Section C - Diagrams

1/64

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

65 Terms

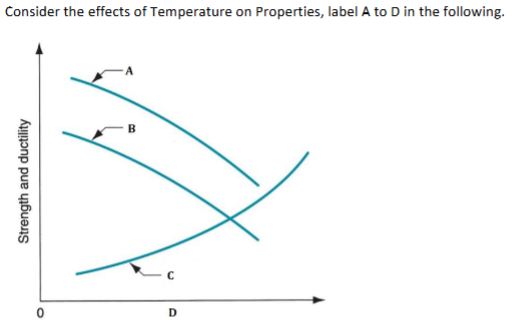

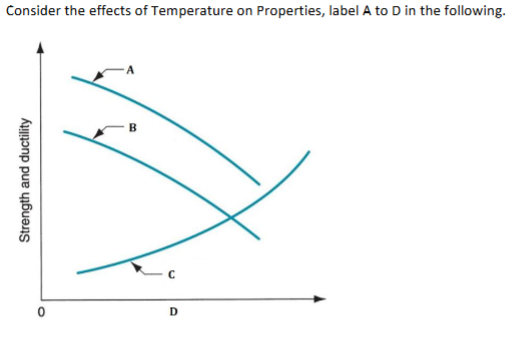

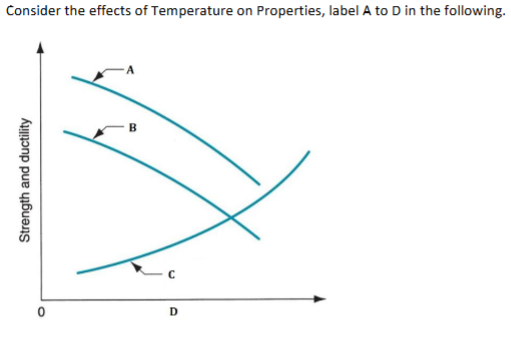

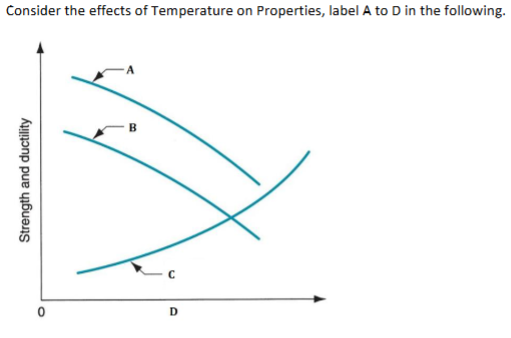

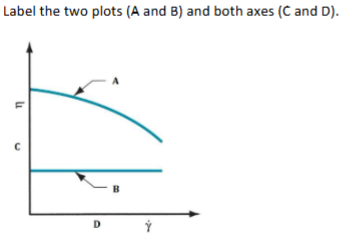

Label A

Tensile strength

Label B

Yield strength

Label C

Ductility

Label D

Temperature

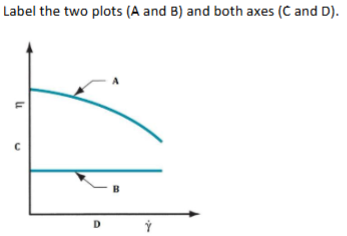

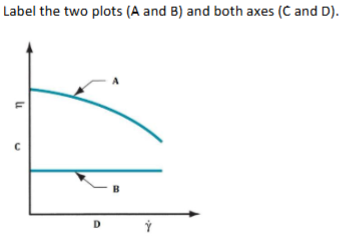

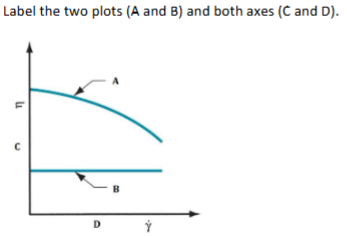

