MAX - Air Systems

1/26

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

27 Terms

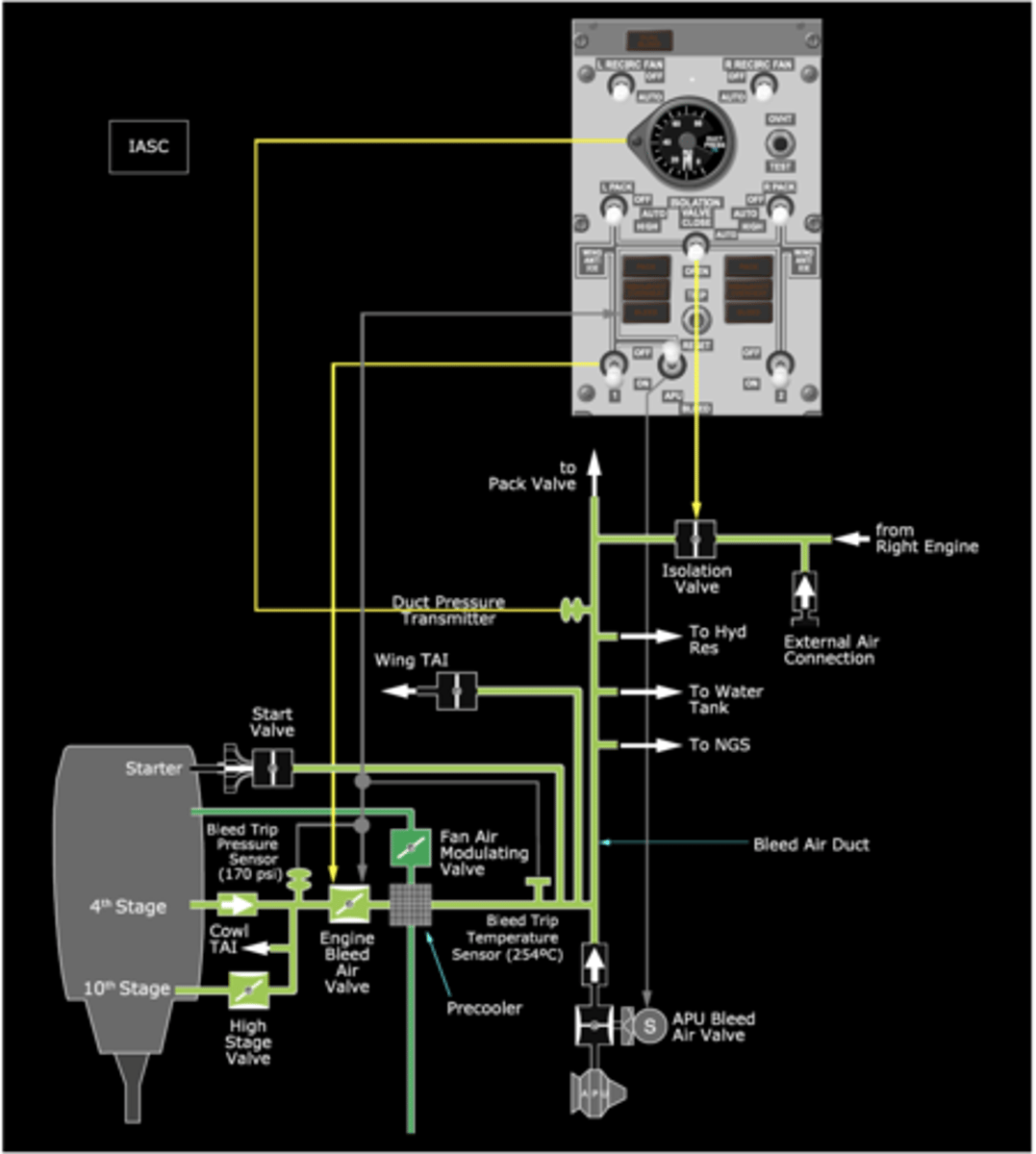

What are the sources of air the Bleed Air System?

Bleed air can be supplied by the engines, Auxiliary Power Unit (APU), or an external

pneumatic/conditioned air source (on the ground).

What is the purpose of the Air Supply Controller (ASC)?

Engine bleed air is controlled electronically by the Integrated Air Supply Controller (IASC).

The IASC has two subsystems: the Air Supply Controller (ASC) for bleed regulation and;

the Pack Flow/Temperature Control (PFTC) for pack output temperature and flow control.

