Chapter 4: Further Applications of Newton's Laws: Friction, Drag, and Elasticity - Review Terms

1/73

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

74 Terms

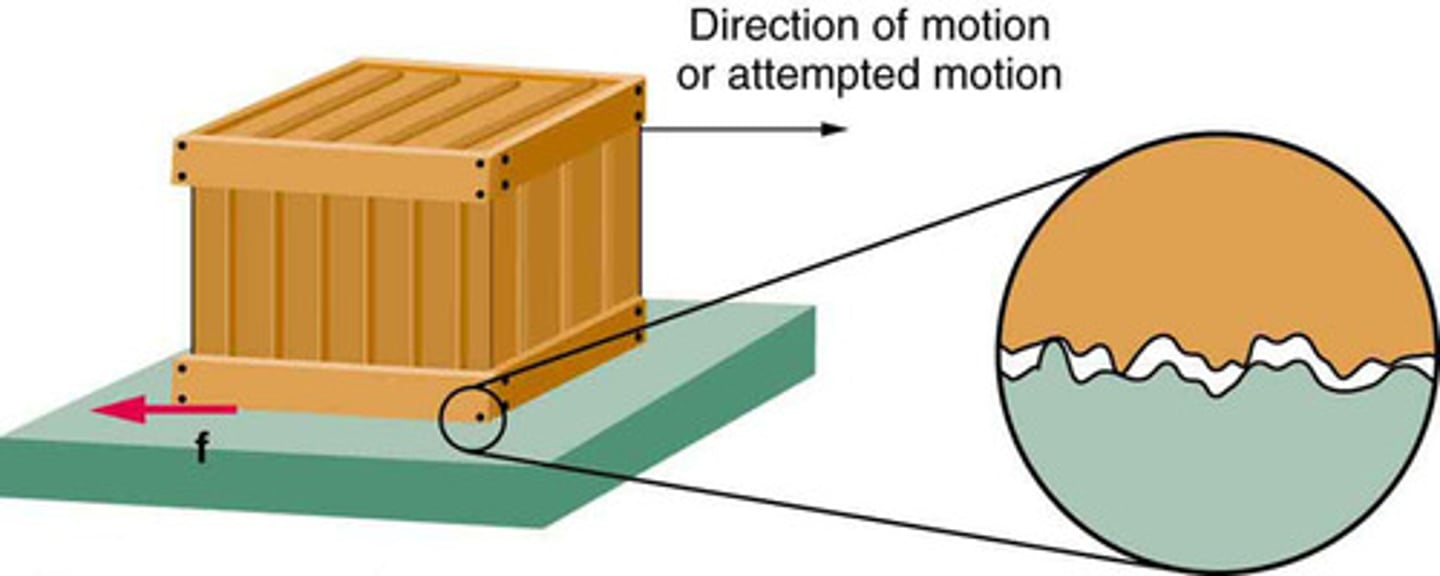

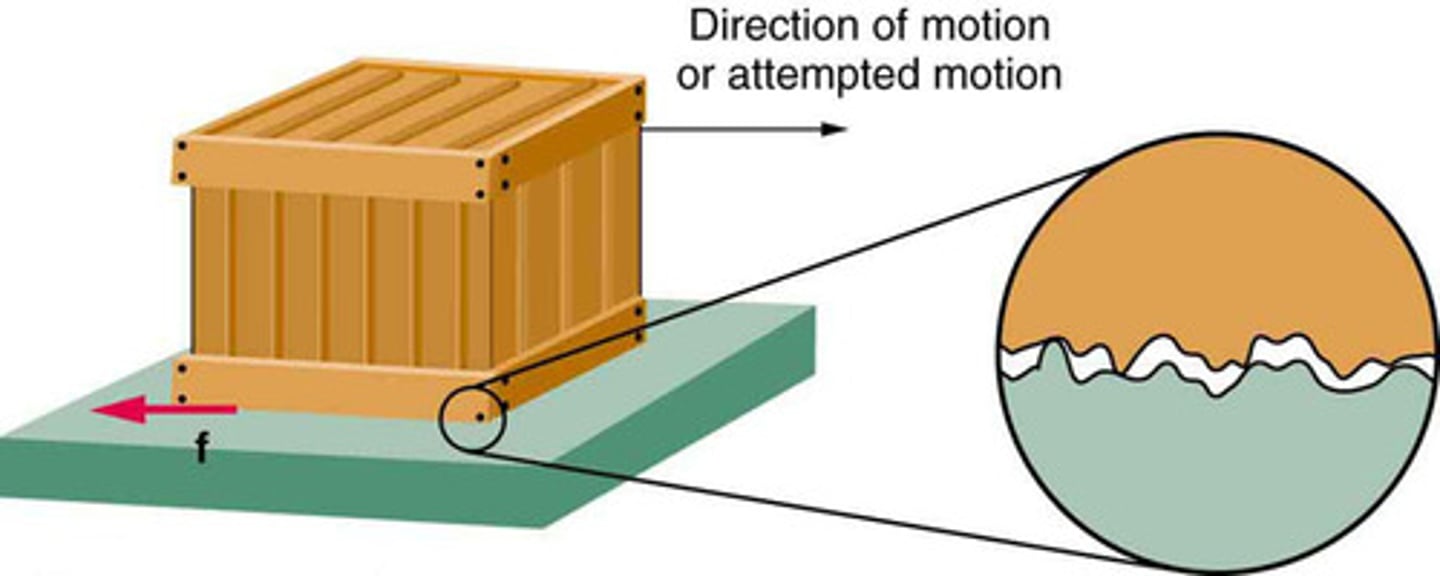

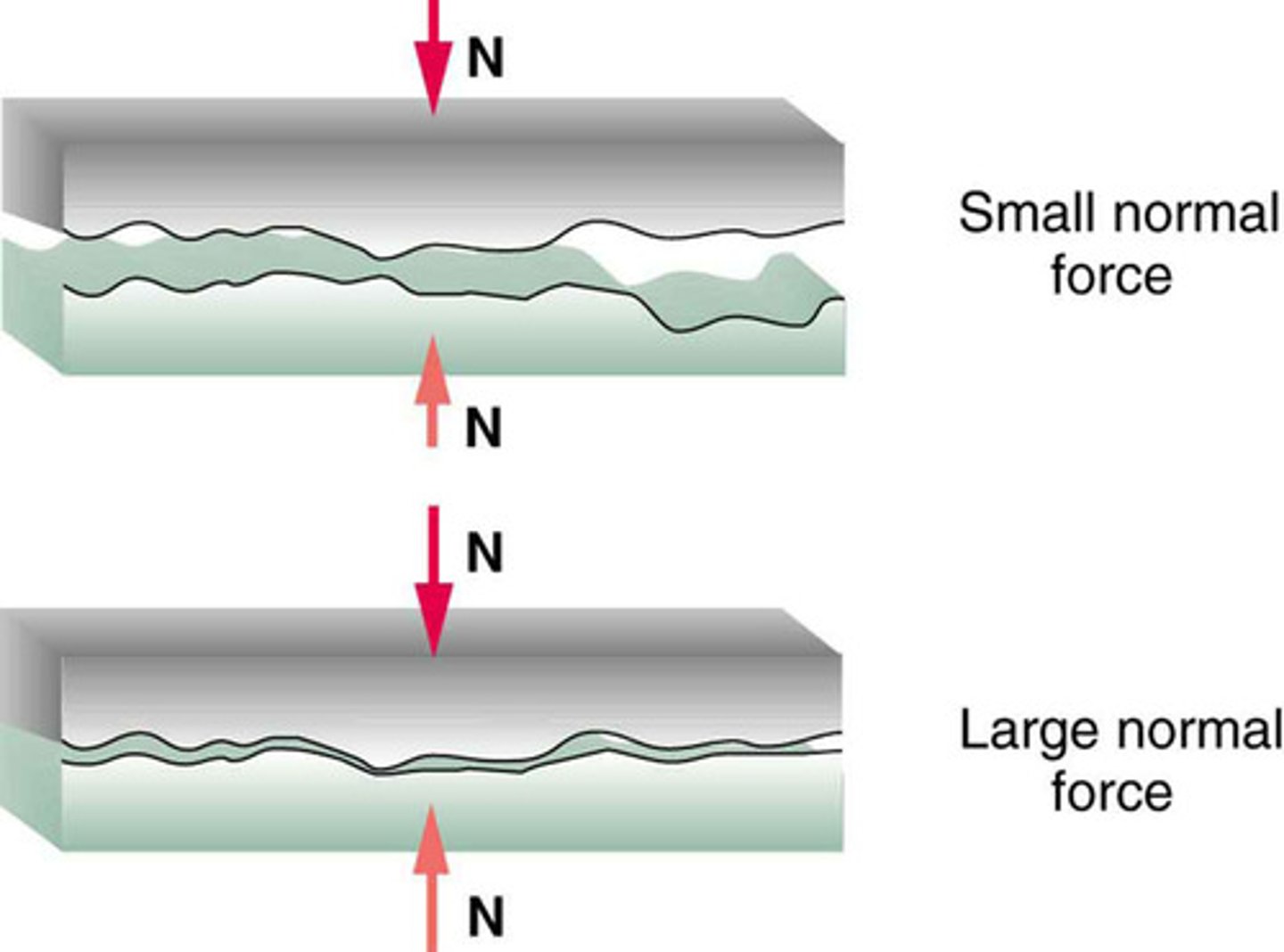

Friction

A force that opposes relative motion between surfaces in contact.

Kinetic Friction

The friction between two surfaces that are in contact and moving relative to one another.

Static Friction

The friction that acts between surfaces that are not moving relative to each other, usually greater than kinetic friction.

Coefficient of Static Friction (μs)

A dimensionless constant denoting the ratio of the maximum static frictional force to the normal force.

Coefficient of Kinetic Friction (μk)

A dimensionless constant denoting the ratio of the kinetic frictional force to the normal force.

