LESSON 3: Five Performance Objectives to Operations Management

1/29

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

30 Terms

quality, speed, dependability, flexibility, and cost

To allocate resources effectively, operations performance must be recorded, monitored, and reviewed using appropriate measures. The five key performance objectives—q____, s____, d____, f____, and c____—help assess competitiveness. These objectives are central to operations management, which focuses on efficiently using resources and effectively meeting customer needs by transforming inputs into goods and services.

reliability, performance and aesthetics.

From a customer perspective quality characteristics include r____, p____ and a____.

closely

quality of conformance

From an operations viewpoint quality is related to how _____ the product or service meets the specification required by the design, termed the ‘q____ of c_____’.

Cost

Quality

Speed

Dependability

Flexibility

The big 5 of operations performance objectives add value for customers and contribute to competitiveness by being able to satisfy the requirements of its customers, as follows:

1. ____ – being productive

2. ____ – being right

3. ____ – being fast

4. ____ – being on time

5. ____ – being able to change

Cost (being productive)

volume, variety, variation, and visibility

It is important to organizational competitiveness as it enables efficient production while ensuring returns. Reducing resource costs and eliminating waste boost productivity. The 4 V’s—vo___, va___, va___, and vi___—affect production costs. When managed well, quality, speed, dependability, and flexibility not only deliver external benefits but also help lower operational costs.

Quality (being right)

It refers to assessing a product’s performance, reliability, and durability. Consumers often evaluate specification quality by comparing it to competitors, while producers focus on conformance quality—ensuring products meet set standards.

Speed (being fast)

It refers to the time taken to complete an operations process—from start to finish. Externally, it is the time between a customer’s request and delivery, while internally it is the time from input of materials to finished output. Faster operations improve dependability and reduce costs by minimizing the need to manage resources over extended periods

Dependability (being on time)

- It means delivering goods or services on time as promised. Internally, it reflects how reliably processes provide resources to one another. Strong dependability saves time, reduces costs, and ensures operational stability.

Flexibility (being able to change)

– It refers to an operation’s ability to adjust product/service variety, mix, volume, and delivery. It enables faster responses, saves time, and supports dependability. ____ also includes innovating and introducing new products. Mass customization exemplifies this by producing a wide variety at scale while controlling costs.

operations with customer priorities

Business strategy success relies on aligning _____________ with _____________. Since firms cannot excel in all five performance objectives simultaneously, managers must prioritize, often making trade-offs.

Skinner (1969) stressed focusing on one clear goal, while

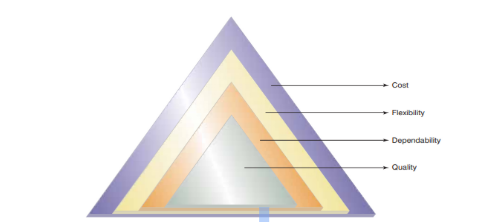

Ferdows and de Meyer’s (1990) sandcone model argues that capabilities are cumulative: build quality first, then dependability, flexibility, and finally cost efficiency. Sustainable competitiveness comes from improving all capabilities together rather than sacrificing one for another.

Hayes and Wheelwright’s (1984) four-stage model further emphasizes that strategically developed operations can serve as a powerful source of competitive advantage.

Skinner (1969)

stressed focusing on one clear goal

Ferdows and de Meyer’s (1990)

sandcone model argues that capabilities are cumulative: build quality first, then dependability, flexibility, and finally cost efficiency. Sustainable competitiveness comes from improving all capabilities together rather than sacrificing one for another.

Hayes and Wheelwright’s (1984)

four-stage model further emphasizes that strategically developed operations can serve as a powerful source of competitive advantage.

Design of Goods & Services

Deciding what goods and/or services the organization will offer. Includes characteristics, features, durability, styling, quality, technological content, sustainability, etc.

Managing Quality

Establishing quality standards (customer expectations), designing processes and controls to meet them, continual improvement. Use of TQM, Six Sigma, statistical process control.