What causes the engine bleed air valve to automatically close?

The Integrated Air Supply Controller (IASC) will automatically trip both the Pressure Regulating Shutoff Valve (PRSOV) and High Pressure Shutoff Valve (HPSOV) closed in response to high temperature (254°C) or overpressure (170 psi for 5 seconds).

What does the illumination of the BLEED light indicate?

• bleed sensor(s) have closed the associated engine bleed air valve for over-temperature or excessive pressurization of the bleed duct, or

• a failure within the Bleed Air System that may not be resettable, or

• an incorrect bleed configuration after takeoff or go-around

What causes the automatic closure of the APU bleed valve?

The valve will automatically close when the APU is shut down, regardless of switch position. Selecting OFF will close the valve.

What is the position of the isolation valve with the ISOLATION VALVE switch in AUTO?

In AUTO, the isolation valve is controlled by engine BLEED and PACK control switches.

With both engine BLEED switches ON and both PACK switches in AUTO or HIGH, the

isolation valve is closed; manually placing any engine BLEED or PACK switch to the OFF position will automatically open the isolation valve.

What does the illumination of the DUAL BLEED light indicate?

The DUAL BLEED light illuminates when two sources of bleed air (Engine and APU) could be pressurizing the left bleed duct.

The following BLEED panel configurations potentially expose the Bleed Air System to this condition:

• Engine No. 1 (left bleed) switch ON and APU bleed air valve open

• Engine No. 2 (right bleed) switch ON, ISOLATION VALVE OPEN, and APU bleed air valve open

In the event of a single pack failure at altitude, the remaining pack is capable of maintaining cabin pressure and comfort up to what altitude?

A single pack in high airflow mode can maintain pressurization and acceptable temperatures up to the maximum certified ceiling.

What causes a pack to automatically switch to high airflow?

The AUTO position also has an automatic high airflow mode. If a pack or an engine fails when the aircraft is airborne with Flaps UP and both engine BLEED switches ON, the operating pack will automatically switch to high airflow mode. Additionally, positioning a PACK switch OFF in flight with the Flaps UP will also cause the remaining pack to go into high airflow mode. This automatic function is inhibited on the ground or with flaps extended to preserve engine power for single-engine operation.

NOTE: The illumination of the EQUIP SMOKE light of the Equipment Cooling System will automatically switch both packs to high airflow mode to protect against smoke entering the cabin.

