OSCM FADI TOLD US

1/50

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

51 Terms

7 major factors that affect location decisions

labor productivity,

exchange rates and currency risk

costs (tangible and intangible)

political risk, values, and culture

proximity to market

proximity to suppliers

proximity to competitors

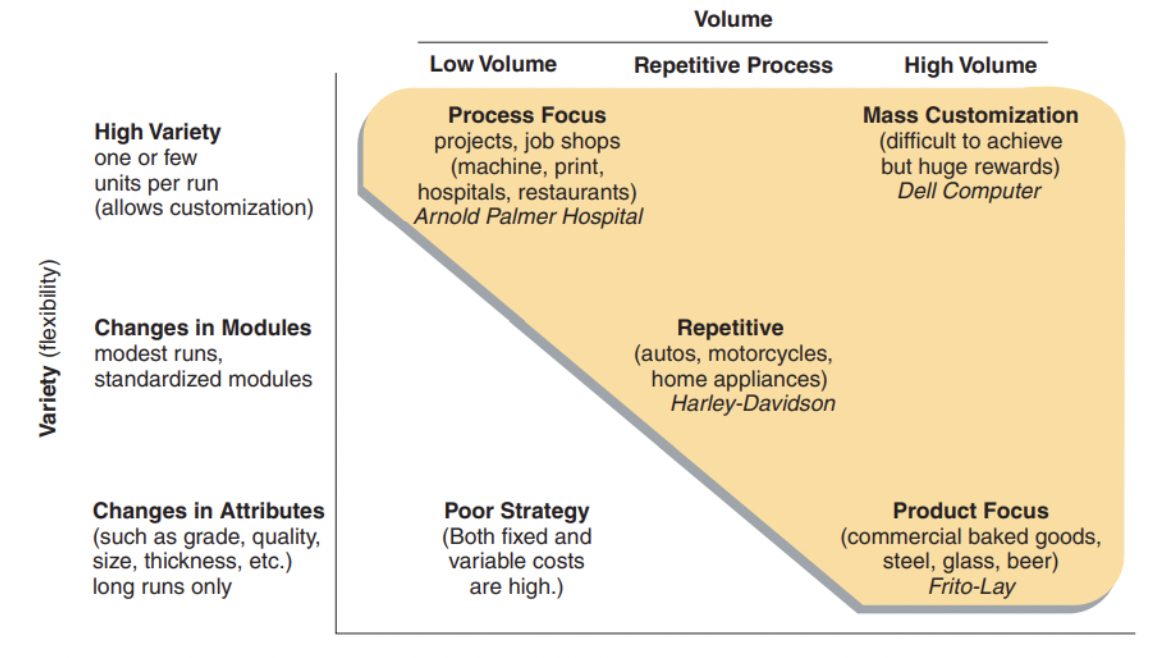

4 types of process strategies

process focus

product focus

repetitive focus

mass customization focus

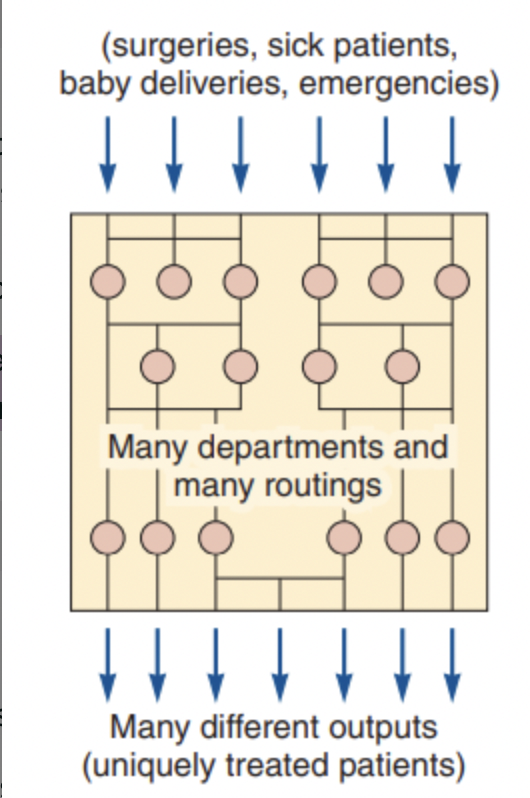

process focus

production facility organized around processes to facilitate low-volume, high -variety production

