back rolls???

1/101

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

102 Terms

greenhouse

a structure covered with a transparent

material that admits natural light for plant growth and is

typically heated

floriculture

The art and science of growing and utilizing plants valued for

their aesthetic characteristics (other than woody plants used

in outdoor landscapes).

GH industry originated where and when

netherlands 1600s

venlo greenhouse

low profile, ridge and furrow. primarily used in netherlands

site selection should include plans for

expansion

vertical farming

maximize production space and environmental control; high electric costs

food deserts

area with low access (more than 1 mile away) to supermarket or local grocery in urban areas

CEA benefits

local and space efficient production; consistency and quality of products; water efficient; reduced disease pressure; year round production

what does environmental control cover

temp, humidty, light, CO2, nutrition

cons of CEA

skilled labor; high cost; energy intensive; some crops dont make sense; more research needed

best crops for CEA

young plants; edibles; public display/research

bad crops for CEA

staple crops like wheat/corn/potatoes/rice; plants used for energy (sugarcane, rapeseed); large trees (obviously)

considerations for locating a greenhouse

room for expansion; topography/microclimates; land use prediction (urbanization/taxation/zoning/fire codes); economic stability (labor supply/access to roads/water/utilities); n/w orientation

microclimates to avoid when siting a greenhouse

fog, topographic shadows, high winds, hail!

why do you need access to roads/considerations for roads

receiving and shipping; accomodate all seasons; truck weight vs. road condition

greenhouse water use

up to 30,000 gal/day/acre

greenhouse sources of water

ground water (deep wells best, may need permits); municipal water (cost and quality high, may contain mineral inclusions); drainage ponds (may contain chemicals, algae growth); rain (can be collected by oneself, clean); surface water (may need filters)

run ridges of single span greenhouses where?

E/W

run ridges of multi-span houses where?

N/S

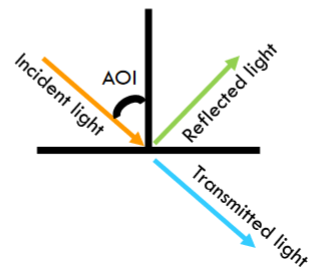

‘fates’ of light

reflected/transmitted/absorbed (photosynthesis, heat, chlorophyll fluorescence)

angle of incidence (AOI)

angle that a light ray striking a surface makes with a line perpendicular to the surface

% of light entering greenhouse depends on

angle of incidence; AOI = 0 ideal (straight down); reflective loss increases as AOI increases to 90

greenhouses below 40 latitude

ridges of all houses run N-S; better light distribution> light transmission optimization

light intensity also depends on

glazing, the superstructure, shade curtains, other overhead obstructions, plant spacing

locate a greenhouse how much from obstructing object

x2

plan for a greenhouses

ultimate size; plan for materials and product movement (height of carts, width)

common head house components

Offices, restrooms, breakroom, etc.

Work areas: potting, seeding, transplant lines

Storage: substrates, pots, pesticides, etc.

Fertilizer room

Coolers

Seed germination chambers

Central heating boilers

Loading dock(s) for shipping and receiving

where to locate headhouse

north side

easy access to roads and GH

Size related to greenhouse size

13 to 15 % of small ranges (<40,000 sq. ft.)

10% of medium ranges

7.5% of large ranges (>80,000 sq. ft.)

