1.4 Paper and Board Forming Processes

1/4

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

5 Terms

What are die cutters?

Die cutters are tools used to cut out paper or card 'nets' or 'developments' that, when folded and assembled, form 3D shapes such as boxes.

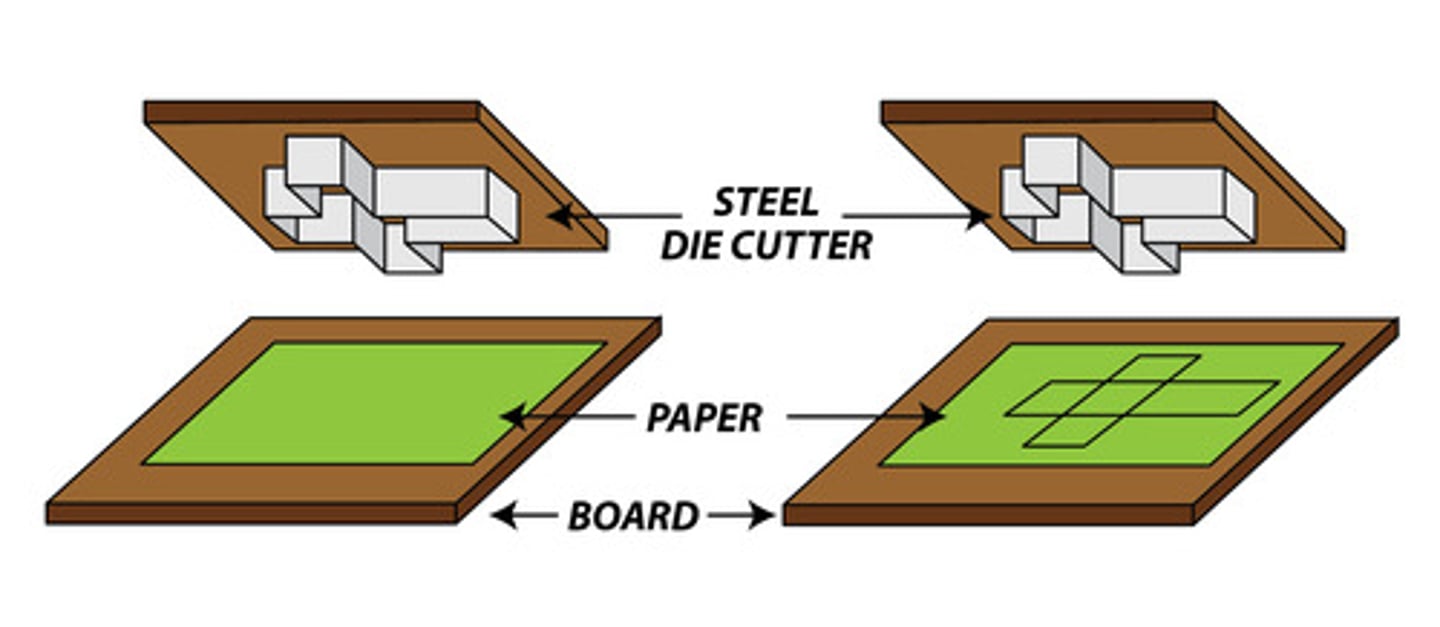

Imagine and explain a diagram of steel cutting dies

Die cutters use a plywood substrate board, into which steel cutting dies and creasing rules are inserted.

- Cutting Dies: Sharp and used to cut out the net shape.

- Creasing Rules: Blunt and lower than the cutting dies, used to score the material where folds are needed.

- The stock material is placed under the board, and a press pushes the board into the material to cut and crease.