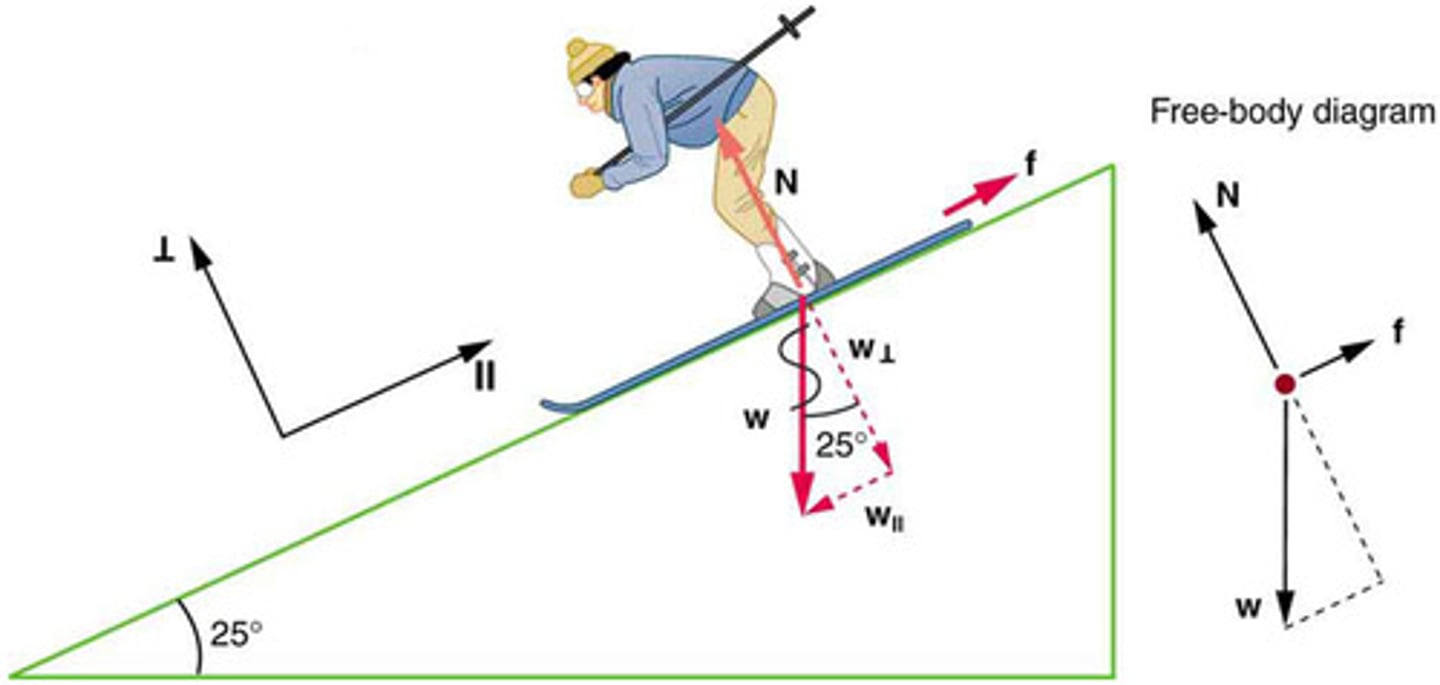

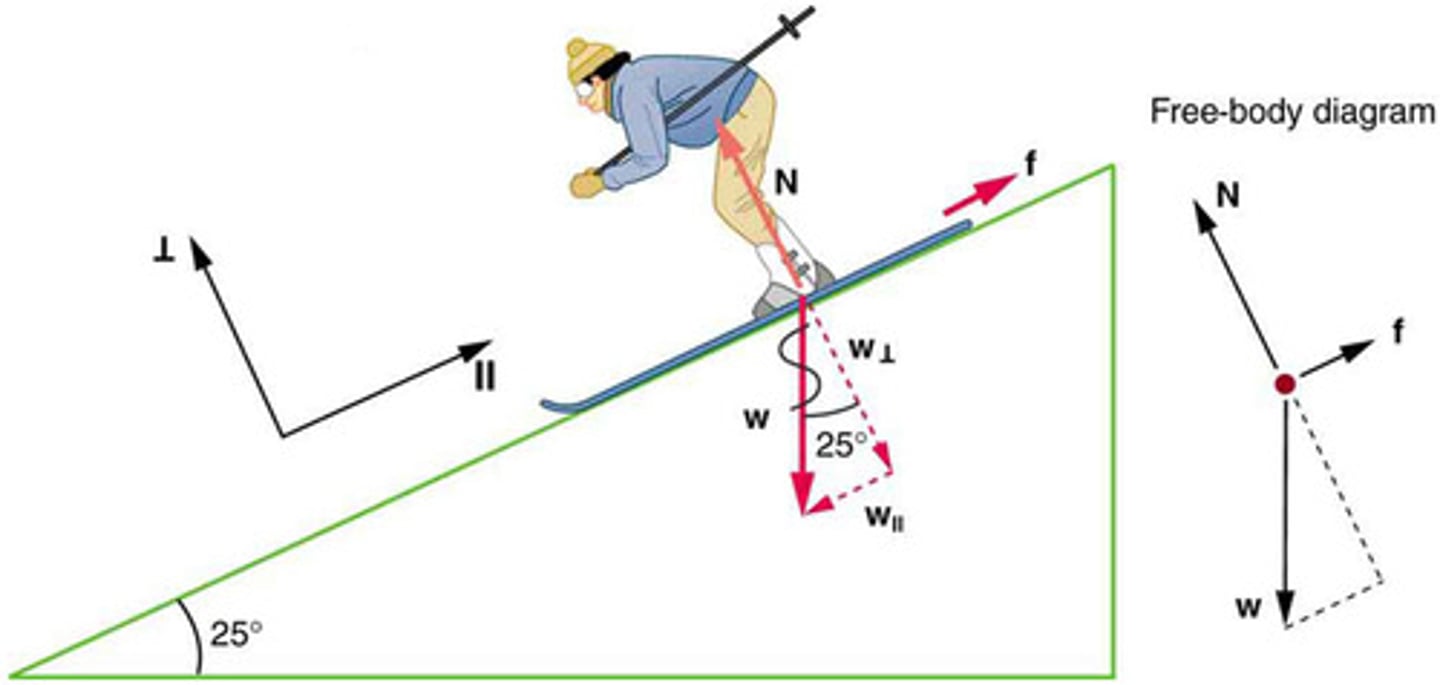

Normal Force (N)

The force perpendicular to the contact surface between objects.

Magnitude of Static Friction (fs)

fs ≤ μsN, where fs is the static frictional force, μs is the coefficient of static friction, and N is the normal force.

Magnitude of Kinetic Friction (fk)

fk = μkN, where fk is the kinetic frictional force, μk is the coefficient of kinetic friction, and N is the normal force.

