09 stress-stain, hookes law

1/45

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

46 Terms

density for steel

7.84 g/cm³

density for aluminum

2.7 g/cm³

density for polycarbonate

1.20-1.40 g/cm³

aluminum modulus in psi

10 × 10^6

steel modulus is psi

30 × 10^6

polycarbonate

500 × 10³

what is hookean?

the elastic part of the graph, usually linear

what is proportional limit (PL)

the maximum stress it can handle before it deviates from linear

what 3 things can happen after a proportional limit?

line is STILL elastic, but in a way it is deformed but NOT PERMANENTLY

linear

flat

non linear

ex: after stretching rubber band a few times, it goes back the way it was but wonky

what is recoverable strain?

elastic (material is not PERMANENTLY deformed, can still go back to before)

what is nonrecoverable strain?

plastic (deformed, no way to go back to original state)

what is yield stregth?

the point where plastic (permanent) deformation begins

after this point material DOES NOT return to original state

CANT be reversed

Stress us NECESSARY

What is UTS (ultimate tensile strength)

The highest stress a material can withstand

necking happens afterwards

What is ROA (reduction of Area)

Measures the material’s ductility, or ability to withstand plastic deformation before breaking

%ROA = (A0-Af)/A0 × 100

delta(area)/original area x 100

strain to failure

strain at which specimen is breaking

total strain at failure

elastic + plastic

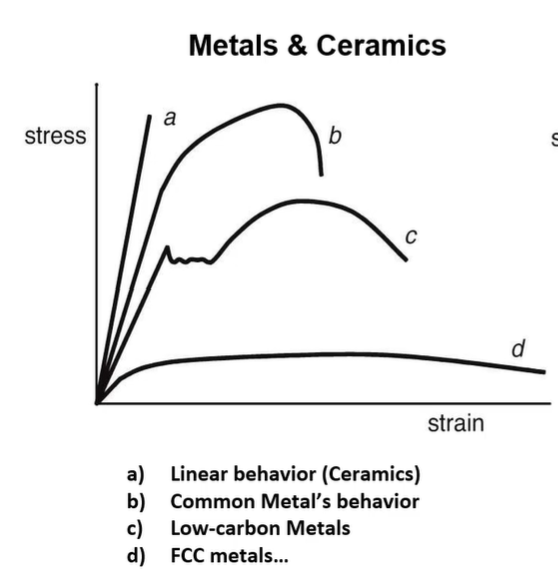

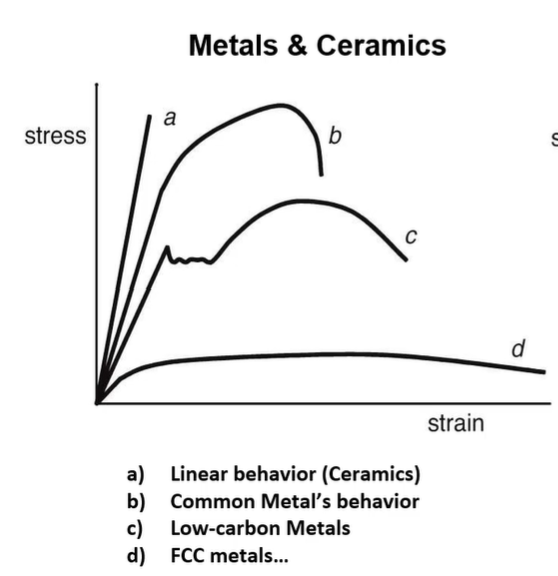

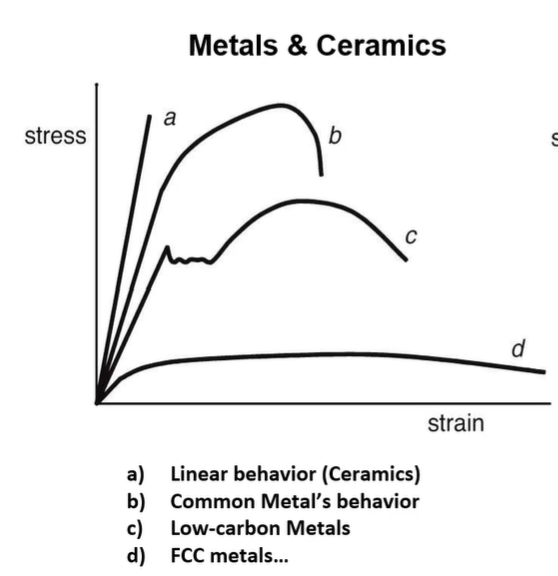

stress strain curve in ceramics

linear behavior

high stress = low strain

stress strain curve in common metal’s

curve

elastic, plastic, and breaking

stress strain curve in low carbon metals

ups and down after yield point

curve → break

stress strain curve in FCC metals

low stress = high strain

What are the effects of temperature and strain rate in stress vs strain graphs?

As temperature increases = material gets softer (stretchy) = less stress to deform

higher temperature = more ductile, less brittle

What happens when strain rate is high?

atoms don’t have enough time to rearrange themselves, so it makes material stronger = stiffer

harder to deform

requires more stress

elastic deformation is due to ____?

applied stress

bond stretching

volume is NOT constant

because when stretched or compressed = atoms/shape is changing

usually v=0.3

plastic deformation is due to ____?

slipping of dislocations

volume WILL be constant

the only thing happening is the rearranging of atoms

v = 0.5

young modulus?

stress/strain

stretching/compression

what is strain?

HOW MUCH IT CHANGED

amount of deformation material experiences compared to its original size

change in length / original length

what is stress?

