BU375: Quality Management & Productivity

1/39

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

40 Terms

Quality

The characteristics of a product or a service that bear upon its ability to meet or exceed customer needs or expectations under a prescribed set of conditions

A product or service free of defects

Read:

Onset of the oil crisis of the 70s paved the way for the introduction of Japanese vehicles into the north American market and the eventual new age of quality

It was soon realized by some, that quality could be considered less as a cost and more as a means of reducing pre-sale and post-sale expenses

Pre-Industrial Revolution (Quality control management)

Marked by craftsmen who were responsible for the entire manufacturing process and therefore had an inherent interest in producing quality goods that would be directly associated with them personally.

Industrial Revolution (Quality control management)

This period was marked by the Division of Labour whereby workers focused on smaller portions of the mfg process and as a result were distanced from the final product.

Quality Control became more the responsibility of shop floor supervisors and quality control inspectors

1950s (Quality control management)

This period saw the rise of the term quality assurance. Workers were once again encouraged to take responsibility for product quality

Quality Assurance

Providing confidence that a products quality will be good by preventing defects before they occur

Late 1980s (Quality control management)

ISO 9000 was introduced as a quality management system which began to be accepted on an international basis

TQM (Total Quality Management)

An approach to quality management that involves everyone in an organization in the management of quality and in ongoing efforts to continually improve quality and customer satisfaction.

Focused on customer satisfaction

Instituted as a plant-wide process that involved all levels of workers and management

Led to the concept of continuous process improvement

Continuous Improvement – Never-ending improvements to key processes as part of Total Quality Management

The quality standard is “no defects”

Management must provide genuine leadership

1980s (TQM)

TQM began to be accepted as a strategic management approach that replaced the earlier themes of quality control and quality assurance

Key Steps to Total Quality Management (TQM)

Focus on Customer satisfaction

Determine what customers want

Design a product that meets or exceeds customer wants

Design processes that facilitate the production of the properly designed product

Instituted as a plant-wide process that involved all levels of works and management

Management must provide genuine leadership

Continuous Improvement

Never ending improvements to key processes as part of TQM

The quality standard is ‘no defects’

Keep records of performance to ensure continuous improvements

Extend these concepts to suppliers

Present Day (History and Evolution of Present Day Quality Control Management)

We are seeing the rise of a new problem solving and process improvement system known as Six Sigma.

Six Sigma

A project-oriented methodology that helps businesses improve their processes. An increase in performance through a decrease in process variation leads to a reduction in defects and an increase in quality and an increase in profitability.

“All quality improvement occurs on a project-by-project” basis with elements of kaizen-type employee involvement.

Dimensions of Quality (Definition)

Made up of the aspects of quality that may affect a wide range of customers depending upon their individual tastes and perspectives

In other words, quality may mean different things to different people

Dimensions of Quality of Manufactured Goods (8)

Performance

Basic characteristics or functions of a good

Aesthetics

Appearance, feel, smell, taste

Special Features

Something extra that differentiates the product from the basic item

Safety

Assurance that a customer will not be harmed from the use of the product

Reliability

Probability that a product will operate properly for a prescribed period of time

Durability

How long a product will ‘last’ before it needs to be replaced

Conformance

How well the product meets some pre-established set of standards (or expectations)

Serviceability

Ease with which a product can be serviced or repaired

Dimensions of Quality of Services (6)

Time and Timeliness

How long must a customer wait for a service?

Is it completed on time?

Consistency

Is same level of service provided to each customer each time?

Courtesy

How are customers treated by employees?

Accessibility and Convenience

How easy is it to obtain the service?

Accuracy

Is service performed right every time?

Responsiveness

How well does company (organization) react to unusual situations?

Name the 6 Quality Gurus mentioned in class:

Walter Shewhart

W. Edwards Deming

Joseph M. Juran

Armand V. Feigenbaum

Philip Crosby

Kaoru Ishikawa

Walter Shewhart (Evolution of Quality Management: Quality Gurus)

In 1920s, developed control charts

Introduced term “quality assurance”

W. Edward Deming (Evolution of Quality Management: Quality Gurus)

Developed courses during WW II to teach statistical quality-control techniques to engineers and executives of military suppliers

After war, he began teaching statistical quality control to Japanese companies

Joseph M. Juran (Evolution of Quality Management: Quality Gurus)

Followed Deming to Japan in 1954

Focused on strategic quality planning

Quality improvement achieved by focusing on projects to solve problems and securing breakthrough solutions

Armand V. Feigenbaum (Evolution of Quality Management: Quality Gurus)

In 1951, introduced concepts of total quality control and continuous quality improvement