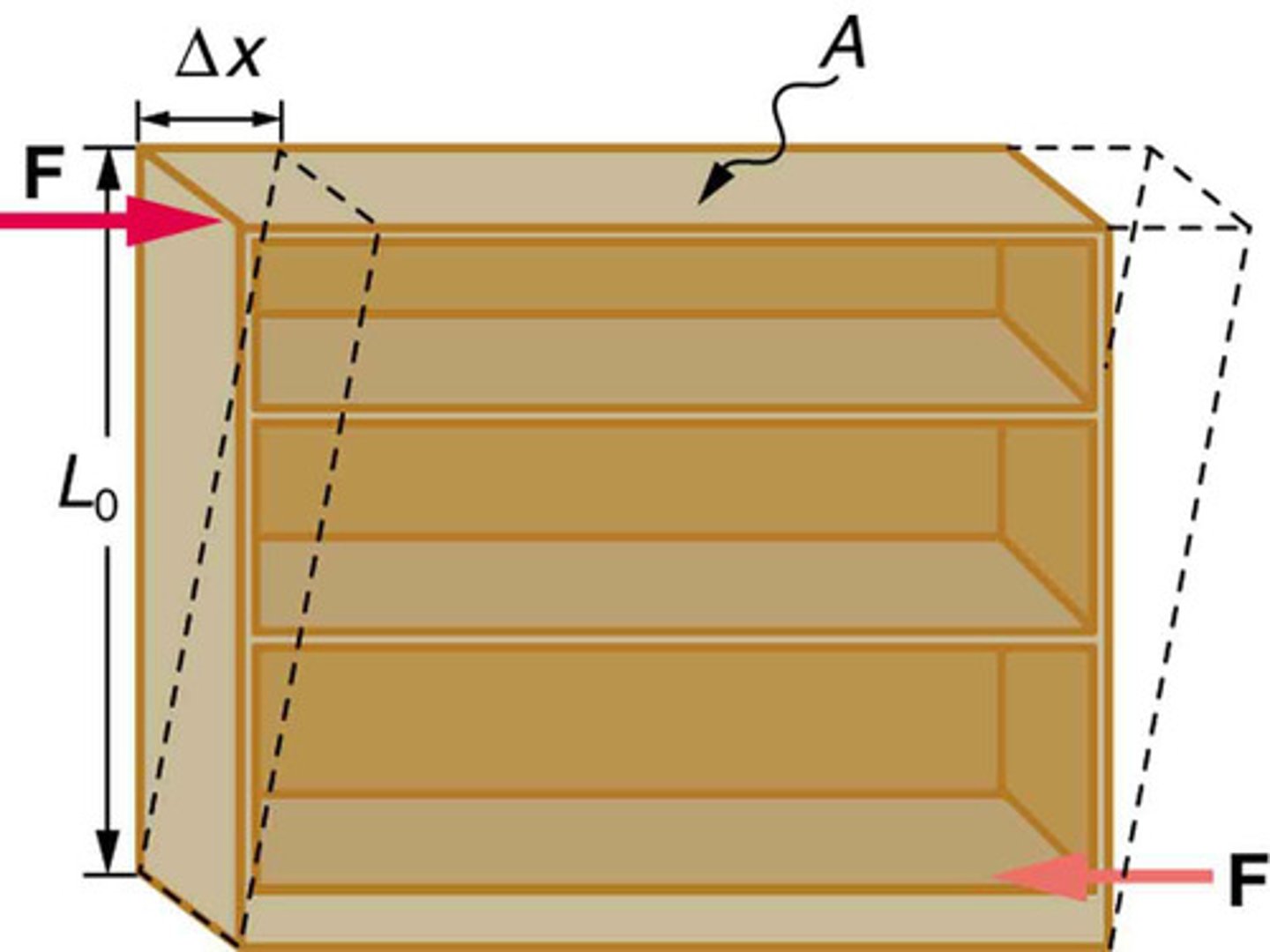

Shear Stress

A stress that occurs when forces are applied parallel or tangential to a surface.

Macroscopic Characteristics of Friction

Observable large-scale features of friction, such as its proportionality to normal force.

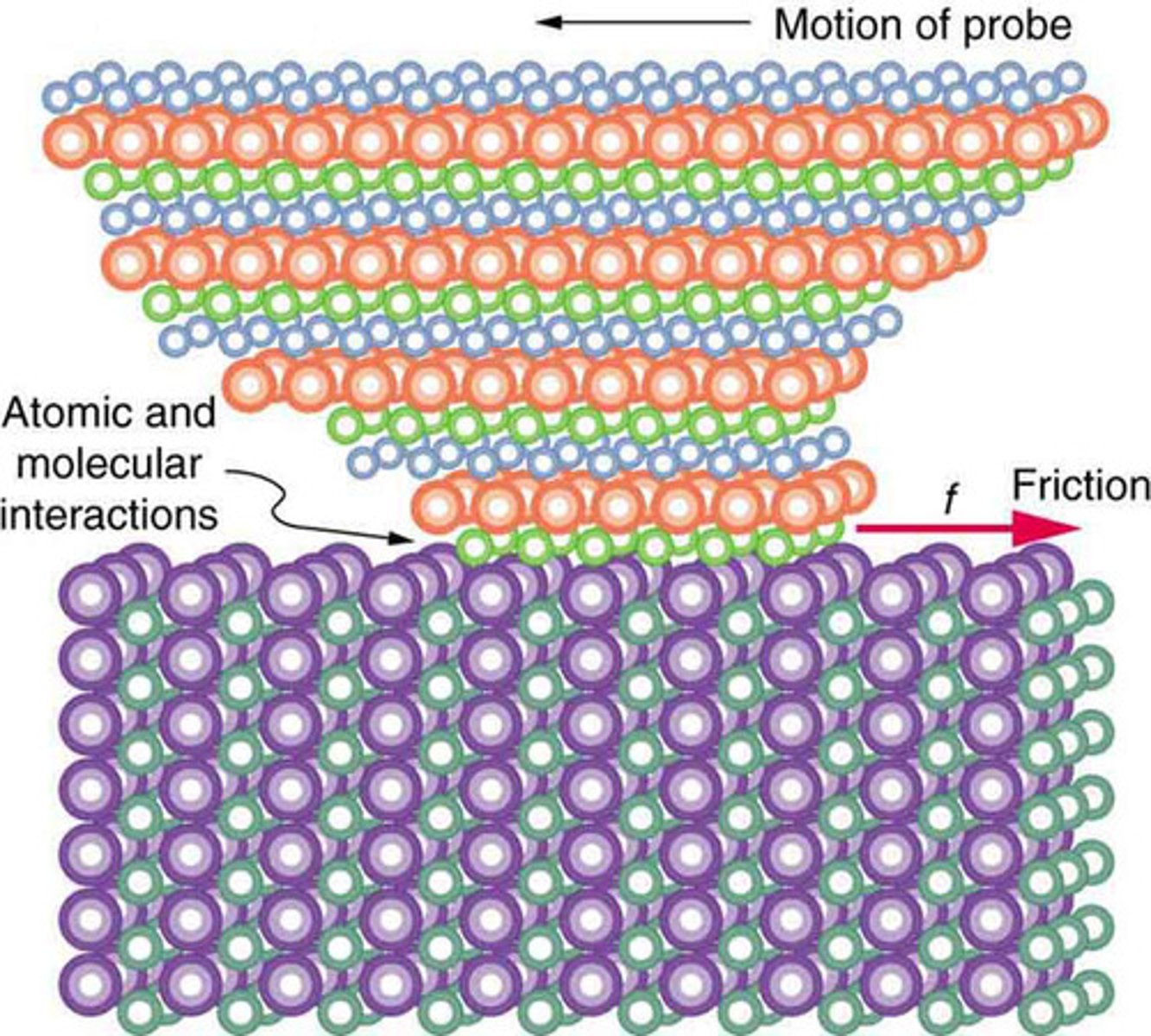

Microscopic Characteristics of Friction

Atomic-scale features of friction, including adhesion and lattice vibrations.

