Polymers Final

1/53

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

54 Terms

polymer solution

polymer is solute (substance being dissolved), some low-molecular weight species are the solvent (doing dissolving)

good solvent

-X < 1/2, B > 0

-solvent molecules separate

B > 0

-good solvent

-monomers on different chains are happy enough to be surrounded by solvent

-when two coils approach to each other, there is steric repulsion (excluded volume) and the chains separate

poor solvent

-Χ > 1/2, B < 0

-polymer chains prefer self interaction

B < 0

-poor solvent

-polymer is barely able to stay dissolve in solution

-monomers find it energetically favorable to be close to other monomers

-when two coils approach each other, there is a tendency to cluster

-all solvent molecules excluded from polymer chain that is coiled, can’t penetrate polymer

theta solvent

-Χ = 1/2, B = 0

-"not-very-good" solvent

-excluded volume and relatively unfavorable solvent-solute interactions cancel one another in the net

-Following Flory-Huggins, it's a θ solvent

interaction parameter (chi - Χ)

-represent exchange energy per molecule normalized by thermal energy kT

-used in enthalpy (H) of mixing for RST

-small Χ or negative allows chains to mix

-lower X → smaller H → more likely to dissolve

solubility parameter (delta - δ)

materials with similar energy of vaporization would have similar intermolecular force, therefore might intend to be soluble with each other

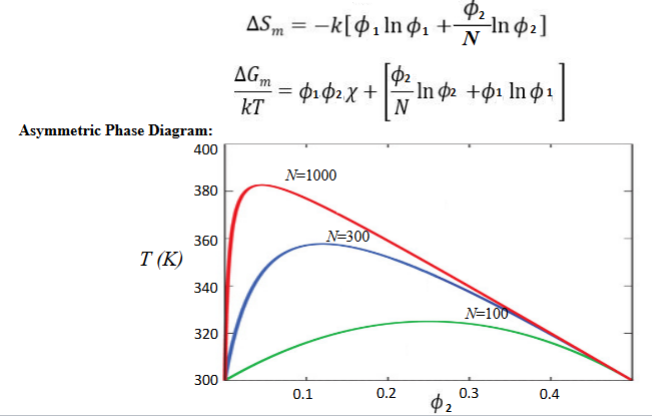

N

-contributes to entropy (S)

-if small, limited contribution

chi N > 10.5

-for block polymer

-indicates polymers will be phase separated

-chi from H (enthalpy) contribution, N from S (entropy) contribution

chi N > 2

-for polymer blends

-indicates polymers will be phase separated

gauche state

preferred configuration for more flexibility because ready to change conformation

molecular weight

-_ must be similar to favor mixing and ensure compatibility in solution

-high _ makes it dissolving of polymer harder

Regular Solution Theory

-description of mixtures of non-polar small molecule liquids with positive or zero mixing enthalpy

-relatively simple statistical model to express free energy of mixing for a binary solution of two

components

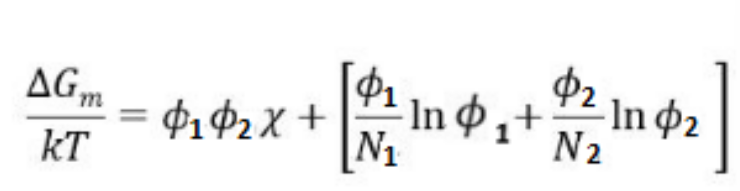

regular solution theory where one of the components is a polymer

Flory Huggins Theory

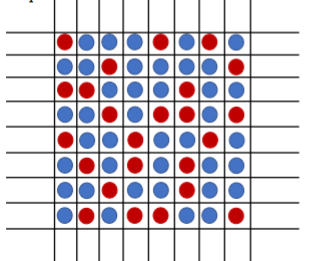

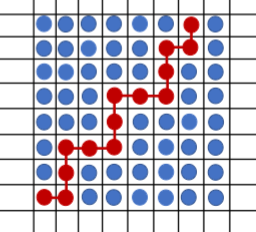

ENTROPY (S) of mixing, S > 0 favors mixing

adopt same lattice model as RST but:

-each lattice site has one solvent molecule

-each polymer occupies N lattice sites

-N is proportional to degree of polymerization

-monomer unit was same volume as solvent

uses volume fractions instead of molar fractions (phi, Φ)

polymer-polymer mixtures

-enthalpy contribution does NOT allow for polymer mixing in this case due to N → infinity

-when N → infinity, prevents mixing because S → 0

entropy (S)

-a measure of the disorder of a system

-higher _ favors mixing

enthalpy (H)

-total energy/heat of a system

-considers internal change

-high _ opposes spontaneous mixing

-opposes mixing when Χ > 0

-temperature at which an amorphous polymer transitions from a brittle state to a ductile state

-at this temperature, enough energy for polymer chains to slide past each other

-not a thermodynamic property of polymer, can adopt a range of values

factors that affect Tg

-flexibility of polymer backbone (more flexible = lower), means can accommodate to additional change like temperature

-steric effects of pendant groups, more mobility = lower

-configurational isomerism, inefficient packing causes drop

increase free volume

-poly dispersity

-low molecular weight

-plasticizers

-branches

-residual solvent

-inefficient packing

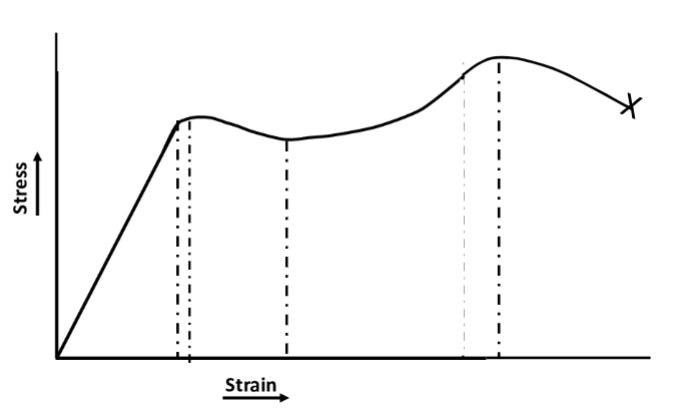

stress vs strain for a semicrystalline polymer

-shows both elastic and plastic deformation regions

-Initially, the material exhibits linear elastic behavior, followed by yielding and eventual necking before fracture.

-amorphous solid→ no long-range order or symmetry in the packing of molecules

-kinetically trapped

-over some range of temperature, molecular motion will become so slow, that an equilibrium packing of molecules can’t be attained during experiment → sample has undergone _

-each polymer has this

-polymer chains locked up in place under Tg, not enough thermal energy to allow chains to slide past, strain prior to fracture is small

-large stresses are dissipated by fracture of covalent bonds, only small strain can be recovered

-smaller stress can be dissipated by local rotation of bonds, sub-Tg relaxation mechanism that contributes to toughness of polymer sample

-glassy polymer still tougher, absorbs more energy prior to fracture than ceramic in general

-changes at Tg less drastic since crystalline regions unaffected

-between Tg and Tm, this polymer is composed of rigid crystallites dispersed in a rubbery amorphous matrix

-at Tm, crystallites melt leading to a viscous state

-heated from low T region, volume expands at constant rate

-at Tg, rate of expansion increases abruptly; change in physical behavior from hard brittle, glassy solid below to a soft rubbery region above