ex. Arnold Palmer Hospital, many inputs many outputs

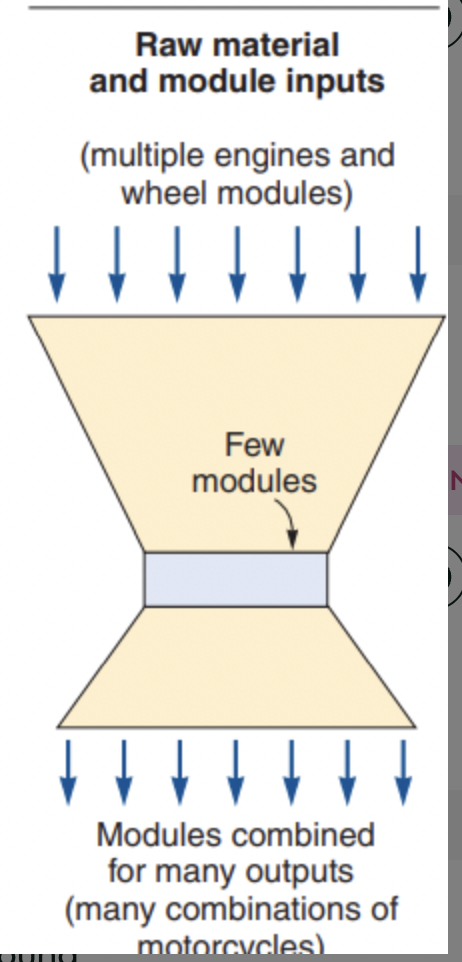

repetitive focus

Product oriented production process that uses modules

ex. Harley Davidson, raw materials and module inputs,

multiple inputs, few modules, multiple outputs

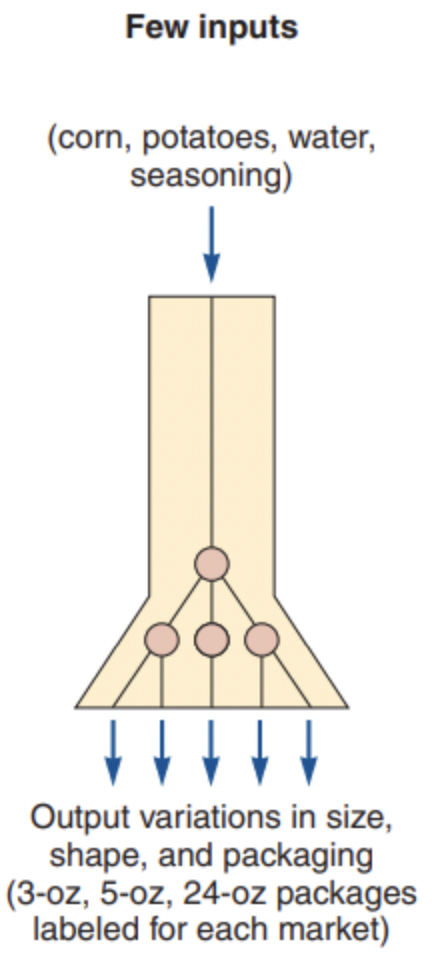

product focus

facility organized around products; a product-oriented high-volume, low-variety process (also called continuous processes)

ex. Frito-Lay, few inputs, many outputs

repetitive process

classic assembly line, product-oriented production process that uses modules

process strategy

organizations approach to transforming resources into goods and services

objective

create a process that can produce offerings that meet customer requirements within cost and other managerial constraints