Drag Force

A force that opposes the motion of an object through a fluid, proportional to the square of the object's speed in the fluid.

Drag Coefficient (C)

A dimensionless quantity that represents the drag per unit area of an object moving through a fluid, determined empirically.

Terminal Velocity

The constant speed that a freely falling object eventually reaches when the resistance of the medium prevents further acceleration.

Equation for Drag Force

FD = 1/2 C ρ A v^2, where FD is the drag force, C is the drag coefficient, ρ is the fluid density, A is the cross-sectional area, and v is the velocity.

Density (ρ)

Mass per unit volume of a substance, often used in calculating drag force.

Stokes' Law

Fs = 6πrηv, where Fs is the drag force, r is the radius of the object, η is the fluid's viscosity, and v is the velocity.

Viscosity (η)

A measure of a fluid's resistance to flow, affecting the drag force on small particles.

Empirical Determination

The process of determining values like the drag coefficient through experimental methods such as wind tunnel testing.

Aerodynamic Shaping

Designing objects to reduce drag force, thereby improving efficiency and performance, such as in cars and sports equipment.

Net Force at Terminal Velocity

The net force is zero when the drag force equals the gravitational force, resulting in no acceleration.

Effect of Mass on Terminal Velocity

Heavier objects require a higher speed to reach terminal velocity because the drag force must equal the greater gravitational force.

Streamlining

The design or arrangement of an object to reduce resistance to motion through a fluid, often seen in animals and vehicles.

Galileo's Experiment

An experiment demonstrating that objects of different masses fall at the same rate in the absence of air resistance, highlighting the effect of drag.

Effect of Shape on Drag

The shape of an object affects its drag coefficient and, consequently, the drag force experienced during motion through a fluid.

Effect of Area on Drag

The cross-sectional area of an object facing the fluid affects the magnitude of the drag force experienced.