Label A

Pseudoplastic fluid

Label B

Newtonian fluid

Axis C

Viscosity

Axis D

Shear rate

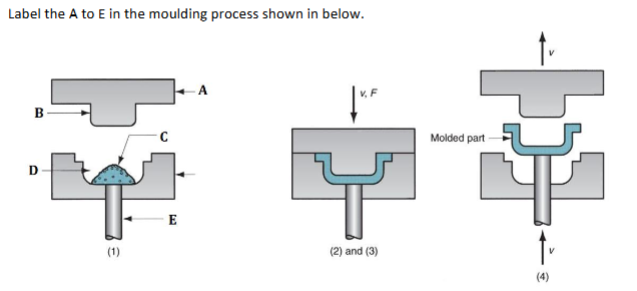

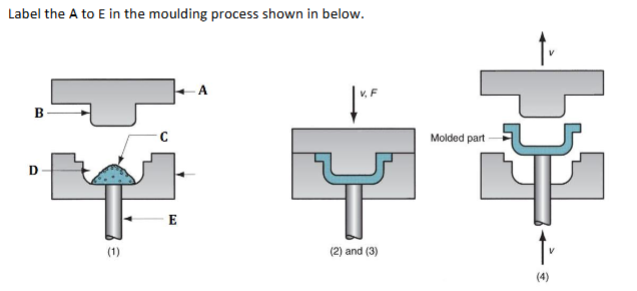

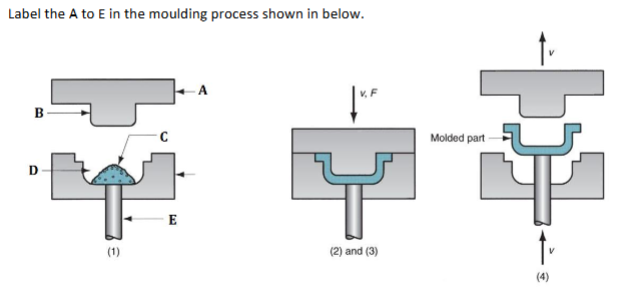

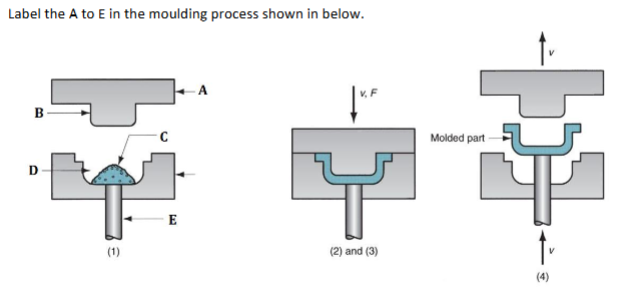

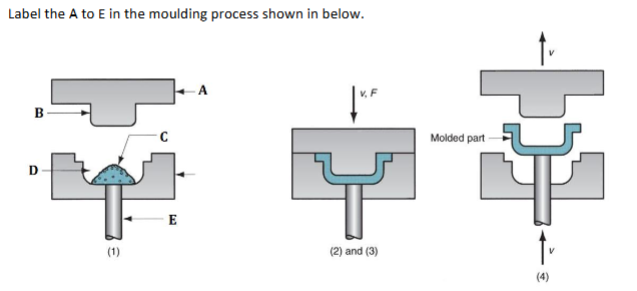

Label A

upper mould

Label B

punch

Label C

charge

Label D

cavity

Label E

knock out pin

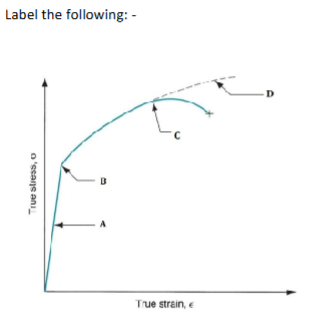

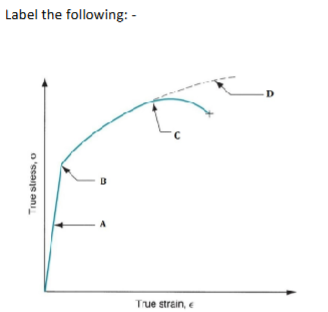