-further heating changes from rubbery to viscous liquid

-becomes stretchy before starts to deform permanently

-entropic elasticity is the dominant restorage force

-~0-10% strain

-stretching a little bit more but slowly, it yields

-breaking the crystalline domain apart and realign them along the strain axis

-suspend it and wait for a day, it will get to the point of ultimate strain

-creep, which is associated with viscoelasticity of polymer samples

-it doesn’t store any mechanical energy, they just dissipate all

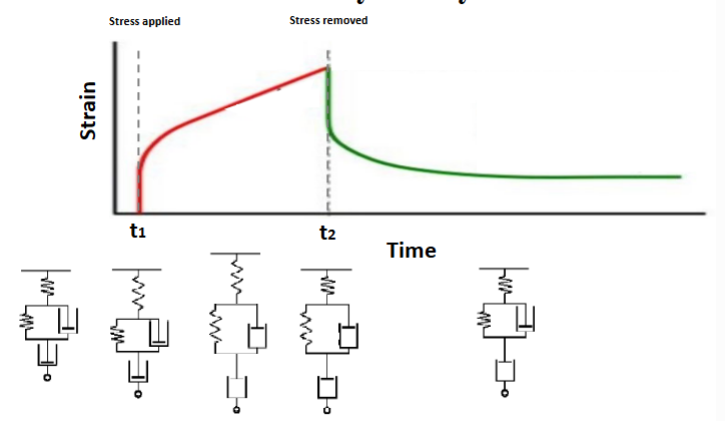

creep

time-dependent deformation at elevated temperature and constant stress

viscosity

-measure of a fluids resistance to flow

-high = thicker fluid, resists motion

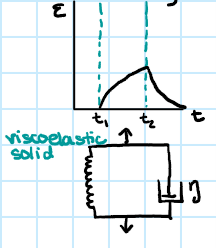

-property of materials that exhibit both viscous and elastic characteristics

-when deformed have time-dependent strain behavior that combines elastic recovery with energy dissipation

time-temperature superposition

-a measurement at a certain temperature and time (or frequency) is equivalent to a measurement at a lower temperature and longer time

-experimental time too short → lower temperature to make response long

glassy state

-below Tg

-locked polymer chains

rubber state

-occurs from Tg to Tm

-chain conformations are available

-directly observed shape deformation

sticky fluid

-occurs after Tm

-all polymer chains can slide past each other

-deformation cannot recover

T and S

always positive for dissolving process, system becomes more chaotic after mixing (favors spontaneous mixing)

metal reaction to heat

-heat stretches the metal lattice, causing expansion and changes in properties

-heat enables vibration of molecules → expands

rubber reaction to heat

-rubber is entropic controlled

-stretch out rubber band → heats up

-contract → cools down

unique properties of rubber materials

-entropy (S) driven; in a stretched state, entropic degree of freedom has been reduced

-large deformation

-totally recover after removing stress

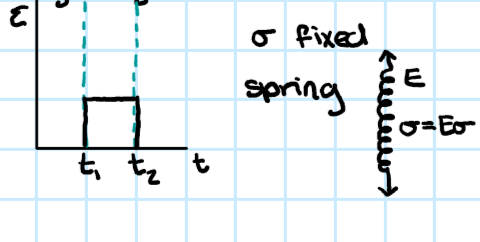

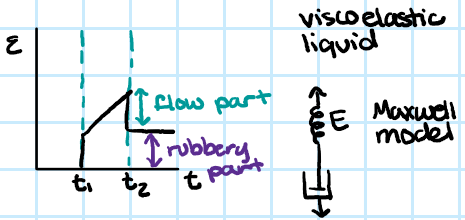

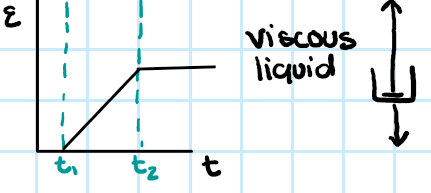

creep (for viscoelasticity)

-stress is suddenly applied to a polymer

-resulting strain is a function of time

stress relaxation

-stress is suddenly applied to a polymer

-resulting stress is monitored as a function of time showing dissipating energy

glassy polymer viscoelasticity

-behaves like a real solid

-E > 1 GPa

leathery polymer viscoelasticity

-requires time to return to original shape

-time dependence to its elasticity

rubber polymer viscoelasticity

-time dependence partially goes away

viscous polymer viscoelasticity

polymer molecular mechanism when stretched

-involves chain slippage and realignment under stress, allowing for energy dissipation and recovery

-chain realignment

metal molecular mechanism when stretched

-involves dislocation movement and slip systems, leading to deformation and strain hardening -accumulation of dislocations

