MATE 210 Lecture 15-18

1/19

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

20 Terms

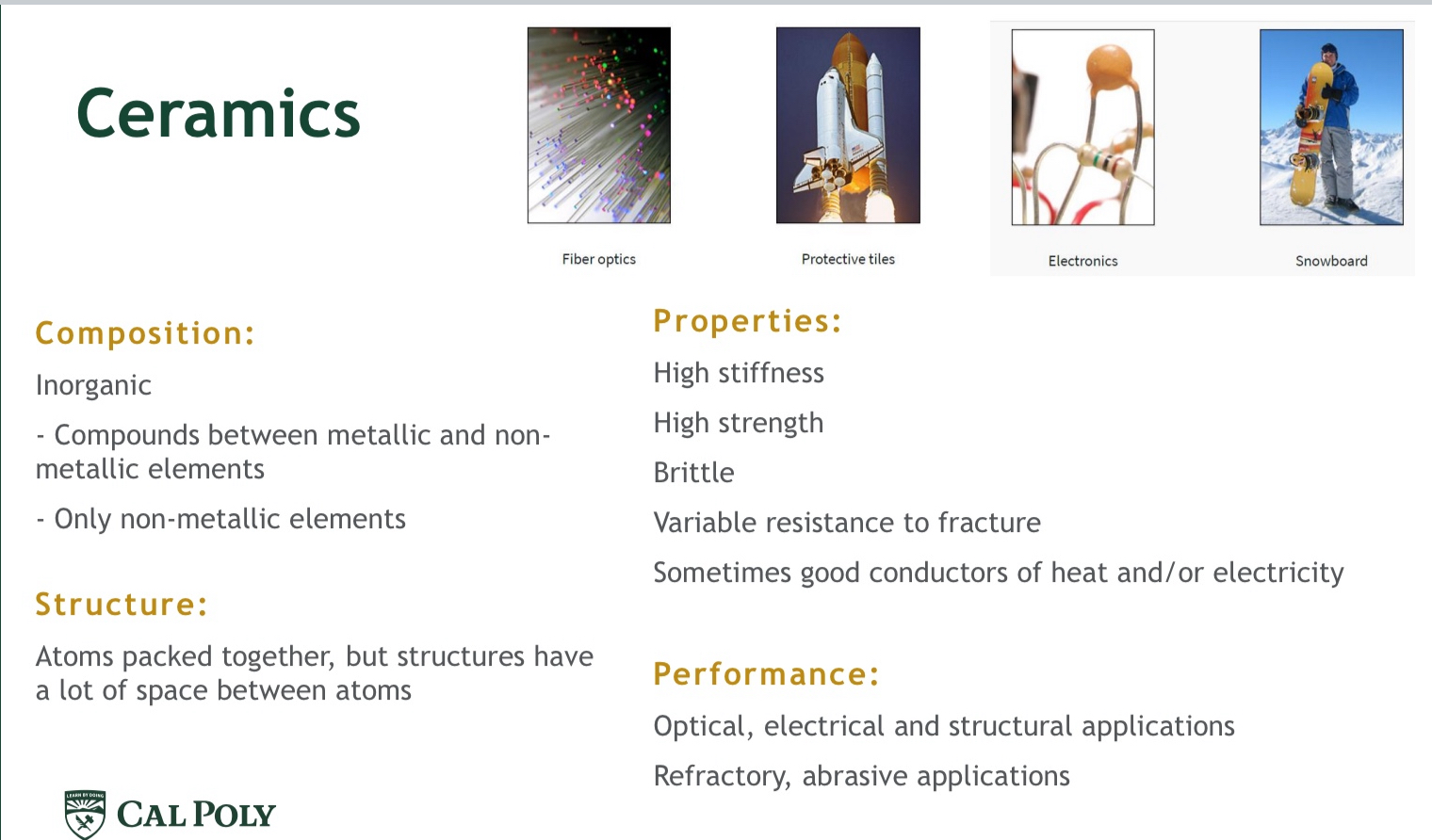

Ceramics- properties, composition, performance, structure

Structure- ceramics tend to have more complex structures than metals

Types of ceramics

Glasses, clay products, refractories, abrasives, cements, ceramic bio materials, carbons, advanced ceramics

Refractories

Clay

R- withstand high T without melting or decomposing, resistance to thermal shock, basically good in extreme temps