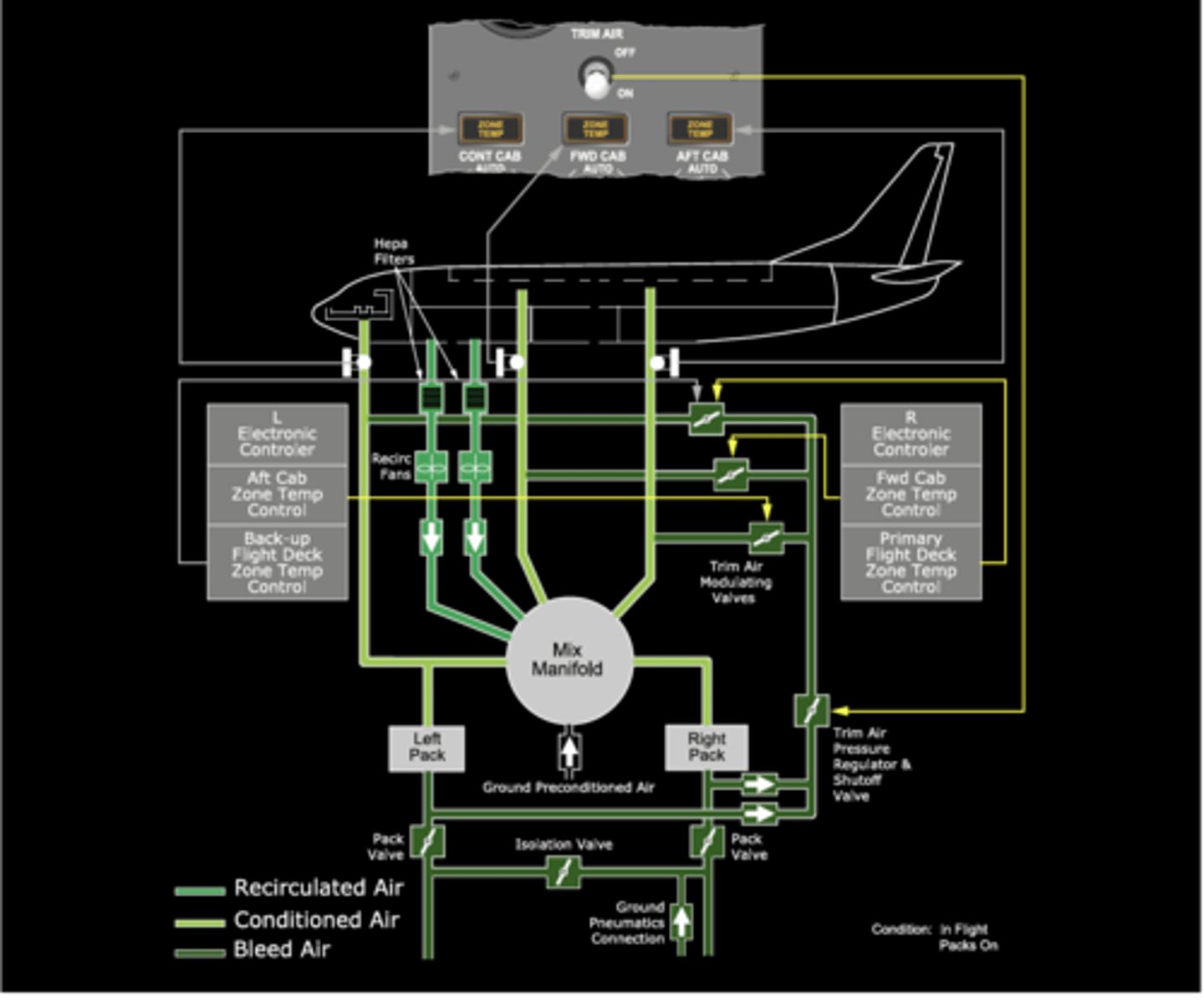

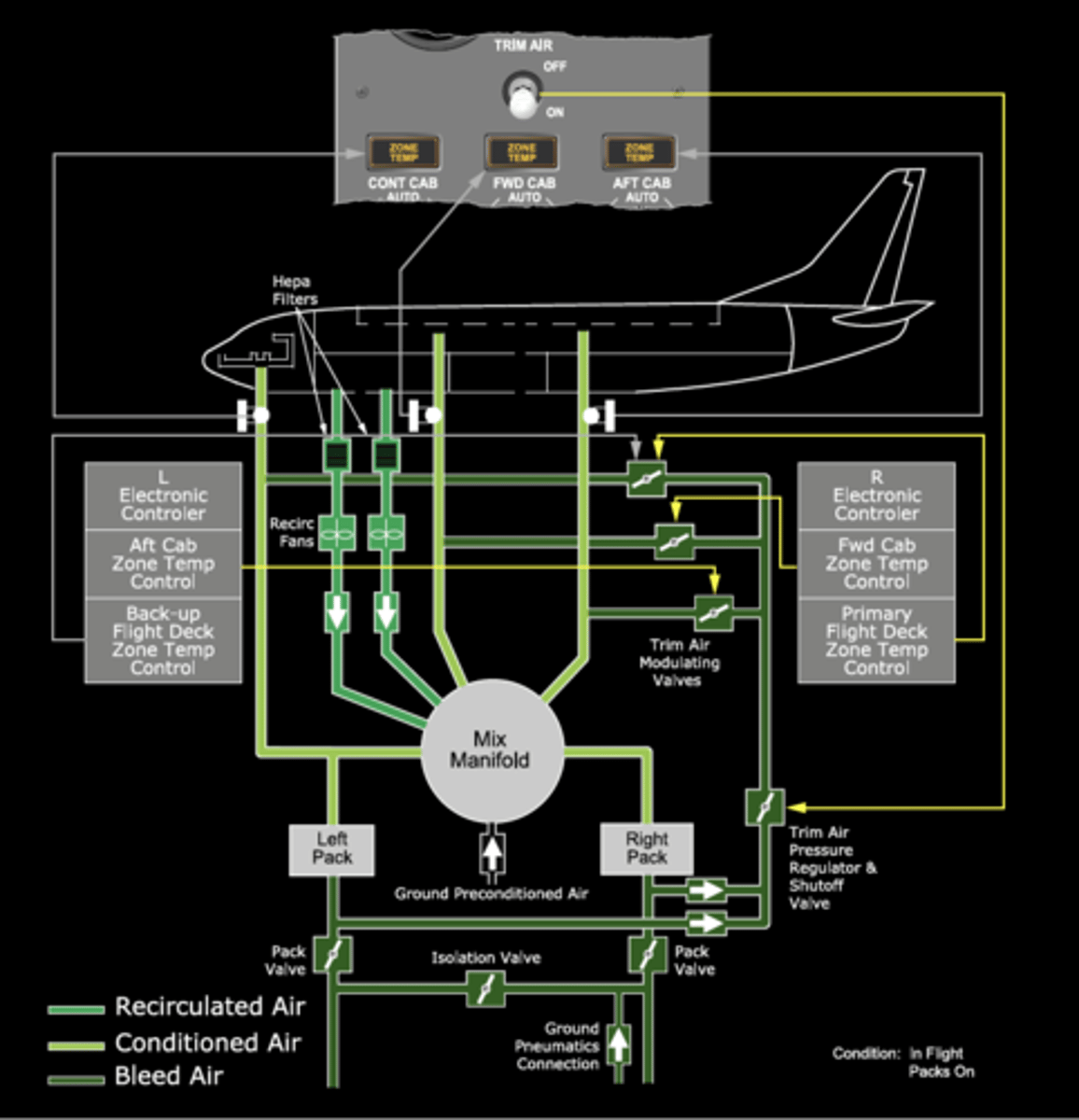

How many controllers does each pack have?

Both air conditioning packs have two integrated pack/zone electronic controllers. Each controller has a digital primary channel to control its respective pack and an analog channel that provides backup control for the opposite side pack.