lean to

placed against existing wall, south facing, hobby or institutional ghs

even span

two slopes of equal pitch/width; most common

uneven span

roofs of unequal width and pitch; good for slopes and high latitude sites

freestanding ghs

best option for small operations

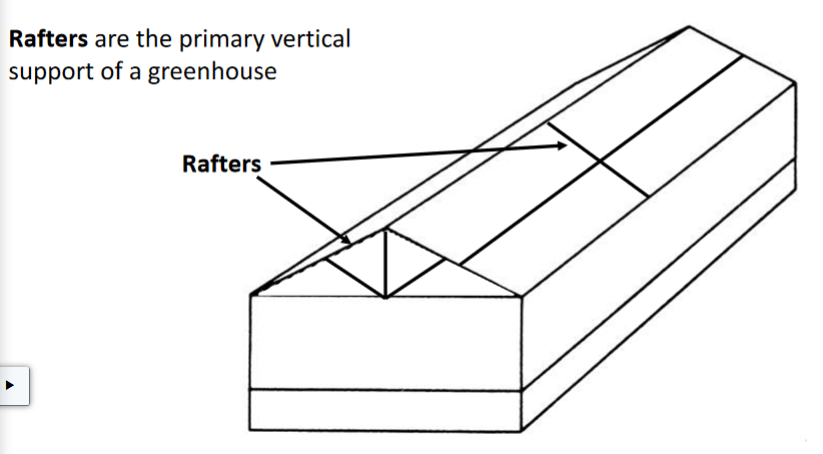

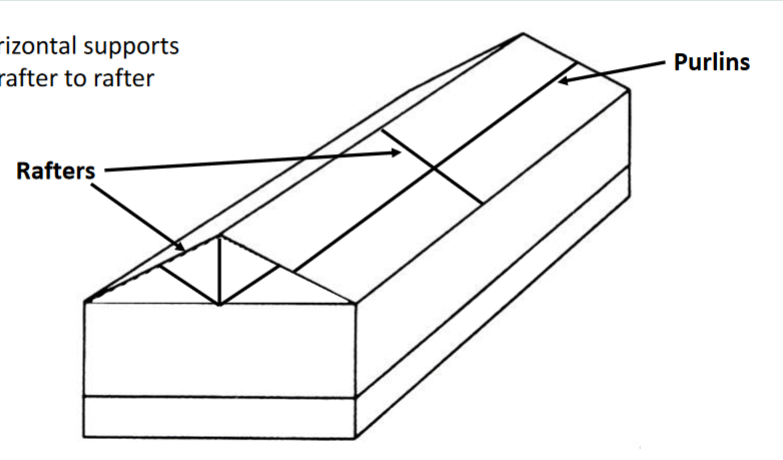

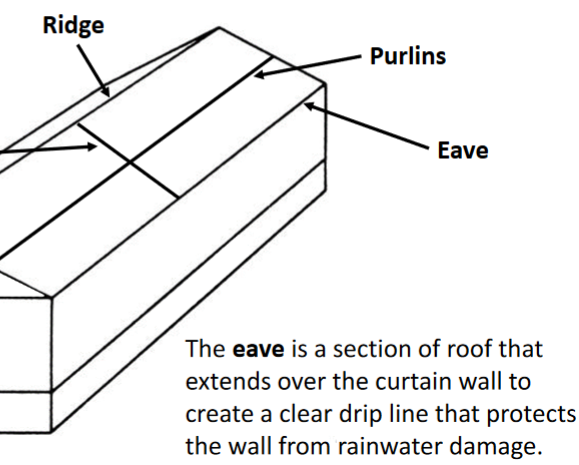

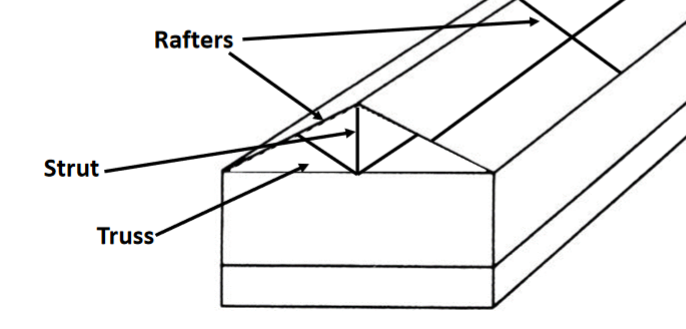

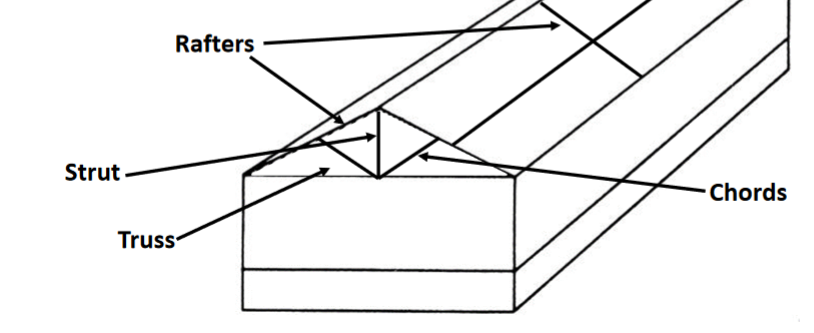

truss frames

consists of rafters, chords, struts

rafters

primary VERTICAL support

purlins

horizontal supports that run rafter to rafter

ridge

peak of the roof

eave

section of roof that extends over curtain wall to create drip line to protect wall from water damage

curtain wall

non-

structural outer covering of a

greenhouse utilized only for

temperature management.

