee training

how much of solid food waste is service related? from food production and prep areas?

-60-70%

-30-40%

define source reduction

Reducing the amount of waste going into the waste stream from a foodservice operation (source).

define recylcing

Act of removing materials from solid waste stream for reprocessing into valuable new materials and useful products.

Many of the traditional packaging materials, including paper, metals, plastic, and glass, can be recycled.

define composting

Controlled application of the natural process of organic degradation.

Any organic material, including food waste and paper or cardboard that has been contaminated with food, can be composted.

define combustion

Form of solid waste recycling in which the energy value of combustible waste materials is recovered

define biological solution

use bacteria to break down animal fats and food products that clog drains

employee facilities

-what should be provided for them

-type of flooring

-closeness to work area

Locker rooms should be provided for employees to change clothes

Individual lockers with locks are needed for storing street clothes and personal effects when employees are working

Floors should be tile laid in cement or other nonabsorbent materials

Employee facilities should be located near the work area

guest restrooms

should be easily accessible from the dining room

Keeping both employee and guest restrooms clean can be a major management problem

Employee restrooms should be maintained at the same quality as those for guests