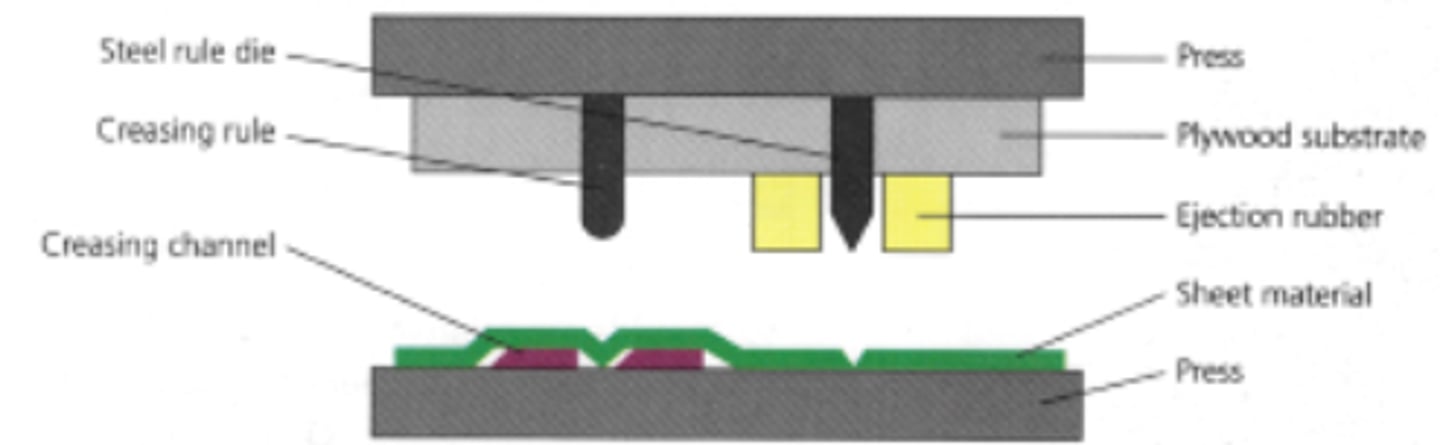

Imagine and explain a diagram for a Die Cutting Machine

A die cutting machine has various parts:

Creasing Channels: Raised parts on the bed that, together with creasing rules, create fold lines.

Cutting Dies: Sharp components that cut out the net outline.

Rubber Pads: Help prevent the material from sticking to the press as it moves up and down.

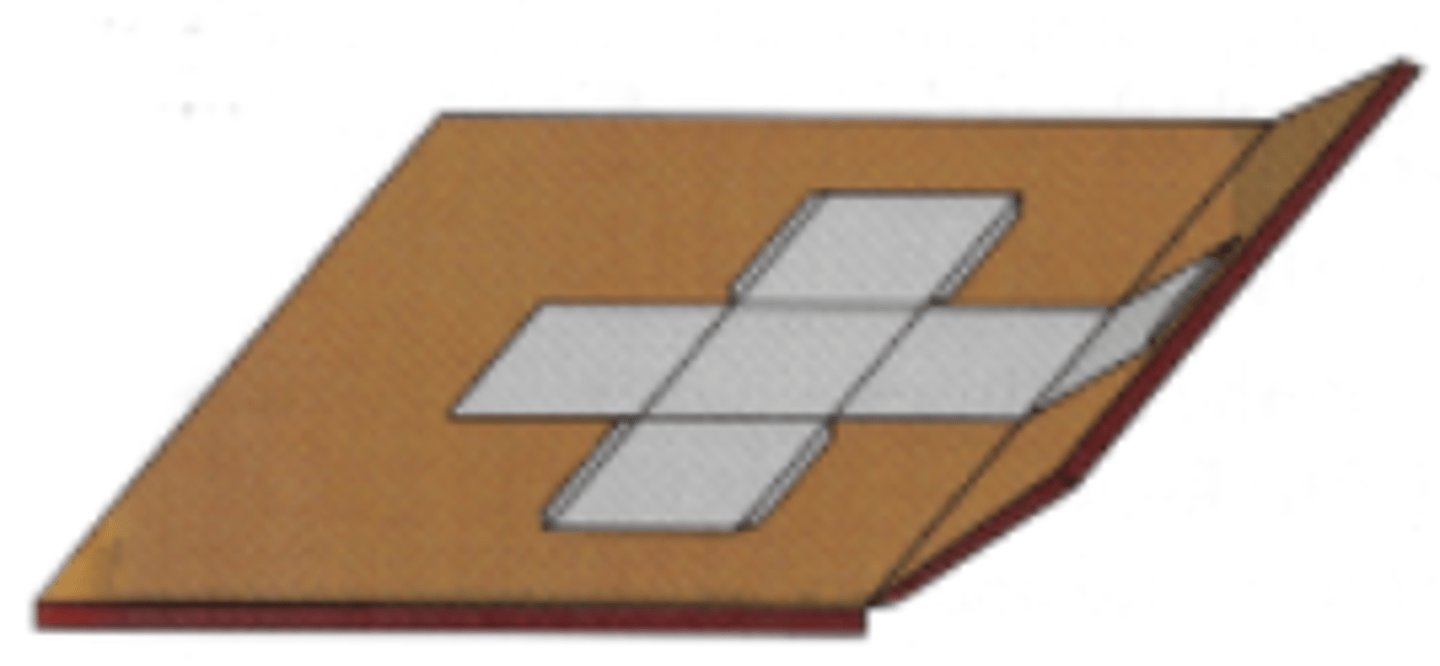

Describe the bending process for a stamped-out net

Once a net is stamped out, it is placed on a folding table, where moving parts assist in automatically bending or folding the net. For example, when making boxes, the die-cut net is held in place while the sides of the box are bent along the creased lines.