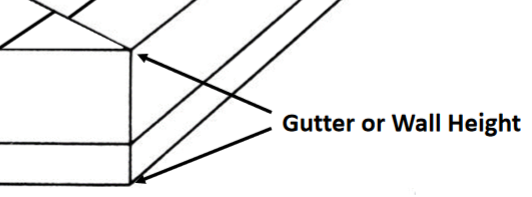

gutter/wall height

height of the GH gutter to gutter

strut

support of the greenhouse frame under compression force

chords

supports under tension

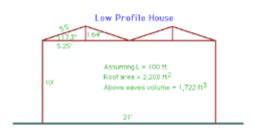

dutch venlo/low profile

two small roofs per greenhouse = reduced roof area = reduced heating costs

high light transmission compared to high profile

high profile/american

one large roof per greenhouse = larger roof = increased heating costs

gutter height

traditional - 8-10’

taller is easier to ventilate (16-24’) and great for high wire crops

14’ common for floriculture

quonset frames

raised arch

gothic arch

sawtooth venting

only used in warm climates without snow i.e florida

designed to utilize wind for cooling, reduce light and limit rain/water on plants for indoor use

load types

dead load - long term weight of permanent structure (frame, glazing, lights, etc)

live load - short term weight (people, hanging baskets)

snow load - 15 lbs/ft2 of floor minimum

wind load: lateral and lifting forces to resist 70 to 80 mph

foundation: vertical horizontal lifting forces

unusual loads: hurricanes, earthquakes

most common structure materials

galvanized steel - most common but huge cost, strength determined by diameter and thickness (gauge)

aluminum - lightweight, strong, low maintenance - high cost, typically for sash bars

glazing selection criteria

material

solar angle

cleanliness of glazing

age of glazing

shading due to infrastructure

thermal qualities - plastic films contract in cold and expand in warmth

heat retention

thermal radiation

strength and weight

shattering - resistance to breakage

tensile strength - resistance to tearing

flammability, labor to change, life expectancy, cost, etc

type 1 glazing - thin plastic films

2-8 mils

normally 2 layers with air inflation between the layers to provide added insulation

ethylene vinyl acetate - eva

polycarbonate - pc

polyester

polyethylene - pe

polyvinyl chloride - pvc

polyvinyl fluoride

ethylene tetrafluoroethylene - etfe

polyethylene

major film used in us

6mil exterior, 4mil interior for insulation

uv inhibitors added to increase lifespan by 3-5 years

antifog materials to prevent condensation

ir blockers - less heat loss

advantages - inexpensive, easy to install, large sheets readily available

disadvantages - short lifespan, easily damaged, high thermal transmittance

ir blockers

short wave energy into greenhouse, surfaces radiate ir radiation, the films block reradiation

double layer covering

plastic expands and contracts with temperature changes; leave 2-3 inches when warm and pull plastic tight when cold

inflated air space - 6 inchesish between layers

inflation fans maintain the air gap - dont use gh air use outside air for less humidity!!

vinyl/polyvinyl chloride

8-12 mil films - 4-5 year life

high static charge

polyvinyl fluoride

almost 10x more expensive than polyethylene

high light transmission and long lifespan

polyester

mylar

too expensive for glazing - shade cloth

retractable roof material

type 2 - rigid plastic panels

fiberglass reinforced plastic - frp

polycarbonate

acrylic

fiberglass reinforced plastic - frp

advantages - low cost, very resistant to breaking/shattering - crazes instead, low thermal transmittance, flexible and can be bent over quonset frame, more light diffusion than glass

disadvantages - surface easily abraded - bloom fibers, susceptible to uv, highly flammable, not available in double layers

polycarbonate

advantages - low flammability, low thermal resistance, long lifespan, high impact resistance, uv protectant typically added

disadvantages - easily scratched, high thermal expansion-contraction

available as - corrugated, double wall, triple wall

acrylic

advantages - excellent transmittance, superior resistance to heat and weather (wont yellow), very low thermal transmittance

disadvantages - very flammable, easily scratched and some embrittlement with age, high thermal expansion/contraction, high cost

type 3 - glass

annealed, tempered, laminated

glass

only choice until 1950s

advantages - excellent transmittance (better than film plastic and plastic panels), superior resistance to heat, uv, abrasion, low thermal expansion-contraction, low thermal transmittance, more air exchanges - lower RH, less disease, greater evapotranspiration

disadvantages - more leaks - greater heat input, higher initial cost (initial vs long term cost, maintenance over long term is less, plastics require recovering while glass is permanent), heavy, low impact resistance unless tempered