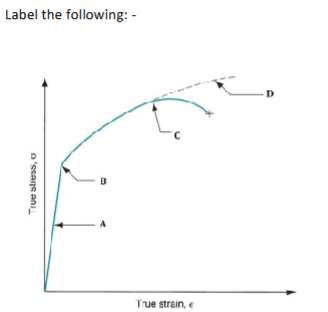

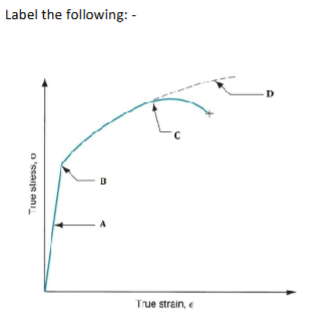

Label A

elastic region

Label B

yield

Label C

necking

Label D

projected curve if necking hadn’t occurred

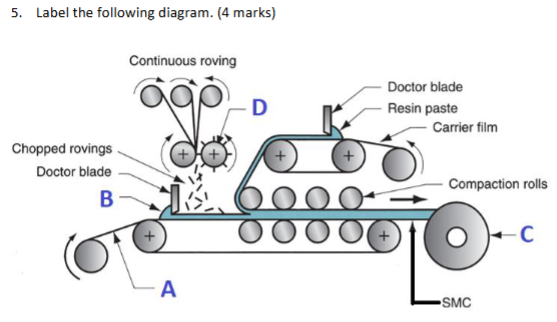

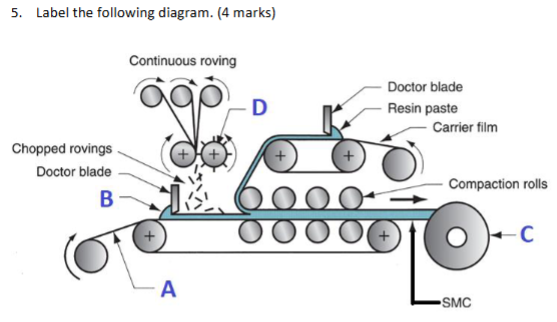

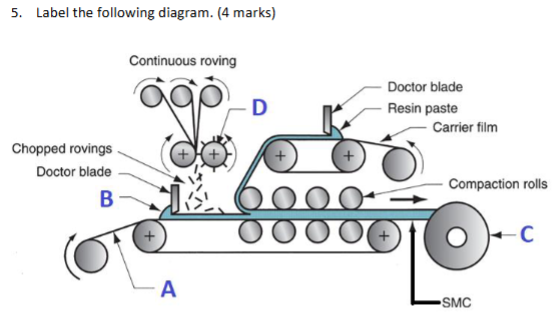

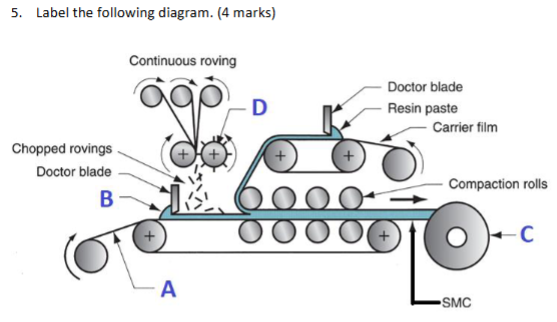

Label A

carrier film

Label B

resin paste

Label C

take up spool

Label D

chopper

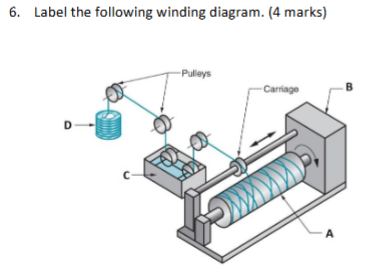

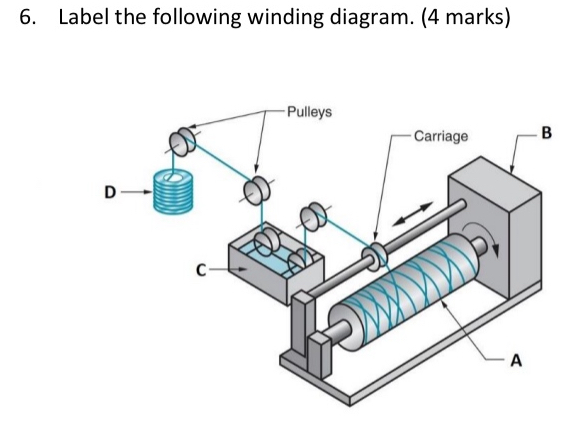

