GCSE DT: Core Content: 1.5 Mechanical Devices used to produce movement

1/38

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

39 Terms

Types of movement

Oscillation (swing back and forth)

Linear (straight line in one direction)

Rotary (rotate)

Reciprocation (Move back and forth along a straight line)

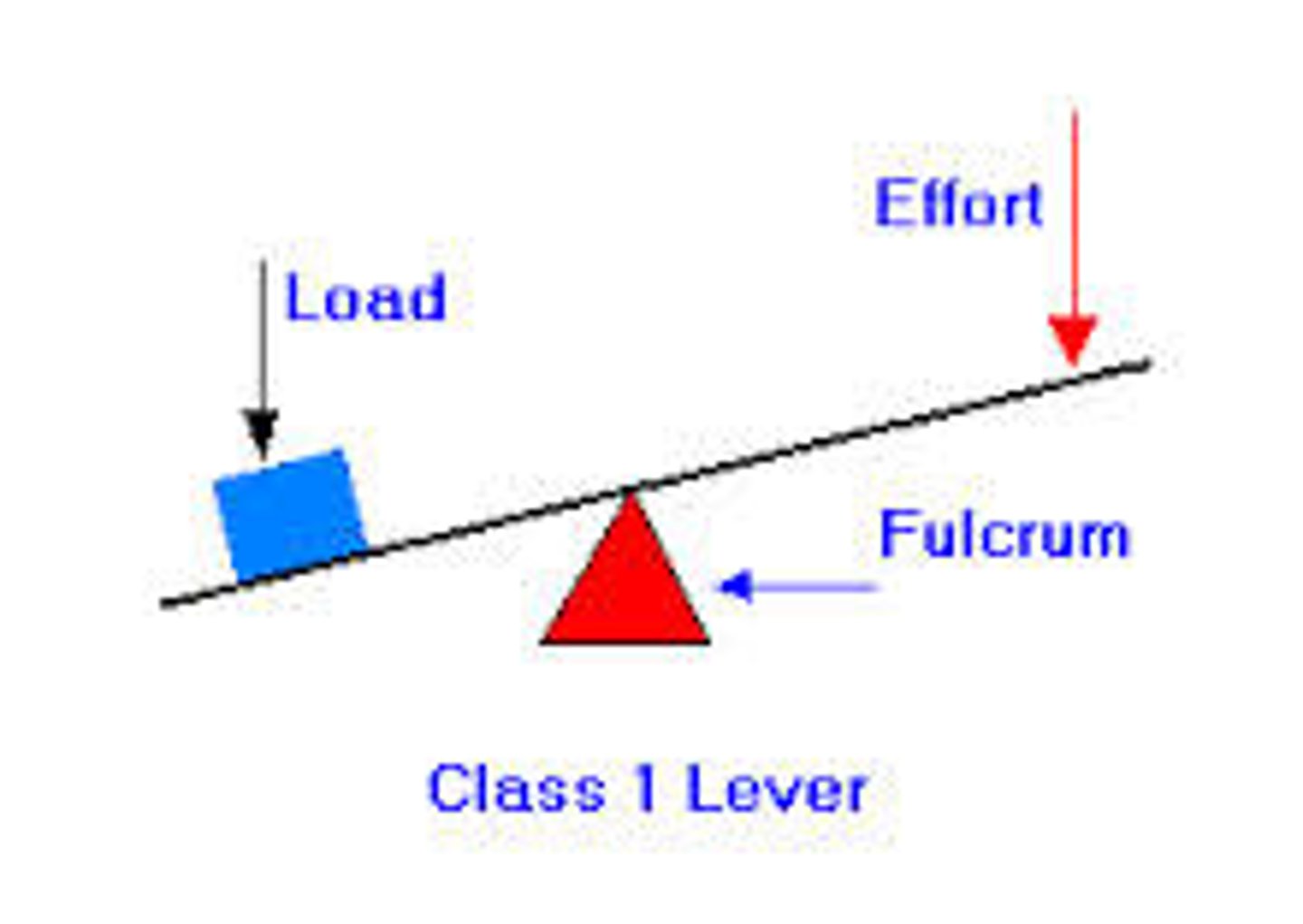

Class 1 Lever

LFE - Seesaw

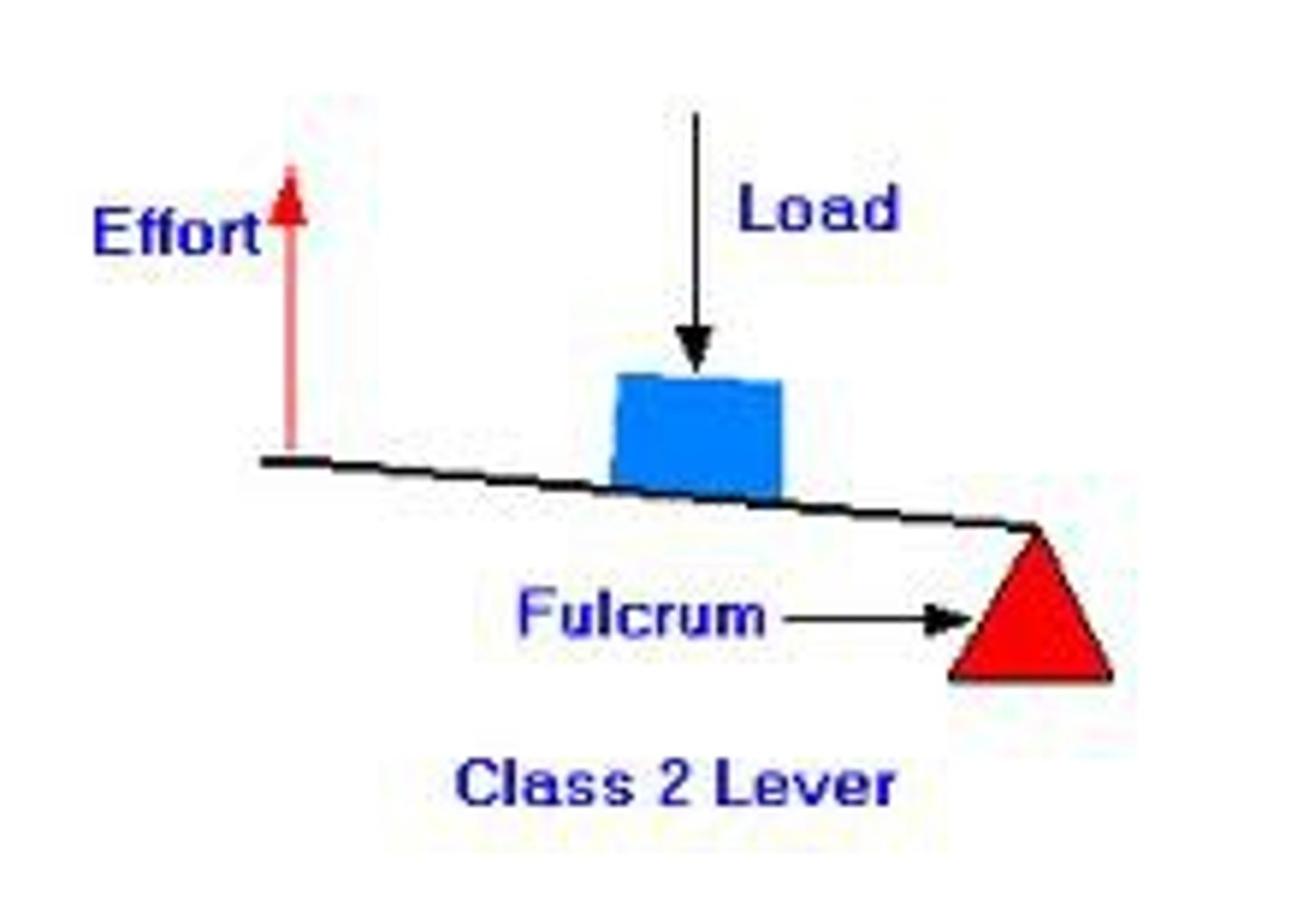

Class 2 Lever

FLE - Wheelbarrow

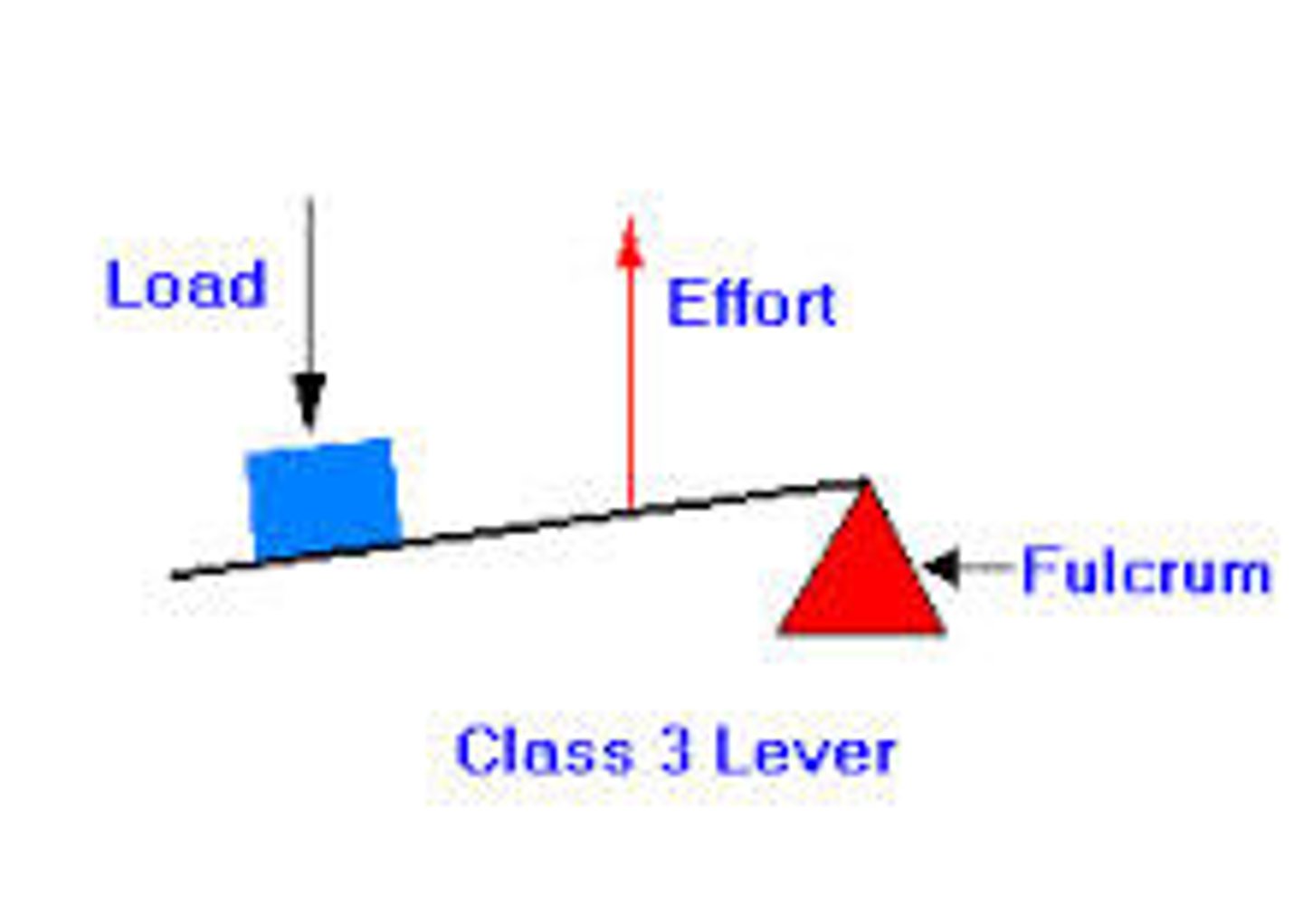

Class 3 Lever

FEL - Tweezers

Mechanical Advantage

Load/Effort

Moment

Force × distance (perpendicular to force)