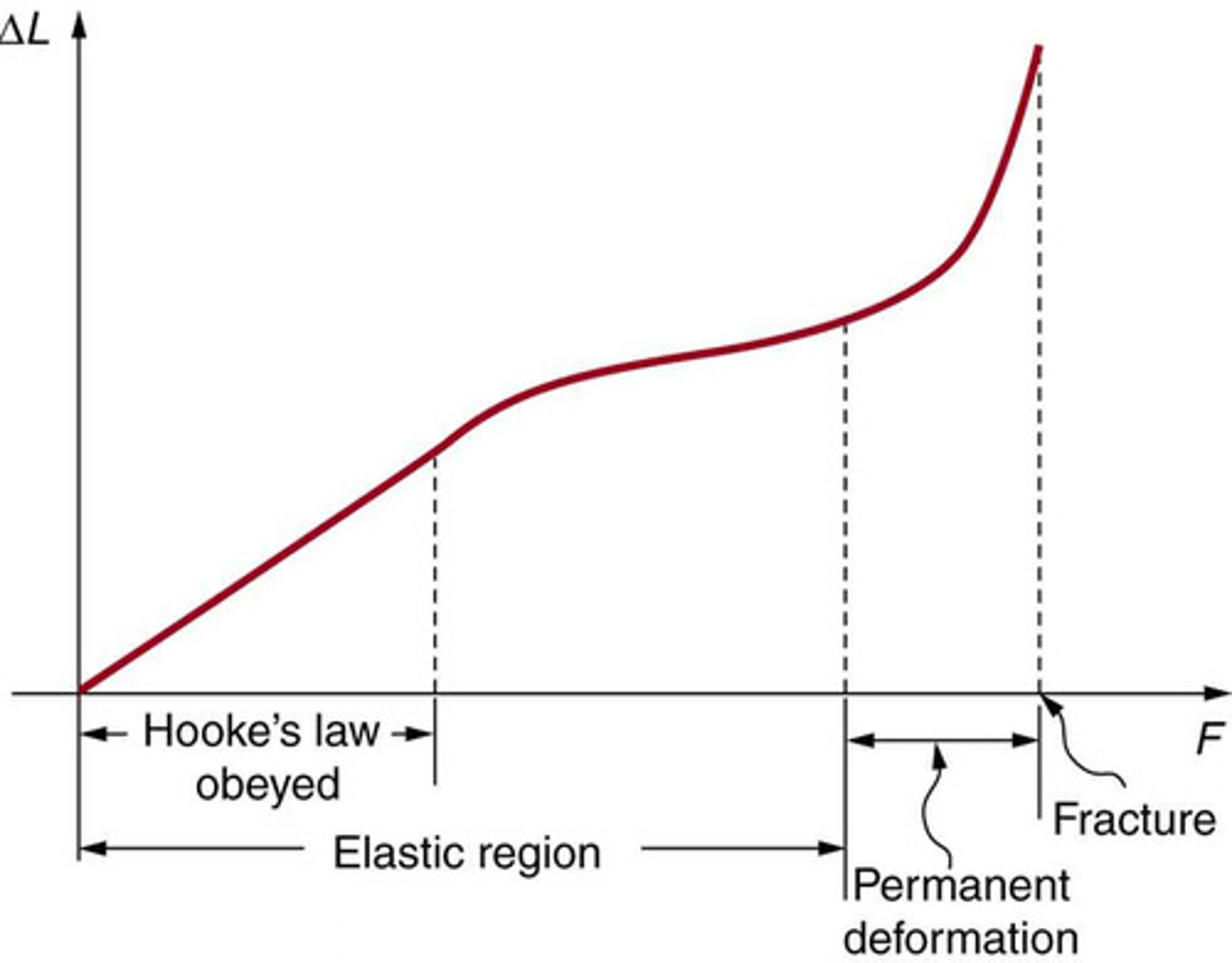

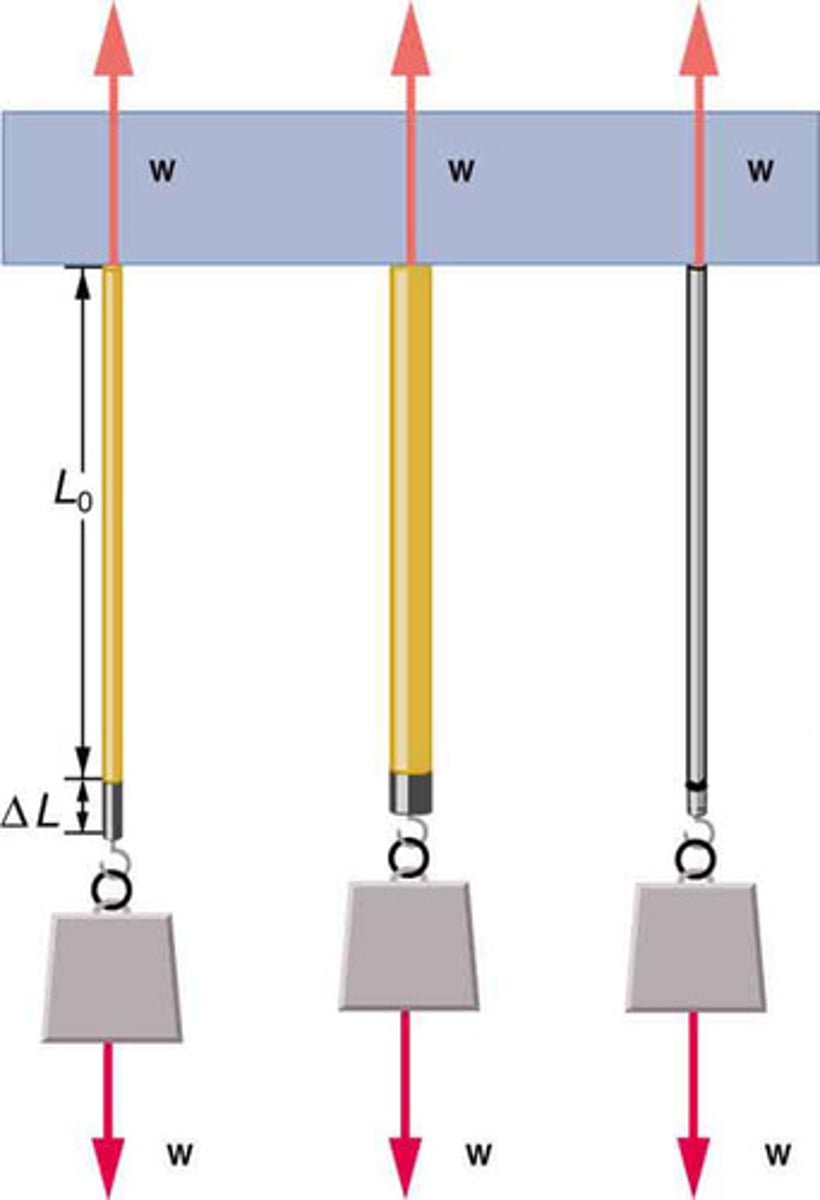

Hooke's Law

Hooke's Law states that the deformation of an object is proportional to the applied force, expressed as F = kΔL, where F is the force applied, ΔL