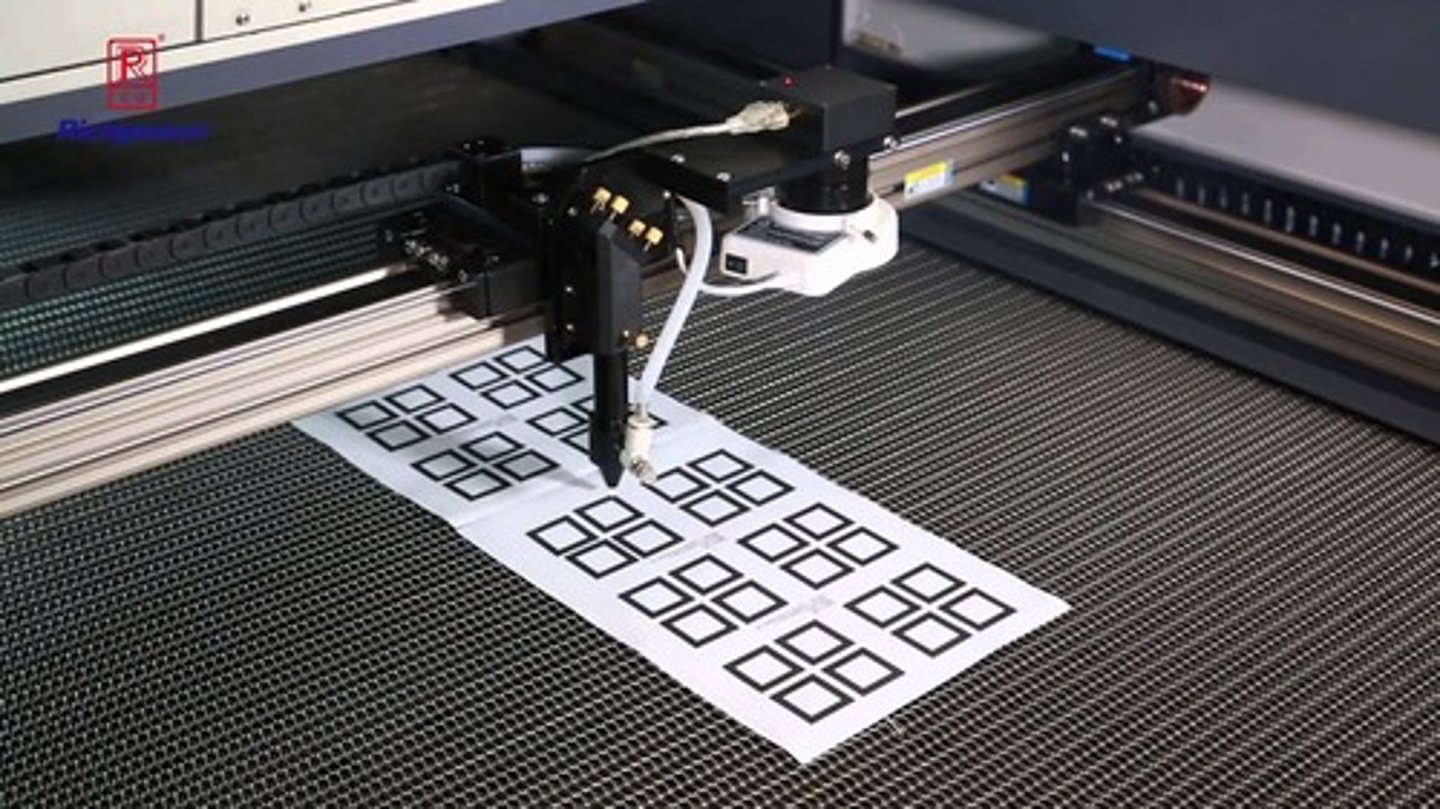

Explain the benefits of using laser cutting as a forming process for paper and board

Prototyping and Small-ScaleProduction: Ideal for fast, small-scale production due to speed, accuracy, and detail.

Flexibility: Lasers can cut, engrave, perforate, and carve, and they are not limited to a single design.

Quick Setup: 2D drawings can be easily uploaded for cutting, making it much faster than using plywood die boards.

Versatility: Can process a wide range of paper and board types.