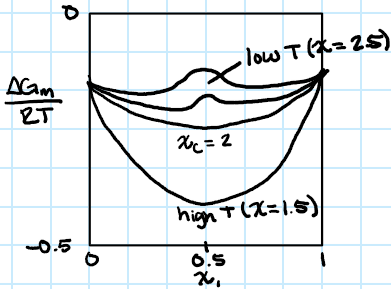

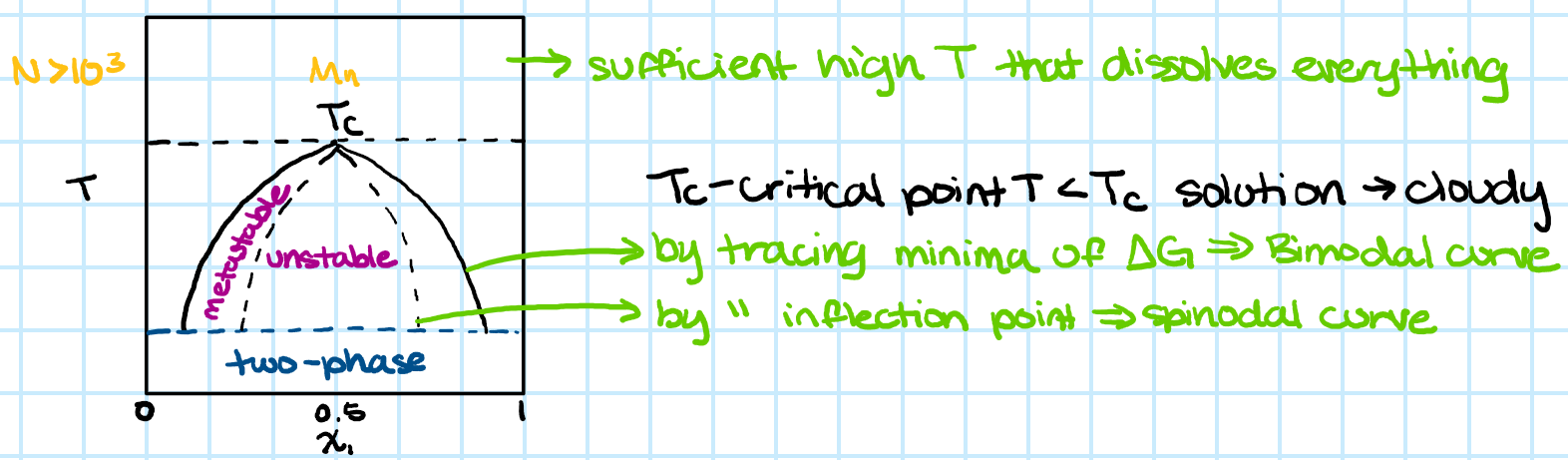

phase diagram (chi vs deltaG/RT)

-chi small → H ignore, G depends on S>0

-chi large → H term produces a local maximum in G which can lead to phase separation or instability in the system

phase diagram (chi vs T)

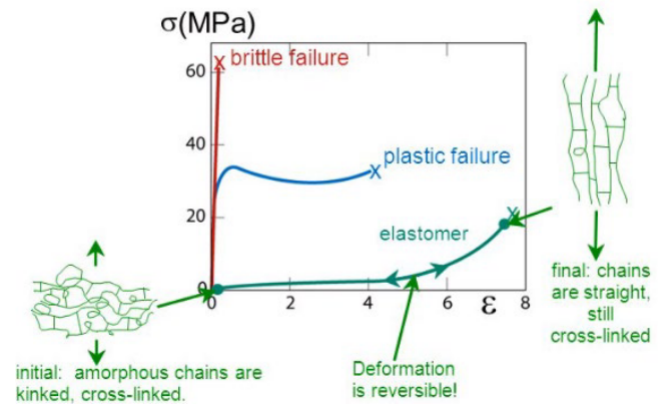

tensile response: elastomer

-no yielding, deformation largely recoverable

-stress increases monotonically up to point of failure

-non-crystalline polymer above Tg has rubber elasticity

-polymer network, gels have rubber elasticity

-rubber elasticity unique to polymeric materials

viscoelasticity of polymers