C- one of most used ceramics, cheap, abundant, layered crystal structures, drying and firing

How cement works

Chemical reactions between water and cement particles

Mix cement and water, cement grains dissolve in water, hydrates precipitate (new solids with higher volume)

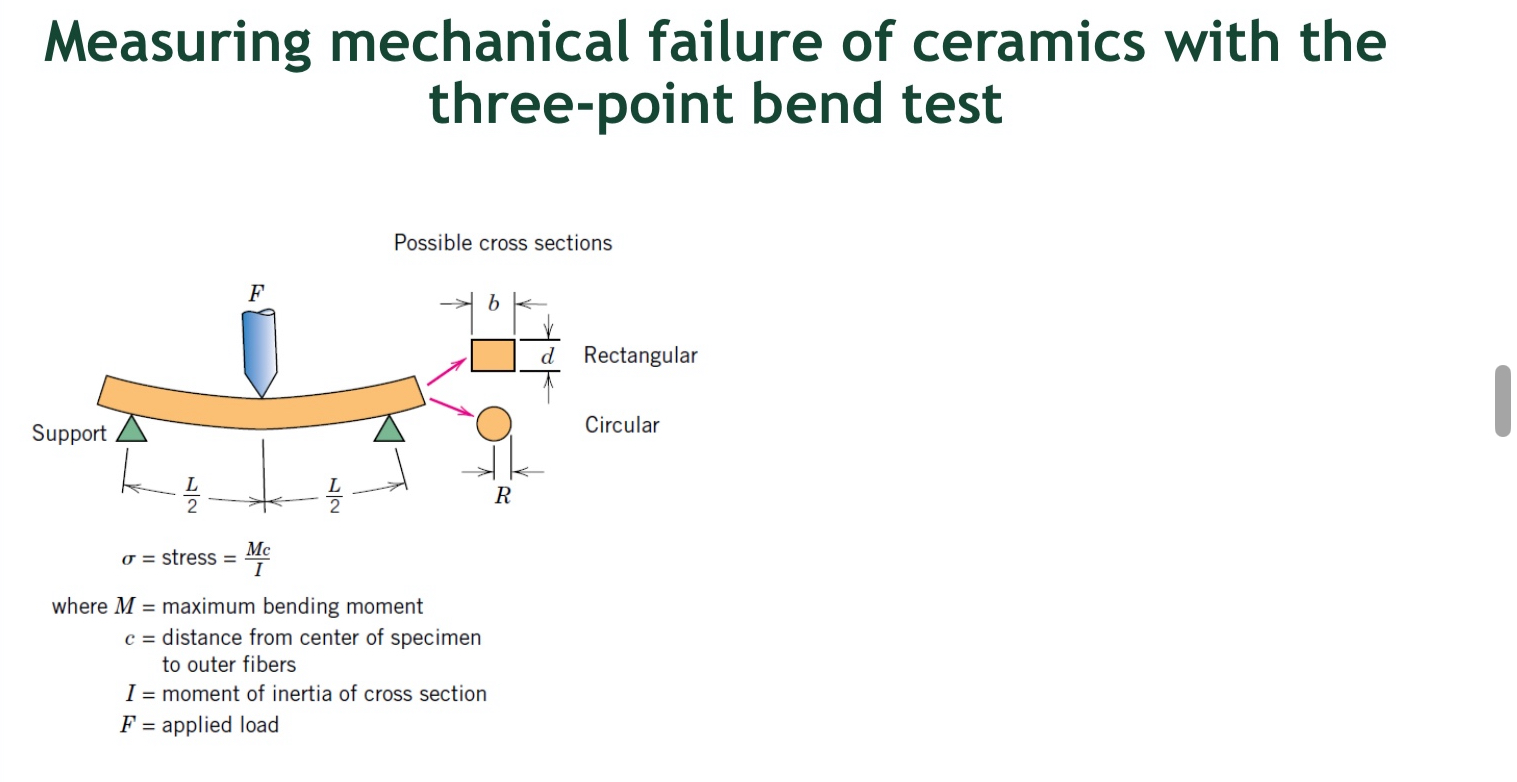

Describe 3 point bend test

What is the 3 point bend test used for