is the change in length, and k is the proportionality constant.

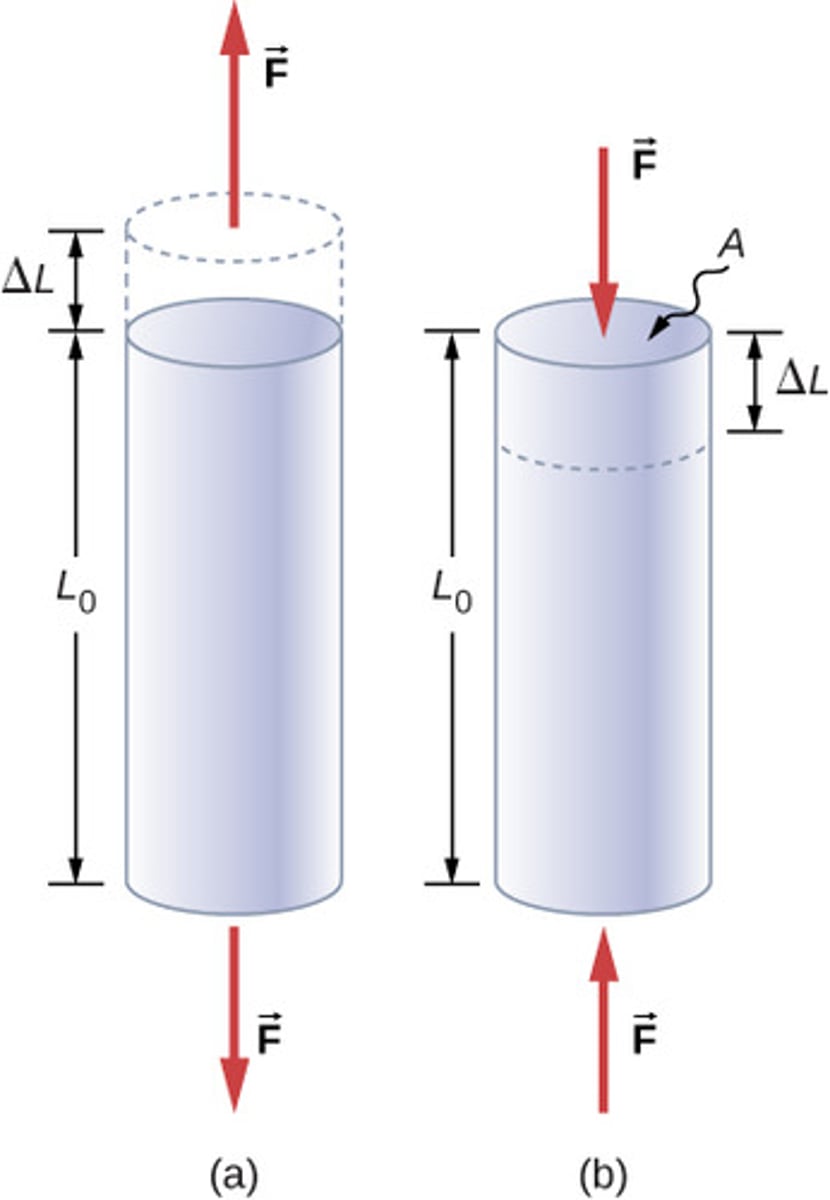

Elastic Deformation

Elastic deformation is a temporary change in shape that is reversible when the applied force is removed.