Velocity Ratio for lever

distance moved by effort/distance moved by load

Efficiency

Mechanical Advantage/Velocity ratio

Linkages

Levers that allow forces and motion to be transmitted in a certain way (e.g., reversing movement or changing its direction)

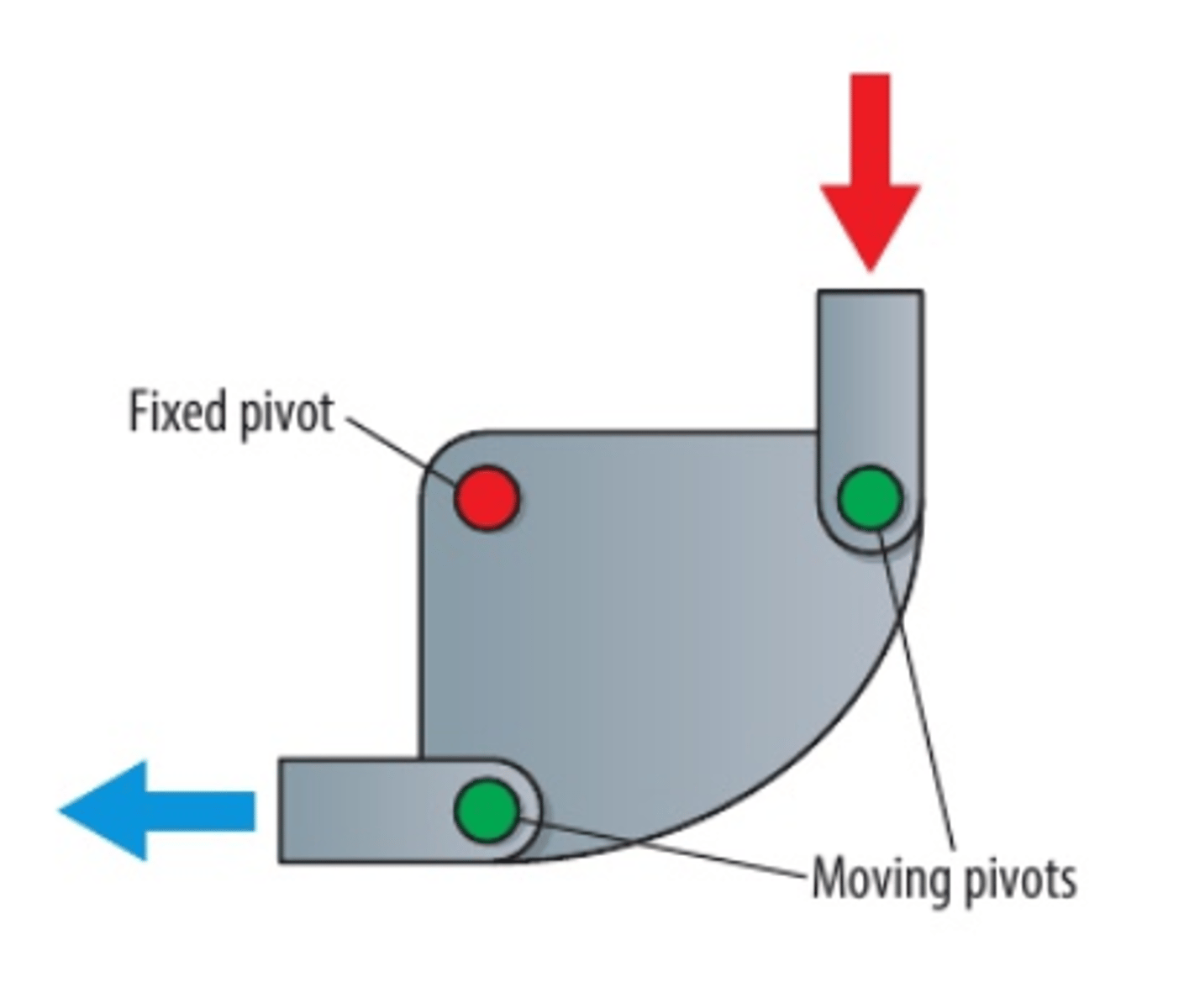

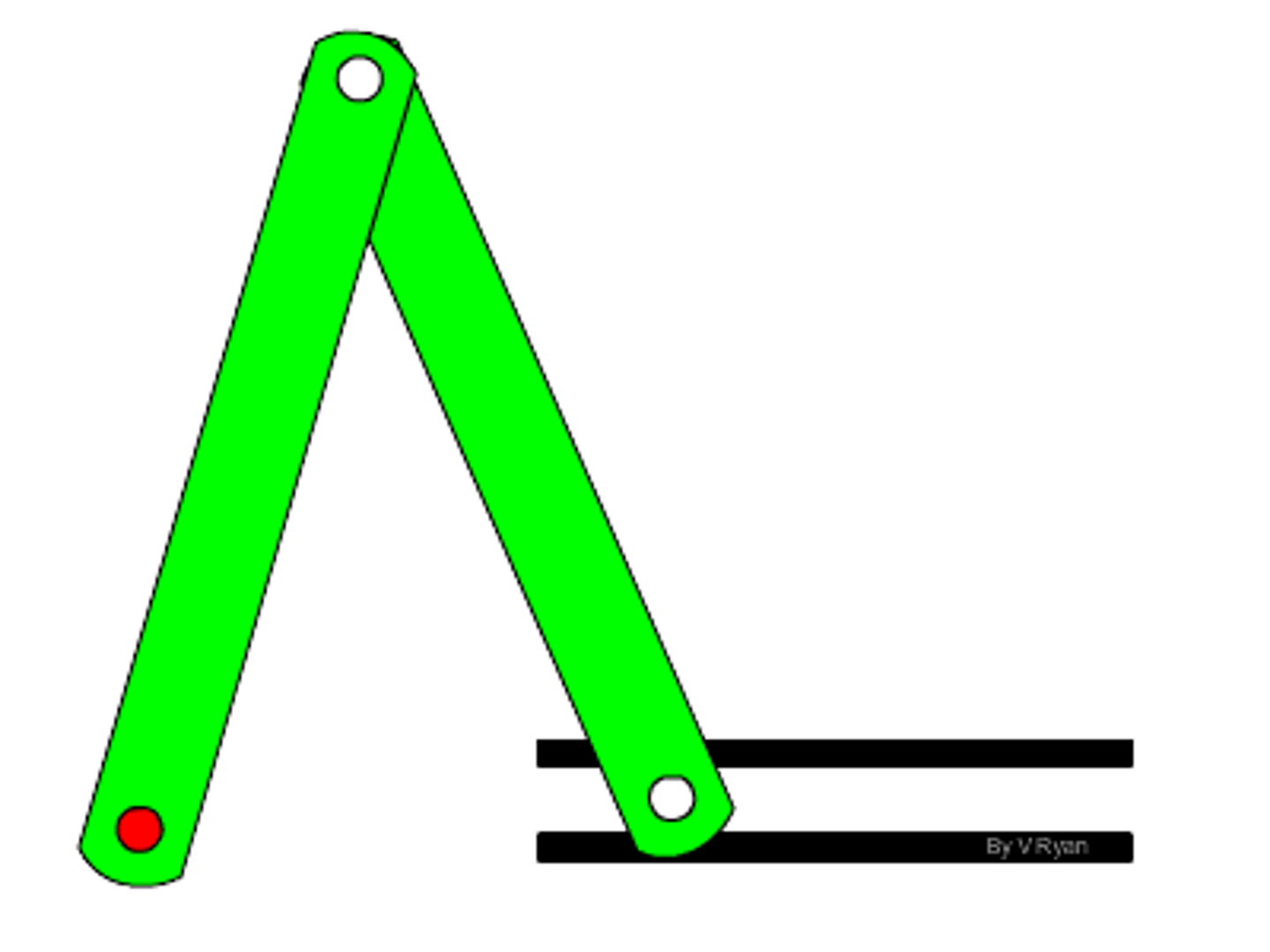

Bell crank linkage

Class 1 lever that can transmit the motion through 90 degrees to allow an input force to be transmitted around a corner