Used for measuring mechanical failure in ceramics

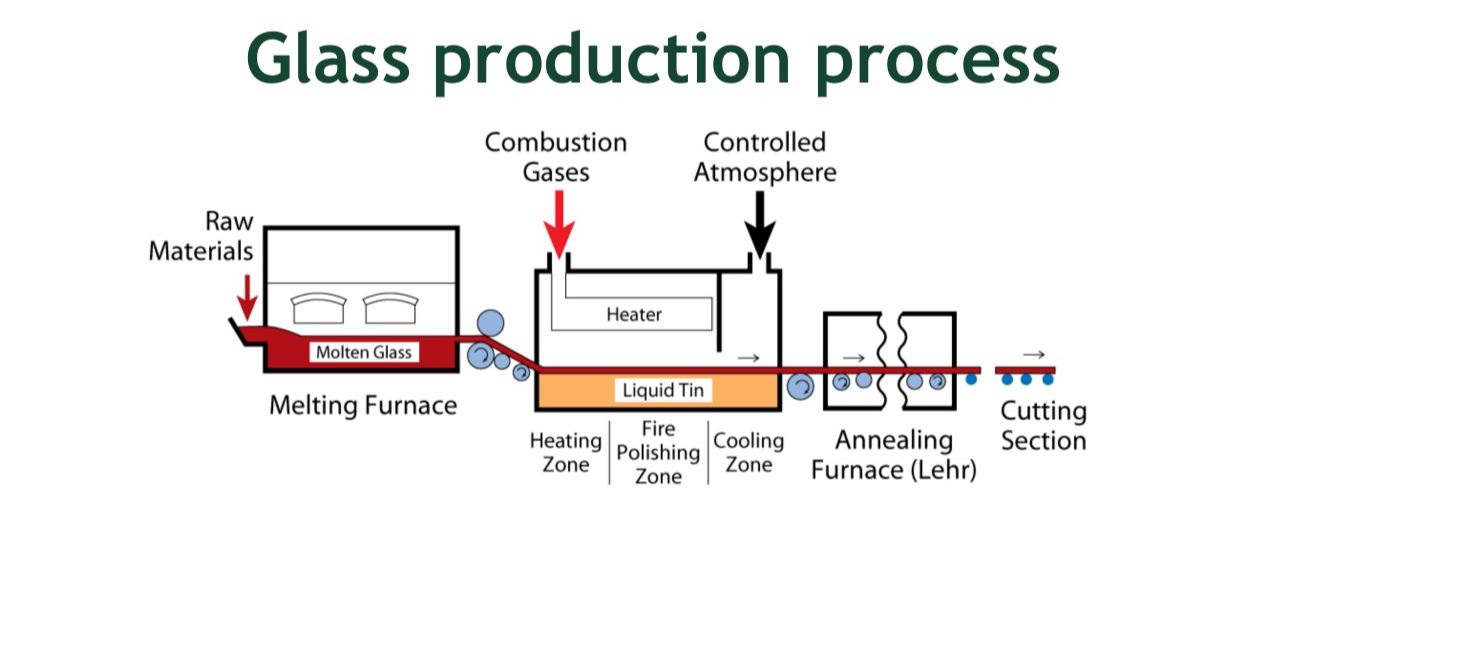

Glasses

Non-crystalline silicates containing other oxides

Properties change drastically at glass transition temperature

Tempering improves properties by inducing compression on glass surface

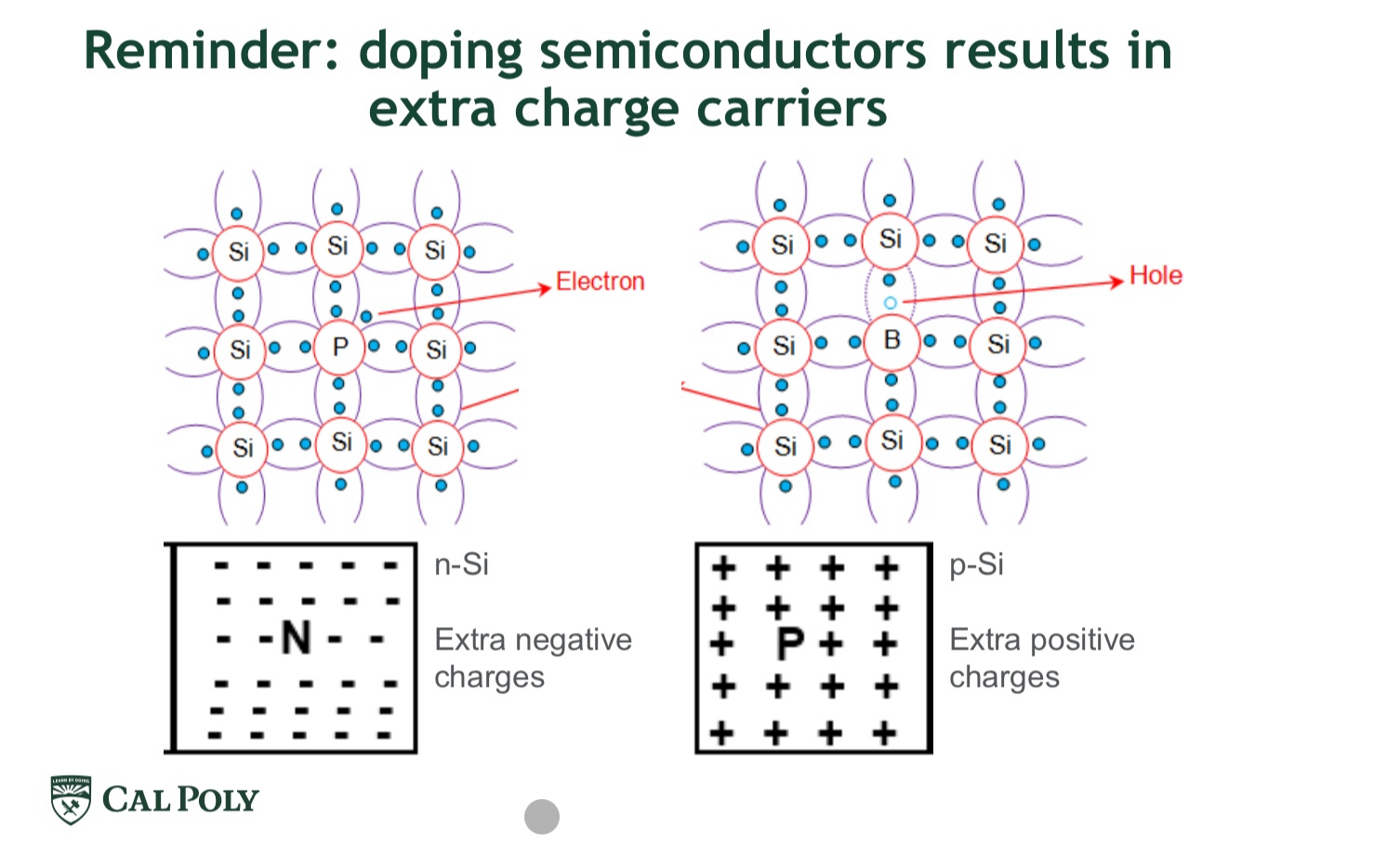

Semi conductors

Materials with low to moderate conductivity due to Their electronic structures (0 eV < Band Gap < 2 eV)

Intrinsic Semiconductors: materials with band gaps in the correct range as pure materials (only Si and

Ge)

Extrinsic Semiconductors: materials with band gaps in the correct range when doped with specific Atoms

N vs p type doping

Polymers (composition, properties, structure, performance)