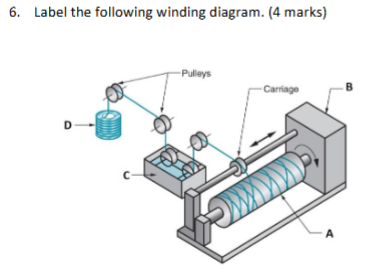

Label A

rotating mandrel

Label B

drive box

Label C

resin bath

Label D

continuous roving

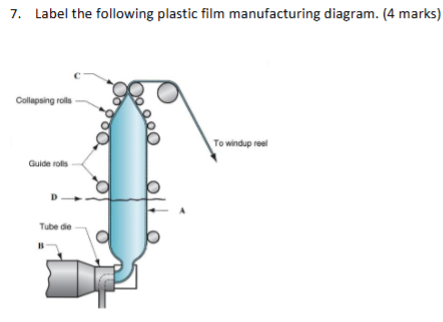

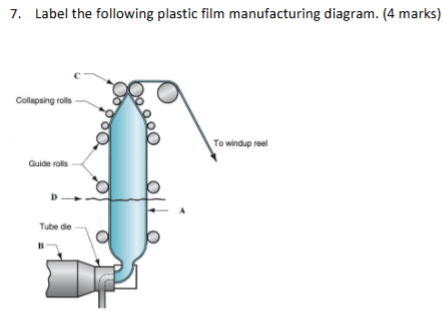

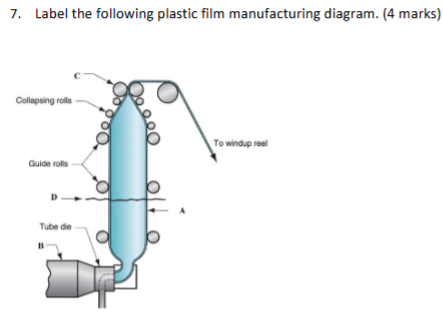

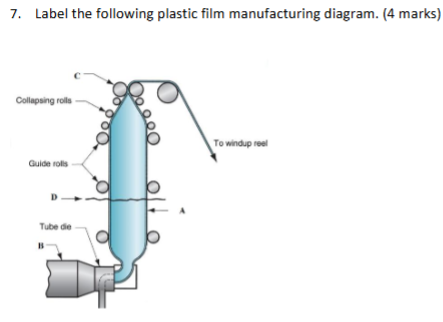

Label A

blown plastic film

Label B

extruder

Label C

pinch rolls

Label D

frost line

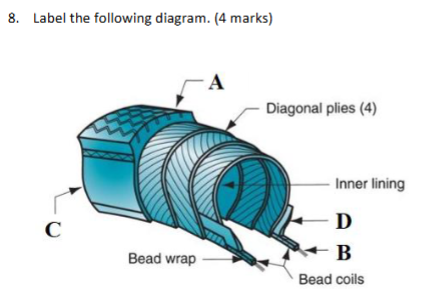

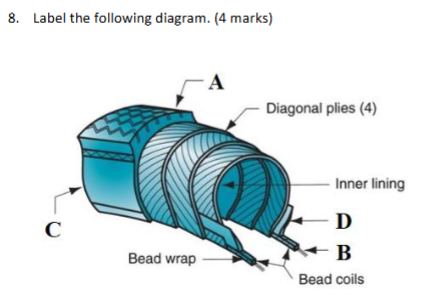

Label A