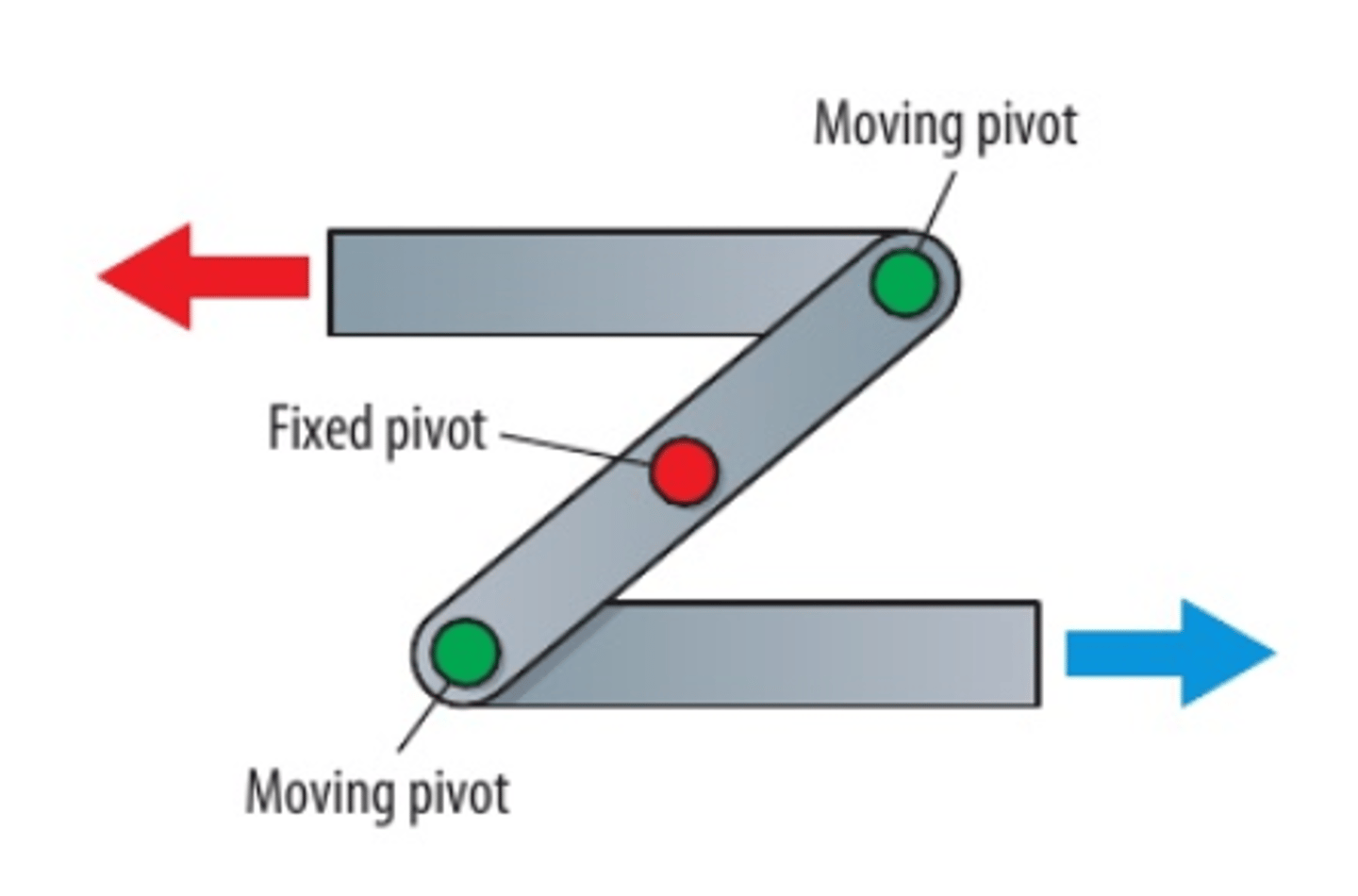

Reverse motion linkage

A class 1 based lever that reverses the motion of the input

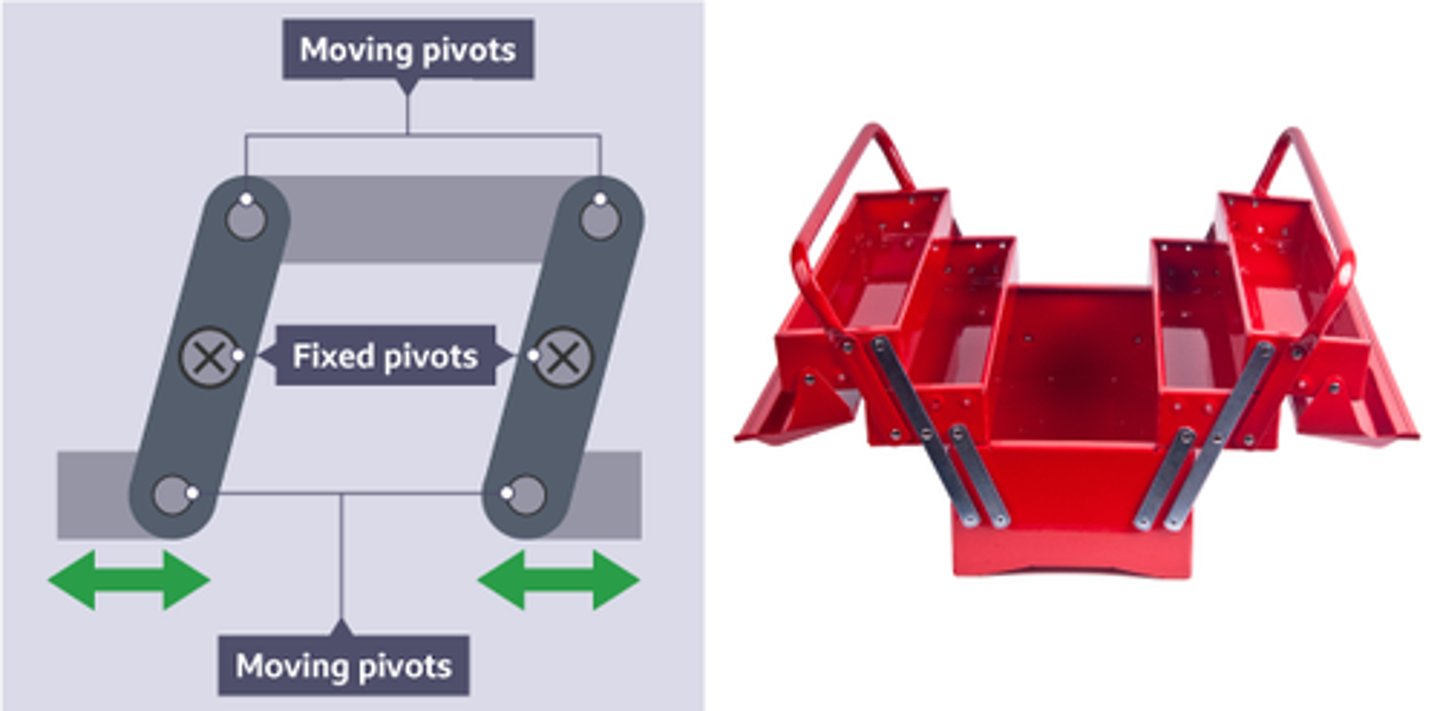

Parallel motion linkage

Crank and slider linkage

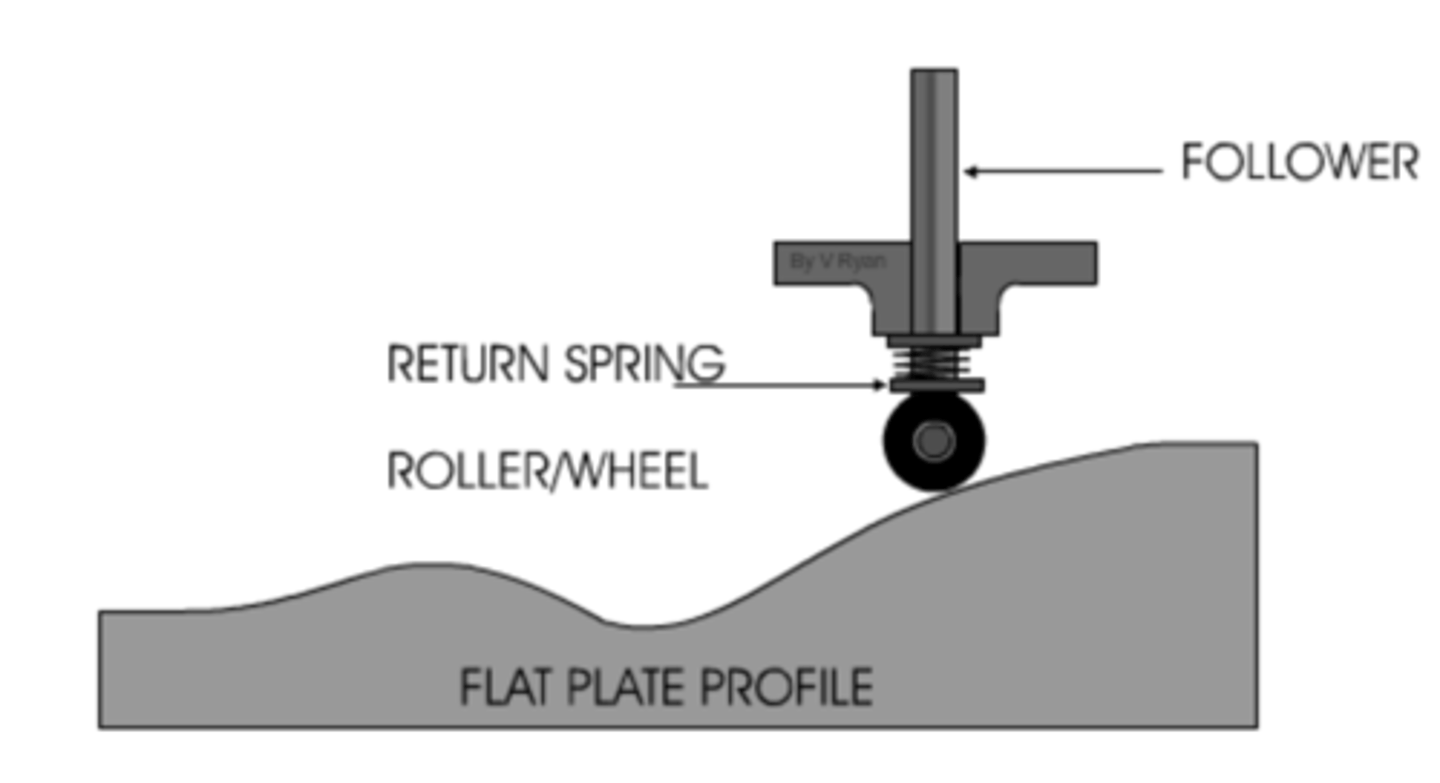

Cam

Converts rotary motion into reciprocating and oscillating motion.