Philip Crosby (Evolution of Quality Management: Quality Gurus)

In 1979, emphasized that costs of poor quality far outweigh cost of preventing poor quality

In 1984, defined absolutes of quality management—conformance to requirements, and “zero defects”

Kaoru Ishikawa (Evolution of Quality Management: Quality Gurus)

Promoted use of quality circles

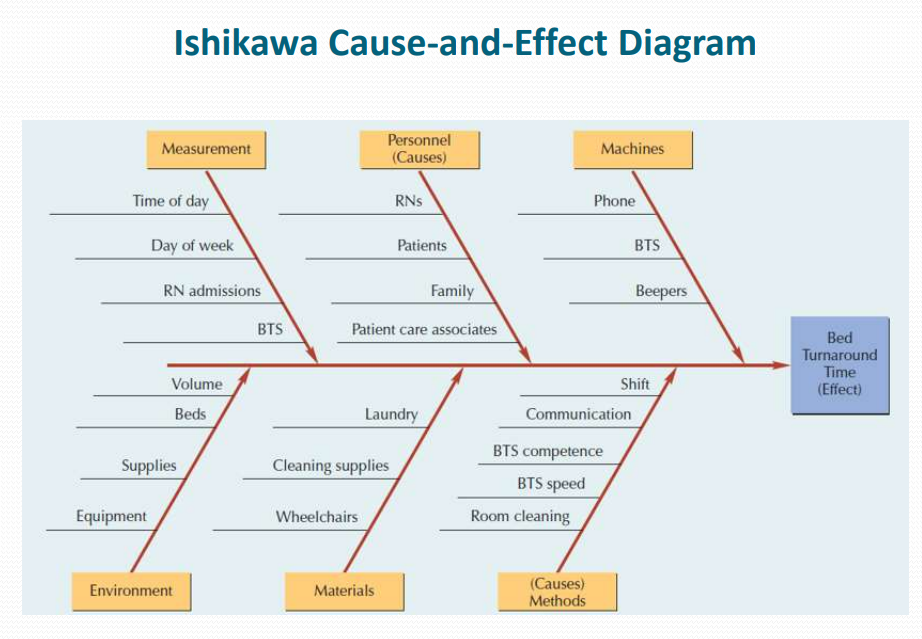

Developed “fishbone” diagram

Emphasized importance of internal customer

Deming’s 14 Points

Create constancy of purpose

Adopt a philosophy of prevention of poor quality

Cease mass inspection

Select a few suppliers based upon quality

Constantly improve system and workers

Institute vigorous training and education programs (worker training)