tread

Label B

steel wires

Label C

sidewall

Label D

filler

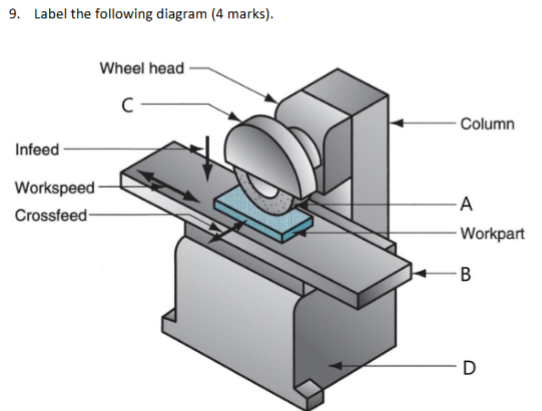

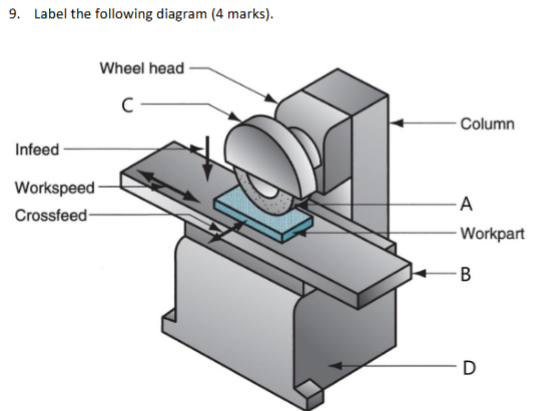

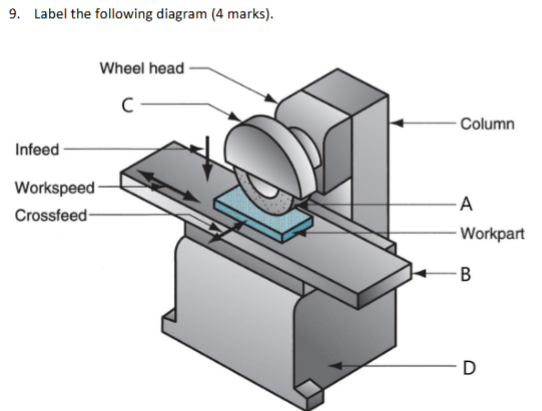

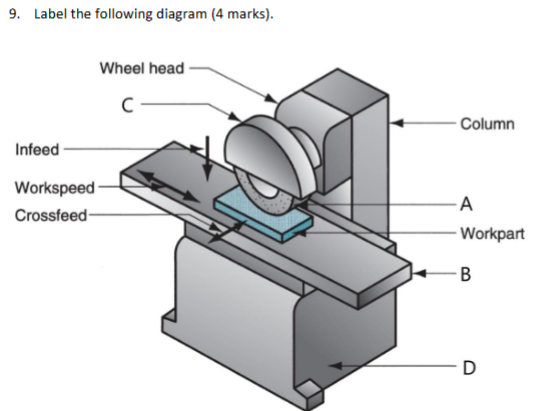

Label A

grinding wheel

Label B

work table

Label C

wheel guard

Label D

bed

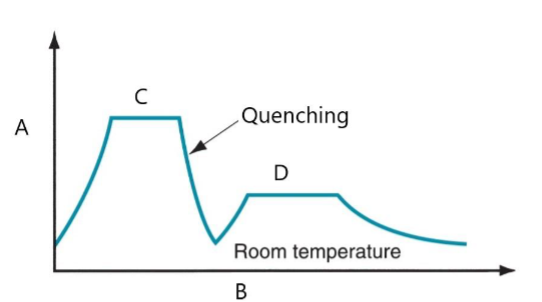

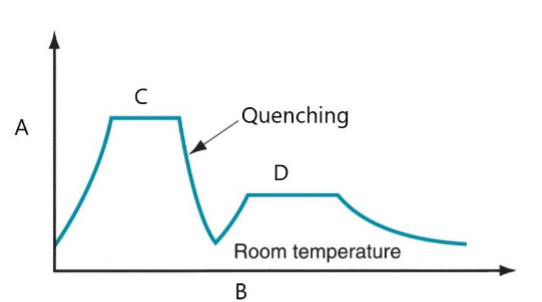

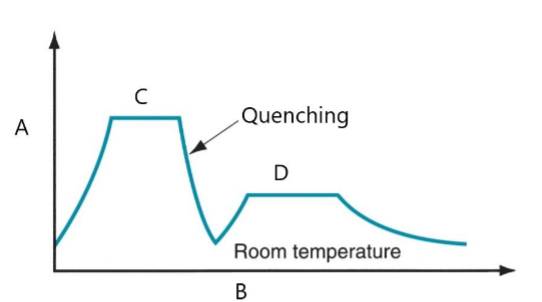

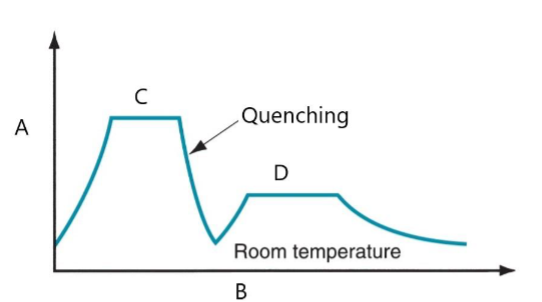

Axis A

temperature

Axis B