Follower

Follows the movement of a cam profile

3 stages of movement in a cam

Rise (follower moves up)

Fall (follower moves down)

Dwell (follower is stationary)

Main types of cam & use

Pear-shaped (opens & closes valves in car engine)

Eccentric/circular (in a fuel pump or in steam engines)

Snail/Drop (hammers/punches or machines needing a sudden drop)

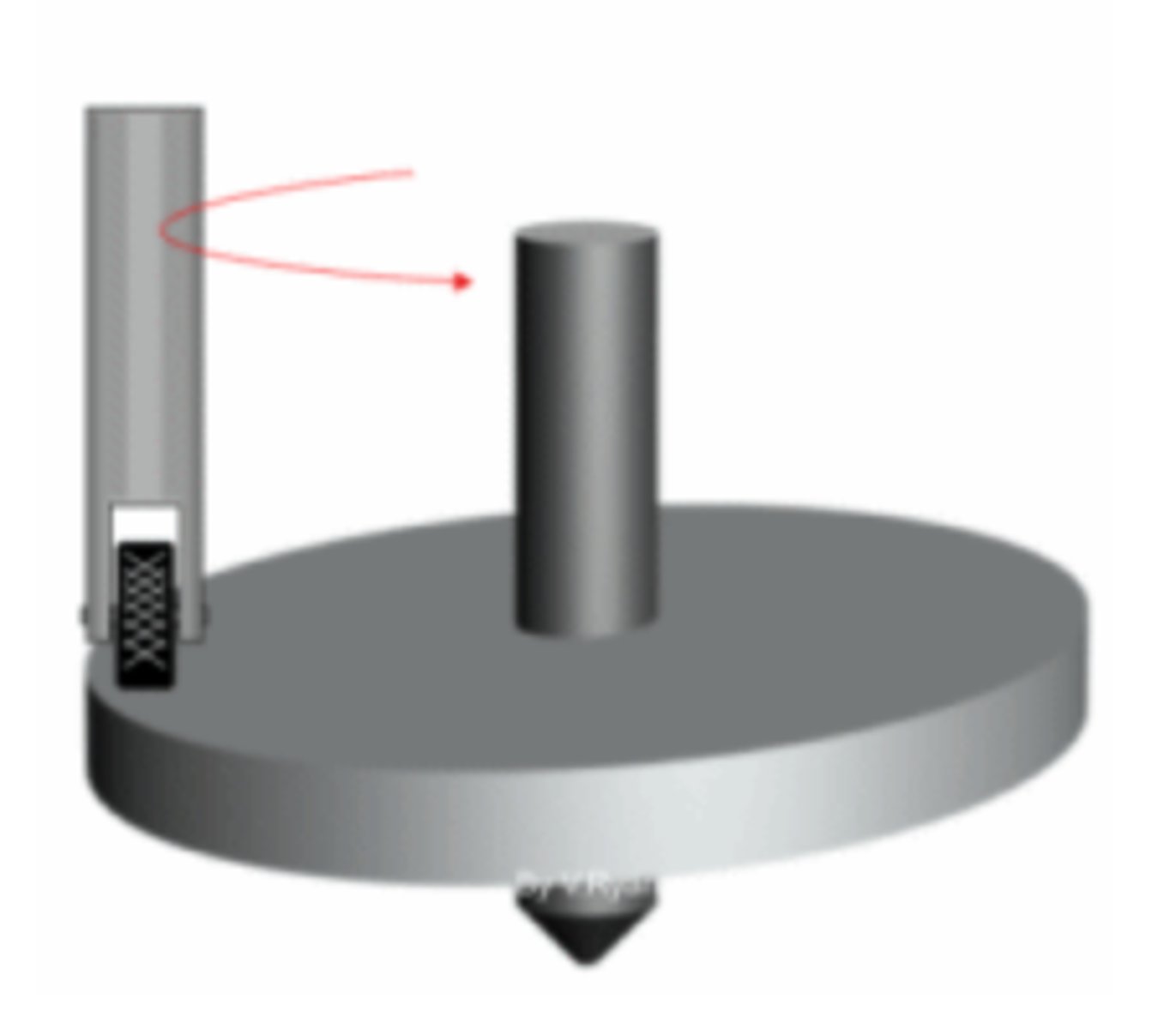

Swash plate cam

Flat plate/linear cam

Box cam

[image]

Barrel cam

[image]

Types of follower and use

Roller (used with high speed due to its low friction but has more parts with forces pushing them to the side)