16-39inch pane widths = wider panes = more light

float glass mainly used in us - 88% light transmission

low iron glass - 90-92% more transmission but way more expensive

tempered glass allows wider panes up to 6 by 13 feet - fewer seals, can be bent to a curve

important lighting definitions + lighting information

Transparent: Allowing light to pass through so that objects behind

can be distinctly seen.

Translucent: Allowing light, but not detailed images, to pass

through; semitransparent.

Opaque: Not able to be seen through; not transparent.

Direct light: Photons of light pass through and are not scattered;

photons pass at just one angle.

Diffuse light: Photons of light are scattered at many angles.

MAXIMIZE light intensity and uniformity

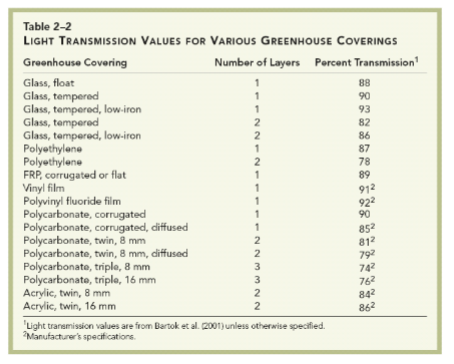

light transmission values

highest = low iron glass

percent transmittance and typical transmission values for glazings

transmitted light passing thru surface / incident light mesured at surface x 100

glass - 60-65%

plastic - 35-50%

acrylic - 55-60%

direct light vs diffuse light

direct light - photons of light pass through and are not scattered; photons pass at just one angle

diffuse light - photons of light scattered at many angles

key is to maximize light intensity and uniformity - percentage of light entering a greenhouse depends on angle of incidence

cost of high tunnel construction

pvc far cheaper than metal

polyethylene far cheaper than glass

most common glazing material in u.s

double layer inflated polyethylene film (6mil)

vent options

ridge vents (roof), side vents (walls), roll up sidewalls, retractable roof

greenhouse heating terminology

thermostatics - science of equilibrium of heat, including heat transfer and thermal properties of materials

heat - quality of being hot; energy produced by accelerated vibration of molecules

temperature - index of heat; scale of hotness and coldness

calorie vs Calorie

calorie (c or cal) - amount of heat required to raise 1 gram of water 1c

Calories (C or Cal) - used by dieticians to indicate energy in foods; really a kilocalorie (1 C = 1,000 c)

1 kcal = 3.9689 Btu

british thermal unit (btu)

amount of energy required to raise temperature of 1lb of water 1F

1 btu = 252 cal

used commonly in greenhouse for heating applications

horsepower (hp)

boiler heat output reported at hp

1 hp = 33,475 btu

convection

mass movement of particles along with their kinetic energy from one point to another

movement en masse of heated molecules from one point to another

moving heat from one point to another within an air mass

conduction

transfer of kinetic energy from one molecule to an adjacent molecule by collisions

energy flows from the higher energy molecules (warmer material) to lower energy molecules (colder material)

rate of flow depends on temperature differential (deltaT)

thermal conductivity - ability of a material to transfer heat energy through conduction, expressed as K

radiation

electrical transfer of heat energy

travels through a medium as an electromagnetic wave without being absorbed by the medium (infrared, long wave, or thermal radiation)

colder temperature of surrounding surfaces, more energy is radiated away

radiator metaphor

radiators only radiate 60% of heat they give off - rest is via conduction and convection

conduction where air molecules collide with radiator; convective currents move molecules away from radiator

energy balance in plants

energy received by plants - absorbed radiant energy from lamps, absorbed infrared radiation from surroundings

energy leaving plants - energy lost through emitting infrared radiation; heat convection, heat conduction, heat loss through evaporation

heat transferred via conduction from leaf cells to air molecules in contact with leaf