time

Label C

solution treatment

label d

precipitation

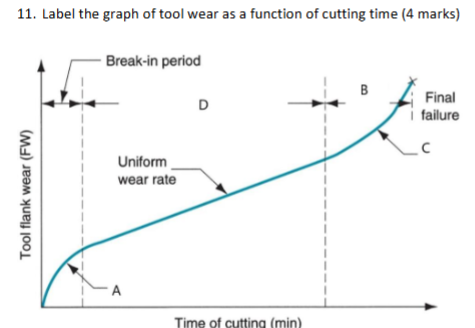

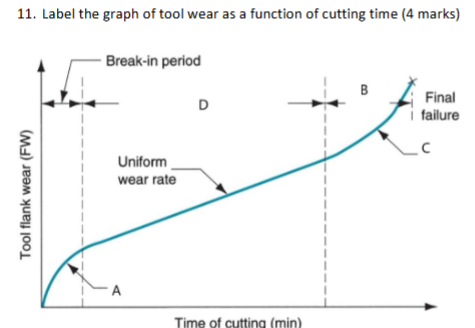

label a

rapid initial wear

label b

failure region

label c

accelerating wear rate

label d

steady state wear region

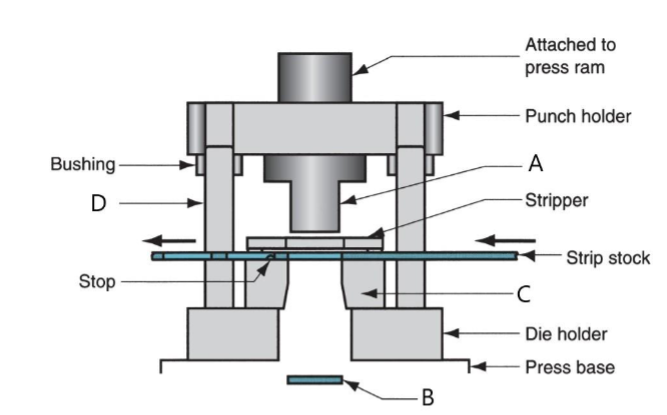

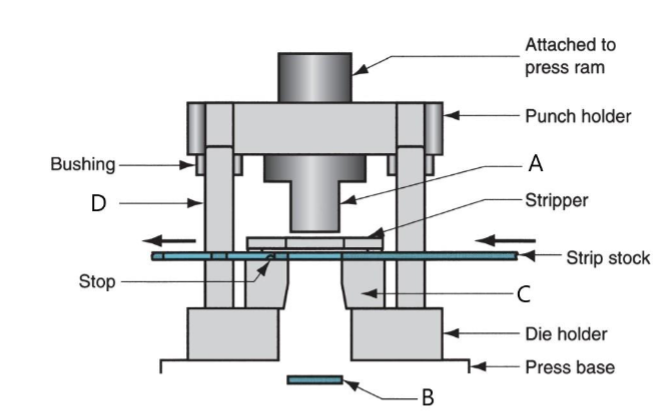

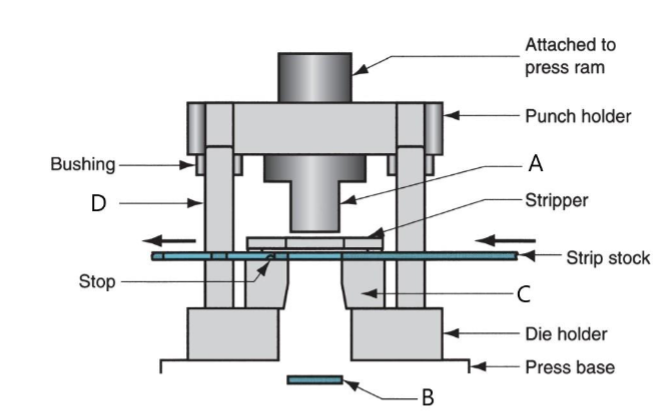

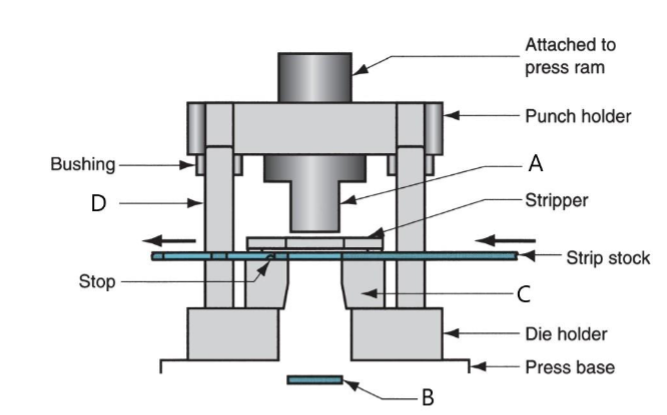

label a

punch

label b

blank

label c

die

label d

guide pins