Knife edge (used for accuracy in following cam profile but suffers rapid wear and forces pushes them to the side)

Flat (used in high load applications such as steam engines and has reduced forces pushing it but has higher friction)

Quick return mechanism

Rotary → reciprocating motion

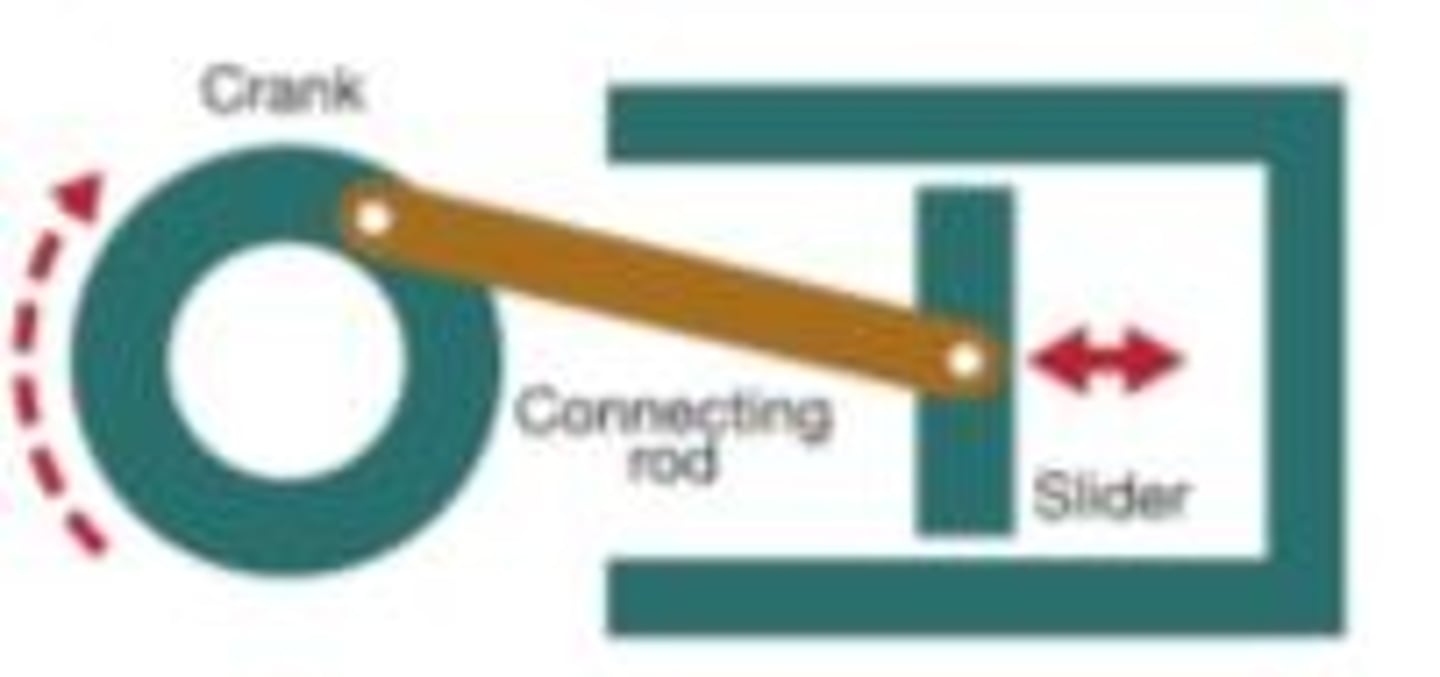

Cranks & sliders (& equation)

Convert rotary motion of crank to reciprocating motion of slider (e.g., crankshaft or compressor) or vice versa (steam engine)

Distance moved by slider = 2 × radius of crank

Instead of crank being wheel, could use a crank arm (its length is radius of crank)