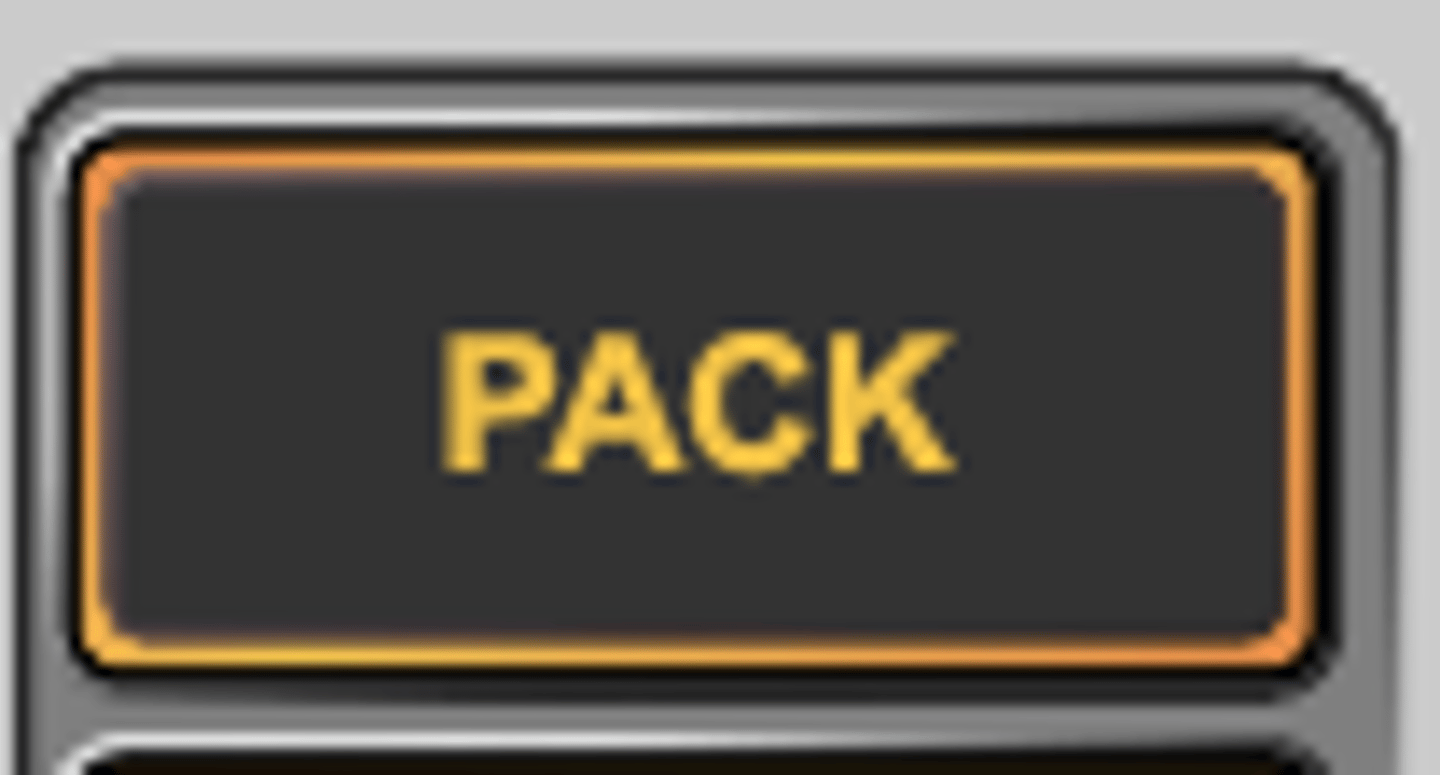

What does the illumination of the PACK light indicate?

• failure of both the primary and standby pack controls for the same pack; the pack will continue to operate uncontrolled unless tripped off by excessive temperature, or

• failure of the pack valve to open when commanded,D or

• an incorrect PACK switch configuration after takeoff

An incorrect PACK switch configuration is when both PACK switches remain in the OFF position for 45 seconds after flaps are retracted to UP following a takeoff, causing both PACK lights to illuminate. Positioning either PACK switch to AUTO or HIGH will extinguish the PACK light for this condition

Do the Flight Attendants have any control of cabin temperature?

Temperature set points for the forward and aft passenger cabin zones can be adjusted ± 3° from the Flight Attendant panel in the cabin

How is the failure of either the primary or standby pack controller indicated on the ground?

The MAINT light and the OVERHEAD System Annunciator and MASTER CAUTION lights will illuminate after landing to indicate failure of the associated zone control.

What provides cooling air for the pack systems?

The Ram Air System provides cooling air for the air conditioning pack heat exchangers.

How is a supply duct overheat indicated?

ZONE TEMP lights indicate a supply duct overheat of the associated temperature zone or failure of both the left and right IASC.

An overheat condition may be reset using the TRIP RESET switch if the supply duct has cooled below limits.

What is the primary source of conditioned air for the Flight Deck?

The Flight Deck receives air directly from the left pack.

What is the purpose of the recirculation fans?