Process & Capacity Strategy

Deciding how to produce (processes, technology, workflow) and how much capacity to have (scale, buffer capacity, flexibility). Includes commitment of technology, human resources, and capital.

Location Strategy

Choosing where to situate facilities (plants, warehouses, service outlets) with regard to proximity to markets/customers, suppliers, infrastructure, labor, regulations, cost, logistics.

Layout Strategy

How to arrange physical facilities: workflow of materials, people, and information; spatial arrangement of equipment, storage, workstations; layout types (product, process, cellular, fixed-position)

Human Resources, Job Design & Work Measurement

Recruiting, training, motivating, retaining people with required skills. Designing jobs so task allocation, roles, responsibilities, incentives are appropriate. Measuring work (time studies, work methods) to set standards.

Supply-Chain Management

Deciding what materials/services to buy, from whom, under what terms; managing relationships with suppliers; logistics; integrating supply chain with operations strategy.

Inventory Management

Decisions about levels of raw materials, work in process, finished goods; ordering policies; hold vs order cost; methods such as EOQ, JIT, safety stock; trade-offs between holding costs vs service levels.

Scheduling

Planning what tasks/jobs run when, sequencing, batching, allocating personnel & equipment, short-term schedules, balancing workloads, handling variability.

Maintenance

Ensuring equipment/facilities are reliable; deciding preventive vs reactive maintenance; planning maintenance schedules; balancing downtime vs cost; ensuring maintenance staff/skills are in place.

vertical relationship

horizontally

Operations strategy has a ______ relationship in the corporate hierarchy with business and corporate strategies, and _____ with the other functional strategies, most notably with marketing strategy. Operations strategy might come about in a top-down or a bottom-up process with regard to business and corporate strategies.

operations strategy

market-led

operations-led

Similarly, an ___________ might be developed in response to market requirements (i.e. _____-led) or be based on the capabilities of its operations resources (i.e. ___-led). This gives rise to four perspectives on operation strategy (Slack and Lewis, 2002). Each perspective places a different emphasis on the nature of the operations strategy process.

Top-Down Perspective

Bottom-up Perspective

Market-Led Perspective

Operations-Led Perspective

The Four Perspectives on Operations Strategy

Top-Down Perspective

sees operations strategy as stemming from the overall business strategy. Operations define their role through performance objectives (e.g., cost for low-price strategy, speed for fast-delivery). In multi-business firms, operations strategy links corporate goals with unit strategies. A unified approach prevents isolated competences and supports synergy, as stressed by Hayes et al. (2005) and Prahalad & Hamel (1990), who warn that unit-level dominance can limit development and cross-unit advantages.

Bottom-up Perspective

sees operations strategy as emerging from everyday decisions and gradual improvements rather than major planned changes. Organizations learn from experience, using the workplace as a “learning laboratory” (Leonard-Barton, 1992). Many practices like JIT, TQM, and SPC developed this way, especially in post-war Japan. A challenge is recognizing the strategy itself, so Mills et al. (1998) suggested mapping past operational events to reveal patterns that define the realized strategy.

Market-Led Perspective

shapes operations strategy in response to market demands. Hill (1985) links operations with marketing by distinguishing between qualifying criteria (basic requirements for consideration) and order-winning criteria (factors that influence customer choice). For instance, airlines must meet schedules (qualifiers) but compete on price or service (order-winners). Platts and Gregory (1990) add that organizations should use gap analysis to identify mismatches between market needs and operational performance, ensuring strategy aligns with customer expectations and competitive factors.

Operations-Led Perspective

sees operational excellence as the driver of organizational strategy, aligning with Hayes & Wheelwright’s Stage 4 model and the resource-based view (RBV) (Barney, 1991; Wernerfelt, 1984). Success depends on leveraging and developing resources and capabilities rather than just market positioning. This approach informs decisions about market entry, exploiting strengths, and defending against competition. Mills et al. (2002) outline six resource types—tangible assets, knowledge/skills, systems, cultural values, networks, and change-related resources—evaluated for value, sustainability, and versatility, with high-scoring resources serving as key sources of competitive advantage.