Lec 4 | Optical Management | Lithography | MS 3012

1/18

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

19 Terms

Under illumination, chain cross-linking is a process that occurs in

a) positive photoresist

b) negative photoresist

c) both

b) negative photoresist

True or False: photolithography processes involving g-line and i-line photoresists require very tight control over the post-exposure bake

False (for g-line and i-line photoresist, the Post-Exposure Bake only serves to harden the photoresist a bit for chemical resistance; however, in DUV photoresist, all of the rxns that determine the solubility of the photoresist occur during the PEB)

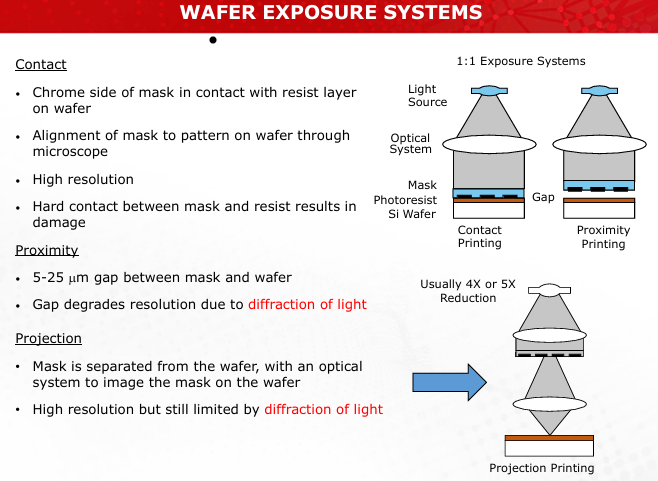

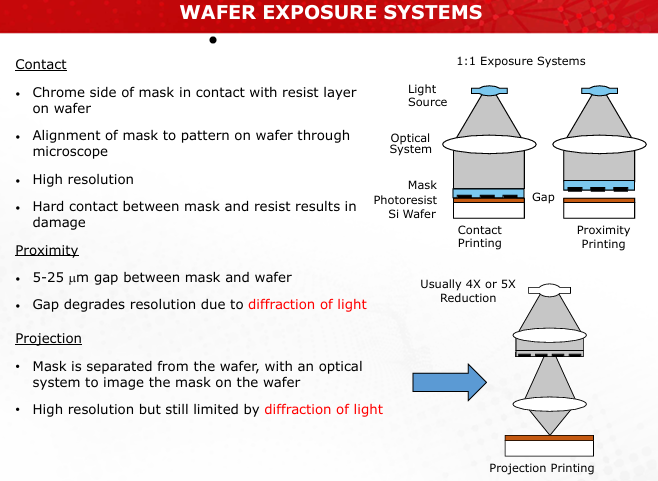

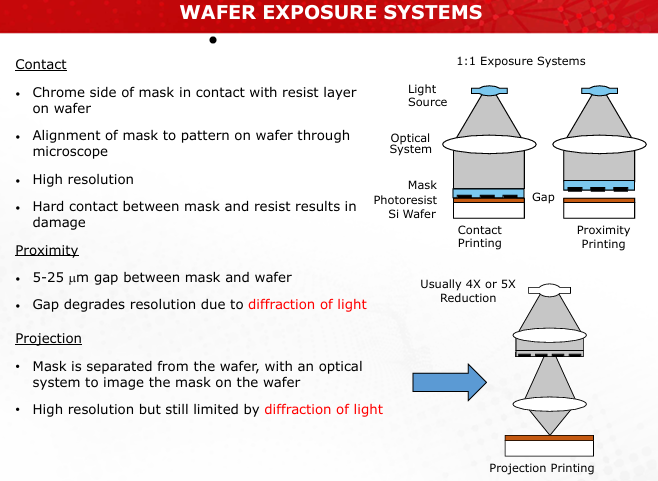

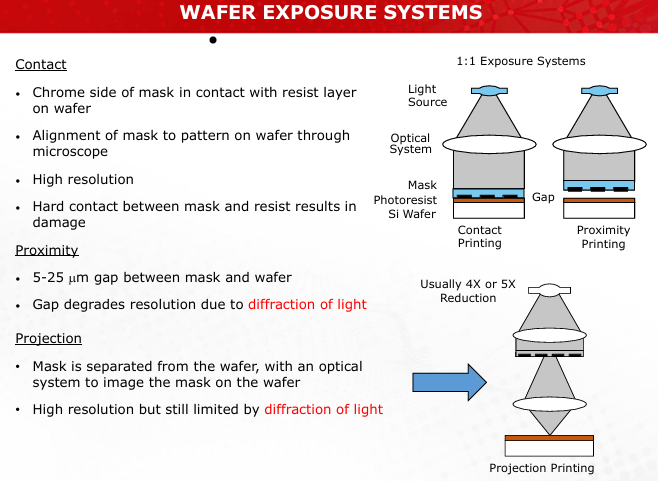

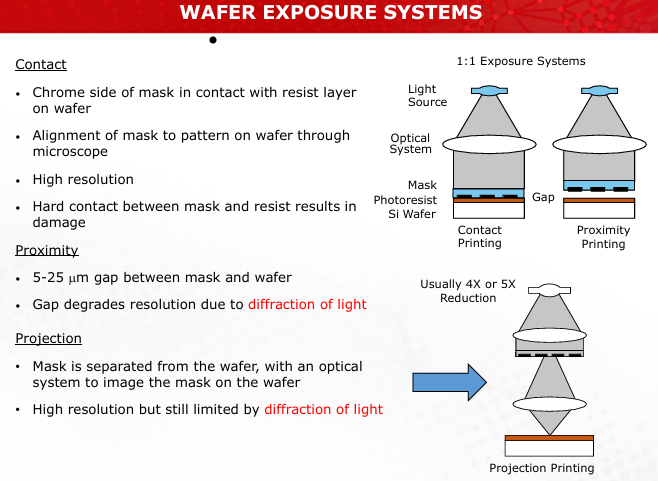

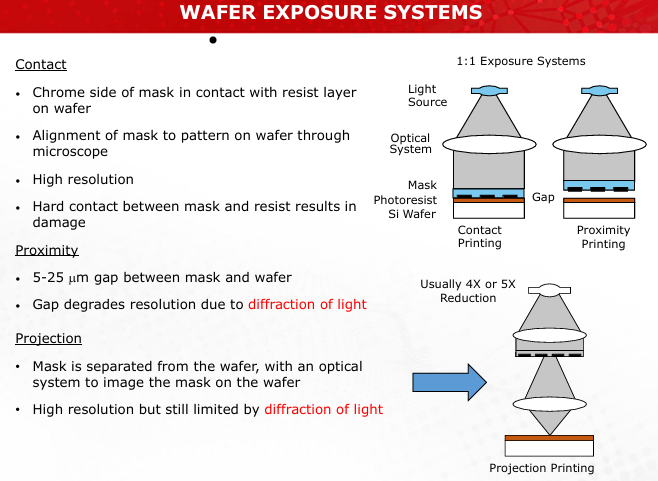

What are the critical differences between contact and proximity printing?

Contact printing offers higher resolution but causes physical wear and damage to masks and resist due to hard contact.

Proximity printing reduces the risk of damage by introducing a gap, but the resolution is degraded due to light diffraction.

(Slides 14, 20)

Compare the advantages and disadvantages of contact, proximity, and projection exposure systems. Which system is most common and why?

Contact: High resolution but mask/resist damage.

Proximity: Safer for the mask but lower resolution.

Projection: Best balance of resolution and mask safety; limited by diffraction but commonly used due to its flexibility with lenses.

Most common system: Projection exposure due to its high resolution and ability to handle modern lithography demands.

(Slides 14, 20)

Draw and label the setup for each type of wafer exposure system (contact, proximity, projection)

Refer to Slide 14 for diagrams. Each setup involves a light source, mask, and wafer with varying distances or optical systems.

(Slides 14, 20)

Define and describe contact exposure in lithography.

Contact exposure involves the mask being in physical contact with the resist layer on the wafer.

It provides high resolution because there is no gap between the mask and resist, minimizing diffraction.

Disadvantage: Physical contact can cause wear and damage to both the mask and resist.

(Slides 14, 20)

Define and describe proximity exposure in lithography.

Proximity exposure involves a small gap (5–25 μm) between the mask and resist.

This setup reduces the risk of mask damage compared to contact printing.

Disadvantage: The gap degrades resolution due to diffraction, limiting the precision of patterns.

(Slides 14, 20)

Define and describe projection exposure in lithography.

Projection exposure separates the mask and wafer with an optical system that projects the mask pattern onto the resist.

It provides high resolution while avoiding physical damage to the mask.