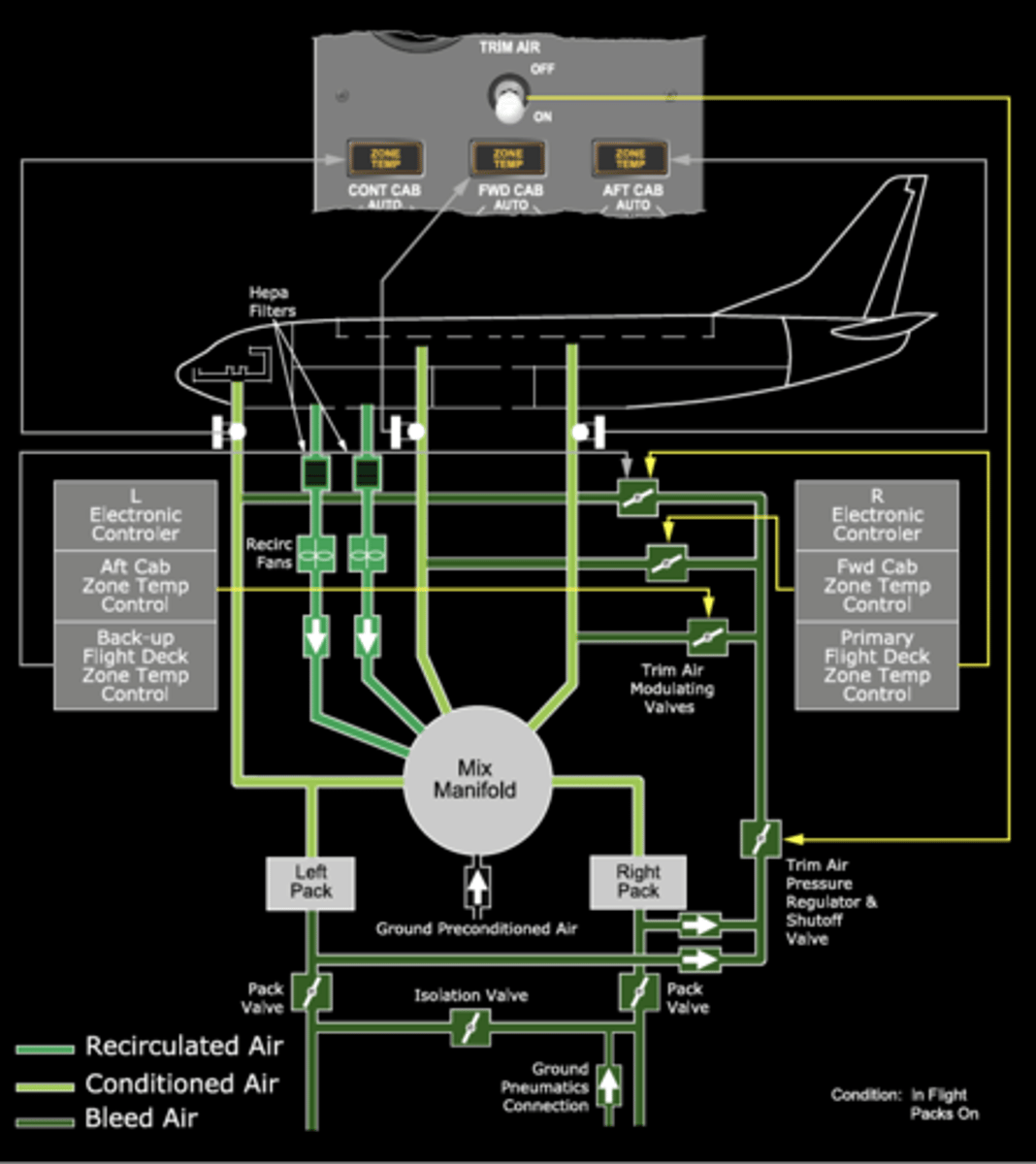

Recirculated air through use of two recirculation fans reduces the Engine Bleed Air and Pack System demands and increases engine efficiency. Roughly 50% of cabin air is recirculated air, which also helps to maintain humidity in the cabin from the very low humidity air from the engine bleeds. Airborne particulates and micro-organisms are filtered through High Efficiency Particulate (HEPA) filters, delivering clean air back to the cabin.