Institute leadership among supervisors

Eliminate fear among employees

Eliminate barriers between departments

Eliminate slogans

Eliminate numerical quotas

Enhance worker pride

Institute vigorous education and training programmes

Develop a commitment from top management to quality

List 7 Quality Tools

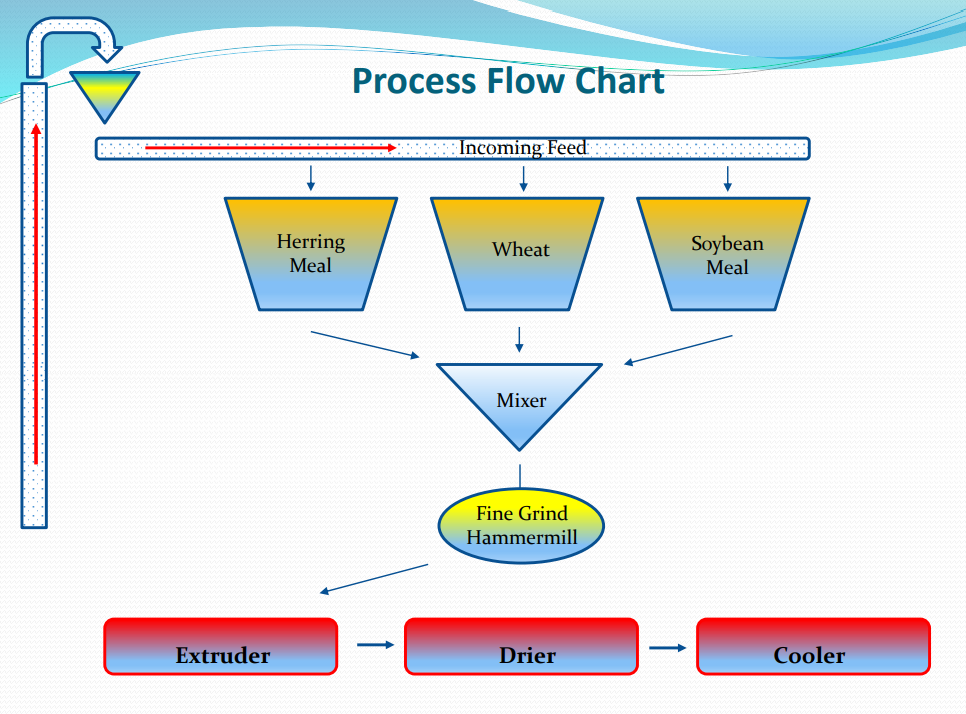

Process Flow Chart*

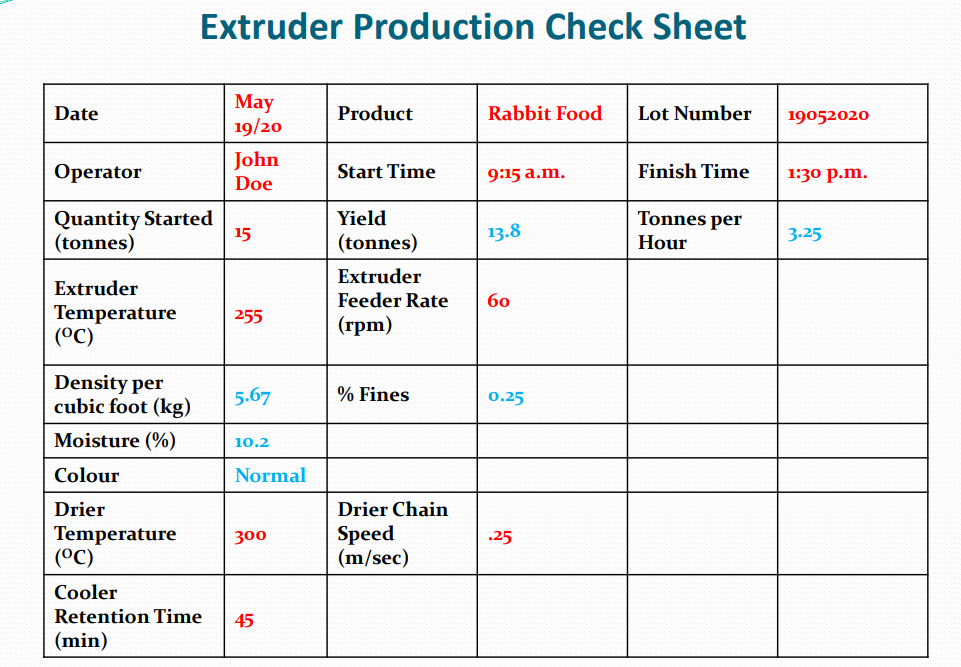

(Extruder Production) Check Sheet*

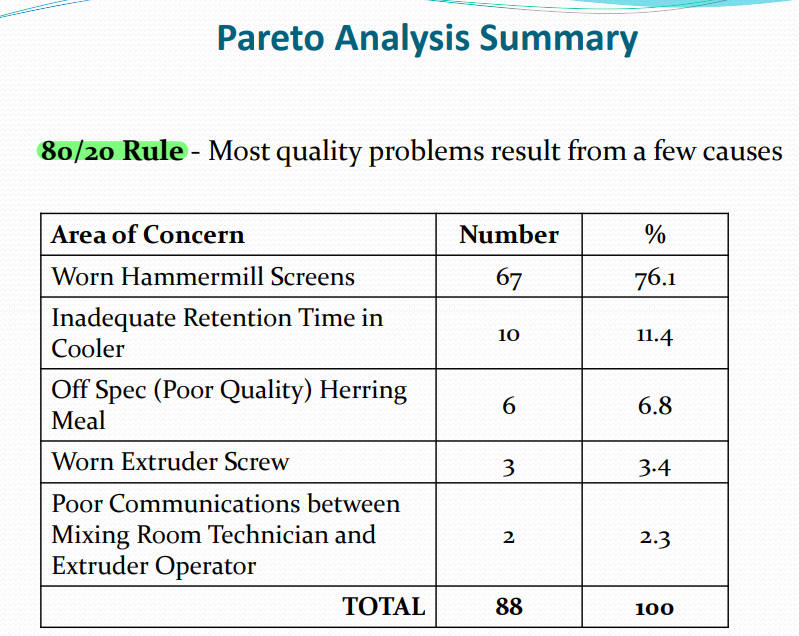

Pareto Analysis*

(Ishikawa) Cause-and-Effect Diagram*

Histogram

Scatter Diagram

Statistical Process - Control Chart

Process Flow Chart (Picture)

(Extruder Production) Check Sheet*

Pareto Analysis*

(Ishikawa) Cause-and-Effect Diagram*

LO 20/41