Disadvantage: Although effective, it is still limited by diffraction effects and requires complex optical systems.

(Slides 14, 20)

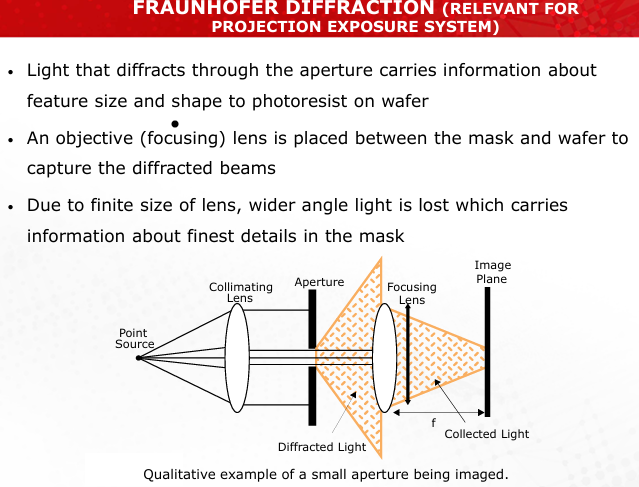

Explain diffraction and its effects on lithography. Why is it considered a major challenge?

Diffraction occurs when light bends and spreads out while passing through apertures.

It limits the resolution of lithographic processes as finer features cause greater spreading, degrading the accuracy of the pattern.

(Slides 16, 22)

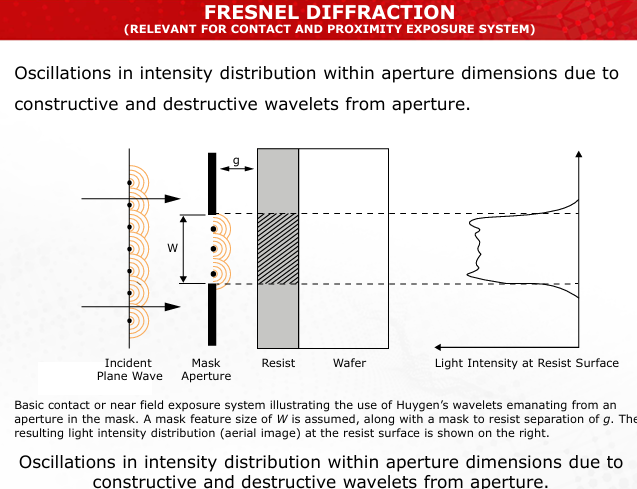

Illustrate the Fresnel and Fraunhofer diffraction principles. How do they differ in their applications to lithography?

Fresnel diffraction applies to near-field systems (contact and proximity) where light intensity varies within the aperture size due to interference.

Fraunhofer diffraction applies to projection systems and involves capturing diffracted beams with lenses to improve image precision.

(Slides 19, 22)