Young's Modulus

Young's modulus (Y) is a measure of the stiffness of a material, defined as the ratio of tensile stress to tensile strain.

Shear Modulus

Shear modulus (S) is a measure of a material's ability to resist shear deformation, defined as the ratio of shear stress to shear strain.

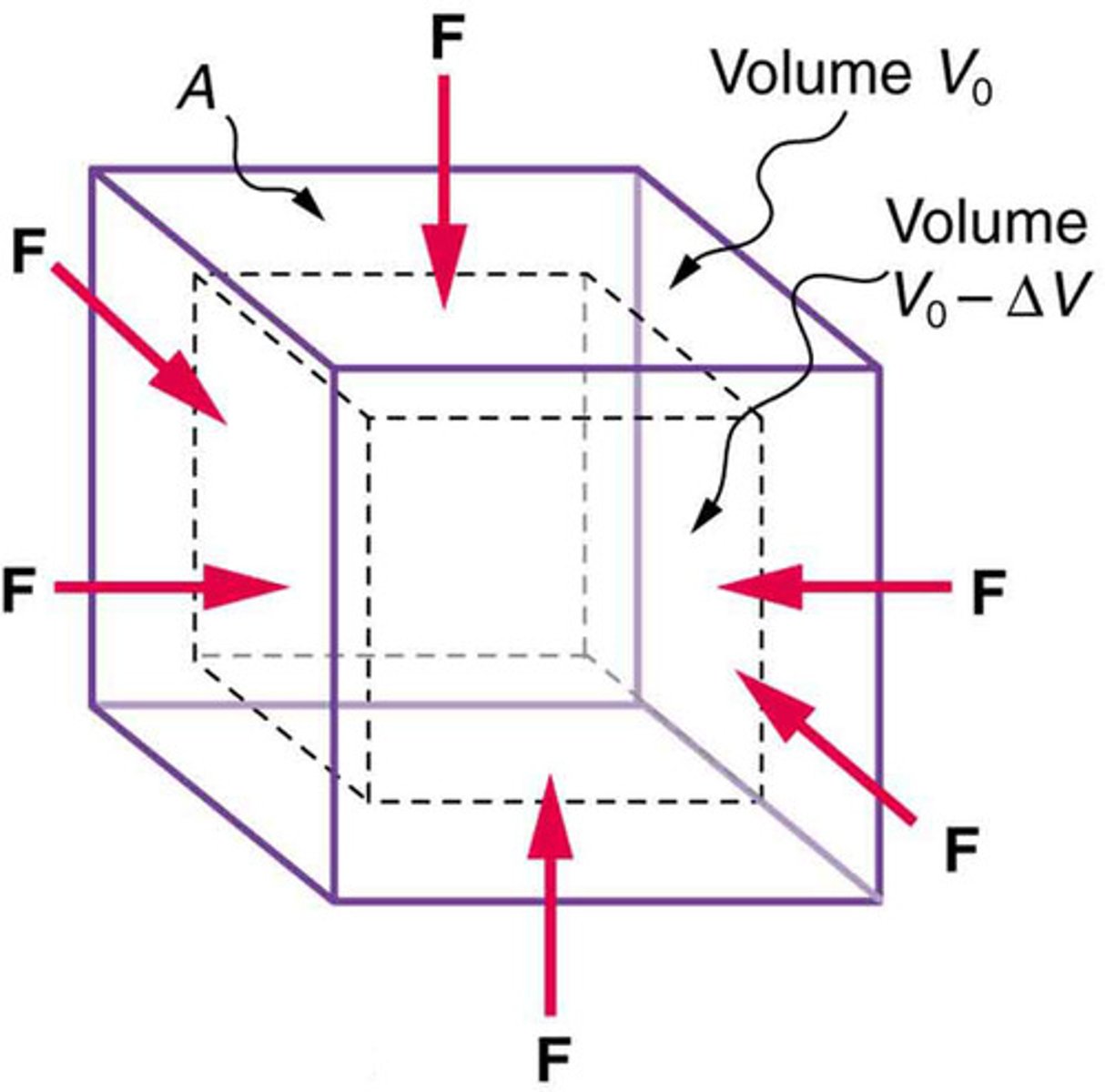

Bulk Modulus

Bulk modulus (B) is a measure of a material's resistance to uniform compression, defined as the ratio of volumetric stress to the change in volume.

Stress

Stress is the force applied per unit area within materials, measured in N/m².

Strain

Strain is the deformation or displacement of material that results from an applied stress, expressed as the ratio of change in length to original length.

Tensile Strength

Tensile strength is the maximum stress that a material can withstand while being stretched or pulled before breaking.

Proportionality Constant (k)

The proportionality constant (k) in Hooke's Law is a factor that depends on the material's shape, composition, and the direction of the force applied.

Elastic Modulus

Elastic modulus is a general term for the ratio of stress to strain in a material, encompassing Young's modulus, shear modulus, and bulk modulus.

Compression

Compression is a type of deformation where an object is shortened by an applied force.

Shear Deformation

Shear deformation occurs when a force is applied parallel to the surface of a material, causing it to change shape without changing volume.

Volume Deformation

Volume deformation refers to the change in volume of a material when subjected to uniform pressure from all sides.

Tension

Tension is a type of deformation where an object is lengthened by an applied force.