Polymers are made up of repeating units bonded together through polymerization

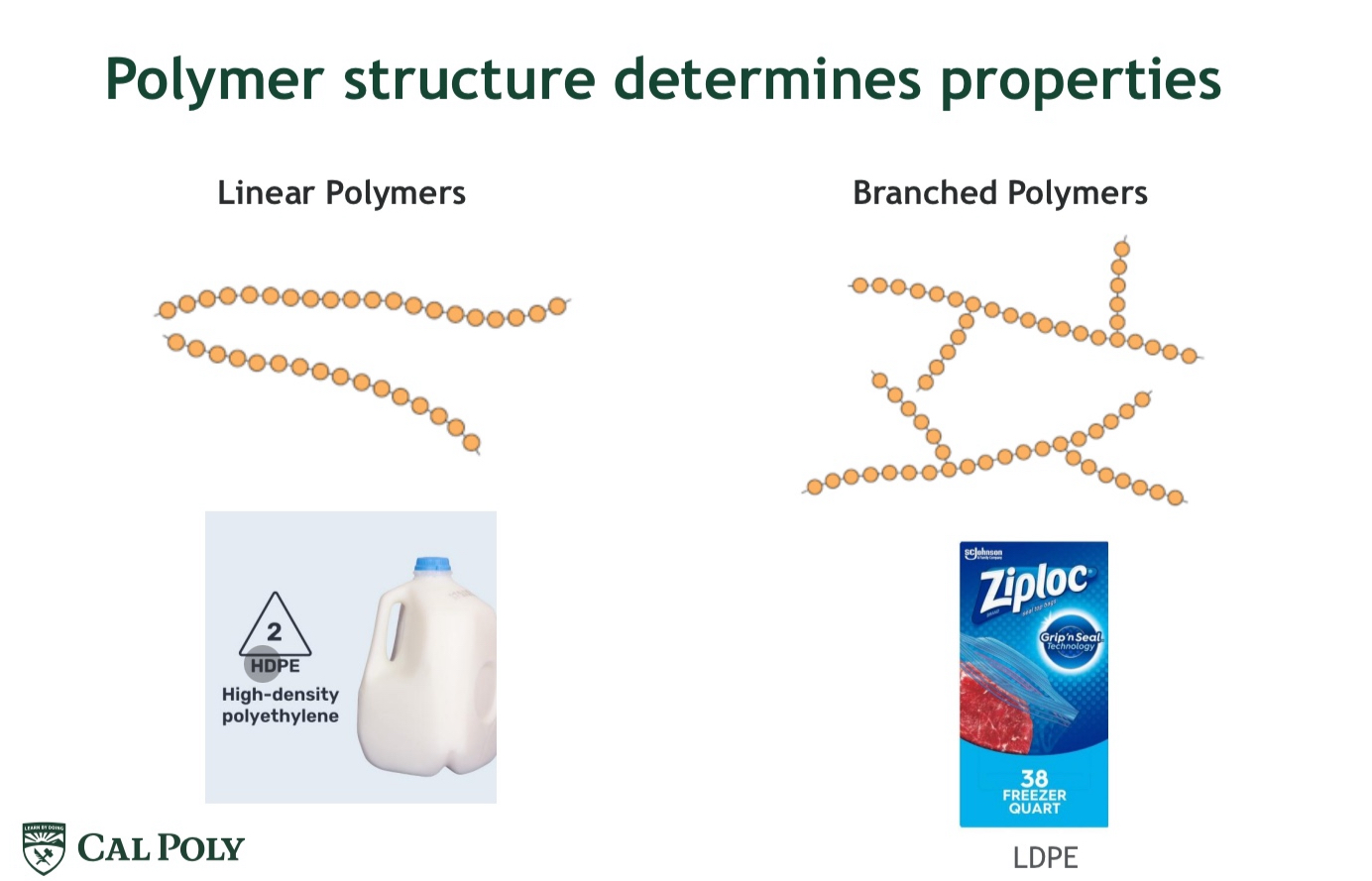

Polymer Structure

Repeating units

Linear vs branched polymers

Copolymers- polymers with different repeating units in their chains types of copolymers: Random, Alternating, Block, Graft

Cross linked polymers- separate chains covalently bonded together

Chemical reactions, light, and temperature Influence cross-linking and properties

What do plasticizers do

How to control crystallinity and density

Use additives called plasticizers to change

glass transition temperature

Extrusion of the material controls density and crystallinity

What is a composite, , what phases are there,

Composite is a combination of two or more materials

Dispersed phase and matrix phase

Dispersed phase

Dispersed phase influences properties of composites- concentration size, shape, orientation, distribution

3 types of composites and things to think about for each

Particle reinforced- how many particles to put in the matrix

fiber reinforced- direction of fibers, length of fibers, random or aligned

structural- laminating sheets with different fiber orientations yields in plane isotropy

Steps in material selection process

Translation- express design requirements as constraints and objectives

Screening- eliminate materials that fail constraints

Ranking- find materials that do job the best

Supporting information- explore top ranked candidates

Impacts on environment

What is impacting the environment? Is it the materials, manufacturing, use, or disposal?

Are you designing for it to be good for environment now or for it to be sustainable for a long time?