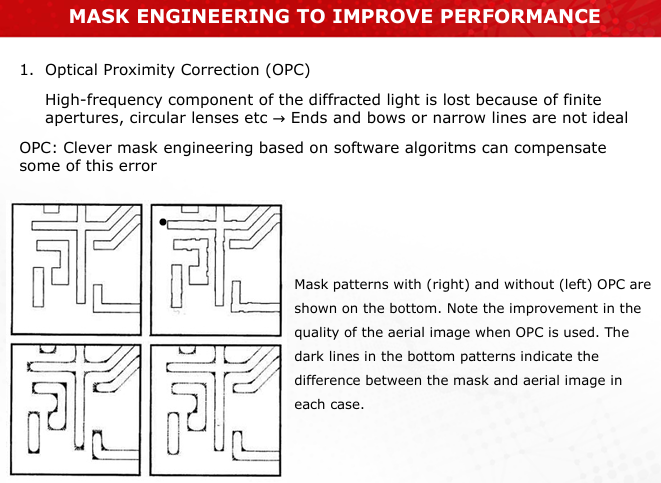

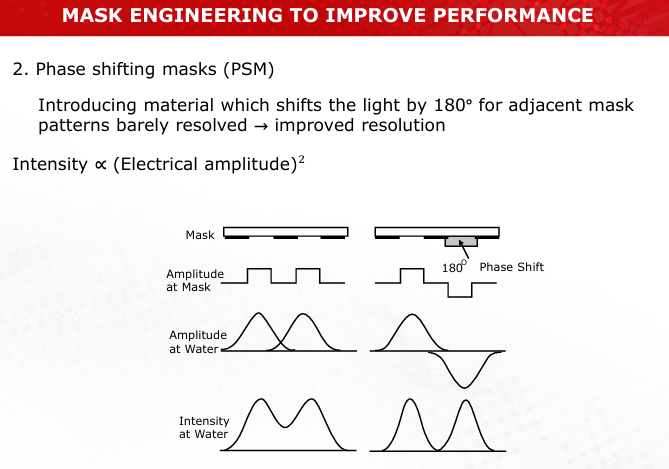

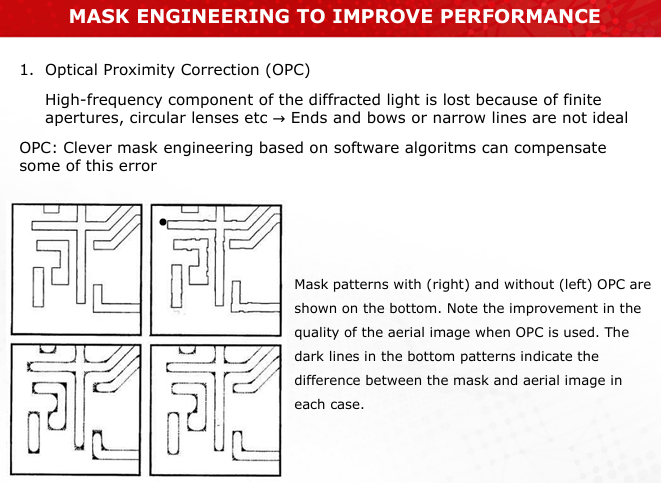

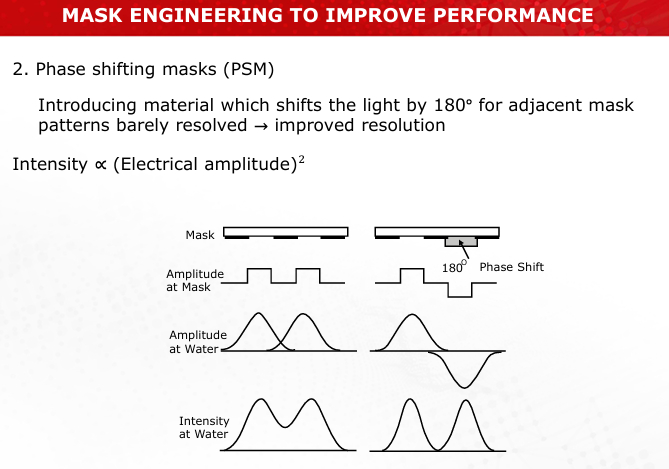

Discuss how OPC and phase shift masks mitigate diffraction challenges.

Optical Proximity Correction (OPC): Alters mask patterns to compensate for diffraction errors. It ensures the aerial image matches the intended design more closely.

Phase Shift Masks (PSM): Introduces a 180° phase shift between adjacent regions to enhance edge definition and resolution.

(Slides 34, 35)