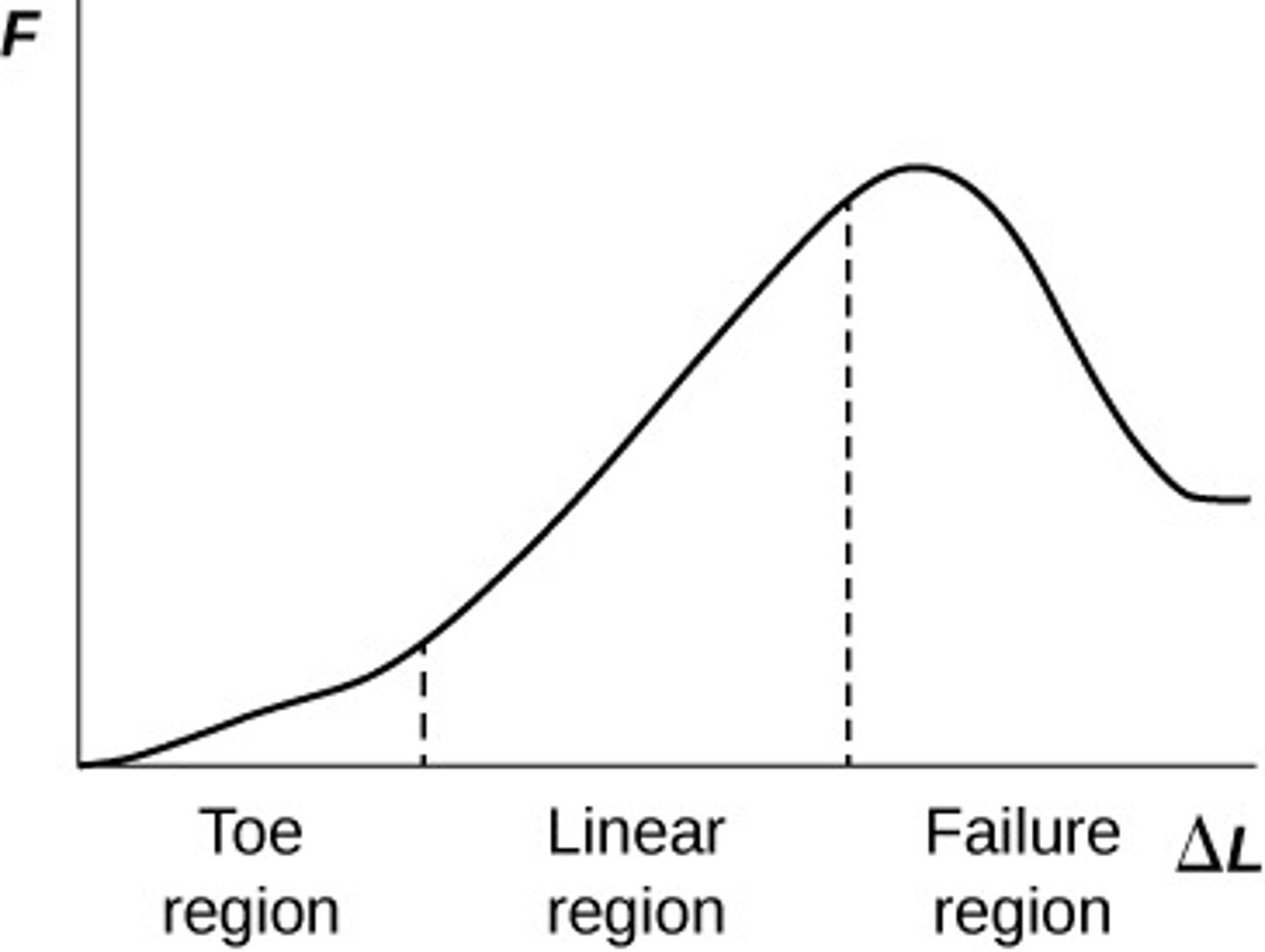

Stress-Strain Curve

A stress-strain curve is a graphical representation of a material's response to stress, showing the relationship between stress and strain.

Uncrimping

Uncrimping is the initial alignment of fibers in a tendon in response to stress, occurring in the toe region of the stress-strain curve.

Failure Region

The failure region on a stress-strain curve is where individual fibers begin to break, leading to material failure.

Linear Region

The linear region of a stress-strain curve is where the material deforms elastically, and the relationship between stress and strain is linear.

Elastic Limit

The elastic limit is the maximum stress that a material can withstand without undergoing permanent deformation.

Permanent Deformation

Permanent deformation occurs when a material is stressed beyond its elastic limit and does not return to its original shape.

Torsion

Torsion is a type of deformation involving twisting of an object due to an applied torque.

Elasticity

Elasticity is the property of a material to return to its original shape after the removal of a deforming force.

Proportional Limit

The proportional limit is the point on a stress-strain curve up to which the stress is directly proportional to strain.

Plastic Deformation

Plastic deformation is the permanent change in shape of a material when the stress exceeds the elastic limit.

Yield Point

The yield point is the stress level at which a material begins to deform plastically.

Elastic Region

The elastic region of a stress-strain curve is where the material returns to its original shape after the stress is removed.

Brittle Material

A brittle material is one that fractures without significant plastic deformation.

Ductile Material

A ductile material is one that can undergo significant plastic deformation before fracture.

Modulus of Rigidity

Modulus of rigidity, also known as shear modulus, measures a material's ability to resist shear deformation.

Poisson's Ratio

Poisson's ratio is the ratio of transverse strain to axial strain in a material subjected to axial stress.

Elastic Hysteresis

Elastic hysteresis is the energy loss due to internal friction when a material is cyclically loaded and unloaded.

Viscoelasticity

Viscoelasticity is the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation.

Creep

Creep is the slow, permanent deformation of a material under constant stress over time.

Fatigue

Fatigue is the weakening of a material caused by cyclic loading, leading to the formation of cracks and eventual failure.

Hardness

Hardness is a measure of a material's resistance to localized plastic deformation, such as indentation or scratching.

Resilience

Resilience is the ability of a material to absorb energy when deformed elastically and release it upon unloading.

Toughness

Toughness is the ability of a material to absorb energy and plastically deform without fracturing.

Anisotropy

Anisotropy is the directional dependence of a material's mechanical properties.

Isotropy

Isotropy is the property of being directionally uniform, meaning a material's properties are the same in all directions.

Necking

Necking is the localized reduction in cross-sectional area that occurs in a material under tensile stress before fracture.

Bending

Bending is the deformation of a material into a curved shape due to an applied force.

Buckling

Buckling is the sudden change in shape of a structural component under load, leading to failure.

Elastic Limit

The elastic limit is the maximum stress that a material can withstand without undergoing permanent deformation.

Plasticity

Plasticity is the ability of a material to undergo permanent deformation without breaking.

Yield Strength

Yield strength is the stress at which a material begins to deform plastically.

Ultimate Strength

Ultimate strength is the maximum stress a material can withstand before failure.

Fracture

Fracture is the separation of a material into two or more pieces under stress.

Elastic Recovery

Elastic recovery is the ability of a material to return to its original shape after the removal of a stress.