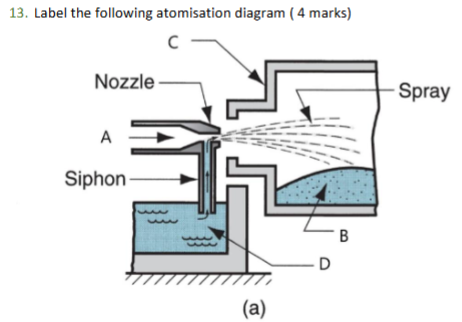

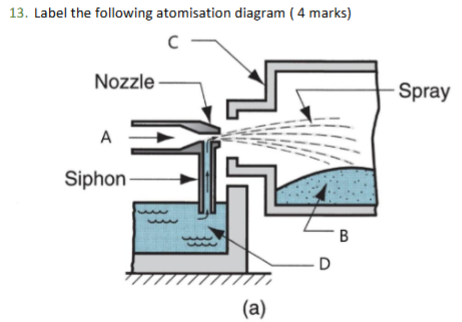

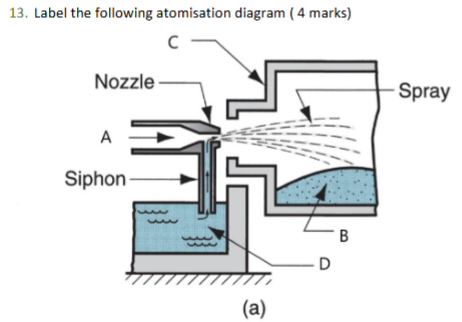

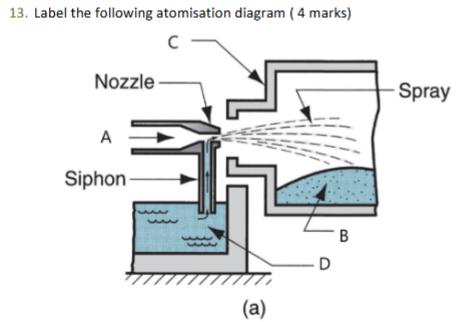

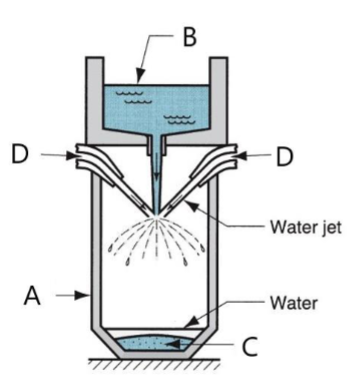

label a

gas

label b

metal powder

label c

collection chamber

label d

molten metal

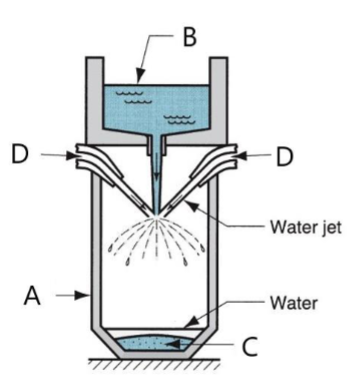

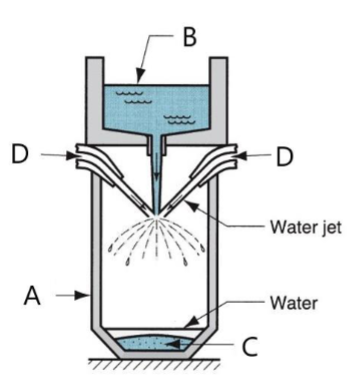

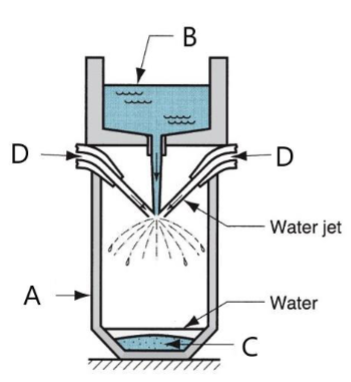

label a

collection chamber

label b

molten metal

label c

metal powder

label d

water