HOW MUCH FORCE IT TAKES before breaking

FORCE

what is yield behavior?

the point where a material starts to deform permanently

what causes yield behavior?

shear stress

yield behavior is the point where a material starts to deform, which shear stress is exactly that

shear stress = slipping of atoms that cause permanent deformation

Hooke’s law?

S = E x e

Stress = Young modulus (stress/strain) x strain

ONLY FOCUSED ON LINEAR PART OF GRAPH

When tension is happening what happens to Area?

gets smaller

When compression is happening what happens to Area?

area gets bigger

what happens when area gets smaller?

Force gets affected = gets smaller

Stress = rises

F = S (stress) x a (area)

Changing Area during test

S = F/Ao

Ao is inaccurate because it doesnt take into mind area changing after deformation

True Strain ?

ln (delta L / Lo) = Ln(1+e)

takes into mind that length is NOT constant (constantly changing)

True stress?

S (1 +e)

engineering stress = f/a

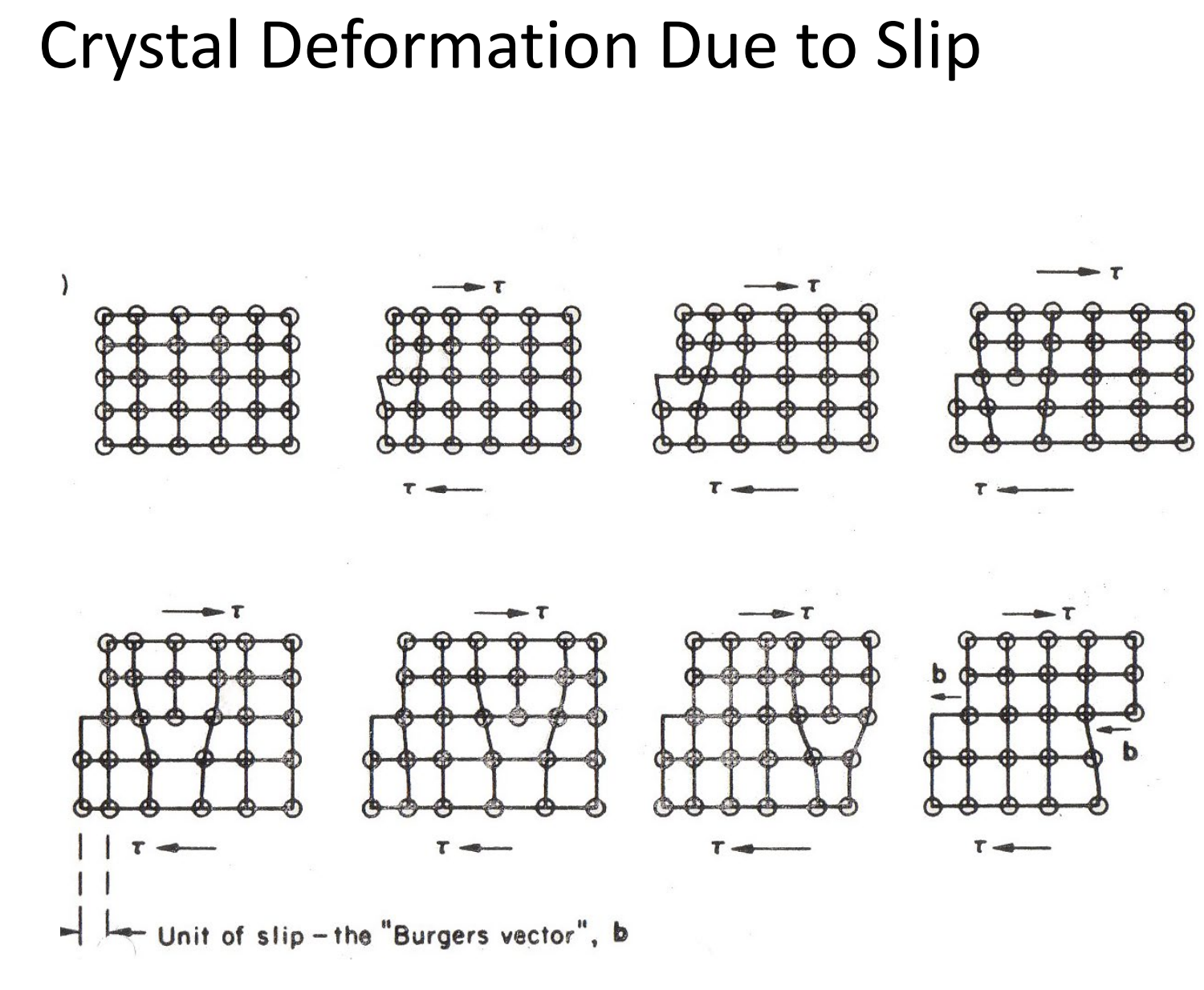

What is the main factor for slip step?

dislocations

what is the actual mechanism of plastic deformation?

dislocation movement through crystals

movement of dislocations cause slippage

Breaking INDIVIDUAL bonds NOT all at once

Where does slip happen on?

Slip systems

What are the requirements for slip to happen?

CLOSED PACKED PLANES

closed packed directions

what is dislocation?

extra half planes on crystal

if it moves = shear stress (slip)

Relation between FCC and Slip:

has MANY crystal planes (slip systems)

Very ductile = easy for ductility

Relation between BCC and Slip:

has an average amount of slip systems

not as ductile = harder for slip to happen

Relation between HCP and Slip:

very few slip systems

LESS ductility = hard to deform plastically

what happens to area in compression?

it expands (increases)

what happens to area in tension?

it decreases

what does true stress show?

shows real material behavior

Force ÷ changing (instantaneous) area