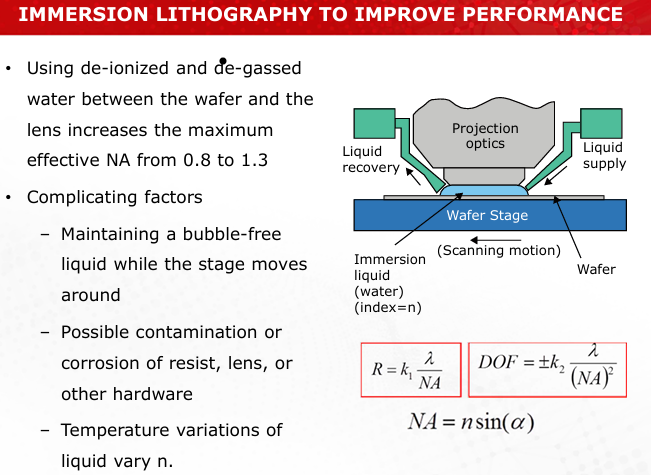

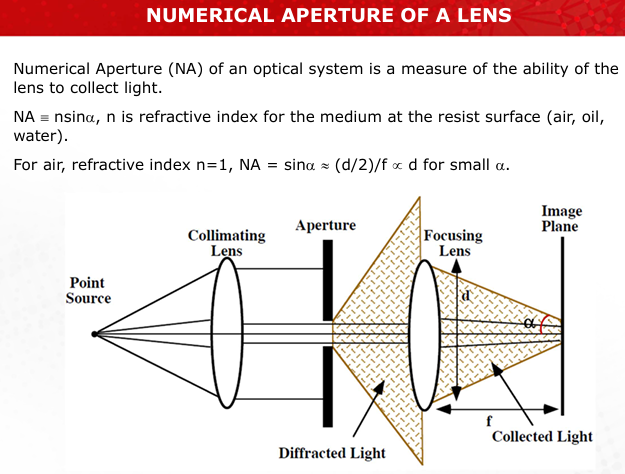

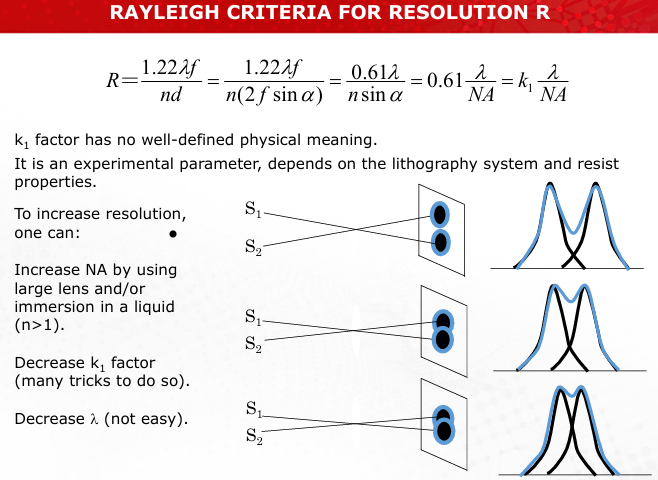

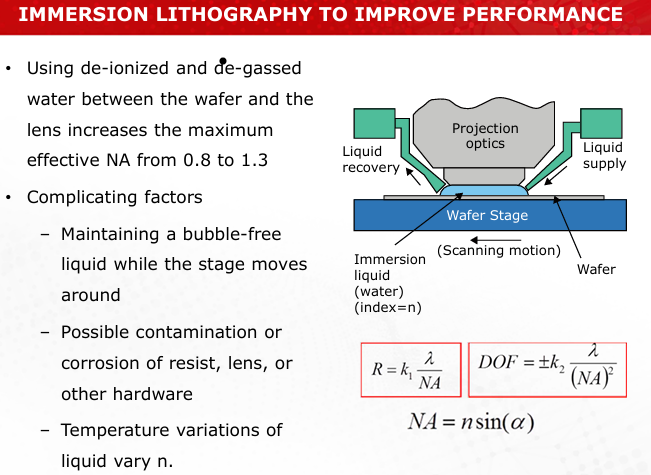

What is the numerical aperture (NA)? How does it affect lithography performance?

NA measures a lens's ability to collect light and is defined as NA=nsinα, where n is the medium's refractive index and α is the maximum acceptance angle.

Higher NA improves resolution but reduces depth of focus.

(Slides 24, 27)

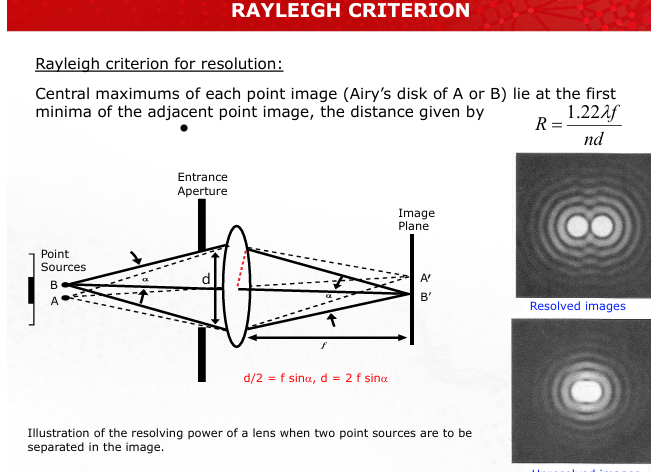

Define the Rayleigh Criterion and its significance in resolution.

The Rayleigh Criterion specifies the smallest resolvable feature size: R=0.61λ/NR

It depends on light wavelength λ, numerical aperture (NA), and the process factor k_1. Smaller R implies better resolution.