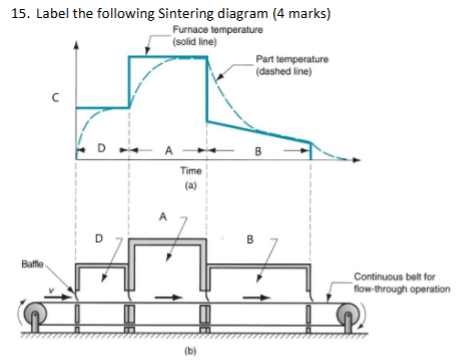

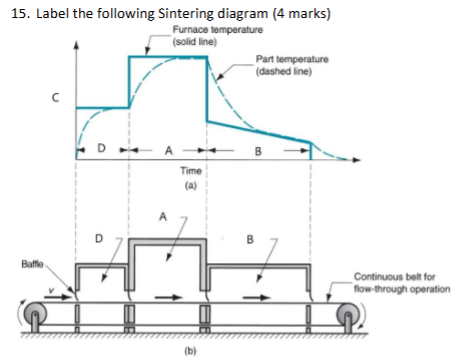

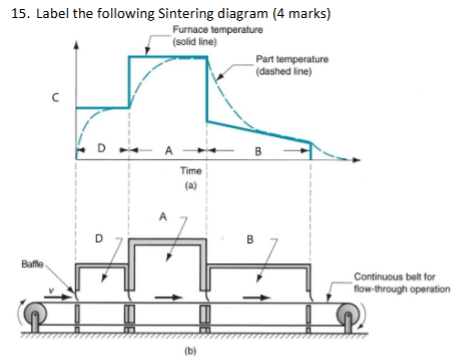

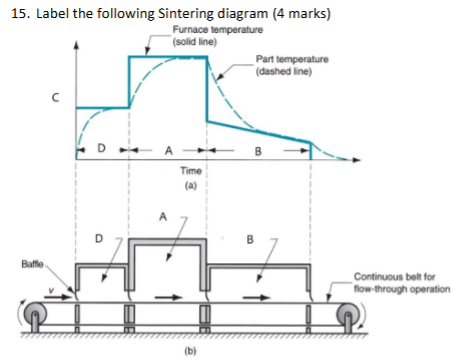

label a

sinter

label b

cool down

label c

temperature

label d

preheat

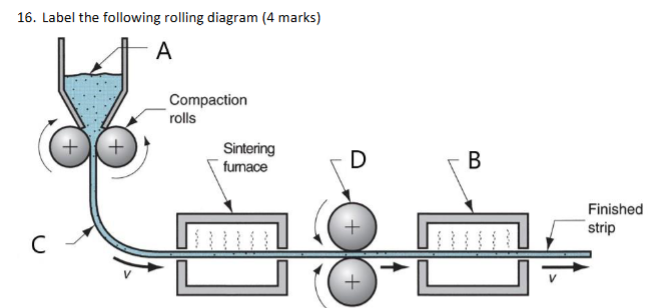

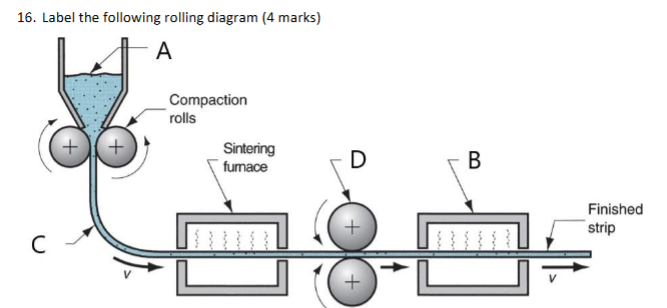

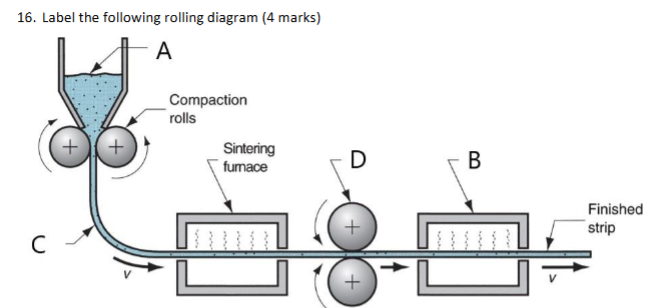

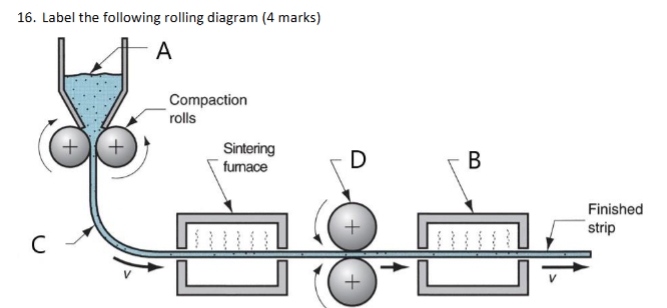

label a

powder

label b

resintering furnace

label c

green strip

label d

cold rolling mill