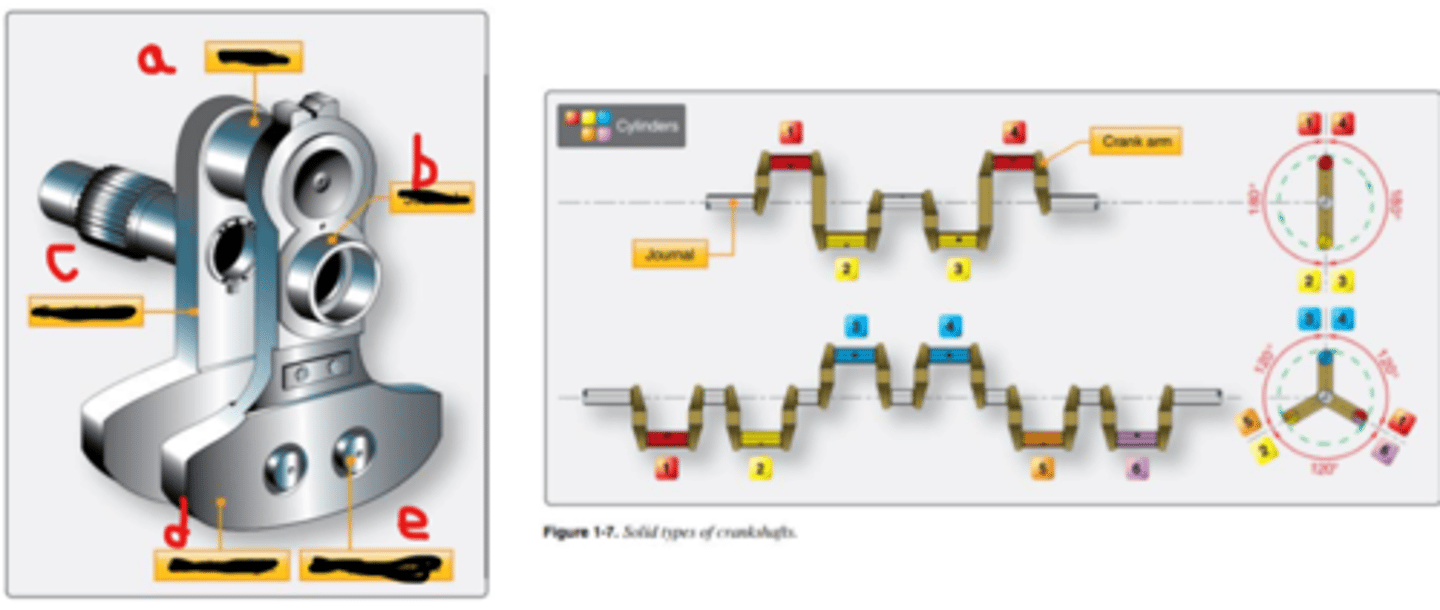

Crank vs crankshaft

Crank: a perpendicular section to the shaft

Crankshaft: A shaft with multiple cranks

Rachet and pawl mechanism

Only turns one way; if you let it go it will not spin back

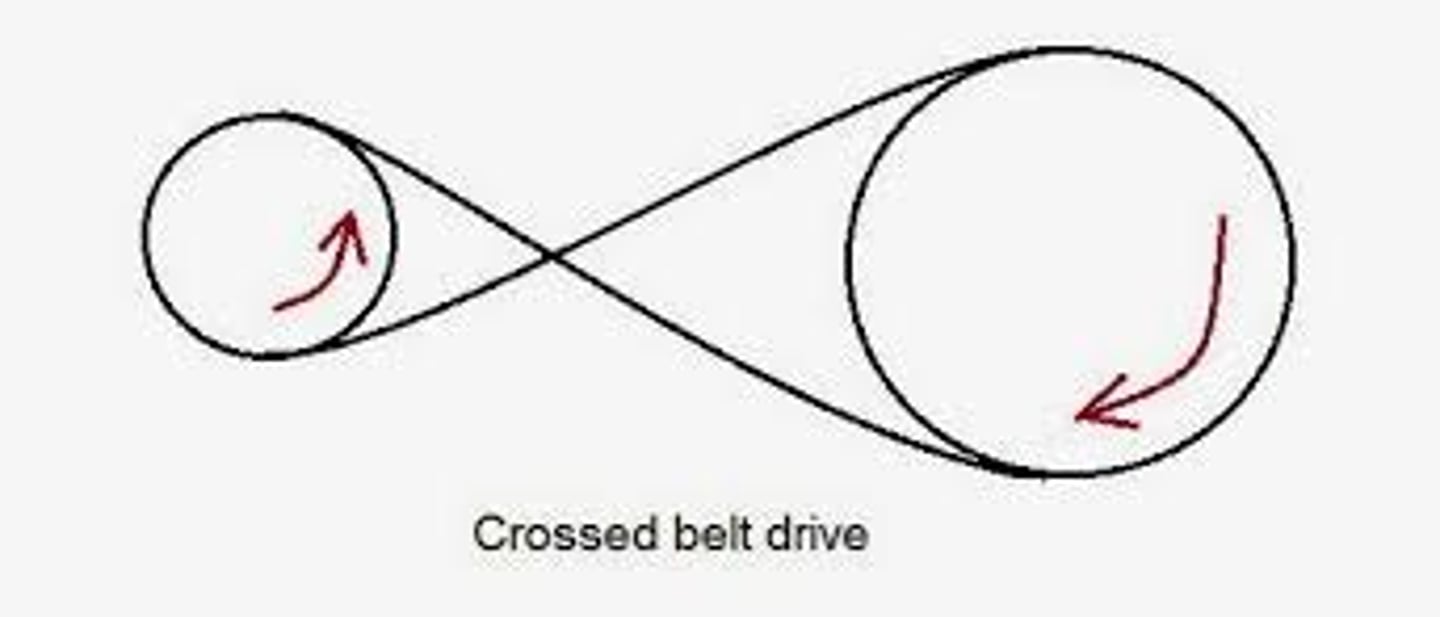

Pulleys and belts

- Transmit rotary motion from a driver shaft to a driven shaft via. friction (rotate same direction)

- A pulley is a wheel with a groove in its rim and the belt fits the groove to connect the two pulleys

- Having a V-belt increases gripping area by having sloping slides increasing efficiency by reducing any slipping and tightens drive surfaces

Reverse direction for pulley system

Mechanical advantage for pulley system (when using to lift loads)

Number of pieces of rope pulling on load

Velocity Ratio for pulley system (2 formulae)

Driven pulley diameter / Driver pulley diameter

Output speed and velocity ratio

Output speed (rpm) = Input speed (rpm) / Velocity Ratio

Gear

A toothed wheel fixed to a shaft that meshes with other gears to change the speed or direction of rotation of a driving mechanism. They have the advantage over pulley systems as the meshing prevents slippage so greater forces can be applied

Velocity Ratio for gear (ie. gear ratio) (2 formulae)

Driven teeth/Driver teeth

Use of an idler gear

Keeps the gears spinning in the same direction with no impact on output speed so VR is still based on driven and driver gears

Simple vs Compound gear trains

Simple has 2 spur gears

Compound has more than 2 and VR is calculated by first pair's VR × second pair's VR

Bevel gear

Transmits rotary motion through 90 degrees. Two same-sized gears are called mitre gears (equal inp/out speeds)

Rack and pinion (and formula for output movement)

Gear wheel and rack changes rotary motion to linear motion or vice versa

Number of teeth on pinion/Number of teeth on rack per metre

Worm gear (and formula for output movement)

Screw thread: worm (has 1 tooth)

Cylindrical gear: worm wheel

Worm always drives worm gear

VR = Driven/Driver = Worm wheel/1

Chain and sprocket

[ignore chain in VR calculations]

Chain cannot slip on the sprocket, and only need 2 sprockets to transmit motion over a distance

![<p>[ignore chain in VR calculations]</p><p>Chain cannot slip on the sprocket, and only need 2 sprockets to transmit motion over a distance</p>](https://knowt-user-attachments.s3.amazonaws.com/82a04d75-5fa0-45bd-8e99-0cff71e32653.jpg)