heat is transferred via convection when air moves across plant

free (natural) and forced caused by wind or fans

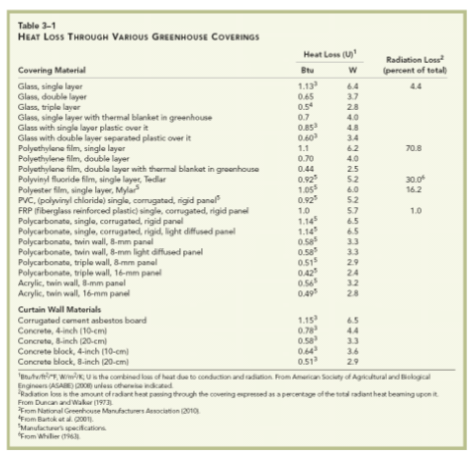

heat loss from greenhouse

exfiltration - warm air moves out of the greenhouse

infiltration - cold air moves into greenhouse

more wind outside = more conductive heat loss

heat lost through greenhouse glazings

insulation rated by R value - 2-30 is increasing insulation

conduction raised by U value - lower U = more energy efficient

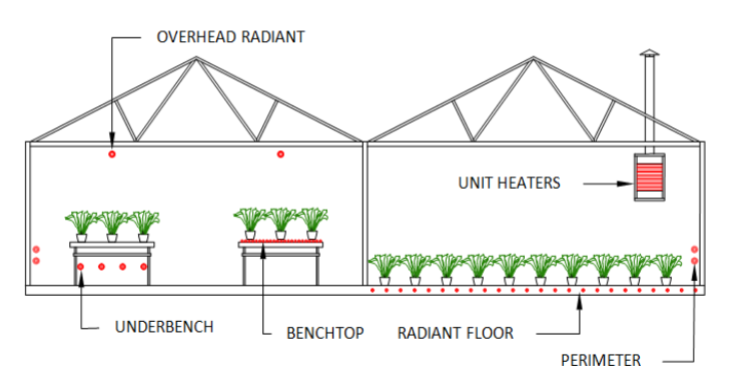

type of heating systems

unit (forced air) heaters

central heat (boiler and pipes)

radiant heat

capacity - meet the needs of heat loss per hour

heating systems locations

overhead radiant

unit heaters

underbench

benchtop

radiant floor

perimeter

central vs localized heating system considerations

initial cost

long term maintenance

backup system in case of failure

fuel cost

efficiency at low heat demand

distribution of heat

unit heaters

multiple independent overhead units

fan driven heat distribution

least expensive

1.00-1.50ft2 of gh floor

common in small operations and individual quonset houses

output capacity - 20-320,000 Btu/hr per unit - MUST have constant supply of OUTSIDE oxygen or itll eat all the GH oxygen - needs sufficient exhaust stack

ethylene and sulfur may contaminate gh air

convection tubes

polyethylene tube running length of greenhouse with holes in pairs on opposite sides every few feet; warm air exits holes, mixes with cool air

can keep tube inflated/blowing even when heater is not running -air movement and temp uniformity and winter cooling

not v popular now

placed below heat and photoperiod curtains if present

place under benches (hard to manage)