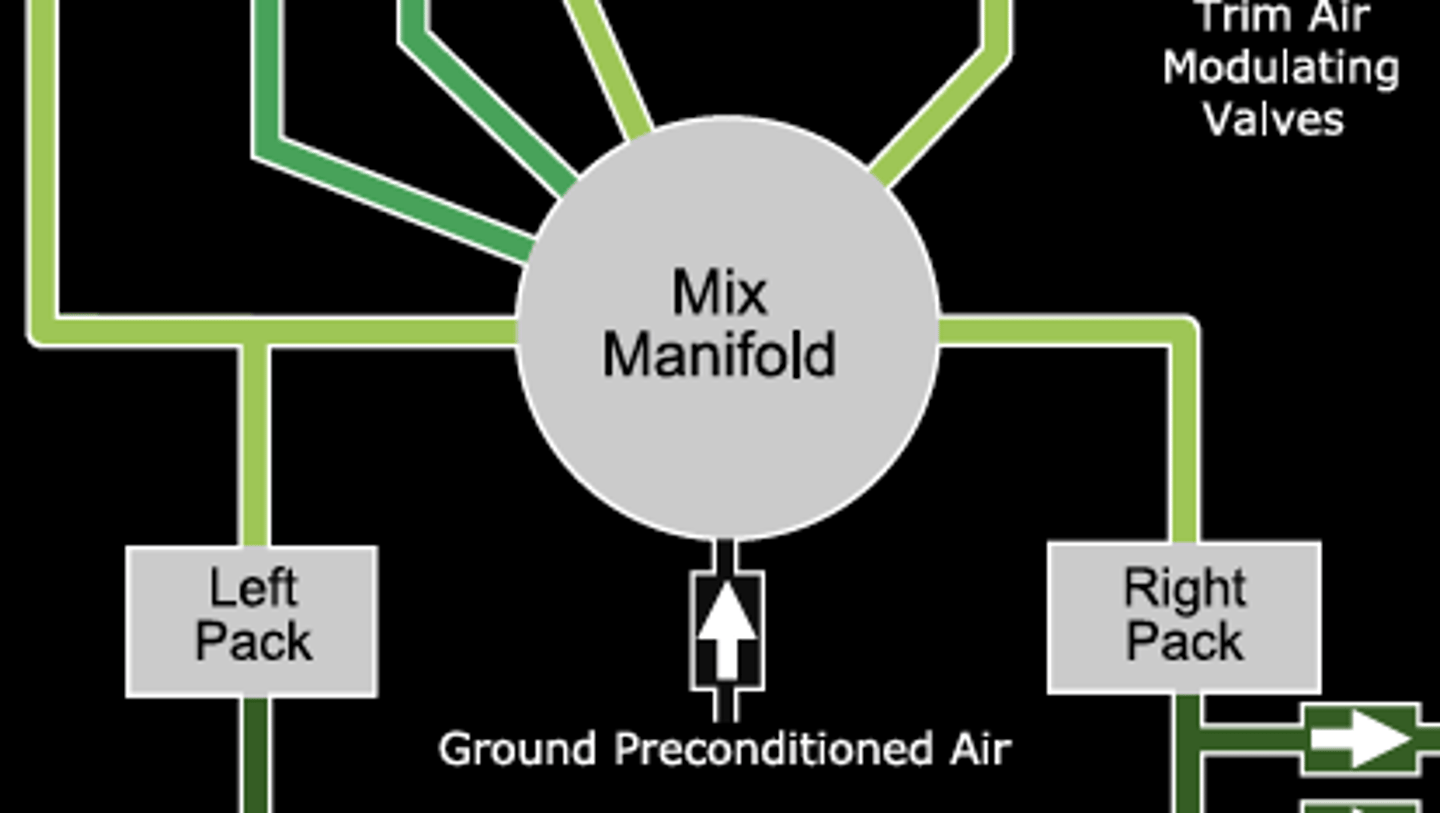

Can pre-conditioned air temperature be controlled by the packs?

When using external conditioned air, the PACK switches should be positioned OFF. The use of packs with external conditioned air greatly reduces the efficiency of the conditioned air cart.

Conditioned air temperature is controlled at the external air source. External air enters the air system at the mix manifold; therefore, the packs have no temperature control of this air source.