(Slides 26-28)

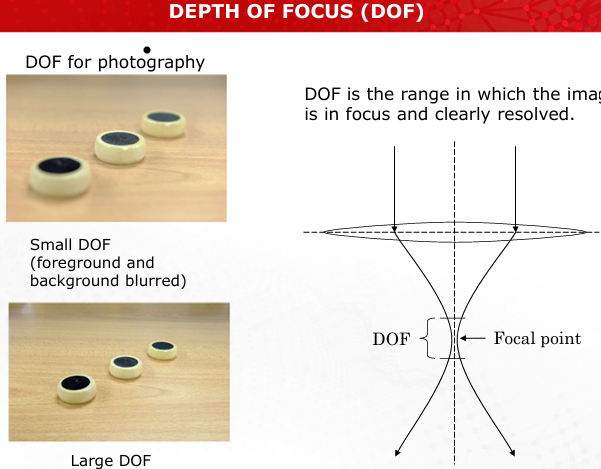

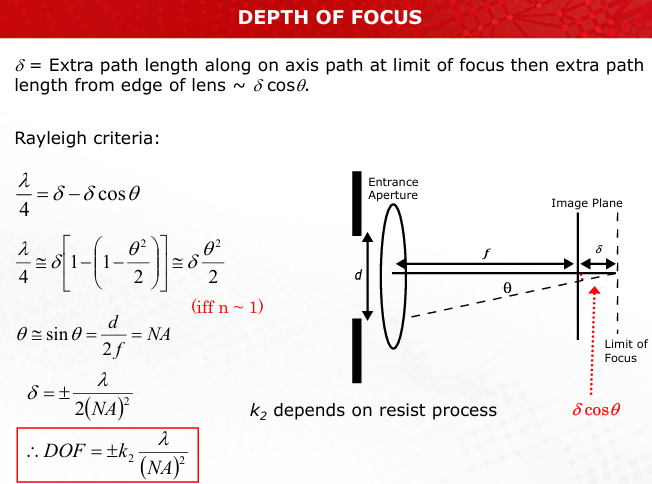

Explain depth of focus (DOF) and how it impacts lithographic processes.

DOF is the range over which the image remains sharply focused.

A high DOF compensates for wafer surface non-uniformities but inversely correlates with resolution.

DOF=±(k2)(λ)/NA2

(Slides 29-31)

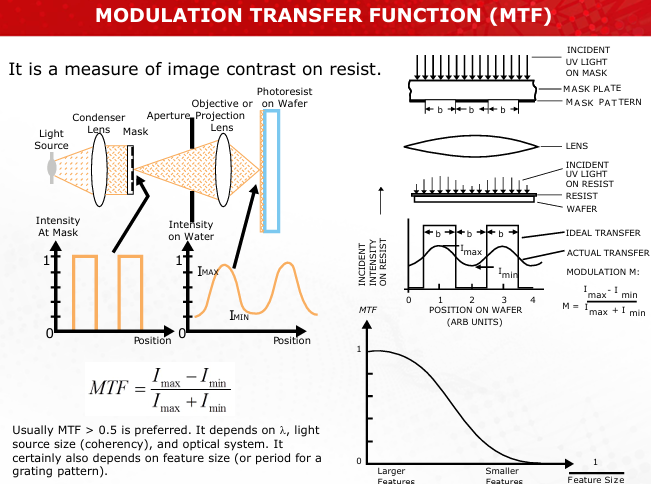

What is the modulation transfer function (MTF)? Why is it critical in lithography?

MTF measures image contrast, defined as M=(Imax-Imin)/(Imax+Imin)

An MTF above 0.5 is essential for maintaining clear feature differentiation on the resist.

(Slide 33)

Explain how Optical Proximity Correction (OPC) works

OPC adjusts mask designs to pre-compensate for diffraction effects, ensuring the projected image matches the desired pattern more closely.

(Slide 34)

How do Phase Shift Masks (PSM) improve resolution?

PSM introduces 180° phase shifts in adjacent mask regions. This constructive/destructive interference sharpens pattern edges and improves feature resolution.

(Slide 35)

What are the advantages and challenges of immersion lithography?

Advantages: Increases effective NA by using a liquid medium (e.g., water), enabling higher resolution.

Challenges: Managing liquid stability, preventing contamination, and handling thermal variations.

(Slide 36)

Illustrate the immersion lithography setup and explain its working principle.

Immersion lithography introduces a high-refractive-index liquid between the lens and wafer, increasing NA and improving resolution.

(Slide 36)