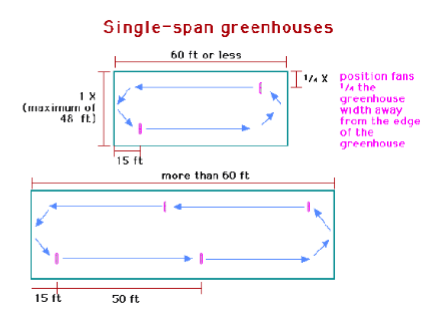

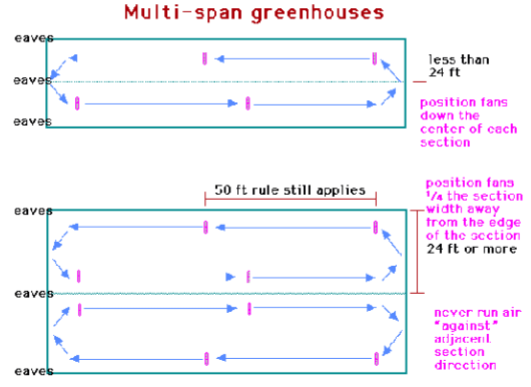

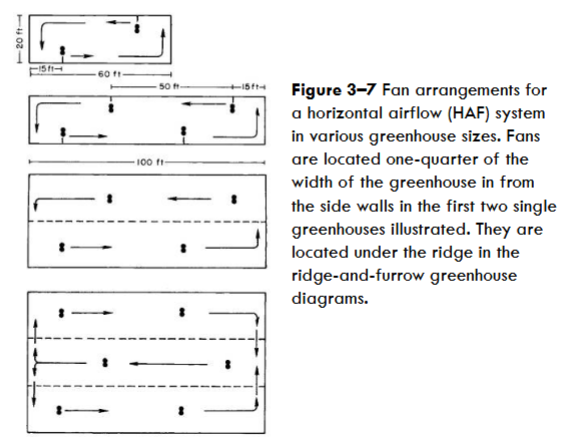

horizontal airflow (HAF) fans

circulate air with better temp uniformity than tube systems

1 fan per 50 ft of gh length

circular pattern

3 ft above crop and below eaves - first fan 10-15 ft from end wall - max of 50 ft between fans on same side

mount ¼ of the house width from sidewalls; last fan per side should be 40-50ft from end wall toward which it is blowing; heaters can serve as corner fans on same side

fan spacing

OOOOWEEEAAAAYYAYYYOOOOAAA

boilers for heating systems

distribution of pipes moving steam/hot water into greenhouse; mostly hot water

more expensive than unit heaters but burn cheaper fuels and require less maintenance

2.50-3.25ft of gh floor area

hot water or steam leaves boiler, heat exchanged in gh via pipe coils/unit heaters

fire tube boiler

gasses run thru tubes surrounded by water; large vol of water, slow to heat n slow to cool

water tube boilers

water runs through tubes or thin plates/gasses surround tubes

quick to heat up and cool down

less expensive and smaller than fire tube

pipe placement of boilers

wall pipe - low and against curtain wall, replace loss of heat thru walls

overhead pipe coils - located above plants, must force heated air down. out of way but has shadows. may be needed for snowmelt

in bed pipe coils - along edges of ground beds, beneath benches, within ground beds, within concrete floor. puts heat near plants

heated floor in floor tubing - v efficient for crops grown on floor, will dry floor quickly (good) if flood irrigation used, may need side and overhead heating

root zone heating - small diameter tubing. 2 “ part along length of lfoor or bench, bidirectional flow (inlet and exit on same end) can often lower air temp in gh reducing voerall heating costs. conduction

radiant heat

4” diameter steel pipes filled w burning gas suspended over plants for full length of greenhouse. aluminum reflectors directed IR down to ground/plants. little air absorption of heat, plants/ground/benches absor most - fuel efficient

Heaters must be at least 5 ft. away from

plants, 4 ft. from roof, and 10 ft. from

walls to prevent damage

Heaters placed 20-30 ft. apart

Little heat is transferred to air

Air temperature will be cooler than plant

Is this an issue?

20-120 btu/hr will heat area 2x height -

fuel types

#2 heating oil

138,000 btu/gal

Natural Gas

1,030 btu/ft 3

Propane

2,500 btu/ft 3

Waste Oil

125,000 btu/gal

Biodiesel

120,000 btu/gal

Hardwood

18-24,000,000 btu/cord

Corn

15-17,000,000 btu/ton

estimating capacity for gh heating

need to know style of gh, glazing material, surface area, minimum outside temp, heat loss, avg wind velocity

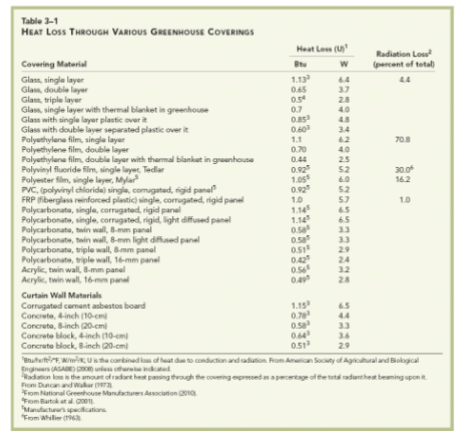

u value

heat loss

lower = better

commonly used for glazing

r value

resistance to heat loss

reciprocal of u value

higher = better

air good insulator

used in construction

insulation rated by r value - 2-30 increasing insulation

conduction - rated by u value; 1.1-.5 increasing insulation

reducing air leaks

lube UP fan shutters; check for cracks and problems in overlapping panes; weather strip doors