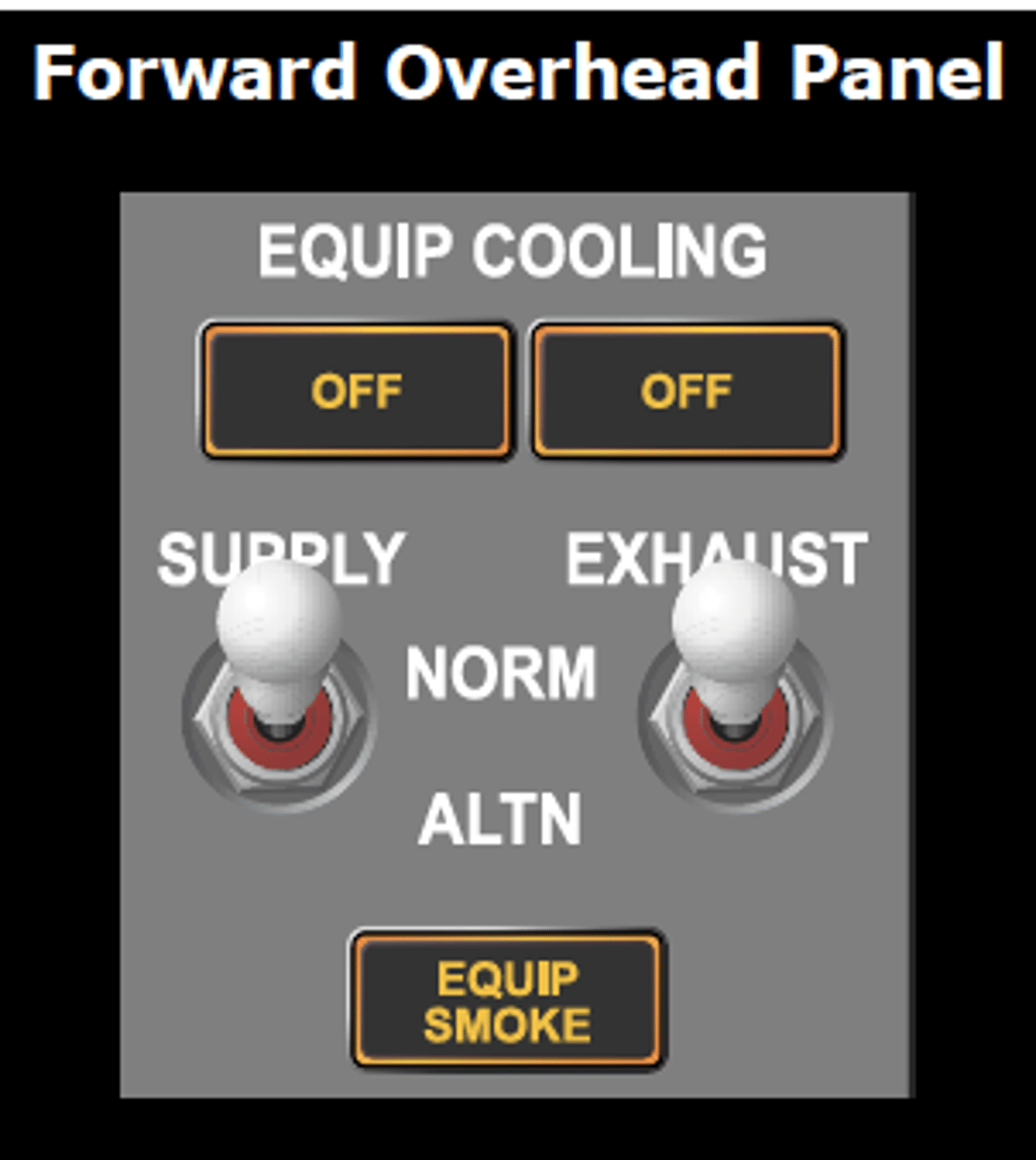

What does the Equipment Cooling System cool?

The Equipment Cooling System cools the electronic equipment in the Flight Deck and Electrical Equipment Bay (E & E Bay).

The Equipment Cooling System consists of a supply duct and an exhaust duct. Each duct has a normal fan and alternate fan.

Which cargo compartment is heated by warm air from the Equipment Cooling System's exhaust fans?

The exhaust duct collects and discards warm air from the Flight Deck displays, the

overhead and aft electronic panels, circuit breaker panels in the Flight Deck, and electronic equipment in the E & E Bay.

An Overboard Exhaust Valve (OEV) is located on the bottom of the fuselage just aft of the E & E Bay access door. The OEV is normally closed during pressurized flight. When closed, exhaust air from the Equipment Cooling System is diffused to the lining of the forward cargo compartment for additional in-flight heating. When the OEV is open (normally on the ground), the warm air is discharged overboard.

What does the EQUIP COOLING OFF light indicate?

The normal and alternate fans are powered from different electrical buses. Loss of airflow due to the failure of a fan is indicated by the illumination of the OFF light and the OVERHEAD System Annunciator and MASTER CAUTION lights. Selecting the alternate fan should restore airflow and extinguish the OFF light within approximately 5 minutes.

What does the illumination of the EQUIP SMOKE light indicate?

Two smoke detectors are installed downstream of the fans. The EQUIP SMOKE light and the OVERHEAD System Annunciator and MASTER CAUTION lights will illuminate if smoke is detected.

When smoke is detected, the system will automatically set the packs to high

flow, turn the E & E Bay cooling supply fan(s) off for approximately 5 minutes, the overboard exhaust valve opens to the smoke position, and the recirculation fans turn off.

How is the alternate pressurization controller selected?

When the pressurization mode selector is in the AUTO position, the Pressurization Control System operates automatically using one of the two automatic controllers. The system changes the active controller with each flight.

Selecting ALTN on the Cabin Pressurization panel will switch control to the standby controller.

How are pressurization controller failures indicated?

The AUTO FAIL light on the Cabin Pressurization panel will illuminate if:

• loss of DC power occurs, or

• outflow valve control fault, or

• cabin pressurization controller fault

If the cabin pressurization controller is not responding properly, the following will also illuminate the AUTO FAIL light:

• Excessive differential pressure (> 8.75 psi)

• Excessive rate of cabin pressure change (± 2000 fpm)

• High cabin altitude (> 15,800 ft)

What would cause the OFF SCHED DESCENT light to illuminate?

Should a descent begin prior to the aircraft reaching the set FLT ALT, e.g., an air turn-back during climb, the OFF SCHED DESCENT light will illuminate, along with the AIR COND System Annunciator and MASTER CAUTION lights.

The CABIN ALTITUDE light and altitude warning horn activate at approximately what altitude?

If the cabin altitude exceeds 10,000 ± 1000 ft, the CABIN ALTITIDE lights illuminate and the cabin altitude warning horn (intermittent) activates.

Can the cabin altitude warning horn can be silenced using the ALT HORN CUTOUT switch above 10,000 ft?

Pushing the ALT HORN CUTOUT switch will silence the intermittent horn, but the CABIN ALTITUDE lights will remain illuminated until the high cabin altitude condition no longer exists.