E1 Paracetamol

1/28

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

29 Terms

Enumerate the quality attributes of a tablet

Elegant

Sufficiently strong and resistant to shock

Uniform in weight and drug content

API must be bioavailable

API must retain all functional attributes

Enumerate the ingredients required for the formulation of paracetamol tablets through wet granulation. Include their purpose/function.

Paracetamol - API

Dicalcium Phosphate - Diluent/Filler

Kollidon CL - Disintegrant

PVP - Binder

Ethanol - Liquid granulation agent

Magnesium stearate - Lubricant

What’s the main difference between the upper punch and lower punch of a tableting machine?

The upper punch has a shorter stem compared to the lower punch

What part/property of the tableting machine determines the size, shape, and thickness of the formed tablet

Die cavity and punches

What are the two types of granulation process? Indicate the differences between the two processes.

Wet granulation which utilizes a liquid in the process and dry granulation that requires no liquid. Dry granulation is use for moisture sensitive drugs and thermosensitive materials

Why should we granulate the drug powder mixture?

To facilitate smooth and free flow of the drug mixture from the hopper into the dies

Enumerate the steps of Tablet manufacturing

Grinding/Milling

Dispensing

Blending

Preparation of Damp Mass (Wet Granulation)

Wet Screening

Drying

Dry Screening

Addition of Lubricant and Final Blending

Compression

What’s the purpose of the grinding/milling step?

To reduce particle sizes and ensure uniformity

Enumerate the ingredients blended together on the V blender for 5 minutes?

Paracetamol

Dicalcium phosphate

Kollidon CL

Kollidon 90F

On preparation of damp mass, the damp mass should be?

Compact, shows a consistency of a damp snow

When pressed in the palm, it separates into two even parts

On wet screening, the moistened mass were pass through what screen?

No. 4 hand screen

On drying, the moist granules were spread on trays and were placed in the drying oven set at what temperature? What parameter of the granules should you check after this step

60°C

Moisture Content

Specify the difference between overwetting and underwetting

Overwetting is when granules are too hard for proper tablet formation

Underwetting is when tablets will become too soft and will tend to crumble

On dry screening, there’s separation of good and fine granules. To do this, the dried granules will pass through what screens?

No. 20 and 40 Screen

Granules that passed through sieve 20 but not 40

Good granules

Granules that passed through sieve 40

Fine granules

What is the optimal ratio of fine and good granules in tablet formation?

90% good granules

10% fine granules

What is the purpose of adding fine granules?

These granules will fill the voids and air spaces left by two good granules, ensuring an evenly compacted tablet

A characteristic related to the inter-particulate friction or resistance to movement between particles. It is a simple technique for estimating the flow properties of a powder.

Angle of Repose

What is measured in the resulting cone to compute for the angle of repose?

Height and diameter of the base

Quality tests done to ensure compressibility of powders

Hausner Ratio and Compressibility Index

Quality test done to ensure uniformity in particle size

Particle Size Determination

Refers to the ratio of the mass of an untapped powder sample and its volume (including interparticulate void volume)

Bulk density

Density attained after mechanically shaking the sample

Tapped density

Technique used to determine particle size distribution and to ensure optimal ratio of fine and good granules

Particle size distribution by Analytical Sieving

Why is the lubricant added prior to compression?

To ensure that the tablet is ejected smoothly w/o sticking or breakage

Magnesium stearate is screened through what screen

No. 80 sieve

In compression, the tablets were compressed using what punches?

7/16 concave punches

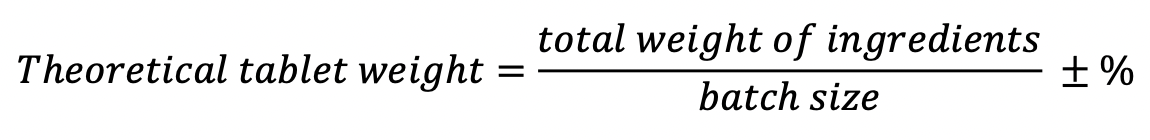

Indicate the formula for theoretical tablet weight