volume and variety chart

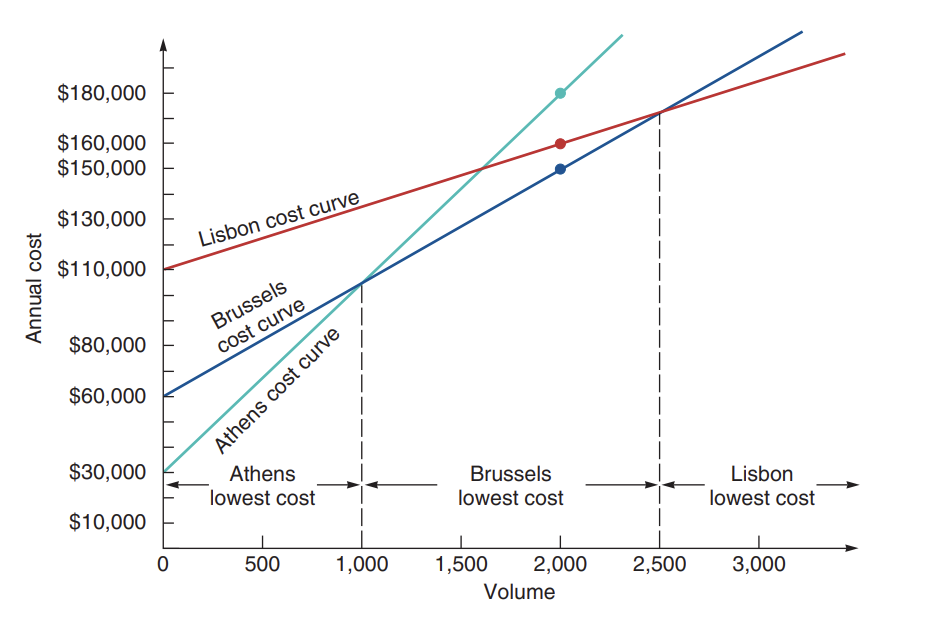

cross-over chart

chart of costs at the possible volumes for more than one process

Where the lines intersect is when you want to change production

starting point on y axis is where fixed costs occur, slope of line is the variable costs

vertical integration

developing the ability to produced goods and services previously purchased or to actually buy a supplier or distributor

a business strategy in which a company takes ownership of two or more key stages of its supply chain

horizontal integration

when a company acquires or merges with another company in the same industry that is operating at the same level in the value chain.

six sourcing strategies

many suppliers

few suppliers

vertical integration

joint ventures

keiretsu networks

virtual companies

bullwhip effect

increasing fluctuation in orders or cancelations that often occurs as orders move through the supply chain

methods of evaluating location alternatives

factor-rating method

locational cost-volume method

center of gravity method

transportation model

factor-rating method

location method that instills objectivity into the process of identifying hard-to-evaluate costs

steps to the factor rating method

develop list of relevant factors (key success factors)

assign weight to each factor

develop scale for each factor (1-10)

have management score each location for each factor

multiply score by weight

make recommendation based on number

center of gravity method

mathematical technique used for finding the location of a distribution center that will minimize distribution costs

locational cost-volume method

method of making an economic comparison of location alternative by identifying fixed and variable costs and graphing by each location to determine which one provides the lowest cost

three steps to LCV method

determine fixed and variable costs

plot the costs for each location (cost on y, volume on x)

select the location with lowest total cost for expected production volume

transportation model

technique for solving a class of linear programming problems

computer integrated manufacturing

manufacturing system in which CAD, FMS, inventory control, warehousing, and shipping are integrated

the manufacturing approach of using computers to control the entire production process

logistics

seeks efficiency of operations through the integration of all material acquisition, movement, and storage activities

inventory turnover equation

= COGS/average inventory investment

the higher the better

percent invested in inventory equation

= (average inventory investment/total asset) x 100

the higher it is the worse off it is

weeks of supply equation

= average inventory investment/ (annual cogs/52 weeks)

better to have it lower

TQM concepts

management of an entire organization so that it excels in all aspects of products and services that are important to the customer

continuous improvement, six sigma, employee empowerment, benchmarking, JIT, taguchi concepts, knowledge of TQM tools

CI-SSEEB-JiT-TAGCO- Know

Continuous Improvement

plan-do-check-act

six sigma

statistical sense - describes a process, product, or service with an extremely high capability

program designed to reduce defects to help lower costs, save time, and improve customer satisfaction

comprehensive system- strategy, discipline, and a set of tools

employee empowerment

involving employees every step of the production process

benchmarking

selecting domenstrated standard of practices that you aim to reach

JIT

only make once ordered

Taguchi Concepts

quality robustness, target oriented quality, quality loss function all used to improve product and process quality

knowledge of TQM tools

check sheets, scatter diagrams, cause-effect diagrams, pareto charts, flowcharts, histograms, statistical process control

how to mathamaticaly solve a crossover chart

set two equations equal to one another and solve for the units

low volume, high variety processes are also known as:

continuous processes

repetitive processes

process focused

product focused

process focused

a crossover chart for process selection focuses on:

labor costs

material costs

both labor and material costs

fixed and variable costs

fixed costs

fixed and variable costs

tools for process analysis include all of the following except:

flowchart

vision systems

service blueprinting

time-function mapping

value-stream mapping

vision systems

customer feedback in process design is lower as:

the degree of customization is increased

the degree of labor is increased

the degree of customization is lowered

both a and b

both b and c

the degree of customization is lowered

computer-integrated manufacturing includes manufacturing systems that have:

computer aided design, direct numerical control machines, and material-handling equipment controlled by automation

transaction processing, a management informations system, and decision support systems

automated guided vehicles, robots, and process control

robots, automated guided vehicles, and transfer equipment

computer aided design, direct numerical control machines, and material-handling equipment controlled by automation

the factors involved in location decisions include:

foreign exchange

attitudes

labor productivity

all of the above

all of the above (foreign exchange, attitudes, labor productivity)

If fender guitar pays $30 per day to a worker in its Ensenda, Mexico, plant, and all the employee completes four instruments per 8-hour day, the labor/cost unit is:

30.00

3.75

7.50

4.00

8.00

7.50 (30/4)

Evaluating location alternatives by comparing their composite (weighted-average) scores involves:

factor-rating analysis

cost-volume analysis

transportation model analysis

linear regression analysis

crossover analysis

factor-rating analysis

On the cost-volume analysis chart where the costs of two or more location alternatives have been plotted, the quantity at which two cost curves cross the quantity at which:

a) fixed costs are equal for two alternative locations

b) variable costs are equal for two alternative locations

c) total costs are equal for all alternative locations

d) fixed costs equal variable costs for one location

e) total costs are equal for two alternative costs

total costs are equal for two alternative costs

A regional bookstore chain is about to build a distribution center that is centrally located for its eight retail outlets. It will most likely employ which of the following tools of analysis?

assembly-line balancing

load-distance analysis

center of gravity model

linear programming

all of the above

center of gravity

What is the major difference in focus between location decisions in the service sector and the manufacturing sector?

there is no difference

the focus in manufacturing is revenue maximization, while the focus in service is cost maximization

the focus in service is revenue maximization, while the focus in manufacturing is cost minimization

the focus in manufacturing is on raw materials, while the focus on service is on labor

the focus in service is revenue maximization, while the focus in manufacturing is cost minimization

the objective to supply chain management is to

build a chain of suppliers that focuses on maximizing value to the ultimate customer

the term vertical integration means to:

develop the ability to produce products that complement or supplement the original product

produce goods or services previously purchased

develop the ability to produce the specified good more efficiently

all of the above

produce goods or services previously purchased

the bullwhip effect can be aggravated by:

local optimization

sales incentives

quantity discounts

promotions

all of the above

all of the above (local op, sale inc, quan disc, promo)

Supplier selection requires:

supplier evaluation and effective 3PL

supplier development and logistics

negotiations, supplier evaluation, supplier development, and contracts

an integrated supply chain

inventory and supply chain management

negotiations, supplier evaluation, supplier development, and contracts

a major issue in logistics is:

cost of purchases

supplier evaluation

product customization

cost of shipping alternatives

excellent e-procurement

cost of shipping alternatives

inventory turnover =

COGS / weeks of supply

weeks of supply / annual COGS

annual COGS / 52 weeks

average inventory investment/COGS

COGS/ avg inventory invest

COGS/ avg inventory invest